Plastic is losing popularity. Your clients want wellness products free from toxins. But switching materials isn't just a design tweak; it breaks your current manufacturing process completely.

stainless steel humidifiers1 require a specialized supply chain because standard plastic molding facilities lack the specific metallurgy expertise, hygiene-grade welding capabilities, and finishing precision needed to prevent corrosion and ensure health safety. You cannot simply swap materials; you must swap your entire manufacturing logic.

Many designers think they can just swap materials in CAD and send the files to their usual vendor. I learned the hard way that it is not that simple. The cadena de suministro2 for steel is a different world. Let me explain why.

Stainless steel manufacturing uses the same supply chain as plastic molding.Falso

Stainless steel requires specialized metallurgy, stamping, and welding expertise that plastic injection factories do not possess.

Wellness market trends are shifting away from plastic due to PFAS concerns.Verdadero

US media and government regulations are increasingly promoting zero-plastic solutions to avoid chemical leaching.

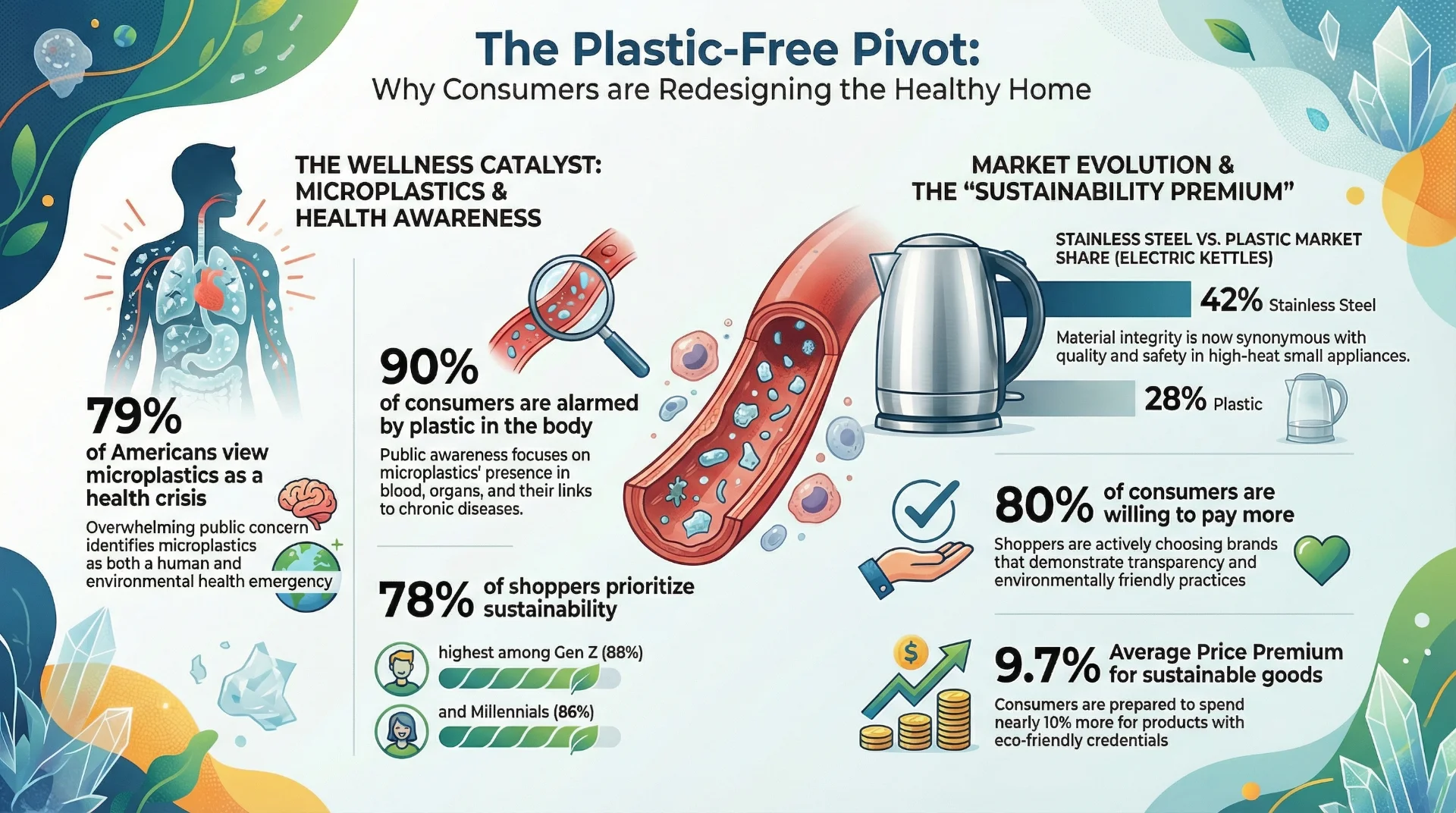

1. The Shift to Stainless Steel: Is It Just a Trend or a Requirement?

The US market is scared of microplastics. Your customers are demanding "zero plastic" to avoid PFAS. Ignoring this trend puts your product relevance at risk immediately.

