We see "green" labels everywhere today. It is frustrating for designers and consumers alike because often, it is just marketing fluff. You want to design products that actually help the planet, not just products that claim to.

True eco-friendly design goes beyond recycled cardboard packaging. It requires a fundamental shift toward "Buy-for-Life" materials like stainless steel, AI-driven energy efficiency1, and washable filtration systems. These innovations differentiate premium brands from cheap commodities by offering durability and reducing long-term waste.

I have spent years in the mold industry. I have seen thousands of plastic shells that end up in landfills after a few years. It bothers me. I know you, as a designer, face the same conflict. You want to build quality, but the market pushes for cheap speed. But things are changing. High-end buyers are waking up. They want luxury that lasts. This shift is your opportunity to design something better.

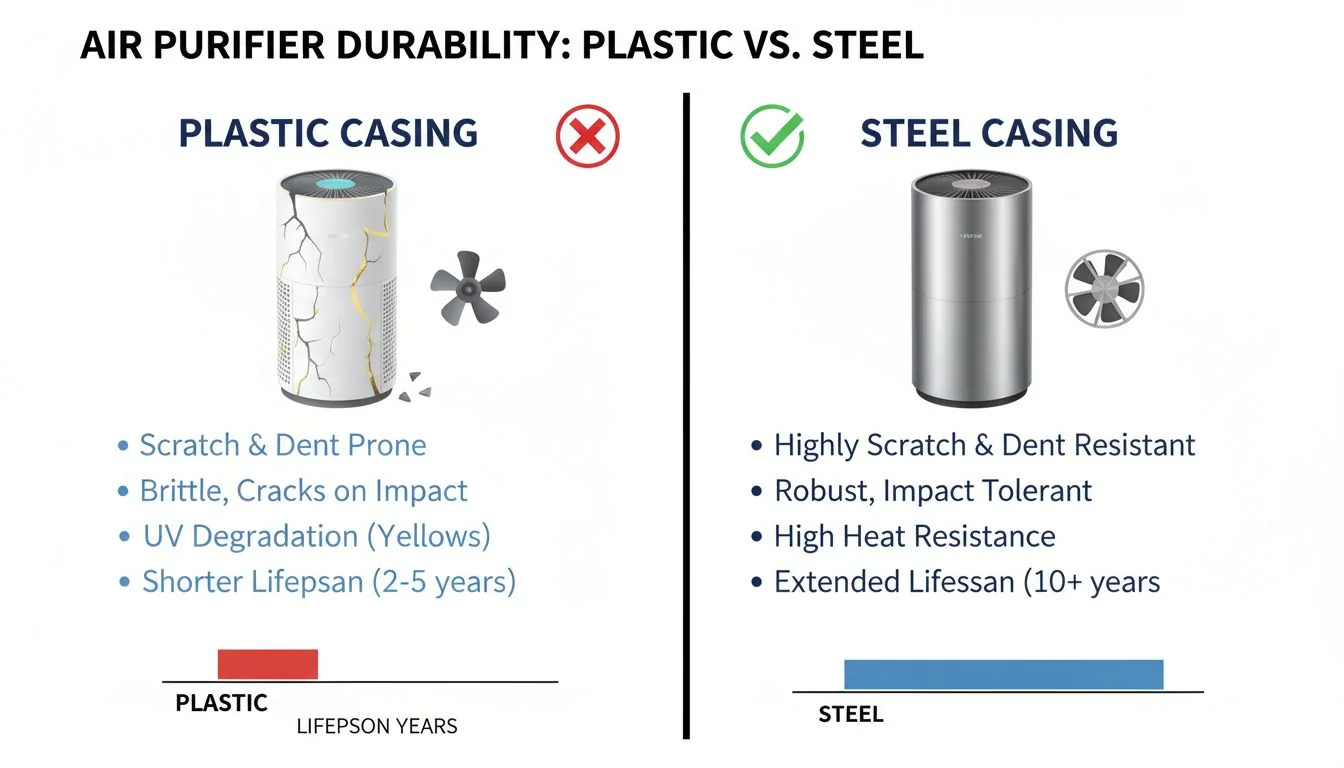

Stainless steel products have a lifespan 500% longer than average plastic alternatives.Verdadero

Steel is more durable and resistant to degradation compared to standard ABS plastics used in consumer electronics.

Recycled plastic is the only solution for sustainable design.Falso

While better than virgin plastic, durability and longevity (using metals or glass) are often more sustainable strategies than recycling weak materials.

Why Must We Move Beyond Simple "Greenwashing"?

Consumers are smart, and they are tired of fake promises. They know that a green sticker on a cheap plastic box does not save the planet. This skepticism creates a barrier for honest brands trying to make a difference.

