As HisoAir’s Chief Revenue Officer, I’ve spent over 20 years watching Dongguan, China evolve from a general purpose factory town into the world’s go-to hub for humidifiers and other air-quality devices. Brands like Vornado and Pure Enrichment flock here because Dongguan offers a rare combination of deep electronics know-how, tightly knit supply chains, and cost efficiency all within the booming Greater Bay Area.

What sets the city apart isn’t just capacity; it’s specialization. Decades of targeted investment have produced an ecosystem of precision component suppliers, skilled technicians, and modern logistics that lets a product move from concept to container faster and more reliably than almost anywhere else. As humidifiers add smart controls, hybrid modes, and stricter safety requirements, that ecosystem becomes mission-critical.

Location seals the deal. Dongguan sits between Shenzhen’s semiconductor brain trust and Guangzhou’s ports, giving manufacturers immediate access to sensors, PCBs, plastics, and global shipping lanes. The result is a supply-chain loop so tight it shaves weeks off development cycles and drives down unit costs without compromising quality.

For any brand weighing production options or for homeowners curious where their quiet-running bedroom humidifier was born Dongguan is more than a dot on a map. It’s the epicenter of a mature, adaptable, and relentlessly innovative manufacturing network that keeps raising the bar for indoor air-care technology worldwide.

The Evolution of Dongguan's Manufacturing Identity

In the 1980s-1990s, Dongguan focused primarily on textiles and footwear. As China's economic reforms deepened, the city pivoted toward higher-value electronics manufacturing through government initiatives, technology transfer incentives, and specialized industrial parks. By the early 2000s, Dongguan had established itself as a key node in the global electronics supply chain, coinciding with rising demand for air quality products.

Case Study: Vornado's Manufacturing Journey

Vornado exemplifies how global brands leverage Dongguan's capabilities. Initially manufacturing in the US, Vornado began exploring Chinese production in the early 2000s as demand for affordable air treatment products grew. Their approach evolved from simple contract manufacturing to sophisticated partnerships, gradually transferring production of increasingly complex models to Dongguan while maintaining quality standards at competitive price points.