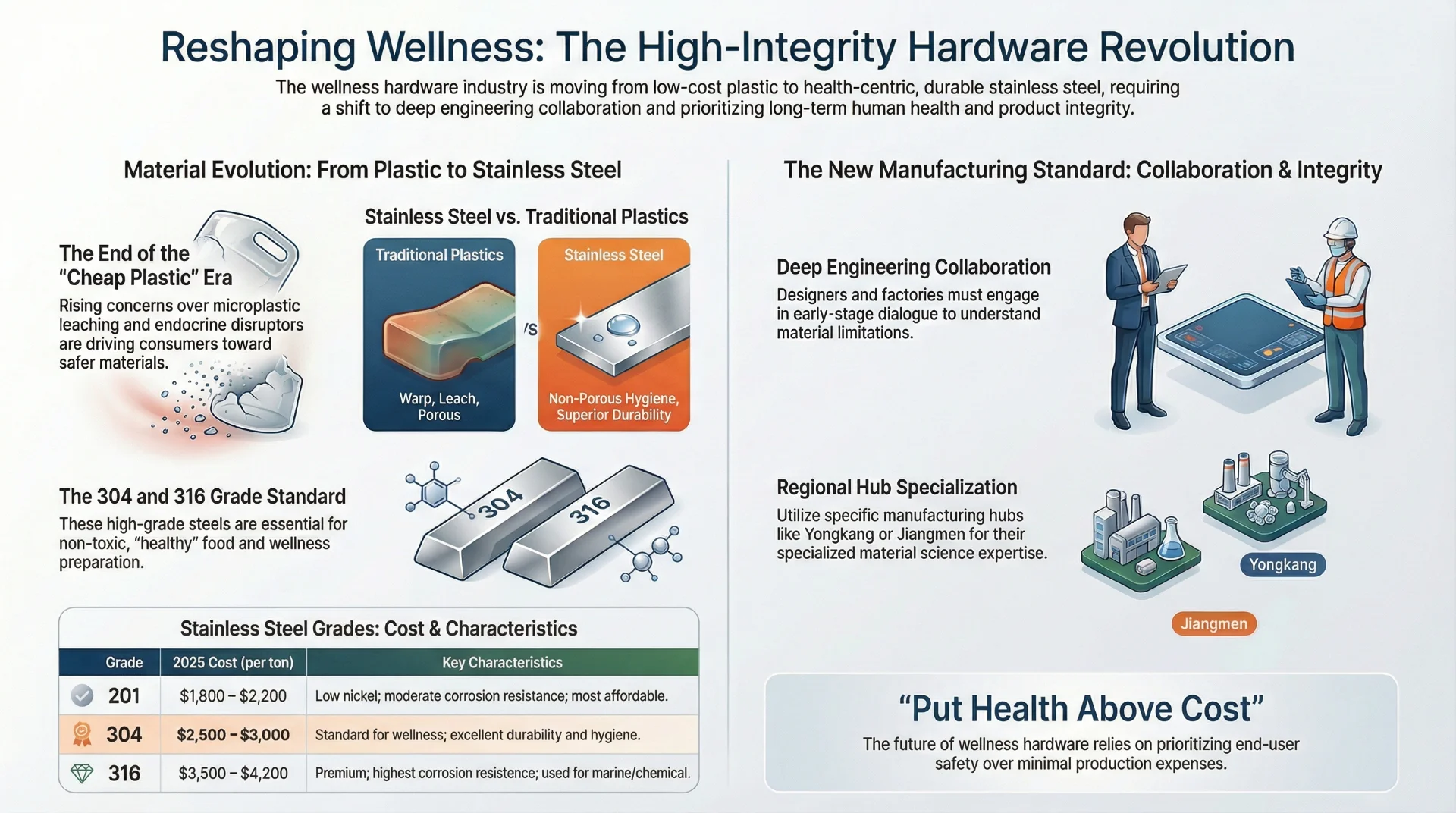

This shift is driven by health awareness. Consumers now view stainless steel as the only safe option for wellness hardware3, forcing brands to abandon traditional plastic supply chains to meet "clean air" standards and avoid toxic chemical exposure.

We need to look at the market data. Especially in the US market, the media and the government are educating end-users about the dangers of PFAS (forever chemicals). People are realizing that "wellness" is not just about the water vapor; it is about the machine itself. If the machine is plastic, they worry about what they are breathing.

This creates a massive push for stainless steel. But for us as designers, this is hard. We are used to plastic. We know how to design ribs and bosses. Stainless steel does not work that way.

Why the Market is Moving

- Health Anxiety: Users fear microplastics in their lungs.

- Durabilidad: Steel lasts longer than plastic.

- Hygiene: Steel is easier to clean and does not harbor bacteria like porous plastic.

For a brand like Hiso, or any wellness brand, we have to solve these supply chain problems. We must find partners who understand this material. It is not just about making a shape. It is about making a safe product.

PFAS concerns are a primary driver for the shift to stainless steel in wellness products.Verdadero

Consumers are actively seeking products that eliminate exposure to 'forever chemicals' found in plastics.

Stainless steel is purely an aesthetic choice for humidifiers.Falso

It is a functional choice driven by hygiene, durability, and health safety requirements.

