Your D2C brand1 is stuck in a price war, selling a generic product that looks like everyone else's. It's time to break free by creating an appliance that is truly your own.

You are likely ready to develop your own appliance if you're stuck in a commodity market, tired of apologizing for product flaws you can't fix, your brand story is better than your product, and you already have a clear vision for a "Version 2.0."

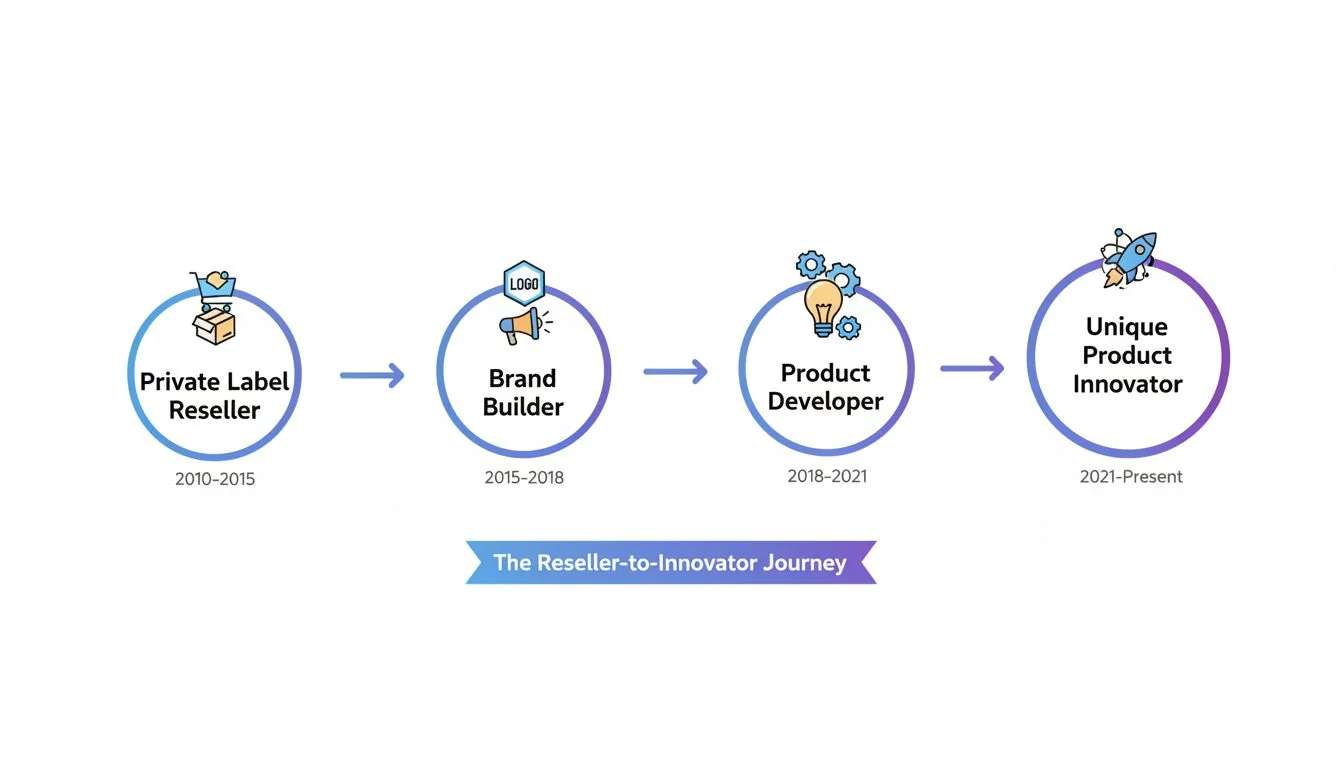

Recognizing these signs is the first step. I've been in the manufacturing world for a long time, and I've seen countless brands make the leap from simply reselling to truly innovating. It’s a game-changer. But this path from reseller to innovator is also full of traps that can sink a business before it even gets started.

Let's walk through these signs together. I want to help you see if you’re really ready for this journey. And more importantly, I want to show you how to do it the smart way.

