Consumers are losing faith in clean water claims because of the materials used to store it. Plastic components in "purified" systems are silently eroding brand value and customer trust.

Zero-Plastic1 water systems build trust by eliminating "post-filtration" contamination risks. By utilizing medical-grade stainless steel instead of plastic for internal tubing and tanks, brands ensure water remains pure after filtration. This engineering choice creates a "no-compromise" narrative that appeals to health-conscious consumers and future-proofs against regulations.

Many designers overlook the journey water takes after the filter, focusing only on the filtration process itself. Let’s explore why changing materials from plastic to steel is the ultimate design upgrade for premium brands.

Plastic water storage tanks are completely immune to bacterial growth over time.Falso

Plastic surfaces can develop biofilms and degrade, potentially leaching chemicals or harboring bacteria over long periods.

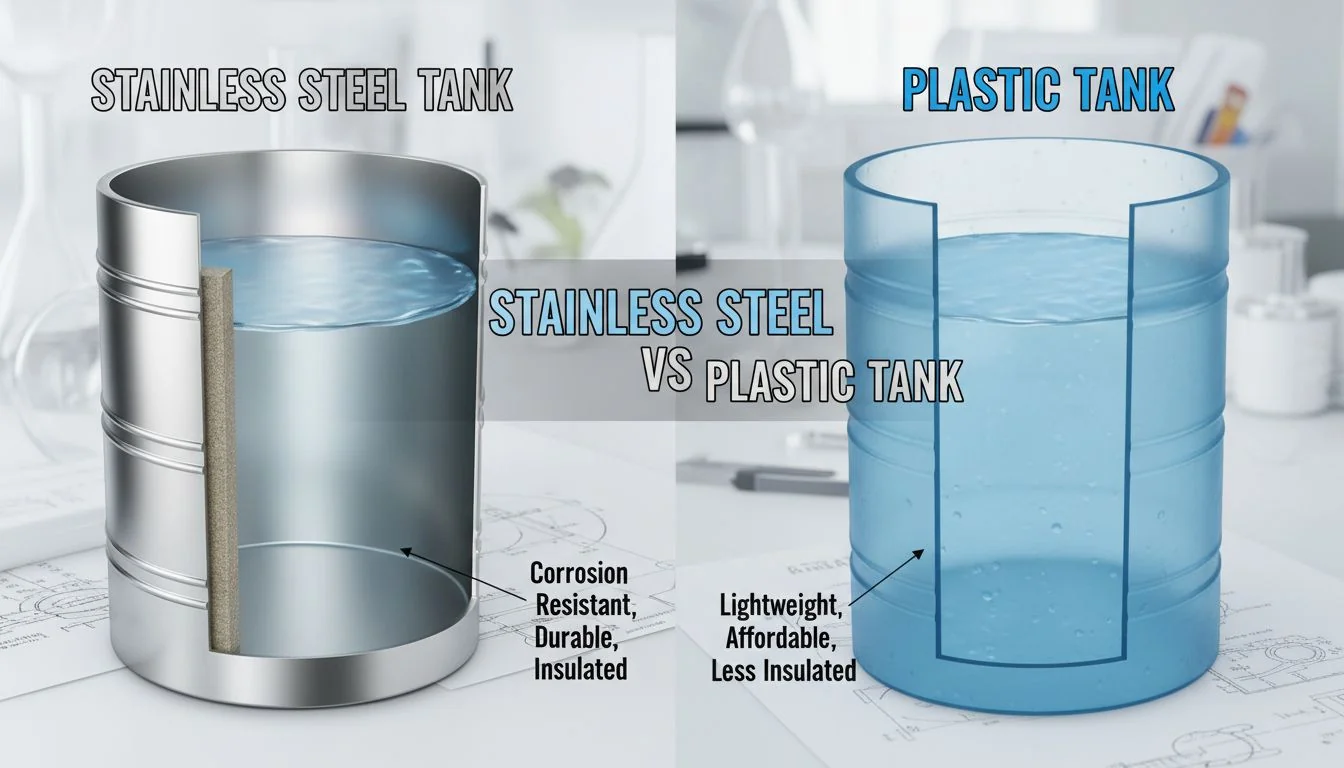

Stainless steel is non-porous and resistant to leaching, making it safer for long-term water storage.Verdadero

Medical-grade stainless steel does not degrade or release microplastics, maintaining water purity after filtration.

Why Is There a Crisis of Trust in the Water Aisle?

The market is flooded with filters that claim to remove everything, yet consumers are still skeptical. We need to understand why high specifications are no longer enough to win sales.

The crisis stems from a disconnect between "pure water" marketing and "plastic hardware" reality. When a customer buys a premium filter but tastes plastic or reads about microplastics, they feel cheated. Brands must address the entire water journey, not just the filter element, to regain consumer confidence.