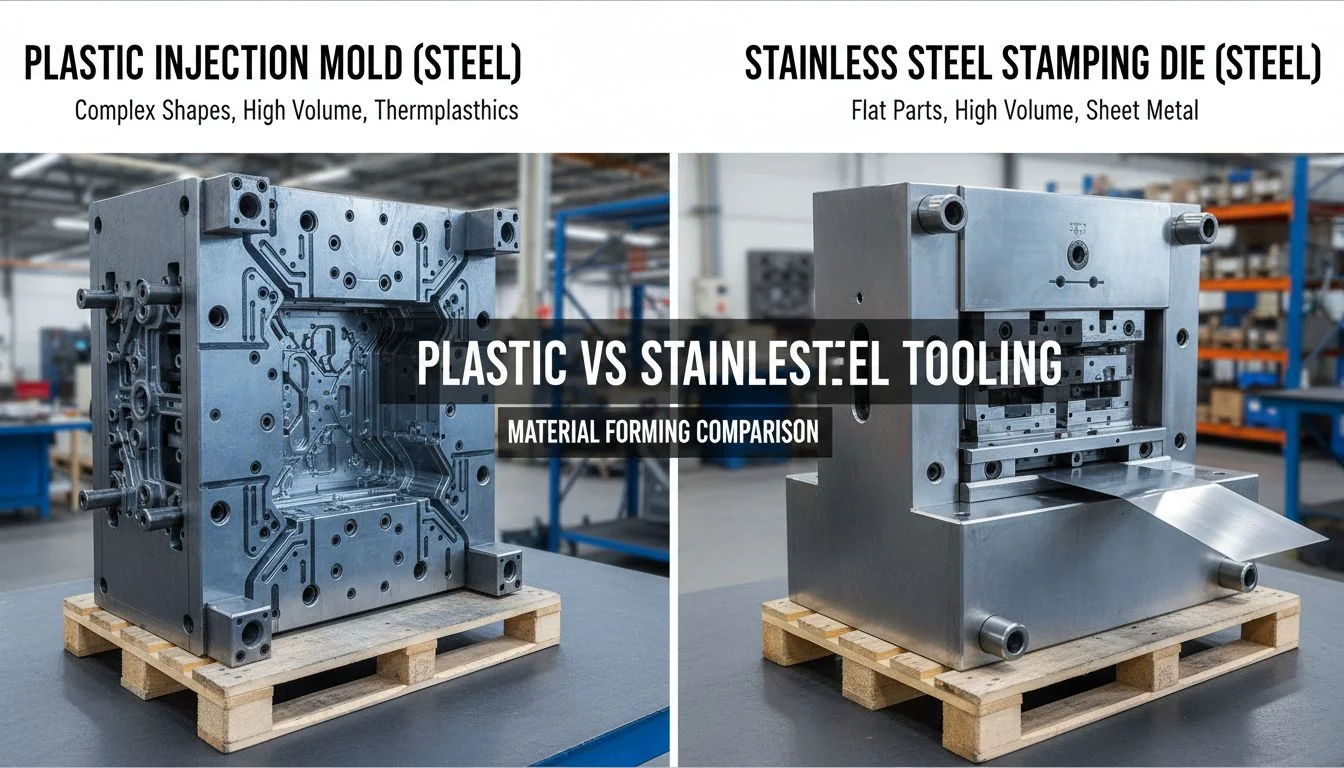

2. Stainless Steel ≠ Plastic Upgrade: Is It a Different Engineering Path?

You know plastic injection molding. You think steel is similar? It is not. Treating steel like plastic leads to leaks, rust, and massive production failures.

Stainless steel engineering requires deep knowledge of deep drawing4, hydroforming, and laser welding. Unlike plastic, you cannot easily hide sink marks or flash; the material properties demand entirely different tooling and tolerance calculations.

Stainless steel is much more challenging than plastic. In my years in the mold industry, I have seen many projects fail because the engineer treated steel like plastic.

With plastic, you inject molten material into a mold. You worry about shrinkage. With stainless steel, you are often stamping, drawing, or welding sheets of metal. You worry about "spring-back" and material thinning.

Key Engineering Differences

| Característica | Plastic Injection | Stainless Steel Fabrication |

|---|---|---|

| Forming | Molten flow | Cold working / Stamping |

| Connection | Snaps / Screws / Glue | Welding / Riveting |

| Tolerance | High precision easy | Harder to control spring-back |

| Surface | Texture in mold | Polishing after forming |

For Hiso, we have to find partners with specific engineering capability. They need to know how to weld without leaving gaps for bacteria. They need to know how to polish the inside so it does not rust. This is a complication that standard plastic factories cannot handle.

You can use the same design files for plastic and stainless steel manufacturing.Falso

Material properties like spring-back and forming limits require completely different design geometries.

Stainless steel fabrication involves more post-processing than plastic molding.Verdadero

Steel often requires welding, grinding, and polishing, whereas plastic parts often come out of the mold finished.