The Specialization Advantage

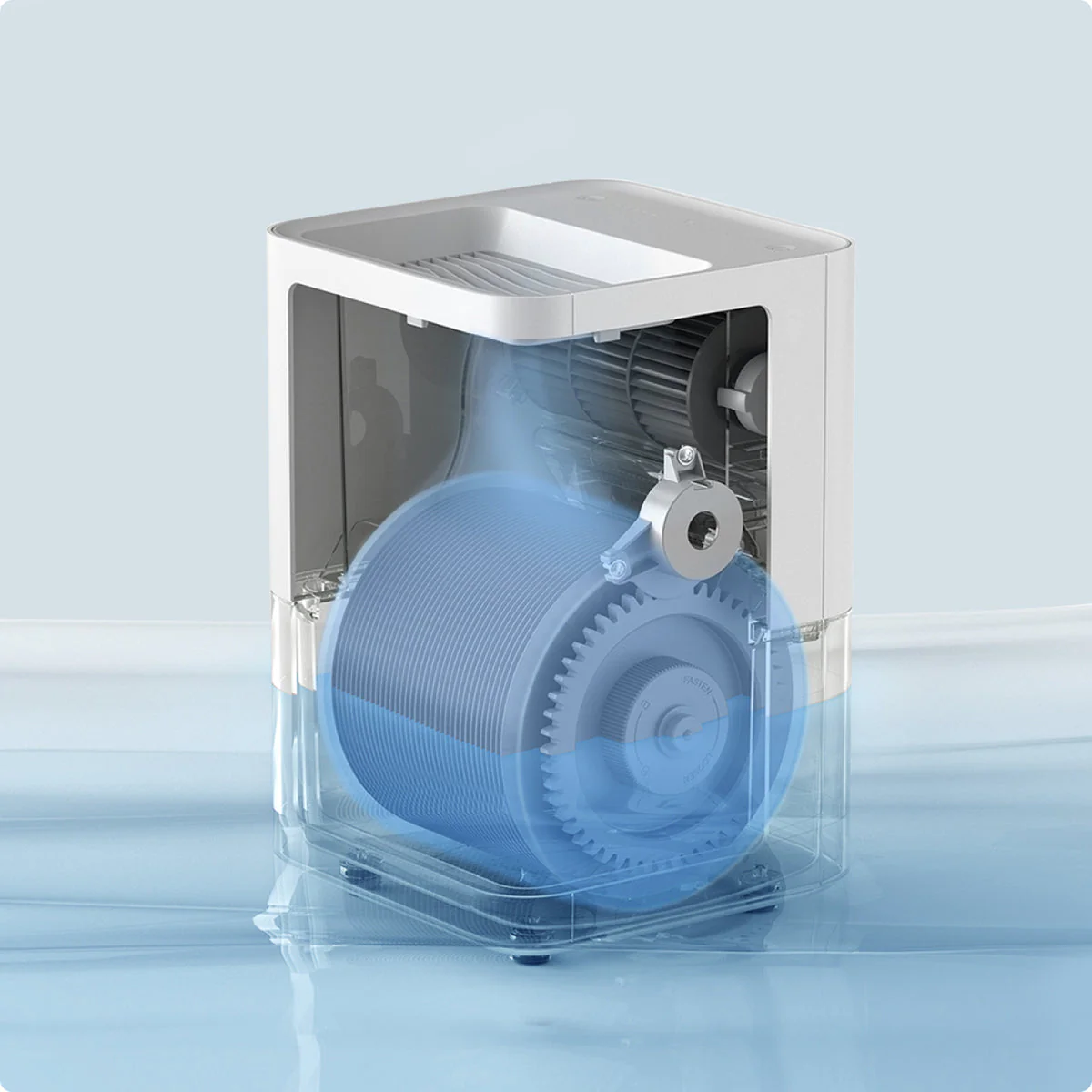

Dongguan's key strength lies in its high specialization in specific product categories, including air treatment devices. For humidifier brands, this translates to factories with deep expertise in water containment systems, ultrasonic nebulizers, fan mechanisms, and electronic controls specifically tailored for humidification devices—offering not just manufacturing capacity but accumulated knowledge about optimizing performance and production.

| Period | Manufacturing Focus | Key Developments | Impact on Humidifier Production |

|---|---|---|---|

| 1980s-1990s | Textiles, Footwear | Initial industrial development | Limited humidifier production |

| 2000-2010 | Electronics, Appliances | Specialized industrial parks | Growing production, improved quality |

| 2010-2015 | Advanced Electronics | Automation, Quality control | Premium production, smart features |

| 2015-Present | High-tech Manufacturing | Industry 4.0, R&D centers | Sophisticated devices, rapid innovation |

Regulatory Expertise and Market Adaptability

Dongguan's manufacturers have developed expertise in navigating complex regulatory requirements for humidifiers across global markets. Equally important is their remarkable adaptability to changing consumer preferences and business models, quickly developing capabilities in IoT connectivity, accommodating smaller production runs, and enabling faster development cycles—essential capabilities in today's rapidly evolving market.

What Makes Dongguan's Electronics Manufacturing Ecosystem Ideal for Humidifiers?

Dongguan offers a uniquely comprehensive environment specifically suited to humidifier production, extending far beyond simple cost considerations.

