Choosing a supplier based on price alone is a huge risk. Your entire project could be stopped at the border, costing you thousands and ruining your reputation.

To ensure a supplier meets US and EU standards, you must verify their product-specific certificates1. Ask for documents like ETL for the US or CE for the EU, and then independently confirm their validity with the issuing laboratory. This is the only way to protect your investment.

I've seen too many promising projects fail, not because of a bad design, but because of a simple, overlooked question. A client once came to me in a panic. His shipment of electronic enclosures was impounded by customs. His previous supplier gave him a "certificate," but it was for the wrong product. He lost his entire initial investment and missed his launch window. This is why I always tell my clients that compliance isn't just a box to check; it's the foundation of your business. In this post, I'll walk you through the exact steps I use to verify a supplier's claims, so you can avoid these costly mistakes and launch with confidence.

All products sold in the EU must have a CE mark.Verdadero

The CE marking is mandatory for specific product groups to be sold in the European Economic Area (EEA), but not all products require it.

ETL is a product safety standard, just like UL.Falso

ETL (from Intertek) and UL (from Underwriters Laboratories) are both Nationally Recognized Testing Laboratories (NRTLs) that test products to the same safety standards. They are competing certification marks, not the standards themselves.

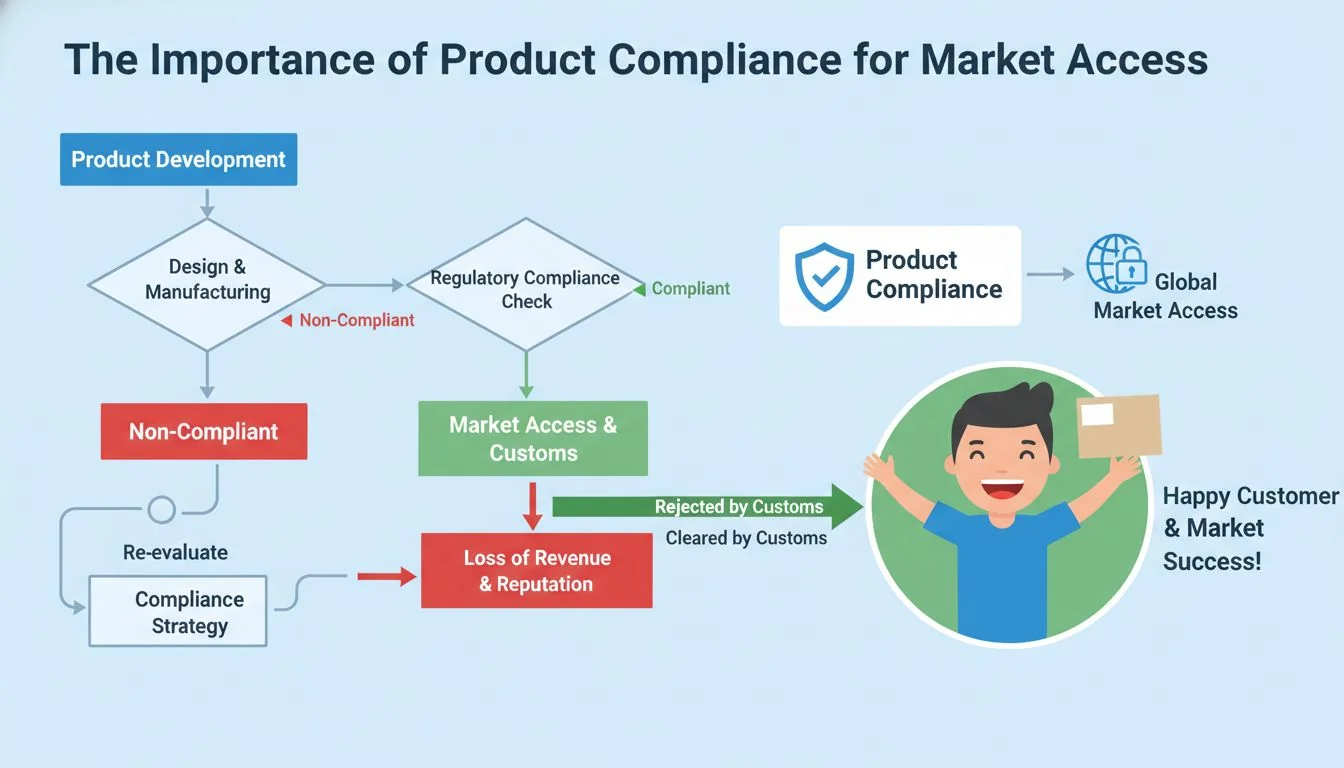

1. Why is "Is it compliant?" the most important question?

Your product's success hinges on market access. If it can't legally be sold, your design, marketing, and investment mean nothing. Compliance is your ticket to entry and your best defense.

Asking "Is it compliant?" upfront makes it your #1 differentiator. It separates you from low-quality competitors and protects your brand's reputation. Proving compliance establishes you as an expert who safeguards your customers' investment and ensures a smooth path from factory to market.