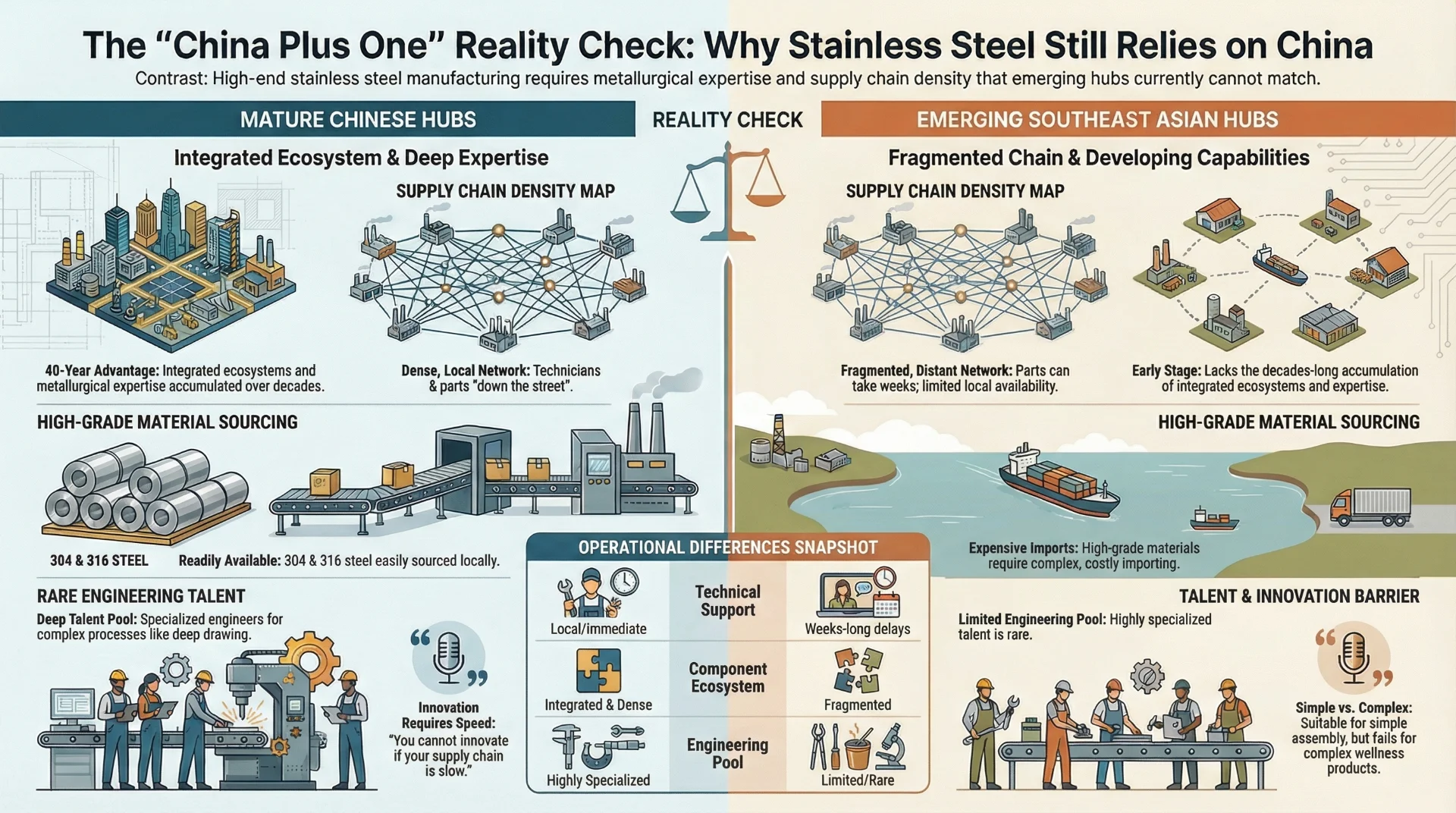

3. Why Does the Traditional "China Plus One" Strategy Fail for Stainless Steel?

Everyone talks about moving to Vietnam or Thailand. But for high-end steel? You will face delays, poor quality, and a lack of skilled engineers.

The "China Plus One" strategy fails here because Southeast Asian hubs lack the 40-year accumulation of stainless steel metallurgy expertise and the integrated ecosystem of component suppliers found in mature Chinese manufacturing regions.

I have helped many clients try to move supply chains. For simple assembly, Vietnam is fine. For complex stainless steel wellness products? It is a disaster.

Vietnam and Thailand do not have the deep supply chain for raw material engineering. They lack the manufacturing talents that China has built over 40 years. In China, if a machine breaks, the technician is down the street. In Vietnam, you might wait weeks for a part.

The "China Plus One" Reality Check

- Material Sourcing: High-grade 304 or 316 steel is readily available in China. In SE Asia, it is often imported, adding cost.

- Talent Pool: China has engineers who have spent 20 years doing only deep drawing. That talent is rare elsewhere.

- Speed: Innovation requires speed. You cannot innovate if your supply chain is slow.

So, for innovative stainless steel products, the "China Plus One" strategy does not work. You need the mature ecosystem.

Vietnam has a mature supply chain for complex stainless steel engineering.Falso

Vietnam lacks the deep component ecosystem and specialized talent pool found in established Chinese hubs.

China has over 40 years of manufacturing accumulation in this sector.Verdadero

This history has created a dense network of suppliers and skilled labor that is hard to replicate.

4. Mapping the Real Supply Chain: Where is High-Grade Hardware Built?

You cannot just pick any factory in China. Most are wrong. If you pick the wrong location, your supply chain becomes a logistical nightmare.