Over 60% of D2C brands use a private label or contract manufacturing model.Verdadero

This is a common and accepted statistic in the e-commerce and D2C space, highlighting the prevalence of the reseller model.

Developing a new electronic appliance from scratch always costs less than $20,000 in tooling.Falso

Tooling and mold costs for a new appliance are almost always significantly higher, often ranging from $50,000 to over $250,000, depending on complexity.

1. Introduction: The "Reseller-to-Innovator" Leap?

You started your brand with a great story and a clear mission. But you're just putting your logo on a generic product from a catalog. The real, sustainable growth happens when you make the leap from reseller to true innovator.

This leap means you stop selling someone else's design and start creating a unique product2 that actually represents your brand. It’s about taking full control of your product's quality, your customer's experience, and your company's future. It is your escape from the crowded commodity market.

I've worked with hundreds of clients over the years. Many start with private labeling. It’s a good way to get into the market. But the brands that build lasting value are the ones that eventually take control of their product. They move from being a passenger to being the driver. This shift is not just about changing a product; it's about changing your entire business model from being margin-driven to being brand-driven. It's the difference between a business that survives and a brand that thrives.

Reseller vs. Innovator: A Quick Comparison

| Metric | The Reseller (private label3) | The Innovator (Unique Product) |

|---|---|---|

| brand equity4 | Low. Your brand is just a logo. | High. The product embodies your brand. |

| Profit Margins | Low. Constantly squeezed by competition. | High. Protected by unique features. |

| customer loyalty5 | Weak. Customers buy on price. | Strong. Customers buy into your vision. |

| Controlar | None. You're at the mercy of the factory. | Total. You control design, quality, and features. |

Brands with strong customer loyalty grow revenues 2.5 times faster than their industry peers.Verdadero

A study by Bain & Company, the source of the Net Promoter Score (NPS), consistently shows a strong correlation between customer loyalty and revenue growth.

All private label products are of low quality.Falso

While private labeling can lead to quality control issues, it is not inherently low quality. Many reputable brands use high-quality private label manufacturers. The issue is the lack of differentiation and control, not always the quality itself.

2. Sign #1: You're Trapped in the "Sea of Sameness"?

Does your air purifier or humidifier look almost identical to ten others on the market? You're forced to slash prices just to compete, and your profit margins are disappearing. This is a huge sign that you need a unique product to stand out.

Being trapped in the "Sea of Sameness" means you are selling a commodity. When your product is a commodity, your only real weapon is price. This leads to endless, destructive price wars and shrinking profits. The only way to escape is with a product that is uniquely yours in its design and function.

I call this the "Commodity Trap," and it's a dangerous place for a brand. I remember a client who was selling a line of kitchen appliances. They had great marketing, but their flagship product was a generic model available from a dozen other sellers. Every quarter, they had to run deeper and deeper discounts just to move inventory. Their brand story was about quality and innovation, but their product screamed "generic." They were spending all their energy fighting for pennies on the dollar instead of building real value. This is the downward spiral of a commodity product. You can't build a lasting brand on it.

The Downward Spiral of a Commodity Product

- Increased Competition: More sellers enter the market with the same product.

- Price Wars: Everyone lowers prices to attract customers.

- Margin Erosion: Your profit on each sale shrinks.

- Reduced Marketing Budget: With less profit, you can't afford to acquire new customers.

- Brand Devaluation: Your brand becomes associated with discounts, not value.

Product differentiation is a key strategy for commanding higher prices and building brand loyalty.Verdadero

This is a fundamental principle of marketing strategy (Porter's Five Forces). Unique products or services face less direct competition and can sustain higher margins.

The only way to compete in e-commerce is to have the lowest price.Falso

While price is a factor, brands successfully compete on quality, customer service, brand story, unique features, and overall customer experience, not just price.

3. Sign #2: You're Tired of Apologizing for Your Product's Flaws?

A customer just left a 1-star review because the water tank on your humidifier is impossible to clean. You're constantly doing damage control for a product you didn't even design. It's time to build a product you can actually be proud of.

When you are always apologizing for the flaws in your private-label product, it's a major red flag. It means you have zero control over the product's design or quality. Every negative review chips away at your brand's reputation. This frustration is a powerful reason to start developing your own appliance.

