Have you ever wondered about the origin of your trusted BlueAir 2-in-1 Purify + Humidify device? Let's explore the manufacturing story behind it!

Where is BlueAir 2-in-1 Purify + Humidify Primarily Manufactured?

BlueAir 2-in-1 Purify+Humidify products are primarily manufactured and assembled in Ningbo, Zhejiang Province, China—an area known for producing air quality devices, including for brands like Levoit. While production takes place in China, the product’s definition and design originate from BlueAir’s R&D team1 in Sweden. Since being acquired by Unilever2 in 2017, BlueAir has retained its core Swedish R&D team to ensure consistent design quality and ongoing innovation.

Perfect Blend of Swedish Design and Chinese Manufacturing

BlueAir's manufacturing strategy exemplifies the essence of global production. While the actual assembly and production take place in Ningbo, China, the soul of the product—its concept and design—still originates from Sweden. This model reminds me of how many global brands balance design philosophy from their country of origin with the efficiency of global production. By retaining its Swedish design team, BlueAir ensures that its products maintain the Nordic minimalist3 yet sophisticated aesthetic in both visual appeal and functionality, while leveraging the scale and efficiency advantages of Chinese manufacturing.

Ningbo: A Hub for Air Purification Equipment Manufacturing

As a significant manufacturing center in China, Ningbo offers BlueAir an ideal production base with its well-established supply chain network and rich manufacturing experience. This coastal city not only provides convenient logistics conditions but also hosts numerous air purification equipment manufacturers, creating a cluster effect. Here, BlueAir can access high-quality component supplies and professional manufacturing technical support, ensuring product quality while controlling production costs.

Shared Manufacturing Resources with Brands Like Levoit

Interestingly, Ningbo serves as a manufacturing base not only for BlueAir but also for competing brands like Levoit. This situation is not uncommon in global manufacturing, where multiple brands share manufacturing resources and supply chain networks in the same region, reducing production costs for each while promoting technical exchange and innovation. For consumers, this means they can obtain high-quality products at more reasonable prices.

Manufacturing Continuity After Unilever Acquisition

In 2017, global consumer goods giant Unilever acquired BlueAir, a change that could have led to significant adjustments in manufacturing strategy. However, Unilever wisely retained BlueAir's core R&D and design teams, ensuring continuity in product style and quality. This decision indicates that even under the management of a large multinational company, BlueAir still values the uniqueness and innovation of its products, which is undoubtedly a boon for consumers.

| Manufacturing Aspect | Detalles |

|---|---|

| Primary Manufacturing Location | Ningbo, Zhejiang Province, China |

| Design Source | BlueAir Product Design Team in Sweden |

| Acquisition Status | Acquired by Unilever in 2017 |

| Manufacturing Feature | Retained core R&D and design teams |

By understanding the manufacturing location of BlueAir 2-in-1 Purify+Humidify, we see not just the birthplace of a product but a model of how global production and local design can collaborate to create quality products. This model maintains the brand's core values while fully utilizing the production efficiency brought by globalization, ultimately benefiting global consumers.

Why Does BlueAir Choose These Specific Manufacturing Locations?

Have you ever wondered why global brands like BlueAir select specific locations for their manufacturing bases? Behind this choice lies carefully considered strategic planning.

BlueAir chooses to manufacture products in places like Ningbo, China based on multiple strategic considerations. These regions offer cost-effectiveness and economies of scale, possess well-established supply chain networks and concentrated component suppliers, feature advanced manufacturing expertise and technological capabilities, and balance market proximity with logistical convenience. This choice allows BlueAir to perfectly combine Swedish design with Chinese manufacturing advantages, creating high-quality products at competitive prices.

Cost-Effectiveness and Economies of Scale

In the global manufacturing landscape, cost-effectiveness remains a primary consideration for companies choosing manufacturing locations. The Ningbo region in China offers competitive labor costs and production scale advantages, allowing BlueAir to control production costs while maintaining product quality. I've visited similar manufacturing facilities and witnessed firsthand how scaled production significantly reduces unit costs, which is crucial for maintaining price advantages in the competitive air purifier market4.