High-grade stainless steel hardware is built in specific hubs: Dongguan and Jiangmen5 for precision kitchen-grade manufacturing, and Yongkang for vacuum-insulated vessel expertise, similar to the technology used in Stanley cups.

We found that if we need to find the right partners, we have to look at specific cities. You cannot just go to a general directory. You need to know the geography of manufacturing.

There are only 3 or 4 locations in China that are truly good at this. They handle material sourcing, core engineering, hygiene design, and final assembly all in one place.

The Key Locations

- Dongguan City (Guangdong): Known for high-precision electronics and metal hardware. Good for complex mechanisms.

- Jiangmen City (Guangdong): This is the capital of stainless steel kitchen supplies. They know hygiene. They know how to make things food-safe.

- Yongkang City (Zhejiang): This is the "Hardware Capital." They are experts at making stainless steel water bottles. Think about the Stanley water bottle. That technology comes from here.

If you are building a humidifier, you want the guys who make water bottles or kitchen sinks. They understand water and steel.

Yongkang City is known for its expertise in stainless steel water bottles.Verdadero

It is a major hub for vacuum flask and vessel manufacturing, including brands like Stanley.

Any metal factory in China can produce medical-grade wellness hardware.Falso

Only specific regions like Jiangmen and Dongguan have the specialized ecosystem for hygiene-grade stainless steel.

