Worried about putting all your manufacturing eggs in one basket? Diversifying seems smart, but a poorly planned "China+1" strategy can create more problems than it solves.

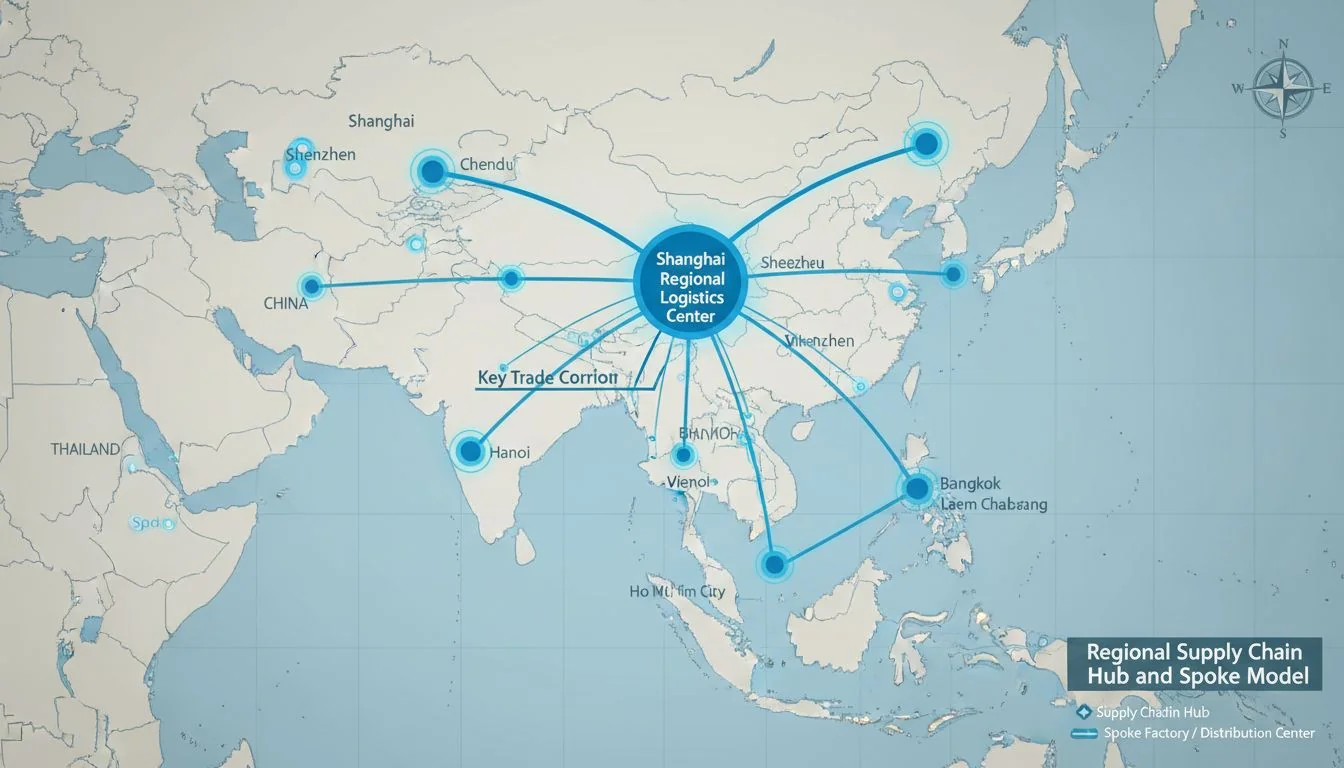

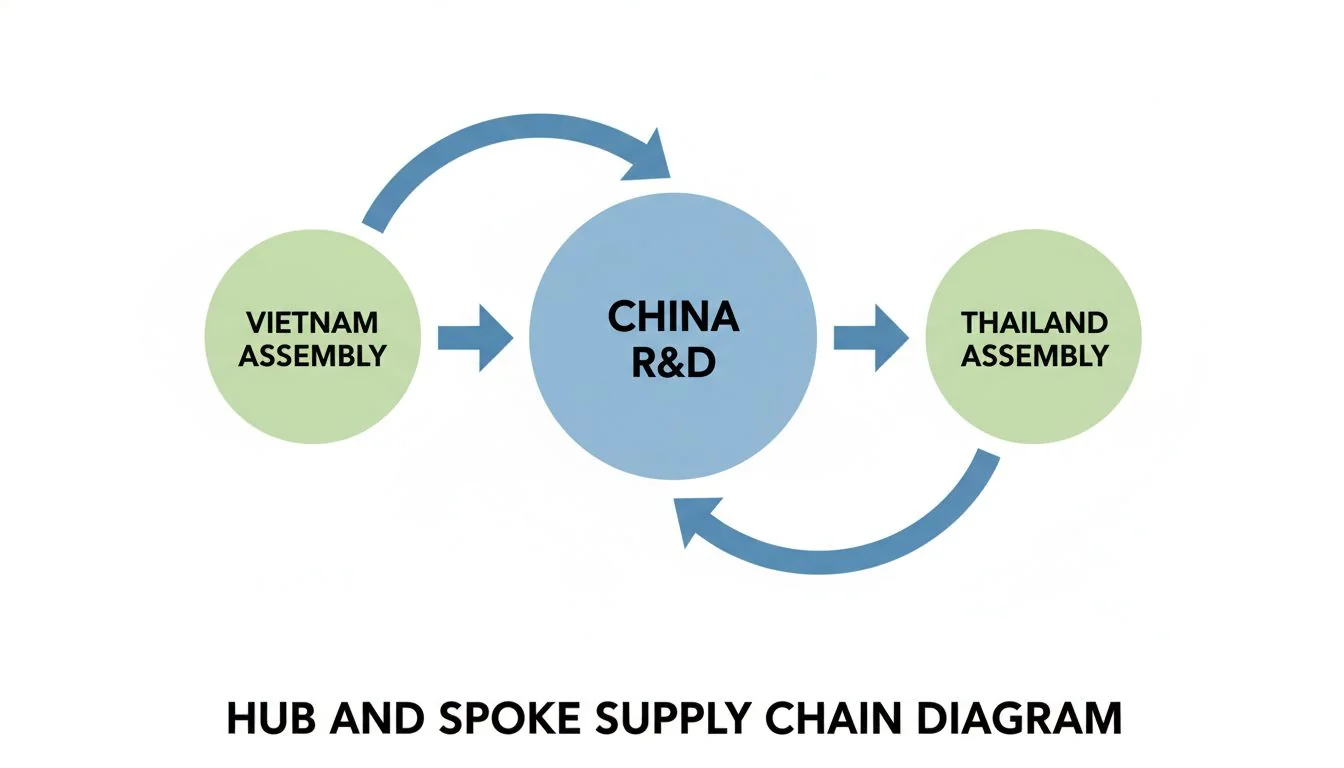

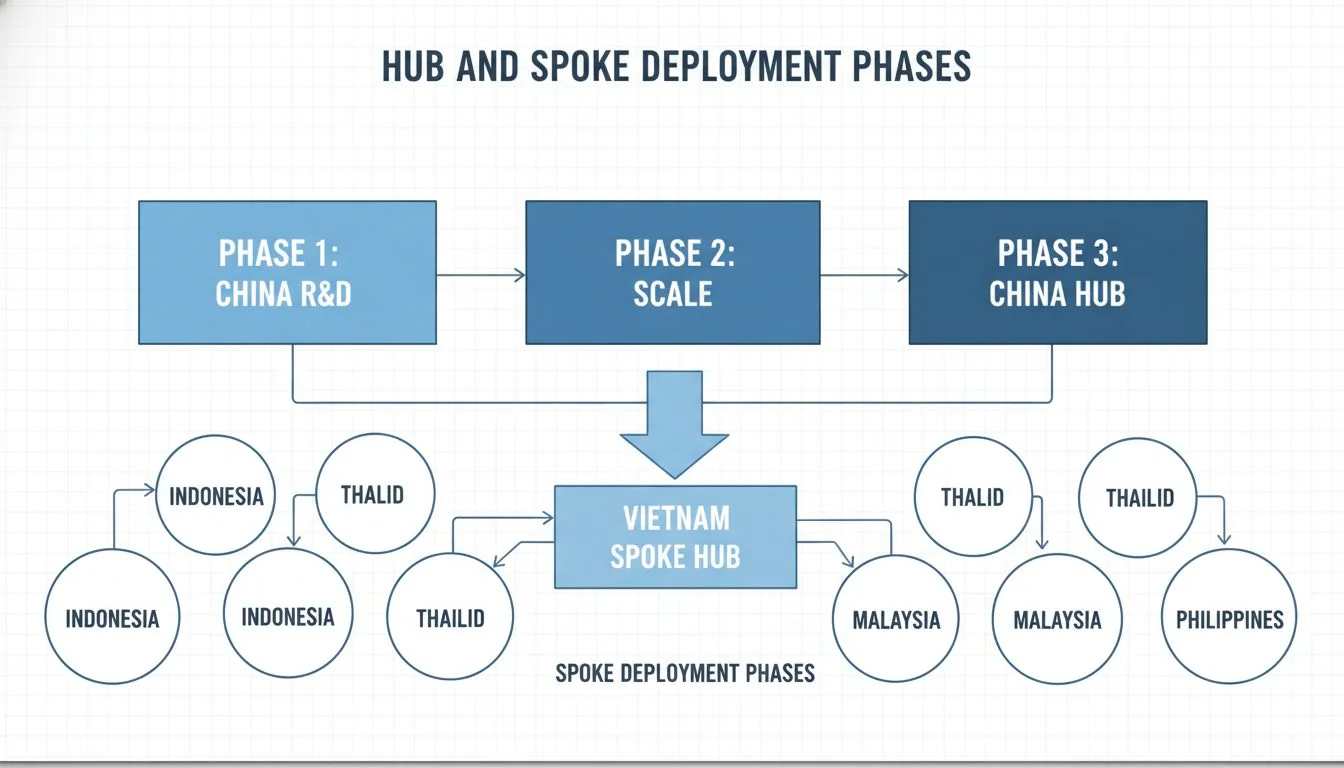

Build a regional supply chain by establishing China as your central "Innovation Hub1" for R&D and complex manufacturing. Then, use Vietnam and Thailand as "Assembly Spokes" for mature products, with your hub partner managing the deployment. This minimizes risk and maximizes innovation.

Everyone is talking about "China+1." It's the hot topic in every boardroom. But I've seen this movie before, and I know how it can end badly if you don't have the right script. The common approach is flawed from the start. It treats diversification like a simple copy-and-paste job, which never works.

This thinking puts you, the C-suite executive, in a reactive position, constantly fighting fires. I want to show you a different way. A way to build a strategy that actually works, turning a potential disaster into your biggest competitive advantage. Let's talk about how to do it right.