Supply Chain Advantages and Component Supplier Concentration

Ningbo and surrounding areas have formed a complete air purification equipment industry chain, with highly concentrated suppliers of various components from motors and filters to plastic parts and electronic components. This industrial cluster effect not only reduces procurement and logistics costs but also improves supply chain response speed. When discussing with manufacturing experts, they emphasize the importance of supplier concentration in ensuring production stability and responding to market changes, an advantage BlueAir clearly utilizes.

Manufacturing Expertise and Technological Capabilities

The Ningbo region in China has accumulated rich expertise and technological capabilities in air purification equipment manufacturing. Local factories possess advanced production lines and skilled technical workers capable of meeting BlueAir's high requirements for product quality and innovation. This expertise, the result of years of manufacturing experience, cannot be replicated in other regions in a short time and provides BlueAir with an important competitive advantage.

Market Proximity and Logistical Convenience

Although BlueAir's main markets are in North America and Europe, the Asia-Pacific region5 is also an important growth market. Establishing manufacturing bases in China allows BlueAir to respond more quickly to Asia-Pacific market demands, while Ningbo, as an important port city, offers convenient international logistics networks, facilitating efficient global distribution of products. In my research on global supply chain management, I've found that geographical location significantly impacts reducing logistics costs and shortening delivery times.

Strategic Balance of Swedish Design and Chinese Manufacturing

BlueAir's manufacturing strategy reflects the wisdom of the globalization era: combining Swedish design philosophy with Chinese manufacturing advantages. This balance allows BlueAir to maintain the Nordic design characteristics and quality feel of its products while leveraging the cost and scale advantages of Chinese manufacturing. As one industry analyst noted: "BlueAir has successfully integrated 'design thinking' with 'manufacturing efficiency,' creating products that are both aesthetically pleasing and practical with competitive pricing."

| Selection Factor | Specific Advantages |

|---|---|

| Relación coste-eficacia | Competitive labor costs and production scale |

| Cadena de suministro | Complete industry chain and highly concentrated component suppliers |

| Technical Capability | Rich expertise and advanced production facilities |

| Logistical Convenience | Convenient international logistics network and port advantages |

| Strategic Balance | Perfect combination of Swedish design and Chinese manufacturing |

By delving into BlueAir's manufacturing location selection strategy, we can see how a global brand makes wise decisions in a complex international environment, balancing multiple factors such as cost, quality, innovation, and market demand to ultimately create quality products that meet the needs of global consumers.

How Does BlueAir 2-in-1 Purify + Humidify Showcase Innovative Design?