The Shift from Pre-Filtration to Post-Filtration

In my years in the mold industry, I have seen thousands of designs for water purifiers. Almost all of them focus on "Pre-Filtration." This means the designers and engineers spend all their energy on the filter cartridge itself. They ask, "How much dirt can we remove?" This is a crowded battleground. Every competitor claims to remove 99.9% of contaminants. It is hard to stand out here.

However, I believe the real opportunity lies in "Post-Filtration." This is the stage after the water passes through the filter. In most standard designs, this clean water sits in a plastic tank or travels through plastic tubes before it hits the glass. This creates a logical flaw. Why clean the water if you are going to store it in a dirty or degradable container?

I have noticed that premium buyers are smart. They are starting to ask, "Why is my pure water touching plastic?" This argument is logically irrefutable. If you shift your design focus to keeping the water clean after it is filtered, you create immediate doubt about your competitors. You show that you understand the complete cycle of hygiene. This is not just a marketing trick; it is a fundamental design philosophy that respects the purity of the final product.

Most water purifier marketing focuses on the storage tank material.Falso

The vast majority of marketing focuses on the filter's ability to remove contaminants (Pre-Filtration), ignoring storage risks.

Post-filtration contamination is a valid concern for water purity.Verdadero

Clean water can be re-contaminated by leaching chemicals or biofilms if stored in improper materials like low-grade plastic.

What Is the "Invisible Breach" When Hardware Betrays the Filter?

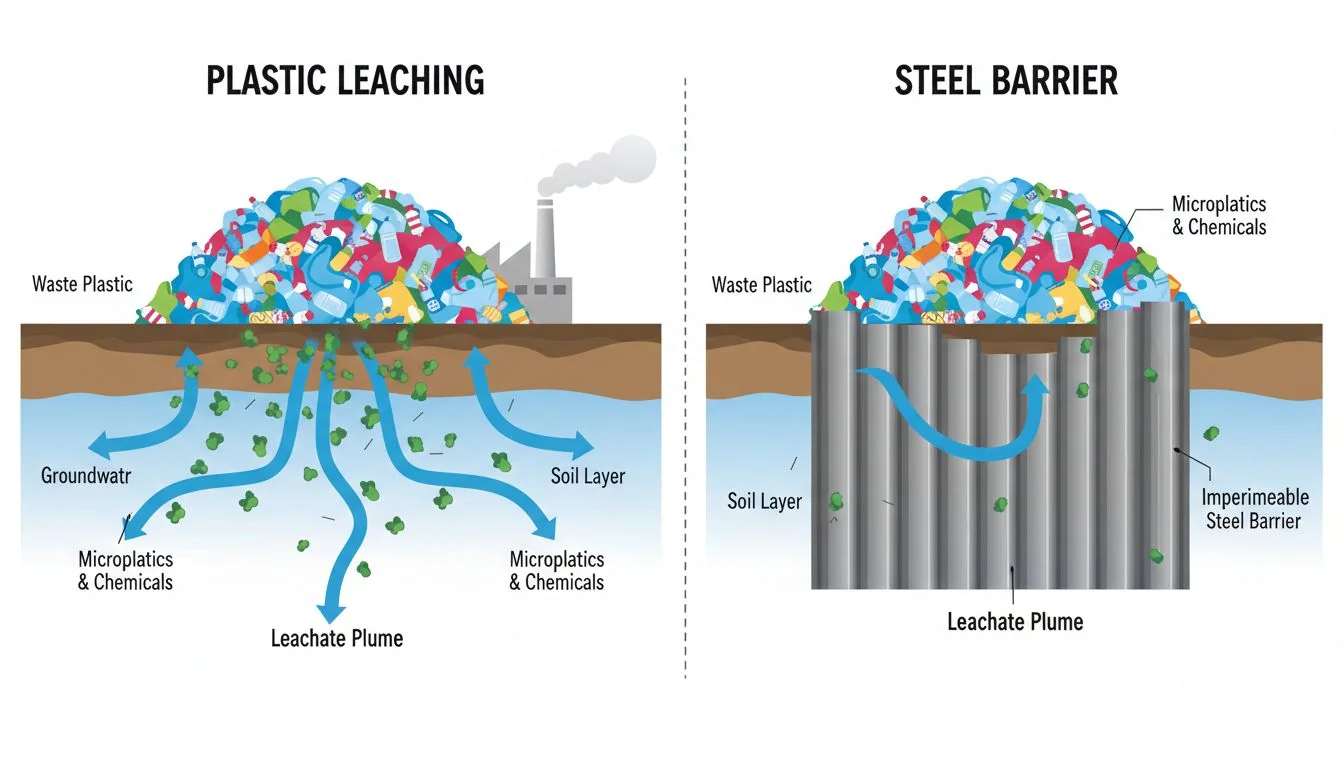

We cannot see plastic leaching with our eyes, so it is easy to ignore during the design phase. However, this invisible failure is exactly what destroys the long-term reputation of a product.