By 2025, over 50% of global companies plan to regionalize their supply chains.Verdadeiro

Surveys from firms like Gartner and McKinsey consistently show a strong trend towards supply chain regionalization to build resilience against global disruptions.

Moving a factory to Vietnam automatically cuts costs by 50%.Falso

While labor costs may be lower, this ignores costs related to logistics, training, lower productivity during ramp-up, and the potential for quality control issues, which can negate initial savings.

Are You Thinking Beyond "China+1" to a "Regional Hub" Strategy?

The pressure to diversify your supply chain is immense. But simply adding a factory in Vietnam or Thailand without a core strategy is a recipe for failure and headaches.

A "Regional Hub" strategy reframes diversification. Instead of replacing China, you leverage its R&D power as the central engine. This "hub" then intelligently feeds and supports "spoke" factories in other countries, creating a stronger, more flexible, and innovative network.

I had a client, a promising D2C brand, who felt immense pressure from their board to move production out of China. They rushed to find a supplier in Vietnam for their new smart home device. They thought "China+1" meant finding a second, cheaper factory. A year later, they were bleeding cash. The Vietnamese factory couldn't replicate the complex mold, quality was inconsistent, and they missed their product launch window. Their competitor, who stayed focused on R&D in China, launched a superior product and captured the market. My client didn't have a supply chain problem; they had a strategy problem. They tried to copy and paste, but they forgot that you can't copy and paste innovation. This is a C-suite level decision about risk and long-term value, not just a procurement task to find a cheaper price.

China's R&D spending is projected to surpass that of the United States.Verdadeiro

Multiple economic reports indicate that China's investment in research and development is growing at a rate that puts it on track to become the world's top R&D spender.

Any product made in China can be easily replicated in Vietnam or Thailand.Falso

While simple assembly is transferable, complex products requiring deep engineering expertise, specialized tooling, and a mature material supply ecosystem are extremely difficult to replicate elsewhere without significant investment and time.