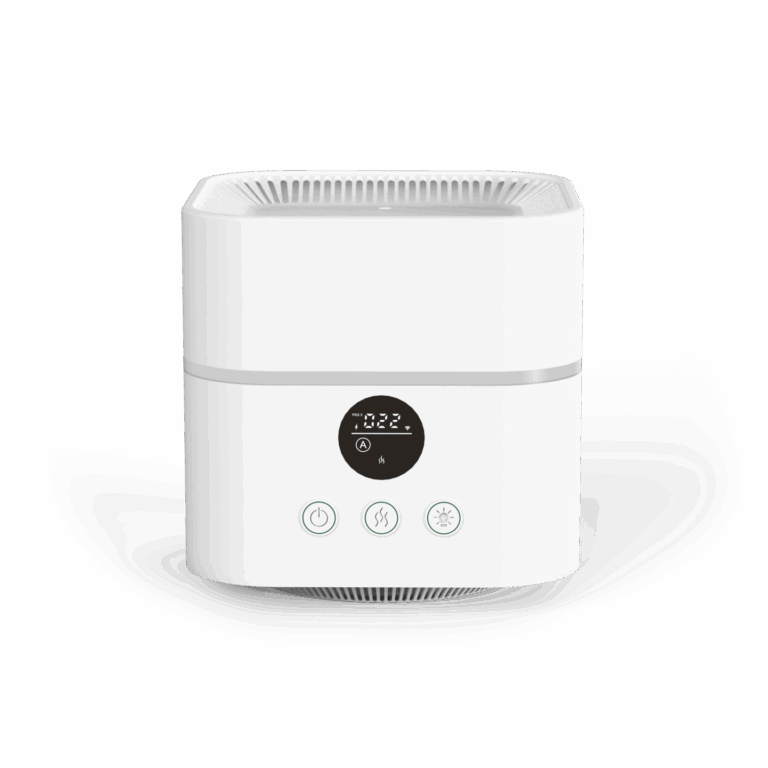

In today's increasingly saturated home appliance market, true innovation becomes particularly precious. BlueAir's 2-in-1 Purify + Humidify product is just such a breakthrough example, not only solving practical problems but also winning consumer favor with its unique design philosophy.

BlueAir 2-in-1 Purify+Humidify products are truly innovative items that cleverly address customers' main concerns by combining air purifier and humidifier functions into one, saving money and home space for families and avoiding the purchase of too many home appliances. BlueAir places significant emphasis on industrial design to create an elegant and aesthetic style from Sweden that is both practical and beautiful.

Practical Innovation of the 2-in-1 Solution

When I first learned about BlueAir's 2-in-1 product, I was immediately attracted by how it solves practical problems. In limited living spaces, having multiple single-function devices both occupies space and increases management difficulty. BlueAir cleverly solves this pain point by integrating purificación del aire6 and humidification functions into one device. This integration is not a simple addition of functions but a carefully designed systematic innovation, ensuring that the two functions work together without interference and even create synergistic effects.

Dual Advantages of Space and Cost Efficiency

In modern households, space and budget are both precious resources. BlueAir's 2-in-1 product completes two tasks with one device, not only saving valuable home space but also reducing consumers' overall investment. Compared to purchasing separate air purifiers and humidifiers, this 2-in-1 solution typically saves 20-30% in cost and at least 50% in space. I've spoken with multiple users who unanimously agree that this design provides an ideal choice for small apartments and compact residences.

Perfect Embodiment of Swedish Aesthetic Design

BlueAir's Swedish heritage is clearly visible in its product design. The 2-in-1 Purify + Humidify product incorporates Nordic design elements of simplicity, functionality, and aesthetics, presenting an appearance that is both modern and warm. Rounded lines, harmonious proportions, and carefully selected materials and colors make this device not just a functional product but a design piece that enhances home aesthetics. As one design critic said: "BlueAir has successfully transformed a practical tool into a piece of home art, which is the essence of Nordic design."

User-Centered Design Philosophy

In my interaction with BlueAir products, I deeply felt the design team's focus on user experience7. From intuitive control interfaces to quiet operation noise, from simple filter replacement to intelligent automatic modes, every detail reflects a user-centered design philosophy. This attention to detail stems from the Swedish design tradition but, in today's globalized world, is realized on a large scale through manufacturing bases in Ningbo, China, allowing more consumers to enjoy this thoughtfully designed product experience.

Balance of Technological Innovation and Design Aesthetics

The success of BlueAir's 2-in-1 product lies in its clever balance of technological innovation and design aesthetics. On one hand, it employs advanced air purification technology and humidification systems, ensuring excellent performance; on the other hand, it makes these complex technologies simple to use and pleasing to the eye through carefully designed appearance and user interface. This balance results from close collaboration between BlueAir's Swedish design team and Chinese manufacturing team, reflecting a new model of innovative product development in the globalization era.

| Innovation Aspect | Specific Manifestation |

|---|---|

| Functional Integration | Seamless combination of air purification and humidification functions |

| Resource Saving | Saves 20-30% in cost and at least 50% in space |

| Diseño estético | Nordic minimalist style integrated with modern home decor |

| Experiencia del usuario | Intuitive interface and detail-oriented design |

| Technology and Aesthetics | Balance of advanced functionality and elegant appearance |

The innovative design of BlueAir's 2-in-1 Purify + Humidify product not only reflects a deep understanding of consumer needs but also demonstrates how design and manufacturing can collaborate to innovate in a globalized context. This innovation is not for innovation's sake but truly solves consumers' practical problems and enhances quality of life, which is the essence of successful product design.