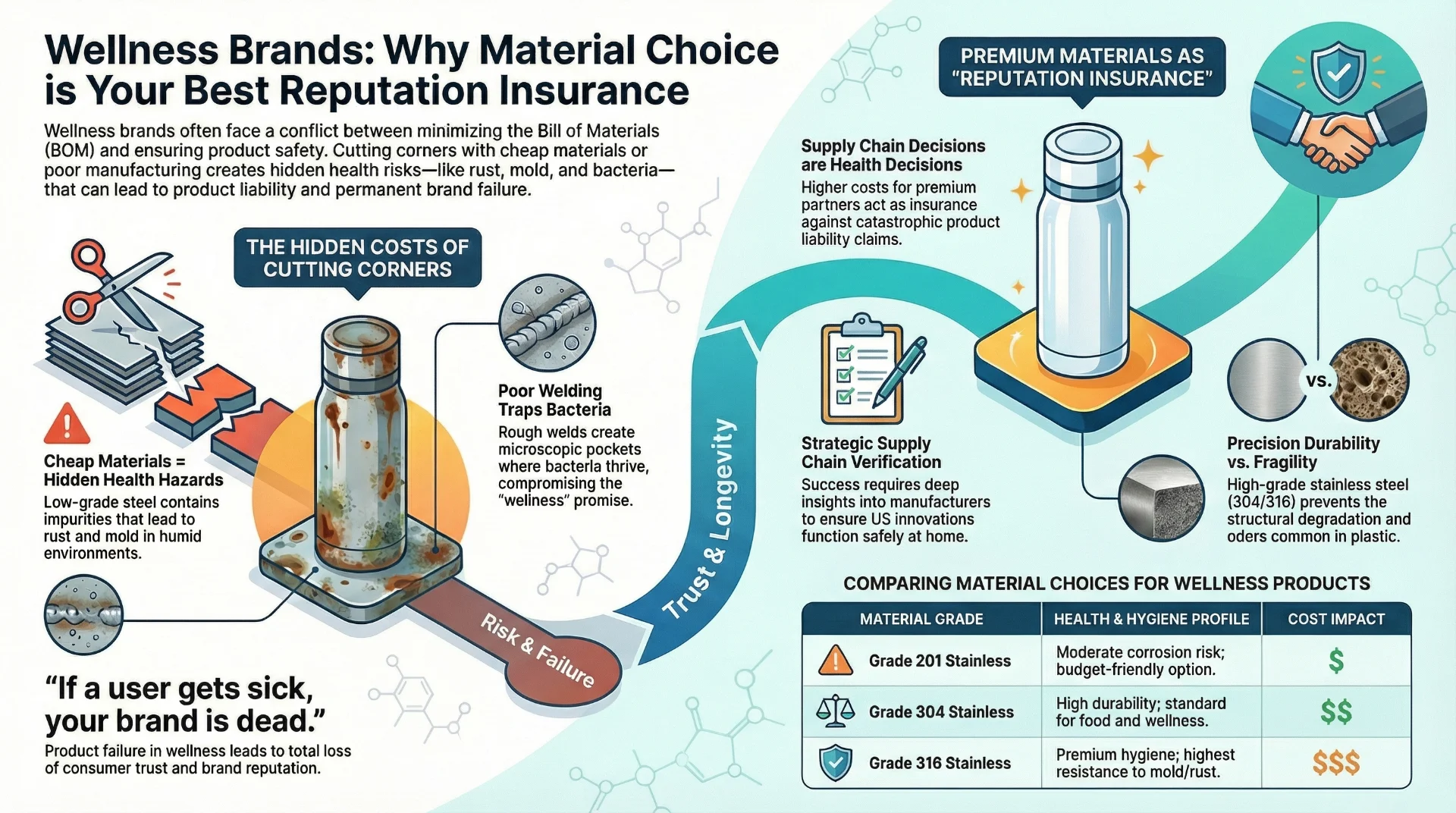

5. What Does This Mean for Wellness Brands: Balancing Cost vs. Health Risks?

Stainless steel costs more. You worry about the BOM. But cutting corners on materials creates health risks that can destroy your brand's reputation forever.

For wellness brands, supply chain decisions are health decisions. Using cheap steel or poor welding introduces rust and bacteria, meaning the higher cost of premium partners is actually insurance against product liability.

In wellness products, supply chain decisions are health decisions. This is the most important thing I can tell you.

If you buy a cheap plastic toy and it breaks, it is annoying. If you buy a humidifier and it rusts or grows mold because of bad welding, you get sick.

The Hidden Costs

- Poor Material: Cheap steel contains impurities. It rusts.

- Bad Welding: Rough welds trap bacteria. This ruins the "wellness" promise.

- Liability: If a user gets sick, your brand is dead.

Finding the right partners, like Hiso did, is a critical decision. It requires deep insights into the China supply chain. You are not just paying for a product. You are paying for safety. You are paying for the assurance that your US innovation will actually work when it reaches the customer's home.

Supply chain decisions in wellness products directly impact user health.Verdadero

Poor manufacturing quality can lead to rust, bacteria growth, and contamination.

The lowest cost supplier is usually the best choice for wellness hardware.Falso

Low cost often means compromised material quality or hygiene standards, which are unacceptable for health products.

6. Conclusion: Are We Reshaping How Wellness Hardware is Built?

The old ways of manufacturing are changing. If you stick to traditional methods, you fall behind. We must rethink how we build wellness hardware.