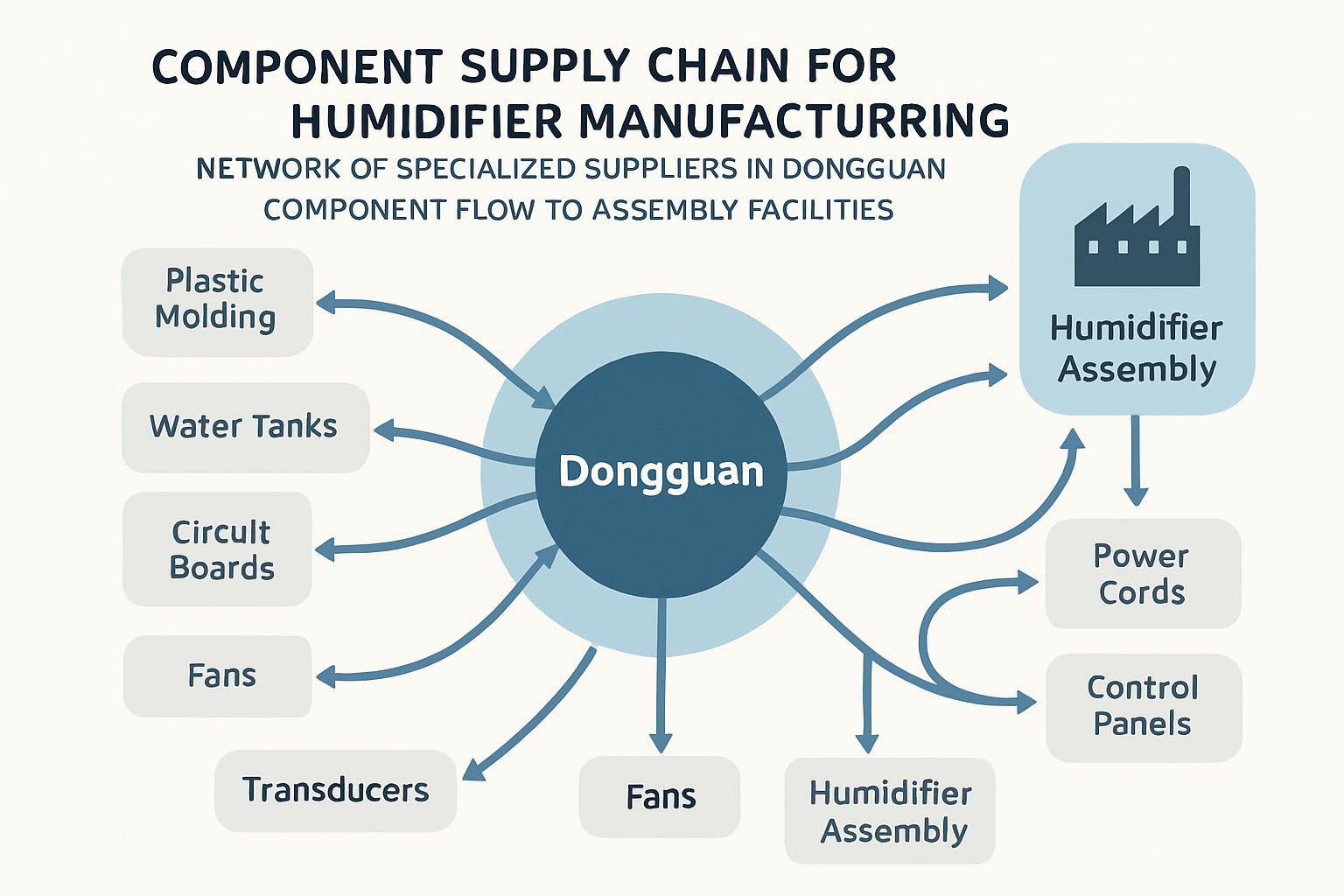

Dongguan's mature electronics ecosystem houses thousands of specialized factories creating a complete supply chain for humidifier production—from precision molds and PCB manufacturing to final assembly and quality testing—all within a compact geographic area.

The Component Supply Chain Advantage

Dongguan's remarkable density and diversity of component suppliers sets it apart. Within a 50-kilometer radius, manufacturers can source virtually every humidifier component: precision plastic molding for water tanks, ultrasonic atomization components, specialized fan motors, electronic control boards, displays, filters, and packaging. These suppliers possess deep understanding of humidifier-specific requirements, such as water-tight sealing techniques and leak-resistant tank design—specialized knowledge developed through years of experience with leading brands.

Vertical Integration Flexibility

The ecosystem's completeness enables varying degrees of vertical integration. Brands can work with a single ODM managing the entire production process or coordinate directly with multiple specialized suppliers while using an assembly partner. This flexibility accommodates different market positions—premium brands maintaining control over component sourcing, value-oriented brands leveraging turnkey solutions—with Dongguan supporting both approaches seamlessly.

Knowledge Networks and Innovation Diffusion

The concentration of humidifier-related manufacturing creates powerful knowledge networks driving continuous improvement. This knowledge sharing occurs through engineer mobility, supplier-manufacturer collaborations, industry associations, and technology demonstrations. For brands, this means access to continuously improving manufacturing capabilities without necessarily driving all innovation themselves.

| Ecosystem Component | Specialization for Humidifiers | Benefit to Brands |

|---|---|---|

| Plastic Molding | Water-tight designs, transparent tanks | Reliable performance, reduced returns |

| Electronic Components | Humidity sensors, water level detection | Accurate operation, safety features |

| Testing Labs | Specialized humidifier test protocols | Faster certification, market compliance |

Specialized Testing and Regulatory Support

Dongguan's ecosystem includes specialized testing laboratories and certification consultants with deep experience navigating humidifier regulatory requirements across global markets. These support services significantly streamline the certification process, reducing time-to-market and minimizing compliance risks.

Why Do Global Brands Choose Dongguan's Skilled Workforce?

Behind every precision-engineered humidifier lies something technology alone cannot provide: human expertise. Dongguan's workforce offers compelling advantages for global humidifier brands.

Dongguan's workforce brings decades of specialized experience in consumer electronics manufacturing, with skilled technicians capable of maintaining consistent quality across high-volume humidifier production runs while adapting quickly to new product specifications.

Generational Manufacturing Knowledge

Dongguan's labor force value stems from accumulated knowledge developed over decades. Many workers represent the second generation in their families to work in electronics manufacturing, creating powerful knowledge transfer systems. This expertise manifests in assembly precision, quality inspection capabilities, and production supervision that automated systems cannot replicate.