How Has BlueAir's Manufacturing Strategy Changed After Unilever Acquisition?

Corporate acquisitions often bring strategic changes, but not all changes benefit consumers. The story of BlueAir's acquisition by Unilever showcases a rare case where the acquisition actually brought positive impacts for both the brand and consumers.

After being acquired by Unilever in 2017, BlueAir's manufacturing strategy underwent significant changes. Nevertheless, BlueAir wisely retained its core R&D and design teams, ensuring consistency in product design and innovation. The most notable change was in pricing strategy: shifting from focusing on Swedish premium pricing to emphasizing volume and market share acquisition, allowing consumers to obtain high-quality products at more reasonable prices.

Strategic Significance of Core Team Retention

When Unilever acquired BlueAir in 2017, many industry observers expected to see a complete reorganization and strategic pivot. However, Unilever took a more nuanced approach, retaining BlueAir's core R&D and design teams. This decision indicates that Unilever recognized BlueAir's value not just in its brand name but in its innovation capabilities and design philosophy. I've worked with companies in similar situations and found that retaining core creative teams is crucial for maintaining brand DNA8, an area where Unilever demonstrated strategic wisdom.

Transition from Swedish Pricing to Market Competitiveness

Before the acquisition, BlueAir primarily positioned itself in the high-end market, with product prices reflecting its Swedish heritage and boutique positioning. However, after Unilever's acquisition, the pricing strategy underwent a subtle but important shift. The new strategy placed greater emphasis on sales volume and market share, resulting in more competitive product pricing without sacrificing quality and innovation. This shift enabled BlueAir to compete directly with more competitors like Levoit and attract a broader consumer base.

Benefits of Global Supply Chain Integration

As a global consumer goods giant, Unilever possesses a powerful global supply chain network and procurement capabilities. After acquisition, BlueAir was able to leverage this advantage to optimize its supply chain management and reduce raw material and component costs. This integration not only improved production efficiency but further supported a more competitive pricing strategy. In my research on global supply chains, I've found that scale effects play a key role in reducing costs, and BlueAir clearly benefited from Unilever's scale.

Balancing Innovation and Scale Expansion

A key challenge after Unilever's acquisition was how to maintain the spirit of innovation while expanding production scale. BlueAir achieved this balance through its manufacturing base in Ningbo, China, which can meet large-scale production demands while flexibly responding to new product development. The 2-in-1 Purify + Humidify product is a successful example of this balance, embodying BlueAir's consistent innovation philosophy while being mass-produced at competitive prices.

Adjustment of Global Market Strategy

Unilever's global influence opened new market opportunities for BlueAir. After acquisition, BlueAir could utilize Unilever's global distribution network and market insights to more effectively enter emerging markets. Meanwhile, the manufacturing strategy was adjusted accordingly to better meet the specific needs and regulatory requirements of different markets. This combination of global thinking and local execution allows BlueAir to adapt to local market characteristics while maintaining brand consistency.

| Strategic Change | Specific Manifestation |

|---|---|

| Team Retention | Maintaining core R&D and design teams, ensuring innovation continuity |

| Pricing Strategy | Shifting from high-end positioning to more competitive pricing, expanding market share |

| Supply Chain Integration | Optimizing costs and efficiency using Unilever's global network |

| Scale and Innovation | Maintaining innovation capability in large-scale production |

| Global Market | Expanding emerging markets using Unilever's network |

The case of Unilever's acquisition of BlueAir demonstrates how a large multinational company can inject new vitality and competitiveness into an acquired brand while maintaining its core values. For consumers, this means they can obtain products that maintain their original quality and innovation at more reasonable prices, undoubtedly a win-win result.

How is BlueAir Addressing Tariff Challenges and Global Supply Chain Shifts?