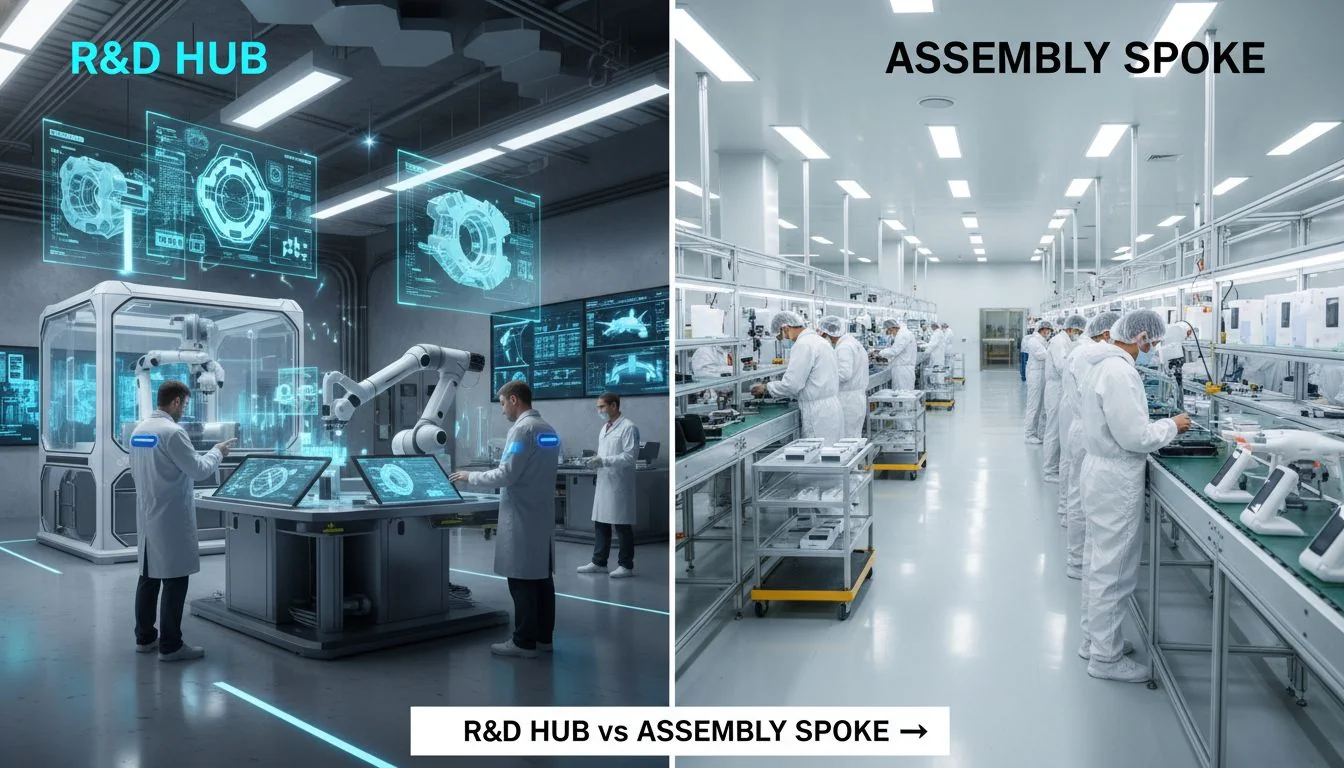

How Do You Define the Roles of an "R&D Hub" vs. "Assembly Spokes"?

You would not ask a junior designer to create your most complex mold. So why treat all your factories the same? Miscasting their roles is a critical, costly error.

Your "R&D Hub," typically in China, handles innovation, complex tooling, and new product introductions. "Assembly Spokes2" in places like Vietnam or Thailand focus on high-volume, stable assembly of mature products that the hub has already perfected. This division of labor is key.

Think of it like a professional kitchen. You have a head chef who creates the recipes, tests new ingredients, and perfects the cooking techniques. This is your R&D Hub. Then you have line cooks who execute those perfected recipes at scale, consistently and efficiently. These are your Assembly Spokes. You need both to run a successful restaurant, but they have very different skills and you wouldn't swap their jobs. In manufacturing, your China partner is the head chef. They have the deep experience in mold making, material science, and process engineering. Your partners in Vietnam or Thailand are the line cooks, excellent at executing a well-defined plan.