Specialized Technical Training

Beyond informal knowledge transfer, Dongguan has developed robust formal training systems specifically for electronics manufacturing. Technical schools collaborate with manufacturers to develop curricula aligned with industry needs, providing training in precision assembly techniques for water-containing devices, quality testing protocols, electronic troubleshooting, and specialized soldering techniques for water-resistant electronics.

| Región productora | Workforce Characteristics | Advantages for Humidifier Production | Limitaciones |

|---|---|---|---|

| Dongguan, China | Electronics experience, specialized training | Consistent quality, rapid adaptation | Rising labor costs |

| Shenzhen, China | Innovation-focused, tech-savvy | Advanced feature implementation | Higher costs, turnover |

| Vietnam (Emerging) | Growing electronics experience | Menores costes laborales | Less specialized experience |

| Mexico (Emerging) | Proximity to US market | Reduced shipping times | Limited humidifier expertise |

Quality Consciousness and Problem-Solving

Dongguan's workforce exhibits strong quality consciousness and problem-solving capabilities. Workers understand these devices directly impact users' health and comfort, creating a sense of responsibility that translates into careful attention to detail. Production teams collaborate effectively to identify root causes and implement solutions, often drawing on extensive experience with similar issues in other electronics manufacturing contexts.

Workforce Stability and Knowledge Retention

While labor turnover has challenged some Chinese manufacturing regions, Dongguan has achieved relatively good workforce stability through improved working conditions, career advancement opportunities, performance incentives, and technical skill development programs. This stability ensures specialized knowledge accumulates rather than being lost to turnover, contributing significantly to manufacturing consistency.

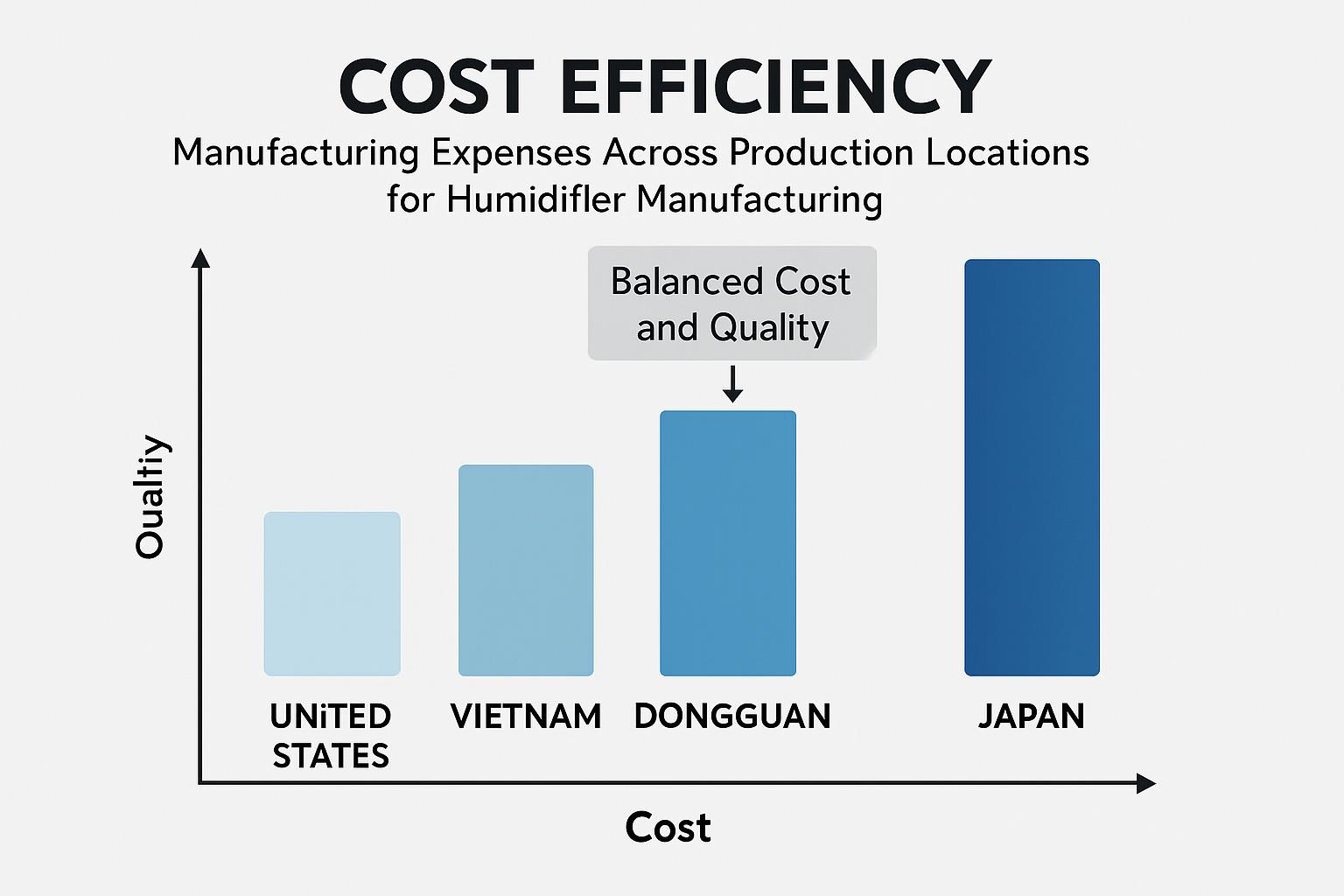

How Does Dongguan's Cost Efficiency Compare to Other Manufacturing Hubs?