Reshaping wellness hardware requires partnering with experts who understand hygiene design and material science, moving beyond simple assembly to deep engineering collaboration that prioritizes end-user health over rock-bottom manufacturing costs.

We are at a turning point. The era of cheap plastic is ending for the wellness industry. The future is durable, clean, and safe materials like stainless steel.

But this future requires a new way of working. We cannot just send a drawing and wait for a sample. We need to collaborate. We need to understand the limitations of the material.

The New Standard

- Collaboration: Designers and factories must talk early.

- Specialization: Use the right hub (Yongkang/Jiangmen) for the right task.

- Integrity: Put health above cost.

For Jacky, and for all of us in design, this is a challenge. But it is also an opportunity. If we master this supply chain, we can build products that truly improve people's lives. That is why we do this.

The future of wellness hardware relies on deep collaboration between designers and specialized manufacturers.Verdadero

Complex materials like stainless steel require early engineering input to ensure manufacturability and safety.

Plastic will remain the dominant material for high-end wellness products.Falso

Market trends and health concerns are driving a strong shift toward stainless steel and other non-toxic materials.

Conclusión

To build safe stainless steel humidifiers, you must abandon generalist supply chains. Focus on specialized hubs like Yongkang and Jiangmen to ensure hygiene, engineering precision, and true product safety.

References

-

Explore the advantages of stainless steel humidifiers for health and safety. ↩

-

Understanding the unique supply chain requirements for stainless steel can enhance product quality. ↩

-

Explore emerging trends in wellness hardware and their implications for design. ↩

-

Gain insights into deep drawing and its significance in stainless steel fabrication. ↩

-

Learn about key manufacturing locations for high-quality stainless steel products. ↩