Hub vs. Spoke: A Clear Division

| Caraterística | R&D Hub (China) | Assembly Spoke (Vietnam/Thailand) |

|---|---|---|

| Função principal | Innovation, NPI, Problem-Solving | Scaling, Cost-Efficiency, Execution |

| Key Activities | Complex Mold Design3, Prototyping | High-Volume Assembly, Standardized QC |

| Product Stage | New, Complex, High-Margin | Mature, Stable, Standardized |

| Value Creation | Creates the "How-To" Playbook | Executes the Playbook at Scale |

The Pearl River Delta region in China has one of the world's highest concentrations of engineers and technicians specializing in mold making and manufacturing.Verdadeiro

This region is a global epicenter for manufacturing, with a deep talent pool and a highly integrated supply chain for tooling, materials, and electronics that has been built over decades.

Labor is the only significant factor in manufacturing cost.Falso

Total landed cost includes materials, tooling amortization, logistics, quality control, rework, and intellectual property risk. Labor is often a smaller component than many executives assume, especially for complex products.

What is the "Fatal Flaw" of a "Hub-less" Supply Chain?

You've found factories in China, Vietnam, and Thailand. You think you're diversified. But now you're managing three separate, competing suppliers, and your innovation has ground to a halt.

The fatal flaw of a "hub-less" chain is the loss of a central innovation engine. Without a dedicated R&D partner, you fragment your development process, lose quality control, and end up with "me-too" products. The biggest risk isn't tariffs; it's becoming irrelevant.

As a CEO or COO, you are paid to manage risk. But we need to be clear about the real risk. Everyone is focused on geopolitical risk, like tariffs. I'm telling you to focus on Market Risk4. For a direct-to-consumer brand, launching a 1-star product is infinitely more dangerous than a 25% tariff on a 5-star product. A great product can absorb tariffs; customers will pay for quality and innovation. A bad product is dead on arrival, no matter how cheap it is to make. When you operate a "hub-less" system, you are forced to design products for the lowest common denominator. You simplify your designs so that any of your disconnected factories can make them. You have just engineered innovation and excitement right out of your product. You are now competing on price alone, which is a race to the bottom.

Product-market fit is the single biggest determinant of success for a new product launch.Verdadeiro

Countless studies and startup post-mortems cite a lack of market need or a poor product as the number one reason for failure, far outweighing cost issues.

A 25% tariff will automatically make a product unprofitable.Falso

While a tariff impacts margins, a product with strong brand equity and high perceived value (a '5-star product') can often absorb the cost or pass it to consumers without a catastrophic drop in demand.

Why Must You Secure Your "Innovation Hub" in China First?

You want to build a strong house, but you are starting with the windows. A regional supply chain needs a solid foundation, or the whole structure will collapse under pressure.

You must secure your China "Innovation Hub" first because it is the engine for your entire strategy. This partner develops the product, perfects the tooling, and creates the manufacturing "playbook." Without this hub, your "spokes" in Vietnam or Thailand have nothing to execute on.