This is one of the most painful situations for a passionate brand owner. You believe in your brand, but the product is letting you down. I once worked with a company selling air purifiers. Their customers complained that the filters were hard to find and expensive. The brand owner knew this was a huge problem, but the factory refused to change the design or offer a better filter solution. His hands were tied. He was stuck defending a bad user experience that he couldn't fix. That's when he knew he had to take control.

When 1-Star Reviews Aren't Your Fault (But They Are Your Problem)

Your private-label supplier makes decisions based on their own costs and efficiency, not your customer's happiness.

- They use cheaper materials: This can lead to cracks, leaks, or failures.

- They don't test for usability: This results in products that are hard to clean, fill, or operate.

- They won't change the mold: The tooling is expensive, so they will not make improvements for just one client.

You are the one who has to face the customer. Your brand takes the hit for decisions you never made.

93% of consumers say that online reviews influenced their purchase decisions.Verdadero

Multiple studies, including those by Qualtrics and BrightLocal, confirm that the vast majority of consumers read and are influenced by online reviews.

Factories will always change a product design if a customer complains.Falso

Factories that produce generic goods for many clients are highly resistant to making changes, especially costly ones like modifying a mold, for a single client unless the order volume is massive.

4. Sign #3: Your Brand Story Is Stronger Than Your Product?

You have built an amazing brand with a powerful story about sustainability and thoughtful design. But the generic plastic appliance you sell doesn't live up to that story at all. You need to align your product with your brand by creating something unique.

When your marketing promises innovation but your product is a generic commodity, you create a brand-product mismatch. This gap between your story and the actual product destroys customer trust. It is a clear signal that you need a custom-developed product that can deliver on your brand's promise.

I see this all the time. A brand will talk about being "eco-conscious" and "designed for modern life," but then they sell a standard humidifier made from cheap ABS plastic that you can find anywhere. Your smartest customers see this disconnect immediately. It feels fake because it is. Your product is the most powerful piece of marketing you have. If it doesn't tell the same story as your ads, you have a credibility problem that no amount of marketing can fix.

The Credibility Gap: When Your Product Betrays Your Brand

This is a silent killer for D2C brands.

- It creates customer disappointment: The unboxing experience doesn't match the hype.

- It undermines your marketing: Your claims feel hollow and untrustworthy.

- It prevents true fans: People might buy your product, but they won't fall in love with your brand.

A great brand with a mediocre product is a wasted opportunity. Your product should be the physical proof of your brand's story.

Authenticity is a key factor for consumers, with 86% saying it's important when deciding what brands they like and support.Verdadero

Consumer research from firms like Stackla consistently shows that authenticity is a top value for modern consumers, especially millennials and Gen Z.

A strong brand story can make any product successful, regardless of its quality or design.Falso

While a strong brand story is powerful, it cannot overcome a poor product experience in the long run. The product must ultimately deliver on the brand's promise to retain customers.