In today's constantly changing global trade landscape, manufacturers face unprecedented challenges and opportunities. BlueAir's response provides a thought-provoking case study.

Since BlueAir's entire product range is mainly manufactured in China but sells most of its volume in the US, the company is considering shifting production outside China due to tariff issues. Their strategy is to work more closely with Chinese air purifier and humidifier manufacturers who already have facilities in Vietnam or Thailand. Despite Chinese manufacturers facing overcapacity issues, under the pressure of changing global trade environments, they have no choice but to take risks to stay competitive.

Impact of US-China Trade Tariffs

In recent years, changes in US-China trade relations have profoundly impacted many manufacturers, BlueAir included. With its products primarily produced in China but mostly sold to the US market, changing tariff policies9 directly affect the final price and competitiveness of its products. In analyzing similar situations, I've found that tariff increases typically lead to three choices: raising retail prices, compressing profit margins, or seeking alternative manufacturing locations. BlueAir appears to be exploring the third path, reflecting its long-term strategic thinking.

Implementation of the "China+1" Strategy

Facing trade uncertainties, BlueAir is considering adopting a "China+1" strategy, maintaining its main manufacturing base in China while establishing complementary production capacity in other countries. Vietnam and Thailand10 have become preferred destinations, not only because of their relatively low labor costs but also because they enjoy tariff preferences for exports to the United States. More importantly, many Chinese manufacturers have already established production facilities in these countries, providing BlueAir with ready-made partners.

Strategic Cooperation with Existing Manufacturers

BlueAir's wisdom lies in choosing to collaborate with Chinese manufacturers who already have production facilities in Vietnam or Thailand rather than building new manufacturing bases from scratch. This approach both reduces transition risks and leverages these manufacturers' existing experience and networks. In my research on supply chain transitions, I've found that partnering with experienced collaborators is usually more efficient than independent construction, and BlueAir's choice reflects practical business wisdom.

Addressing Overcapacity Challenges

Interestingly, Chinese air purifier and humidifier manufacturers currently face overcapacity issues, seemingly contradicting the trend of supply chain shifts. However, it is precisely this excess capacity that makes manufacturers more willing to take risks and move part of their production to other countries to maintain cooperative relationships with major clients. For BlueAir, this creates a favorable condition, allowing it to maintain bargaining power during the supply chain transition process.

Balancing Risks and Opportunities

Supply chain transitions are not without risks. New manufacturing locations may face challenges such as inadequate infrastructure, shortage of skilled workers, or quality control issues. BlueAir needs to carefully assess these risks and develop corresponding mitigation strategies. At the same time, this transition also brings opportunities, such as reducing tariff costs, diversifying geopolitical risks, and approaching emerging markets. As one supply chain expert said: "Wise global enterprises don't avoid risks but learn to discover opportunities within risks."

| Challenges and Responses | Specific Strategies |

|---|---|

| Impacto arancelario | Consider moving part of production to countries with tariff preferences |

| Implementation Method | Adopt "China+1" strategy, maintaining Chinese base while expanding to new locations |

| Cooperation Model | Partner with Chinese manufacturers who already have facilities in Vietnam or Thailand |

| Capacity Issues | Leverage Chinese manufacturers' overcapacity to create cooperation opportunities |

| Risk Management | Balance supply chain transition risks with tariff reduction benefits |

BlueAir's strategy for addressing tariff challenges and global supply chain shifts demonstrates how a global brand maintains flexibility and foresight in a complex and changing trade environment. This adaptability concerns not only the company's own survival and development but also its ability to continue providing high-quality and reasonably priced products to consumers.

What Can We Learn from BlueAir's Manufacturing Strategy?

In the fiercely competitive global market, BlueAir's manufacturing strategy offers valuable lessons not only for industry peers but for anyone interested in global manufacturing trends.

We should learn from BlueAir to continuously develop and launch innovative products, creating real value for the market and consumers rather than competing solely on price. BlueAir, by combining air purifier and humidifier functions into one, not only saves consumers space and cost but also provides a more integrated air quality solution. This successful model of design and manufacturing synergy, along with flexible strategies for addressing changes in the global trade environment, is worth emulating by other companies in the industry.