To win trust, we must move from "Greenwashing2" to structural engineering changes. Real sustainability involves designing for longevity and repairability, proving to the customer that the product is an investment in their health and the environment, not just a disposable item.

I remember when I first started my mold trading company. Clients would ask for "eco-friendly" options, but they only meant the packaging. They did not want to change the product itself because it was too hard. But today, that is not enough.

We need to look at the core engineering. "Greenwashing" is when you paint a factory chimney green. Real design is shutting the chimney down. For a product designer like you, this means looking at the lifecycle. If you design a purifier that breaks in two years, it is trash. It does not matter if it is made of 50% recycled plastic. It is still trash.

However, if you design a unit that lasts ten years, you reduce the manufacturing footprint by five times. This is the argument you need to take to your engineering team. We need to stop focusing on the sticker on the box and start focusing on the machine inside. High-end brands separate themselves by doing the hard work here. They do not just say they are green; they engineer it.

| Característica | Greenwashing | Real Eco-Design |

|---|---|---|

| Material | Virgin Plastic with "Eco" label | Stainless Steel / Glass |

| Vida útil | 2-3 Years | 10+ Years |

| Mantenimiento | Disposable Filters | Washable / Long-life Filters |

| Enfoque | Marketing | Ingeniería |

Greenwashing improves long-term brand loyalty.Falso

Consumers eventually realize the lack of substance, leading to distrust and brand damage.

Engineering for longevity reduces total environmental impact more than recycling.Verdadero

Extending product life prevents the energy-intensive manufacturing of replacement units.

Is Stainless Steel the Future of Sustainable Luxury?

Plastic feels cheap. It cracks, it yellows, and it ends up in the ocean. When a customer pays a premium price, they expect a material that reflects that value.

Switching from plastic to stainless steel increases product lifespan significantly. This "durability is the new eco" approach reduces landfill waste and signals premium quality to the consumer, positioning the device as a piece of furniture rather than an appliance.

In my years working with molds, I have learned that "Durability" is the strongest argument against cheap competitors. Plastic is "Fast Fashion." It is designed to be replaced. Stainless Steel is "Classic Luxury."

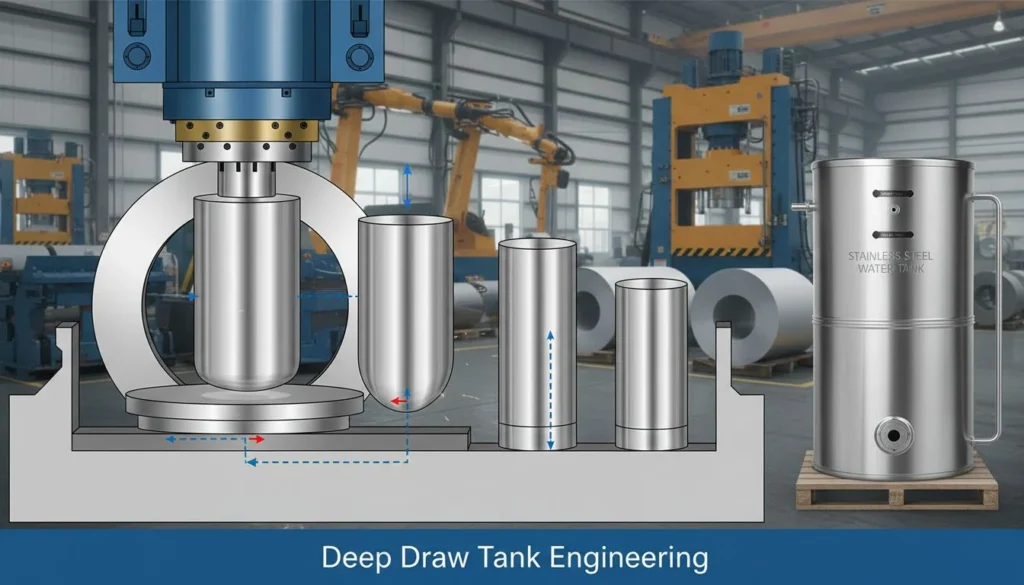

Think about the molds we design. A plastic injection mold is complex and deals with shrinkage rates that drive us crazy. But a stamping die for a steel housing? It creates a part that is robust. It feels cold to the touch. It has weight. When a customer touches a steel air purifier, they feel the value immediately.

You should market longevity as a primary sustainability feature. If a steel unit lasts 10 years instead of 2, it is 500% more eco-friendly. This is simple math. By moving to wall-mounted steel designs, you automatically signal that this is a top-tier product. You separate your design from the "plastic commodity" ocean. It is not just about being green; it is about being premium. The two go hand in hand.

| Attribute | Plastic Housing | Stainless Steel Housing |

|---|---|---|

| Perceived Value | Low / Disposable | High / Luxury |

| Durabilidad | Prone to cracking/UV damage | Extremely High |

| Eco-Impact | High turnover (waste) | Buy-for-Life |

Stainless steel is 100% recyclable without degradation.Verdadero

Unlike plastic, which degrades each time it is recycled, steel retains its properties indefinitely.