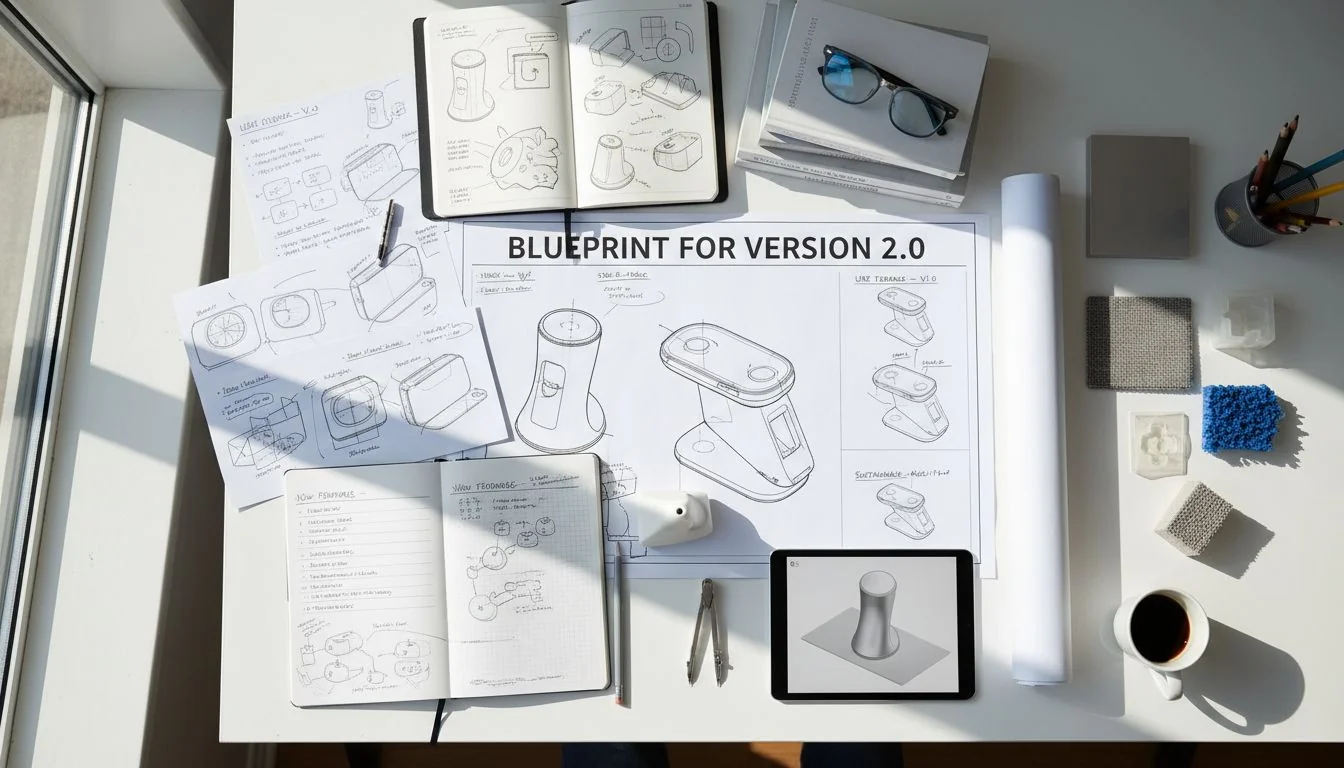

5. Sign #4: You Know Exactly What Your "Version 2.0" Should Be?

Do you have a list of ideas for how to improve your current product? Maybe it's on your computer or in a notebook. But you have no way to make these changes with your current supplier. This vision is your blueprint for your own unique appliance.

If you can clearly list the features, design changes, and material improvements for a "Version 2.0," you are no longer just a reseller. You are a product developer in waiting. This detailed vision is the single strongest sign that you are ready to create your own product.

This is the most exciting sign of all. It means you've moved past the frustration and into the solution. You're not just complaining about the problems; you're designing the answers. I encourage my clients to get very specific here. Don't just say "make it easier to clean." How? A wider opening? A different material? No hard-to-reach corners? This is the thinking of a true product innovator. You have listened to your customers, combined it with your own vision, and created a roadmap to a better product.

From Customer Feedback to a Product Blueprint

Turn your ideas into a concrete plan. Use a simple table like this to organize your thoughts. This is the first step in a real desarrollo de productos6 brief.

| Current Flaw (from Reviews) | My V2.0 Solution | Key Customer Benefit |

|---|---|---|

| "The tank is slimy and hard to clean." | Use a wide-mouth, stainless steel tank. | Hygienic and effortless cleaning. |

| "It's too loud to use in the bedroom." | Use a brushless DC motor. | Whisper-quiet, peaceful sleep. |

| "It leaked all over my nightstand." | Unibody construction with better seals. | Reliable, worry-free operation. |

Customer feedback is one of the most valuable resources for new product development.Verdadero

This is a core tenet of modern product management and lean startup methodologies. Successful companies are customer-centric and use feedback to guide innovation.

Having ideas for a new product is the same as being ready to manufacture it.Falso

Ideas are the first step, but being ready for manufacturing involves understanding costs, supply chains, engineering, certifications, and logistics, which is a far more complex stage.