Cost considerations remain crucial for humidifier brands operating in competitive markets. Dongguan offers a distinctive value proposition that balances manufacturing costs with quality and capabilities.

Dongguan delivers superior cost efficiency for humidifier manufacturing compared to coastal megacities like Shenzhen, offering 15-20% lower operating costs while maintaining supply chain integration, skilled labor access, and export readiness.

The Balanced Cost Position

Dongguan occupies a strategic middle ground in the manufacturing cost spectrum. While not the absolute lowest-cost location globally, it offers significant savings compared to developed markets and even China's tier-one cities like Shenzhen and Shanghai. Simultaneously, it maintains advantages in infrastructure, supply chain integration, and workforce capabilities that purely low-cost regions cannot match.

Operating Cost Advantages

Several factors contribute to Dongguan's cost efficiency:

- Land and facility costs: 20-30% lower than Shenzhen

- Costes laborales: 15-25% lower than coastal megacities while maintaining skill levels

- Utility costs: Competitive electricity rates and reliable infrastructure

- Supply chain efficiencies: Reduced transportation and inventory costs due to supplier proximity

- Scale economies: High production volumes spread fixed costs across more units

The Quality-Cost Equation

For humidifier brands, the true measure of cost efficiency isn't simply the lowest production cost—it's the optimal balance between cost and quality. Dongguan excels in this equation by delivering consistent quality at competitive prices. The region's manufacturers achieve this balance through process optimization, selective automation, and leveraging specialized expertise.

| Lugar de fabricación | Relative Cost Index | Quality Capability | Optimal for |

|---|---|---|---|

| Dongguan, China | 100 (baseline) | Alta | Mid-range to premium humidifiers |

| Shenzhen, China | 120-130 | Muy alta | Premium, innovative models |

| Vietnam | 85-95 | Medium-High | Cost-sensitive models |

| México | 110-120 | Alta | Mercado norteamericano |

| Estados Unidos | 180-220 | Muy alta | Premium, made-in-USA positioning |

Hidden Cost Advantages

Beyond direct manufacturing costs, Dongguan offers significant advantages in reducing hidden costs that impact total product economics:

- Reduced quality control expenses: Lower defect rates minimize inspection and rework costs

- Faster time-to-market: Compressed development cycles generate earlier revenue

- Supply chain resilience: Ecosystem depth reduces disruption risks and associated costs

- Regulatory compliance efficiency: Specialized expertise minimizes certification delays and costs

Why is Dongguan's Location in the Greater Bay Area Strategic for Humidifier Brands?

Dongguan's geographic position within China's Greater Bay Area provides humidifier manufacturers with significant logistical and strategic advantages that directly impact production efficiency and market access.

Dongguan's strategic position within the Greater Bay Area provides humidifier manufacturers with unparalleled logistics advantages—proximity to major ports, airports, and transportation networks enables rapid shipping to global markets while facilitating efficient component sourcing.

Integrated Transportation Infrastructure

Dongguan sits at the heart of one of the world's most developed transportation networks. The city is connected to:

- Shenzhen and Hong Kong ports (within 1-2 hours)

- Guangzhou Baiyun International Airport (45 minutes)

- High-speed rail network linking major Chinese cities

- Extensive highway system connecting the entire Pearl River Delta

This infrastructure enables rapid movement of both components and finished humidifiers, reducing transit times and logistics costs while improving supply chain responsiveness.

Port Access and Export Efficiency

For export-oriented humidifier brands, Dongguan's proximity to major ports represents a critical advantage. Finished products can reach Shenzhen's container terminals within hours, facilitating efficient shipping to North American, European, and Asian markets. This proximity reduces inland transportation costs and minimizes transit delays that can impact seasonal product launches.