The "invisible breach2" occurs when plastic components degrade and release microplastics or chemicals into filtered water. This betrays the filter's work, turning a purification device into a pollution source. Visualizing this risk for clients makes the switch to steel essential.

Visualizing the Migration Paths

As a mold designer, I am used to thinking about wall thickness and shrinkage. But we also need to think about "Migration Paths3." In a plastic tank, the wall is not a solid barrier at the microscopic level. Over time, especially with temperature changes, plastic can degrade. It can release additives into the water. This is invisible to the naked eye, but it is a breach of the system's integrity.

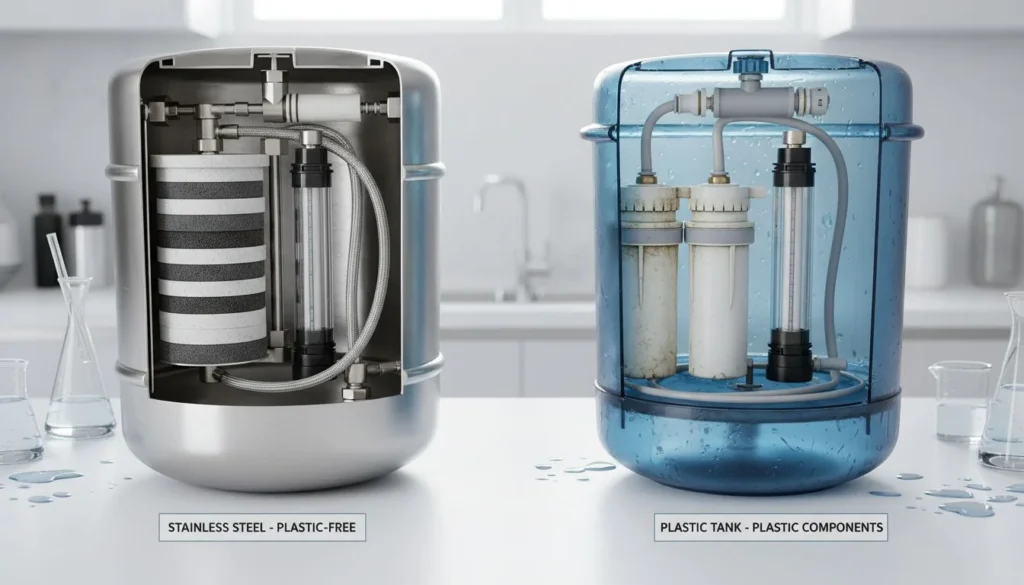

When I consult with clients, I try to make this invisible risk visible. I use diagrams to show the difference between plastic and steel.

- Plastic: I show a porous surface where chemicals can migrate out and bacteria can hide in scratches.

- Steel: I show an "Impenetrable Wall." Nothing goes in, and nothing comes out.

This visualization is powerful. It changes the conversation from "cost saving" to "safety." If you are designing a premium product, you cannot afford this invisible breach. Companies like Hisoair understand this well. They do not just sell a tank; they sell the assurance that the hardware will not betray the filter. By using steel, you are cutting off the migration path. You are ensuring that the water at the tap is exactly the same as the water that just left the filter. This is the engineering reality that backs up the marketing dream of "100% pure water."

Microscopic scratches in plastic can harbor bacteria.Verdadero

Plastic is softer than steel and scratches easily, creating breeding grounds for bacteria that are hard to clean.

You can see plastic leaching with the naked eye immediately.Falso

Leaching is a chemical process that is invisible and happens over time, making it a hidden danger.

What Does "Zero-Plastic" Actually Mean for Design?

"Zero-plastic" sounds like a buzzword, but it requires a complete overhaul of the manufacturing process. It is a commitment to replacing easy molding with precision engineering.

"Zero-Plastic" means that no plastic components touch the water at any point in the system. This requires replacing cheap injection-molded parts with complex stainless steel welding and forming. It is a "dogged pursuit of perfection" that signals a brand cares more about health than cutting costs.

The No-Compromise Narrative

In the mold industry, we love plastic because it is cheap and easy to shape. Moving to "Zero-Plastic" is a headache for manufacturing. You cannot just inject a complex shape in seconds. You have to stamp, weld, and polish stainless steel. It costs more money and takes more time.

But this difficulty is exactly why it is valuable. When a brand claims "Zero-Plastic," they are telling a story of "No-Compromise." They are saying, "We could have saved money by using plastic, but we chose not to because we care about your health."

I have found that premium buyers love this narrative. They want to buy from brands that are obsessed with perfection.

- Wetted Parts: This refers to every single part that touches water. It is not enough to have a steel case if the internal tubes are plastic.