When you lead with compliance, you change the conversation from "How cheap can you make it?" to "How can you guarantee my success?" This is a much stronger position to be in. Your ability to prove you meet US and EU standards is your single strongest sales argument. It builds instant trust. I tell my sales team to not even wait for the question. We lead by providing our ETL, CE, and CARB files proactively. This transparency shows we have nothing to hide and that we are serious partners. It's about selling "risk removal" and "speed-to-market." A client doesn't have to worry about a nine-month testing delay or a failed inspection. We offer a product that is ready to go, today. This is how you win against cheaper, non-compliant factories every single time.

Product compliance is solely the manufacturer's responsibility.Falso

Responsibility is shared. While the manufacturer produces the item, the importer (you) is legally responsible for ensuring products placed on the market meet all relevant standards.

Compliance adds unnecessary costs to a product.Verdadero

While there are upfront costs for testing and certification, they are far less than the costs of a product recall, fines, or being barred from a market, making compliance a crucial investment.

2. Do you know the key standards for the US vs. the EU?

You're designing a product for international markets, but the rules are different everywhere. Using a US certificate for the EU (or vice-versa) is a recipe for rejection at the border.

To sell globally, you must understand the core standards for each region. For the US, focus on electrical safety (ETL/UL) and chemical safety (CARB). For the EU, it's about general safety and health (CE) and hazardous substances (RoHS).

Being an expert on both markets is a powerful tool. When I talk to a client in the US, explaining how our products also meet EU standards like RoHS gives them immense confidence. It proves our compliance system isn't just a one-off for a single market; it's mature and robust. It shows we invest in quality beyond the legal minimum. Many factories can get a basic safety certificate, but having environmental and chemical certifications proves you are a top-tier manufacturer.

Here’s a simple breakdown to help you master the basics:

Key Standards: A Quick Comparison

| Estándar | Región | What It Covers | Key Takeaway |

|---|---|---|---|

| ETL / UL | EE.UU. | Electrical Safety: Fire and shock hazards. | These are competing marks from certified labs (NRTLs). Either is valid proof for the US market. |

| CARB | USA (California) | Chemical Safety: Formaldehyde emissions from composite wood. | Originally a California standard, it's now the de facto benchmark for air quality across the US. |

| CE | UE | Health, Safety, Environment: A broad declaration covering many product types. | Often self-certified by the manufacturer, but must be backed by a technical file and testing. |

| RoHS | UE | Chemical Safety: Restriction of Hazardous Substances (e.g., lead, mercury). | This is a must-have for almost all electronics sold in the EU. It shows environmental responsibility. |

Understanding these differences allows you to ask smarter questions and instantly spot a supplier who doesn't know what they're talking about.

A CE mark guarantees a product was tested by a third-party lab.Falso

For many products, the CE mark is a self-declaration by the manufacturer. Only higher-risk products require mandatory third-party assessment by a Notified Body.

CARB compliance is only necessary for products sold in California.Falso

While it's a California Air Resources Board regulation, major US retailers often require CARB compliance for composite wood products regardless of the state they are sold in.

3. What is the 3-step verification process to actually check?

A supplier sends you a PDF of a certificate. It looks official, but how do you know it's real? Fake or expired documents are common and can lead to disaster.

You must verify every certificate yourself. The process is simple: request the document, analyze its details, and confirm its authenticity directly with the issuing body through their online database.

The core message I drill into my team is "Show, Don't Tell." But for you, the client, the message has to be "Verify, Don't Trust." Any good supplier will welcome this scrutiny. If a supplier gets defensive when you ask to verify their claims, that's a major red flag. I had a client who was about to place a huge order based on a very convincing "UL certificate." I told him to hold on and we ran through this 3-step process. It took us 10 minutes. We discovered the certificate was for a completely different company and product model. He dodged a massive bullet.

Step 1: Ask for the Full Certificate

Don't accept a photo or a summary. Request the complete, unedited PDF document. It should clearly show the certificate number, the manufacturer's name, the specific product models covered, the standards it was tested against, and the issue date.

Step 2: Analyze the Details

Look closely. Does the manufacturer's name and address match your supplier exactly? Is your specific product model number listed? Is the certificate still valid (check the date)? A certificate for "Model A" doesn't cover "Model B."

Step 3: Verify with the Issuing Body

This is the most important step. Go to the website of the issuing lab (e.g., Intertek for ETL, UL's database, or the Notified Body for CE) and search for the certificate number. The online record is the only real proof. If it's not in the database, it's not valid.

You can verify any CE certificate in a central EU database.Falso

There is no central database for all CE-marked products. Verification for self-declared products relies on the manufacturer's Technical File, while high-risk products can be checked with the specific Notified Body that issued the certificate.

An ETL certificate is valid forever once issued.Falso

ETL certifications require periodic follow-up inspections and renewal. You must check the certificate's status and validity date in the Intertek online directory to ensure it is current.

4. Why shouldn't you confuse a "factory audit" with a "product certificate"?

A supplier proudly tells you, "We are ISO 9001 certified!" You might think this means their products are safe and compliant. This is a common and dangerous misunderstanding.