Plastic molds are always cheaper than metal stamping dies.Falso

High-precision plastic injection molds can be extremely expensive, sometimes exceeding simple stamping tooling costs.

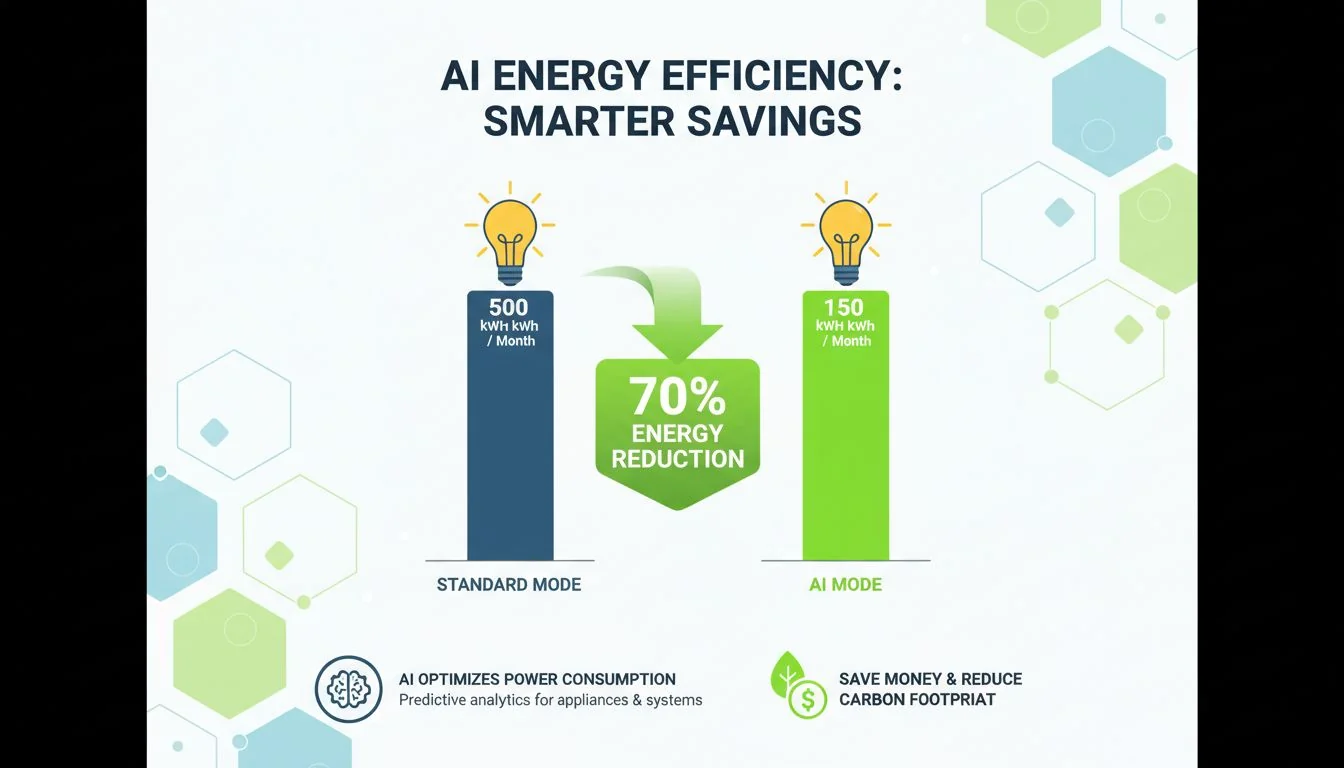

How Does AI Transform Energy Efficiency into a Selling Point?

Energy prices are rising globally. People are scared to leave their appliances running all day. A "dumb" air purifier that runs on high speed is a waste of money.

AI-driven "Smart Eco" modes adjust fan speeds based on real-time air quality sensors. This reduces energy consumption, lowering operating costs and appealing to financially conscious buyers who want to save money while saving the planet.

We need to weaponize "energy anxiety3." Your clients are worried about their electricity bills. This is a financial selling point, not just an environmental one.

I have seen the rise of IoT (Internet of Things) in manufacturing. We can apply this to air purifiers. A standard unit runs blindly. It consumes power even when the air is clean. That is bad design. By integrating AI and precise sensors, the device becomes smart. It "pays for itself" over time.