Component Sourcing Advantages

The Greater Bay Area location also optimizes component sourcing. Manufacturers can access specialized suppliers throughout the region while maintaining tight production schedules. This geographic advantage becomes particularly valuable for just-in-time manufacturing approaches that minimize inventory costs while maintaining production flexibility.

| Logistics Factor | Dongguan Advantage | Impact on Humidifier Manufacturing |

|---|---|---|

| Port Access | <60 minutes to Shenzhen port | Reduced export costs, faster shipping |

| Airport Proximity | 45 minutes to Guangzhou Airport | Expedited shipping for urgent orders |

| Regional Connectivity | Integrated with Pearl River Delta | Efficient component sourcing |

| Customs Efficiency | Streamlined export procedures | Reduced administrative delays |

Business Environment Synergies

Beyond physical infrastructure, Dongguan benefits from the Greater Bay Area's broader business environment. The region offers:

- Financial services supporting international trade

- Professional services with experience in global supply chains

- Technology resources supporting manufacturing innovation

- Regulatory expertise facilitating international compliance

These ecosystem advantages complement Dongguan's manufacturing capabilities, creating a comprehensive environment that supports every aspect of humidifier production and distribution.

Dongguan's manufacturing ecosystem offers remarkable flexibility through OEM/ODM partnerships that enable brands to develop diverse product portfolios across multiple price points and feature sets.

Dongguan's versatile OEM/ODM partnerships enable humidifier brands to simultaneously develop entry-level models for mass-market retailers and premium devices for specialty channels, leveraging the same manufacturing base with differentiated capabilities.

The Spectrum of Manufacturing Partnerships

Dongguan offers multiple partnership models:

- Pure OEM: Brand provides complete specifications, manufacturer executes production

- ODM with Customization: Manufacturer offers existing designs with brand-specific modifications

- Joint Development: Collaborative creation of new products leveraging both parties' expertise

- Full-Service ODM: Manufacturer handles entire process from concept to production

This flexibility allows brands to select the optimal approach for each product tier, balancing control, cost, and time-to-market considerations.

Tiered Product Strategy Support

Dongguan's manufacturers excel at supporting tiered product strategies, producing everything from basic $20 humidifiers to premium $200+ models with advanced features. This capability enables brands to:

- Maintain presence across multiple retail price points

- Address different consumer segments with appropriate feature sets

- Optimize margins across the product portfolio

- Compete effectively against both value and premium competitors

Quality Consistency Across Price Points

A key advantage of Dongguan's manufacturing ecosystem is maintaining consistent quality standards across different product tiers. While features and materials may vary by price point, core reliability and performance standards remain consistent—protecting brand reputation even in entry-level offerings.

| Product Tier | Typical Manufacturing Approach | Principales ventajas |

|---|---|---|

| Entry-Level | Standard ODM designs with minimal customization | Cost efficiency, rapid deployment |

| Mid-Range | ODM with significant customization | Balanced uniqueness and efficiency |

| Premium | Joint development or pure OEM | Maximum differentiation, proprietary features |

Case Study: Tiered Manufacturing Strategy

Leading brands like Vornado demonstrate how Dongguan's manufacturing flexibility supports comprehensive market coverage. By working with different manufacturing partners for different product tiers, these brands maintain distinctive positioning while optimizing production economics across their entire portfolio.

What Role Does Dongguan Play in Multi-Functional Humidifier Innovation?

As consumer expectations evolve, humidifiers are increasingly becoming multi-functional devices that combine humidification with purification, aromatherapy, and smart home integration. Dongguan plays a pivotal role in this product evolution.

Dongguan's engineering capabilities and component ecosystem make it the ideal manufacturing center for developing hybrid humidifier-purifier devices and smart-enabled air treatment products that integrate multiple technologies into unified, cost-effective solutions.

Convergence of Technologies

Dongguan's manufacturing ecosystem uniquely supports technology convergence in humidifier design. The region's expertise spans multiple relevant domains:

- Ultrasonic humidification technology

- Air purification systems and filtration

- IoT connectivity and smart controls

- Sensor integration and environmental monitoring

This convergence capability allows manufacturers to develop integrated devices that would require multiple specialized partners in other manufacturing locations.

Engineering Resources for Complex Products

Developing multi-functional humidifiers requires sophisticated engineering resources. Dongguan offers:

- Experienced electrical engineers specializing in low-voltage, water-safe electronics

- Mechanical engineers with expertise in optimizing airflow and water atomization

- Software developers creating intuitive control systems and app interfaces

- Materials specialists selecting components suitable for water exposure

These resources enable the creation of increasingly sophisticated devices that maintain reliability despite growing complexity.

Component Integration Advantages

Multi-functional humidifiers require integrating components that traditionally belonged to separate device categories. Dongguan's manufacturing ecosystem excels at this integration through:

- Specialized suppliers developing hybrid components

- Testing facilities equipped to evaluate multiple functionalities

- Design expertise in space-efficient component arrangement

- Manufacturing processes that maintain water safety with added electronics

How Does Dongguan Fit into Global Brands' Supply Chain Diversification Strategy?

In today's complex geopolitical landscape, leading humidifier brands are implementing sophisticated supply chain diversification strategies. Dongguan plays a strategic role in these approaches.