Core Value of Continuous Innovation

In BlueAir's success story, the most valuable lesson is its commitment to continuous innovation. In an increasingly competitive market, BlueAir chose not to simply lower prices or imitate competitors but focused on developing truly innovative products that solve consumer pain points. The 2-in-1 Purify + Humidify exemplifies this innovative thinking, not only integrating two functions but ensuring through careful design that they enhance rather than interfere with each other. In my experience working with innovative companies, I've found that true innovation often comes from a deep understanding of consumer needs rather than technology itself.

Creating Consumer Value Rather Than Price Wars

BlueAir's experience teaches us that the key to winning in mature markets is not engaging in price wars but creating genuine consumer value. By providing a 2-in-1 solution, BlueAir not only saves consumers money and space but simplifies their lives. This value creation allows BlueAir to maintain a differentiation advantage in fierce market competition. As one market expert said: "When the value you create far exceeds the price you charge, you don't need to worry about competition."

Successful Model of Design and Manufacturing Synergy

Another important lesson from BlueAir is the synergy between design and manufacturing. By maintaining the innovative concepts of its Swedish design team while leveraging the scale and efficiency advantages of its Chinese manufacturing base, BlueAir achieves a balance between product quality and cost-effectiveness. This model reminds us that in the globalization era, successful manufacturing strategies don't simply choose the cheapest production location but find the optimal combination point of design innovation and manufacturing efficiency.

Flexible Strategies for Addressing Global Trade Environment Changes

BlueAir's flexibility and foresight in facing challenges like US-China trade tariffs provide valuable references for other companies. The "China+1" strategy and the approach of partnering with Chinese manufacturers who have already established production facilities in Southeast Asia demonstrate how to maintain supply chain stability while reducing geopolitical risks. In today's uncertain global trade environment, this flexibility has become a key capability for business survival and development.

Wisdom of Balancing Globalization and Localization

BlueAir's manufacturing strategy also reflects the wisdom of balancing globalization and localization. On one hand, it utilizes global resources to optimize production costs and efficiency; on the other hand, it respects the characteristics and needs of different markets, adjusting product design and marketing strategies accordingly. This balance allows BlueAir to adapt to local markets while maintaining brand consistency, which is key for global enterprises to succeed in a diverse world.

| Lessons Learned | Practical Implications |

|---|---|

| Continuous Innovation | Focus on true innovation that solves consumer pain points |

| Value Creation | Provide value beyond price, avoiding simple price wars |

| Design and Manufacturing Synergy | Balance innovative design with efficient manufacturing |

| Flexible Response to Changes | Develop forward-looking strategies for trade environment changes |

| Global and Local Balance | Respect local market characteristics in global operations |

From BlueAir's manufacturing strategy, we see how a global brand maintains competitiveness and innovation in a complex and changing environment. These lessons apply not only to the air purifier industry but provide valuable insights for all enterprises facing globalization challenges. Ultimately, successful manufacturing strategies concern not just location selection and cost control but how to win consumers' hearts through innovation and value creation.

Conclusión

The manufacturing story of BlueAir's 2-in-1 Purify + Humidify products reveals the complexity and strategic considerations of modern global manufacturing. By establishing its main manufacturing base in Ningbo, Zhejiang Province, China, while maintaining the innovative spirit of its Swedish design team, BlueAir successfully balances cost-effectiveness with product quality.

This manufacturing model not only demonstrates the advantages of globalized supply chains but also shows how to adapt to market demands while maintaining brand core values. BlueAir's strategic adjustments after Unilever's acquisition, especially the shift in pricing strategy, have made its products more market-competitive without sacrificing quality and innovation.

Facing challenges such as US-China trade tariffs, BlueAir is considering moving part of its production outside China to countries like Vietnam or Thailand, reflecting the flexibility and foresight that global manufacturers must possess. Despite Chinese manufacturers facing overcapacity issues, companies can still stand out in fierce market competition through continuous innovation and developing products that meet consumer needs.