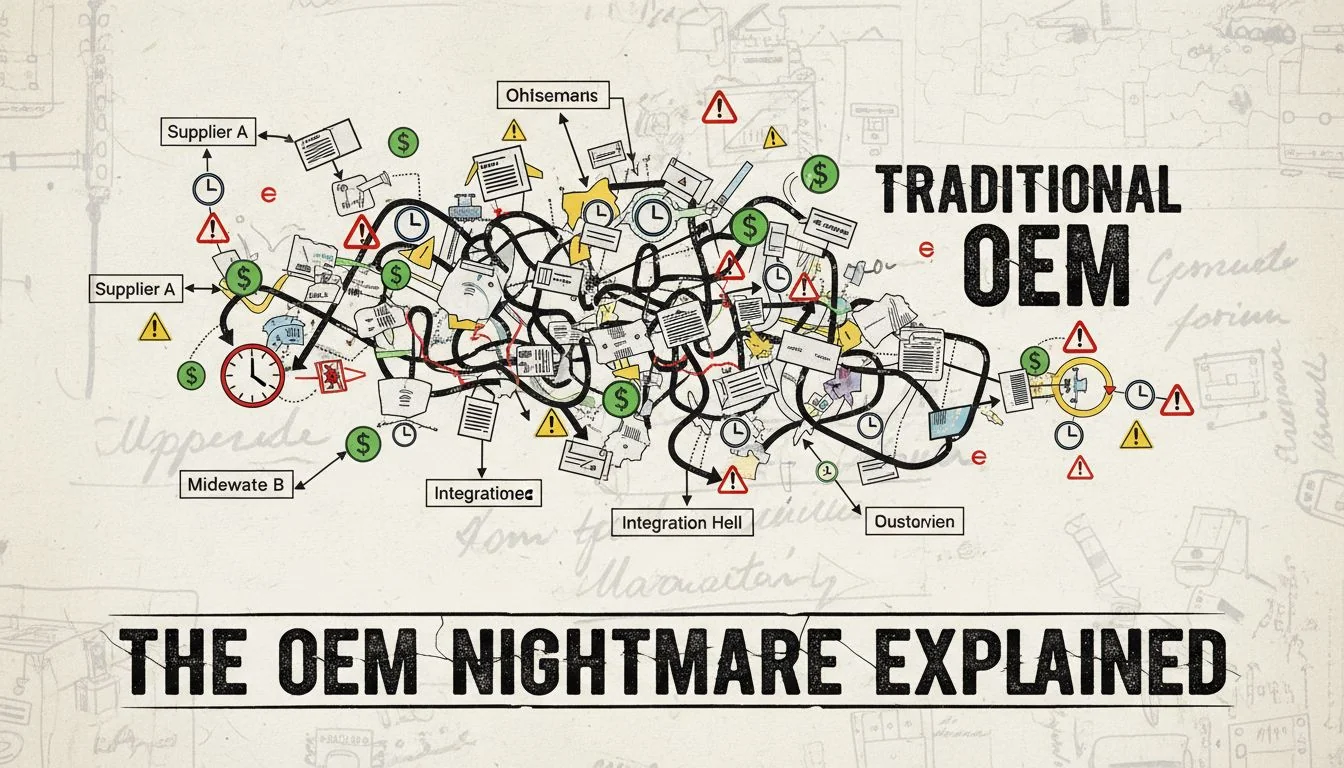

6. You're Ready. But Are You Ready for the "OEM Nightmare"?

So, you're convinced. You're ready to build your own product. But the traditional path of working with an Original Equipment Manufacturer (OEM) is a minefield of high costs, long delays, and huge risks. You must understand this "nightmare" to avoid it.

The "OEM nightmare7" is the trap of traditional, from-scratch product development. It involves huge upfront investments in molds and tooling, managing a complex supply chain, navigating uncertain certification processes, and facing long development cycles with no guarantee of success. It can easily bankrupt a growing D2C brand.