Dongguan serves as a critical node in diversified supply chains for legacy U.S. brands like Vornado, balancing manufacturing across multiple locations to mitigate tariff impacts, reduce disruption risks, and optimize production economics while maintaining quality standards.

The China+1 Manufacturing Strategy

Many established humidifier brands now employ a "China+1" strategy—maintaining primary production in China while developing secondary manufacturing capabilities in other regions. Within this framework, Dongguan often serves as the primary China production base due to its specialized expertise, while brands develop complementary capabilities in locations like Vietnam, Mexico, or Eastern Europe.

Dongguan's Role in Tariff Mitigation

Recent trade tensions have accelerated supply chain diversification. Dongguan manufacturers have adapted by:

- Establishing satellite facilities in non-tariff-impacted regions

- Creating modular designs that allow final assembly in different locations

- Developing specialized component production that remains in Dongguan regardless of final assembly location

- Implementing flexible production planning that can shift volume between locations as needed

Balancing Specialization and Diversification

The most sophisticated humidifier brands maintain a careful balance between leveraging Dongguan's specialized capabilities and developing geographic diversification. This typically involves:

- Keeping advanced model production in Dongguan

- Maintaining critical component sourcing from Dongguan's specialized suppliers

- Gradually transferring mature product lines to alternative locations

- Using Dongguan as the innovation center while other locations focus on scale production

Why is Dongguan's New Product Development Speed Critical in Today's Market?

In the rapidly evolving humidifier market, development speed has become a critical competitive advantage. Dongguan offers unique capabilities that significantly accelerate the product development cycle.