A factory audit and a product certificate are completely different. An audit like ISO 9001 assesses the factory's management processes, while a product certificate like ETL or CE verifies that a specific product has passed safety tests.

Think of it this way. An ISO 9001 certificate is like a chef graduating from a top culinary school. It shows they have a good system and training. But a product certificate is like a health inspector's report for the specific meal you're about to eat. It proves that dish is safe to consume right now. You need both. A great factory should have good systems (like ISO 9001), but you absolutely must have proof that the specific product you are buying is safe and compliant for your target market. I always look for both, but I never, ever accept a factory audit as a substitute for a product-specific safety certificate.

What They Actually Mean

| Document Type | What It Certifies | Ejemplo | What It Tells You |

|---|---|---|---|

| Factory Audit Report | En PROCESS | ISO 9001, BSCI | The factory has a quality management system or meets social compliance standards. It says nothing about any single product. |

| Product Certificate | En PRODUCT | ETL, CE, CARB | A specific product model was tested and found to meet specific safety, health, or environmental standards. |

Don't let a supplier distract you with a factory audit. Always bring the conversation back to the product itself. Your question should be: "That's great you have ISO 9001. Now, can you please show me the ETL certificate for the exact model I am ordering?"

ISO 9001 certification guarantees a product is free of defects.Falso

ISO 9001 certifies that a company has a quality management system in place. It does not guarantee that every single product will be defect-free, but that there are processes to manage quality and continuous improvement.

A BSCI audit means a factory's products are high quality.Falso

BSCI (Business Social Compliance Initiative) is an audit focused on social standards, like working hours and workplace safety. It has no bearing on the product's quality, safety, or performance.

5. Why should you look for an in-house compliance team?

You're vetting two suppliers. One has a dedicated compliance manager, the other says their sales manager "handles it." Which one do you trust more with your investment?

A supplier with an in-house compliance team2 is a sign of maturity and commitment. It shows they treat safety and compliance as a core business function, not an administrative afterthought.

When I started my own trading company, one of the first hires I made was a compliance specialist. It wasn't cheap, but it was the best investment I ever made. Why? Because compliance is always changing. New rules are added, and standards are updated. A dedicated team's job is to stay ahead of these changes. They manage the testing schedules, handle the paperwork, and work with our engineers to design compliance into the product from the very beginning. This proactive approach is what separates the pros from the amateurs. A supplier without this resource is always playing catch-up. They only think about compliance when a client asks, which is often too late. An in-house team means they are investing their own money to protect your business. That's a partner you can rely on.

Signs of a Proactive Supplier

- They have a dedicated compliance manager or team. Ask to speak with them.

- They design for compliance. They consider standards during the R&D phase, not after production.

- They maintain a library of certificates. They can provide documents for all their main products instantly.

- They understand global standards. They can discuss the nuances between CE, RoHS, ETL, and CARB with confidence.

Small factories cannot afford an in-house compliance team.Falso

While a large team may be unfeasible, even small, serious factories will have at least one person who is an expert and dedicated to managing compliance, even if it's not their only role.

A supplier's compliance team can issue official certificates.Falso

The in-house team manages the compliance process, but the official certificates must be issued by an accredited, independent third-party laboratory or Notified Body.

6. What is the smart-cut to partner with a "market-ready" supplier?

You have a great product idea, but the thought of navigating a 9-month certification process is overwhelming. You risk delays, budget overruns, and missing your market window.

The ultimate smart-cut is to partner with a supplier whose products are already "market-ready." This means they have already done the hard work of testing and certification for your target market.

This is the core of my business philosophy. I don't just sell molds or products; I sell "speed" and "certainty." When a client comes to us, they aren't just buying a physical item. They are buying a "US-Market-Ready" or "EU-Market-Ready" solution. This completely changes the dynamic. They don't have to add a year to their project timeline for testing and certification. They don't have to budget an extra $20,000 for lab fees and potential redesigns. They can place an order today and be confident that the product can be legally sold the moment it arrives. This is the single biggest value you can get from a supplier. It removes the biggest risk from your project and dramatically accelerates your speed-to-market. A supplier who provides this isn't a vendor; they are a strategic partner in your growth.

Benefits of a Market-Ready Partner

- Speed: Launch in weeks, not months.

- Cost Savings: Avoid expensive and unpredictable testing fees.

- Risk Removal: Eliminate the chance of being rejected by customs or forced into a recall.

- Trust: Their proactive investment in compliance proves they are a serious, long-term partner.

When you find a supplier who leads with their certificates, you've found a winner.

Using a 'market-ready' product means you have no legal compliance responsibilities.Falso

As the importer, you are still legally responsible. However, partnering with a market-ready supplier who provides valid documentation makes fulfilling your responsibilities infinitely easier and less risky.

Market-ready products are always more expensive.Falso

While the unit price might be slightly higher to cover certification costs, the total project cost is often far lower because you avoid separate testing fees, delays, and redesigns.

Conclusión

Verifying supplier compliance is not optional; it's the most critical step in protecting your investment. By knowing the standards, checking certificates, and partnering with market-ready suppliers, you ensure a fast and safe path to market.