This is where many passionate innovators get stopped in their tracks. As a mold and manufacturing guy, I can tell you this part is not for the faint of heart. You have a great idea, you find a factory, and they give you a quote. The quote includes "NRE" or "Tooling Costs." This is the cost to build the steel molds for your plastic parts, and it's a massive, non-refundable expense. You're paying for the tools before you've sold a single unit. This is just the first step in a long, expensive, and risky process.

The Hidden Costs of "Building from Scratch"

| Risk Category | Descripción | Potential Cost / Time |

|---|---|---|

| Mold & Tooling (NRE) | The upfront cost to create the molds. | $50,000 - $250,000+ |

| Minimum Order Qty (MOQ) | You must commit to buying thousands of units. | 3,000 - 5,000+ units |

| Certification Delays | Navigating safety (ETL) and compliance (CARB, EPA). | 6-12 months, potential redesigns |

| Development Timeline | The total time from concept to a product on the shelf. | 18-24 months |

The average time to develop a new hardware product is over 18 months.Verdadero

Industry analysis from firms like Fictiv and Dragon Innovation shows that the timeline for bringing a new hardware product from concept to mass production typically ranges from 18 to 24 months.

All OEM factories have the same high MOQ and tooling costs.Falso

Costs and MOQs vary significantly between factories based on their size, location, and specialization. However, for a custom electronic appliance, high NRE and MOQ are the industry norm.

7. The "Smart Accelerator" Path: Platform-Based Co-Development?

You feel trapped. The commodity sea is a slow death, but the OEM nightmare is a fast one. It feels like there's no good option to grow. But there is a third, smarter path: platform-based co-development8.

Platform-based co-development is the "smart accelerator" path. It works by using a pre-engineered and pre-certified core product "platform." You then customize the external design, colors, and materials to make it unique to your brand. This gives you a signature product without the massive risk, cost, and time of traditional OEM.

Think of it like building a car. With traditional OEM, you have to design the engine, the transmission, the electrical system, and the chassis from scratch. It's incredibly complex. With platform co-development, you start with a high-performance chassis and engine that is already engineered, tested, and safety-certified. Your job is to design the beautiful, unique body that goes on top. For example, we have a stainless steel humidifier platform. The motor, electronics, and core function are proven and certified (ETL, CARB, EPA). We work with you to design a unique outer shell that reflects your brand.

How a "Certified Platform" De-Risks Innovation

| Característica | Traditional OEM | Platform Co-Development |

|---|---|---|

| Core Engineering | 100% Your Risk | Pre-vetted, proven, and reliable. |

| Certifications (ETL, etc.) | Your Risk, Cost, & Time | Included & Pre-Certified. |

| Tooling Investment | Very High (Full internal & external set) | Bajo (Only for your unique shell). |

| Time-to-Market | 18-24 months | 4-6 months. |

| MOQ | Muy alta | Lower and more flexible. |

This is the secret to getting a unique product to market fast, without betting the entire company. You get to focus on what you do best: brand, design, and marketing. You leave the complex, risky core engineering to a trusted partner.

Using a platform-based approach can reduce product development time by over 50%.Verdadero

This is a widely cited benefit in both software and hardware development. By building on a proven foundation, the time spent on core R&D and testing is drastically reduced.

Platform-based products are not unique.Falso

While the core is standardized, the exterior design, materials, colors, finish, and branding are completely custom. This allows for significant differentiation, creating a product that is unique to the market and the brand.

Conclusión

Recognizing the signs you've outgrown the reseller model is easy. Avoiding the traps of product development is hard. Platform-based co-development offers a smarter, faster path from reseller to true brand innovator.

References

-

Understanding D2C brands can help you navigate the evolving landscape of direct-to-consumer marketing. ↩

-

Creating unique products can set your brand apart; discover the advantages of innovation. ↩

-

Exploring private label options can provide insights into product differentiation and brand control. ↩

-

Understanding brand equity can help you leverage your brand for greater profitability. ↩

-

Building customer loyalty is crucial for long-term success; discover proven strategies to enhance it. ↩

-

Understanding the product development process is essential for successful innovation. ↩

-

Understanding the OEM nightmare can help you avoid pitfalls in product development. ↩

-

Exploring platform-based co-development can reveal innovative paths to product creation. ↩