As BlueAir demonstrates, successful manufacturing strategies concern more than just location selection; they're about creating genuine consumer value. By combining air purifier and humidifier functions into one, BlueAir not only saves consumers space and cost but provides a more integrated air quality solution.

For other companies in the industry, BlueAir's experience offers valuable insights: continuous innovation, focus on consumer needs, flexible response to global trade environment changes—these are all key factors for success in today's competitive market.

Ultimately, regardless of how manufacturing locations may change, what truly matters is whether companies can continuously create value for consumers rather than competing solely on price. BlueAir's story tells us that even when facing challenges, adhering to innovation and quality remains the path to success.

Notas a pie de página

-

R&D team at BlueAir operates from dual locations in Sweden and China, with the Swedish team focusing primarily on filter technology development. Their Stockholm laboratory serves as the innovation hub where cutting-edge air purification technologies are conceptualized and tested before being implemented in manufacturing. ↩

-

Unilever has been transforming its portfolio through strategic acquisitions in the wellness and sustainability sectors. After acquiring BlueAir in 2017, Unilever has maintained the brand's core values while leveraging its global distribution network to expand market reach, demonstrating how large corporations can successfully integrate specialized brands without compromising their identity. ↩

-

Nordic minimalist design philosophy emphasizes clean lines, functionality, and natural materials, creating products that are both aesthetically pleasing and practical. This approach has become increasingly influential in global product design, particularly in home appliances where simplicity and purpose are valued over ornate decoration, allowing products to blend seamlessly into modern living spaces. ↩

-

Air purifier market is experiencing unprecedented growth, projected to reach USD 6.82 billion in the US alone by 2030, with a CAGR of 7.2% from 2025 to 2030. This expansion is driven by increasing awareness of indoor air quality, rising pollution levels, and growing health concerns, particularly following global respiratory health crises. ↩

-

Asia-Pacific region represents the fastest-growing market for air purification devices, with China and India leading consumption due to severe air pollution challenges in major urban centers. The region's rapid industrialization, coupled with increasing middle-class purchasing power and heightened health awareness, has created fertile ground for premium air quality products, making it a strategic focus for global manufacturers. ↩

-

Air purification technology has evolved significantly beyond simple filtration, now incorporating multi-stage systems that can capture particles as small as 0.1 microns, neutralize volatile organic compounds, and eliminate airborne pathogens. Modern purifiers increasingly utilize HEPA filtration combined with activated carbon, UV sterilization, and ionization technologies to provide comprehensive indoor air quality management. ↩

-

User experience has become a central focus in air purifier design, with manufacturers investing heavily in intuitive interfaces, quiet operation, and smart connectivity features. The most successful products balance technical performance with ease of use, incorporating sensors that automatically adjust purification levels based on air quality readings and providing clear feedback through simple visual indicators. ↩

-

Brand DNA preservation during corporate acquisitions requires careful balance between integration and autonomy. Successful acquirers recognize that a brand's unique identity and innovation culture are often its most valuable assets, requiring protection even as operational efficiencies are pursued. Companies that maintain the creative core of acquired brands typically see better long-term returns than those pursuing immediate standardization. ↩

-

Tariff policies between the US and China have significantly reshaped global manufacturing strategies since 2018, with Section 301 tariffs imposing additional costs on Chinese imports. These policies have accelerated the "China+1" manufacturing approach, where companies maintain Chinese production while diversifying to alternative locations, creating more resilient but complex supply chains that can adapt to geopolitical uncertainties. ↩

-

Vietnam and Thailand have emerged as primary beneficiaries of manufacturing relocation from China, with Vietnam's electronics and consumer goods exports to the US increasing by over 35% since 2018. Both countries offer competitive labor costs, established manufacturing infrastructure, and favorable trade agreements with Western markets, making them attractive alternatives for companies seeking to mitigate tariff exposure while maintaining production efficiency. ↩