- The Challenge: Designing molds for steel forming (deep drawing) is different from plastic injection. It requires higher precision and stronger tools.

By embracing this difficulty, you elevate your brand. You are no longer competing on price. You are competing on integrity. This approach transforms a standard kitchen appliance into a piece of high-end engineering. It proves that you are willing to do the hard work to guarantee safety.

Manufacturing with stainless steel is generally cheaper than plastic injection molding.Falso

Stainless steel requires more expensive raw materials and complex processes like welding and polishing, making it more costly.

A 'Zero-Plastic' claim usually refers only to the external casing of the product.Falso

True 'Zero-Plastic' refers to the 'wetted parts'—the internal components that actually touch the water.

How Does the Psychology of Materials Make Steel Equal Trust?

Materials speak a silent language to the user. The way a product feels and looks determines how much the user trusts it to protect their health.

Steel equals trust because it is the material of the medical industry. By using stainless steel, brands borrow the "medical-grade" reputation of scalpels and surgical implants. This positions the water system as a health device rather than just a kitchen appliance.

Medical-Grade Hydration

There is a reason why hospitals do not use plastic trays for surgery. Stainless steel feels clean, sterile, and permanent. Plastic feels warm, temporary, and porous. As a designer, you must understand this psychology.

When you position your product, do not just call it a "Kitchen Appliance." That puts you in the same category as a toaster. Instead, use the term "Medical-Grade Hydration." This is a powerful shift.

- Association: Steel is associated with scalpels, implants, and sterile environments.

- Health Anxiety: Many modern consumers are anxious about toxins. They fear BPA and unknown chemicals. Steel calms this anxiety.

I have seen brands successfully use this strategy. By using materials like SUS304 or SUS316 stainless steel, they tap into the immense trust equity of the medical field. It signals that the water system is built to the same standards as a life-saving device. This appeals strongly to the demographic that reads labels and worries about long-term health effects. You are not just selling a drink; you are selling peace of mind. The cold, hard touch of steel confirms to the user that the product is serious about hygiene.

Stainless steel is commonly used in medical environments due to its sterility.Verdadero

Its non-porous surface and resistance to corrosion make it the standard for surgical tools and implants.

Consumers perceive plastic as a more premium material than steel.Falso

Psychologically, steel is associated with durability and luxury, while plastic is often associated with disposability and low cost.

Is the "Future-Proof" Strategy Immunity from Regulation?

Regulations regarding plastics and food safety are getting stricter every year. Designing with plastic now is a risk for the future.

The "Future-Proof" strategy uses steel to provide immunity from changing regulations and lawsuits. As laws regarding BPA and microplastics tighten, steel systems remain compliant. This acts as "Reputation Insurance4," allowing brands to make bold safety claims without fear of being debunked.

Hisoair as the "Trust Engineer"

We are seeing more news about bans on single-use plastics and new discoveries about toxic additives. If you design a product with plastic today, it might be illegal or considered unsafe in five years. This is a huge risk for a manufacturer.

This is where the concept of "Reputation Insurance" comes in. Companies like Hisoair act as the "Trust Engineer." They provide the engineering reality that protects the brand.

- The Risk: If you claim "100% Microplastic Free" but use a plastic tank, a simple lab test can sue you or debunk your claim.

- The Solution: A steel system is immune to this. It does not age or shed particles like plastic does.

By adopting a zero-plastic approach, you are future-proofing your business. You do not have to worry about the next "BPA" scandal because your material is inert. You can make bold marketing claims with total confidence. This is crucial for B2B pitches. You are telling your retail partners, "This product is safe today, and it will be safe ten years from now." You are removing the liability from their shelves. In an uncertain regulatory world, steel is the safest bet you can make.

Regulations regarding plastic additives in food contact materials are becoming looser.Falso

Governments worldwide are increasing restrictions on plastics (like BPA and PFAS) due to health concerns.

Steel water systems are generally unaffected by bans on plastic additives.Verdadero

Since stainless steel does not contain plasticizers or additives, it is immune to regulations targeting those chemicals.

Conclusion: Integrity is the Ultimate Luxury

To summarize, "Zero-Plastic" is not just a material choice; it is a trust-building strategy5. By moving to medical-grade steel, we solve the "invisible breach" of leaching, satisfy the psychological need for safety, and future-proof our designs against regulation. In the premium market, integrity is the ultimate luxury.

References

-

Understanding 'Zero-Plastic' can reveal how brands build trust and ensure water purity. ↩

-

Discover how unseen risks can undermine water purification efforts and brand trust. ↩

-

Understanding Migration Paths can help in designing safer water storage solutions. ↩

-

Find out how brands can protect their reputation through material choices. ↩

-

Explore effective strategies for brands to build trust with consumers. ↩