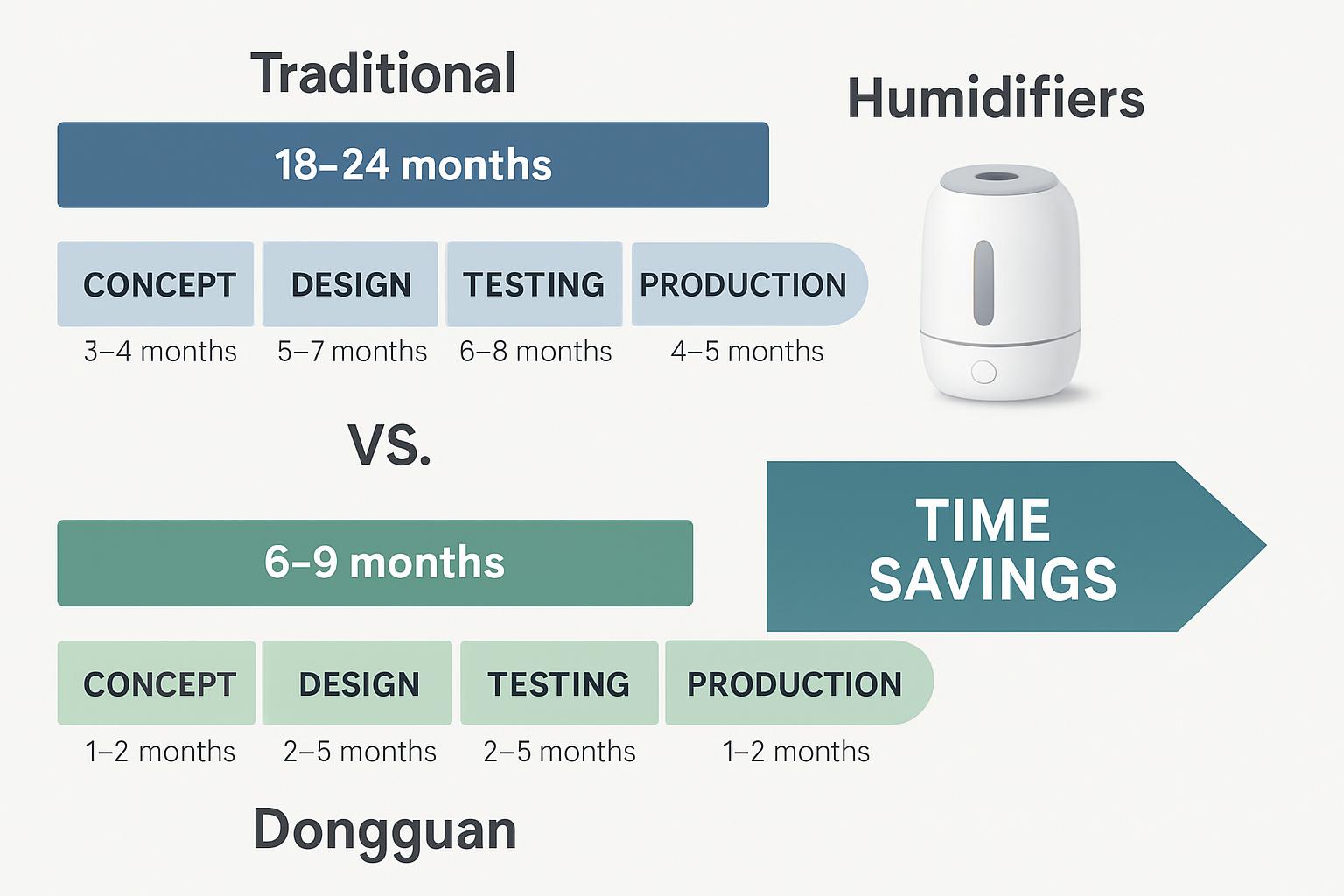

Dongguan's engineering speed and iterative manufacturing capabilities enable brands to compress humidifier development cycles from the traditional 18-24 months to just 6-9 months—a critical advantage against fast-moving e-commerce competitors like Levoit and Dreo.

Compressed Development Timelines

Traditional humidifier development typically required 18-24 months from concept to market. Dongguan's manufacturers have compressed this timeline to 6-9 months through:

- Rapid prototyping capabilities with 3D printing and CNC machining

- Experienced engineering teams that anticipate and prevent common design issues

- Streamlined testing protocols that maintain thoroughness while reducing time

- Efficient tooling development leveraging accumulated expertise

This acceleration enables brands to respond quickly to market trends and competitive threats.

Iterative Development Advantages

Dongguan's manufacturing ecosystem excels at iterative development—the ability to quickly refine designs based on testing feedback. This approach:

- Identifies and resolves design issues earlier in the development process

- Allows multiple design iterations within compressed timeframes

- Reduces costly late-stage changes

- Improves final product quality through progressive refinement

Competitive Response Capabilities

The accelerated development capabilities in Dongguan have become particularly valuable as established humidifier brands face increasing competition from agile e-commerce-native brands. Dongguan enables legacy brands to:

- Respond quickly to competitor innovations

- Rapidly incorporate emerging technologies and features

- Refresh product lines more frequently

- Maintain relevance in fast-changing retail environments

| Development Phase | Traditional Timeline | Dongguan Timeline | Key Accelerators |

|---|---|---|---|

| Concept to Prototype | 3-4 months | 1-2 meses | Rapid prototyping, experienced design teams |

| Engineering Validation | 5-7 months | 2-3 months | Iterative testing, specialized expertise |

| Tooling and Pre-production | 6-8 months | 2-3 months | Optimized processes, supplier proximity |

| Production Ramp-up | 4-5 months | 1-2 meses | Manufacturing experience, ecosystem support |

Case Study: Seasonal Product Development

The humidifier market is highly seasonal, making development timing critical. Dongguan's accelerated development capabilities enable brands to capture full seasonal sales opportunities by ensuring new products are ready for key retail placement windows—a significant advantage in maximizing annual revenue potential.

Conclusión

Dongguan's emergence as the manufacturing hub for leading humidifier brands represents a compelling case study in specialized industrial development and global supply chain evolution.

Dongguan's unique combination of manufacturing expertise, cost efficiency, and strategic location continues to make it the preferred production hub for leading humidifier brands, with its role likely to expand as demand for sophisticated air quality products grows globally.

The Convergence of Advantages

What makes Dongguan particularly remarkable is the powerful convergence of multiple advantages creating an unparalleled manufacturing environment:

- A mature electronics manufacturing ecosystem with thousands of specialized suppliers

- A skilled workforce with decades of accumulated expertise

- Cost efficiency balancing affordability with quality requirements

- Strategic location within China's Greater Bay Area providing exceptional logistics

- Flexible OEM/ODM partnerships supporting diverse product strategies

- Engineering capabilities enabling multi-functional device innovation

- Strategic positioning within diversified global supply chains

- Accelerated new product development capabilities

This convergence creates a manufacturing environment where humidifier brands can optimize across multiple dimensions simultaneously—quality, cost, innovation, and speed-to-market.

Evolving Role in a Changing Landscape

Dongguan's role continues to evolve in response to changing market dynamics and global trade patterns. Several trends suggest how its contribution may develop:

- Increasing focus on premium and complex products as basic production shifts to lower-cost locations

- Greater emphasis on innovation and new product development leveraging engineering capabilities

- More sophisticated integration within diversified supply chains balancing risk and specialization

- Enhanced digital connectivity linking design, production, and distribution globally

The Future of Humidifier Manufacturing

Looking forward, the humidifier category continues to evolve toward greater sophistication, with increasing integration of smart features, multi-functionality, and enhanced performance. These trends play to Dongguan's strengths in electronics manufacturing and engineering capabilities, suggesting the region's role in humidifier production may expand further as product complexity increases.