When you design the PCB housing and sensor placement, you are enabling this efficiency. You are telling the customer: "This machine thinks for you." It only works when it needs to. This creates a narrative of efficiency. It is the difference between a light switch and a motion sensor. One is manual and wasteful; the other is smart and efficient. For a high-end brand, "Smart Eco" mode is a mandatory feature. It justifies the higher upfront cost by promising lower monthly bills.

| Modo | Energy Use | User Effort | Eficiencia de costes |

|---|---|---|---|

| Standard (High) | 100% | Manual | Bajo |

| AI Smart Eco | 20-40% | Automatic | Alta |

AI modes can reduce air purifier energy consumption by up to 50%.Verdadero

By running fans only when pollution is detected, the device avoids wasting energy on clean air.

Sensors do not impact the internal design of the mold.Falso

Designers must create specific channels and housing for sensors to ensure accurate airflow readings.

Can Washable Filters Solve the Consumable Waste Problem?

Changing filters is a hassle. It is also wasteful. High-end buyers hate the constant need to buy and throw away dirty filters.

washable pre-filters4 and ESP (Electrostatic Precipitator) technology eliminate the need for frequent disposable filter replacements. This reduces landfill waste and offers a convenient, low-maintenance user experience that respects the buyer's time.

This is what I call the "Consumable Pivot." For years, the industry made money by selling replacement filters. It is the razor-and-blade model. But luxury buyers are tired of it. It feels like a trap.

Positioning Washable Pre-Filters or ESP Tech is a "Convenience + Eco" feature. It signals that you respect the user's time and the planet. From a design perspective, this changes how we build the chassis. We need easy-access panels. We need water-resistant materials for the filter frame.

I have helped clients source parts for ESP units. It is different from standard HEPA designs. But the payoff is huge. You tell the customer: "Buy this once, and you are done." No more ordering filters every six months. No more throwing dirty plastic frames in the trash. It is a cleaner, smarter way to operate. It aligns perfectly with the "Buy-for-Life" philosophy we discussed earlier.

| Característica | Disposable HEPA | Washable / ESP |

|---|---|---|

| Waste | High (Landfill) | Low / Zero |

| Coste | Recurring | One-time |

| Conveniencia | Low (Must reorder) | High (Wash and reuse) |

Washable filters eliminate 100% of maintenance.Falso

They still require regular cleaning, but they eliminate the need for purchasing and discarding replacements.

ESP technology can capture particles without restricting airflow like dense filters.Verdadero

Electrostatic precipitation uses electrical charges to trap dust, allowing air to pass through more freely.

Why Is Supply Chain Transparency Critical for Modern Brands?

Brands today have targets to hit. They need to report on their carbon footprint. If your factory is dirty, their brand looks dirty.

Manufacturers with ISO 14001 certification5 help brands meet Scope 3 emission targets. Transparent supply chains prove that sustainability extends from the factory floor to the final product, making the manufacturer a strategic partner in ESG goals.

This is where my experience as a business owner comes in. I know that many D2C (Direct to Consumer) brands need to report on their supply chain impact. These are called ESG goals.

You need to position yourself—and your manufacturing partners—as the "Conscious Manufacturer." Use your ISO 14001 status. This is an international standard for environmental management. When I work with a factory that has this, I know they are serious.

You are their "Scope 3 Emission" solution. Scope 3 means the emissions that come from the supply chain, not just the brand's office. If you can prove that your manufacturing process is clean, you help your client hit their targets. It is a massive competitive advantage. You are not just selling a mold or a product; you are selling compliance and peace of mind. In the high-end market, this transparency is just as valuable as the product itself.

| Aspecto | Traditional Factory | Conscious Manufacturer |

|---|---|---|

| Certificación | None / Basic | ISO 14001 |

| Transparency | Black Box | Open Data |

| Client Benefit | Low Cost | ESG Compliance |

Scope 3 emissions often account for the majority of a company's carbon footprint.Verdadero

Supply chain and manufacturing usually generate more emissions than the company's direct operations.

ISO 14001 guarantees a product is eco-friendly.Falso

It certifies the management system for environmental impact, not the specific product itself, though it implies better practices.

Conclusión

Sustainability is the ultimate luxury. By combining durable materials like steel, smart AI efficiency, and honest manufacturing, we create products that justify their price. We build for the future, not the landfill.

References

-

Explore how AI can optimize energy use in devices, saving costs and enhancing sustainability. ↩

-

Learn about Greenwashing to ensure your brand communicates genuine sustainability efforts. ↩

-

Understanding energy anxiety can help you design products that address consumer concerns about energy costs. ↩

-

Discover how washable pre-filters can enhance convenience and reduce environmental impact. ↩

-

Understanding ISO 14001 can enhance your brand's credibility in sustainability and environmental management. ↩