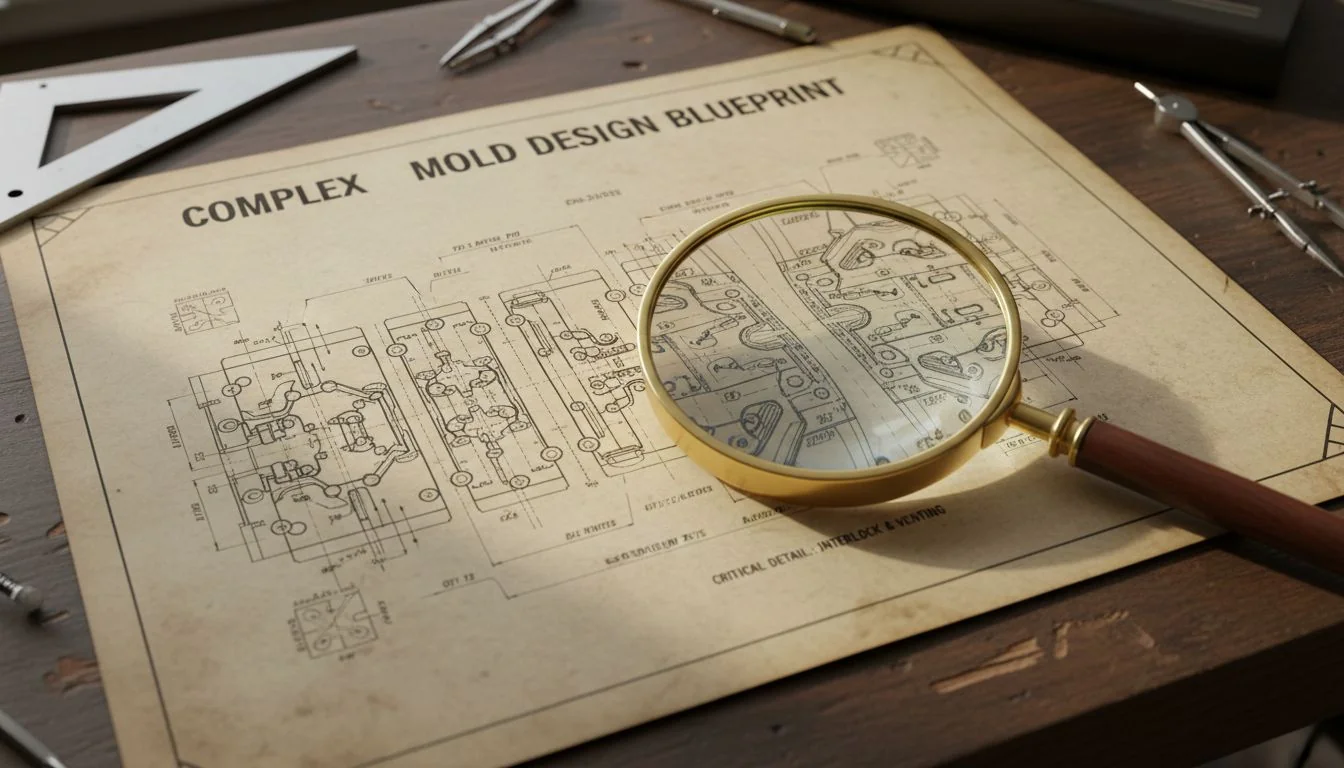

Let me give you a concrete example. A client came to us to develop a high-end baby monitor. The design required a complex housing with an overmolded soft-touch TPE grip on a flame-retardant PC-ABS shell. This is not a simple part. The mold required incredibly precise side-actions, a sophisticated hot runner system to manage the two materials, and deep expertise in polymer bonding. We spent weeks on mold flow analysis just to get it right. This is the kind of work that can only happen in an Innovation Hub. It is high-R&D, high-risk, and requires a team with decades of experience. An assembly factory in Vietnam cannot do this. They lack the specialized tooling engineers and material scientists. By securing us as the "Hub," the client ensured their innovative product could actually be made. We are not just another factory option; we are the prerequisite for the other options to even exist.

Overmolding two different plastics like TPE and PC-ABS requires precise control over temperature, pressure, and chemical bonding agents to prevent delamination.Verdadeiro

This is a well-established principle in polymer engineering. The chemical and physical compatibility of the materials, along with the mold design and processing parameters, are critical for a successful bond.

Any CNC shop can build a complex overmolding tool.Falso

Building a reliable, high-volume overmolding tool requires specialized machinery (like 5-axis CNCs and high-precision EDMs), deep expertise in tool design for multi-material injection, and experience with the specific polymers being used.

How Does the "Hub-and-Spoke" Model Work in Practice?

You are afraid your Chinese partner will resist you moving production to Vietnam. This fear creates conflict and prevents you from building a truly resilient, long-term supply chain.

The model works in phases. Phase 1: Develop and launch the innovative product with your China "Hub." Phase 2: Scale production in China. Phase 3: Your China Hub helps you transfer the mature product and simplified processes to an "Assembly Spoke" in Vietnam.

This is where we change the entire conversation. You stop seeing your Chinese partner as a risk to be managed and start seeing them as your strategic partner for global deployment. You are not afraid of them losing business to Vietnam. In fact, you make them part of the plan. Here is how I structure it with my best clients.

The 3-Phase Deployment Strategy

- Phase 1: Innovation (China Hub). We work together on your most ambitious product. We handle all the R&D, complex mold making, prototyping, and pilot runs. We launch a 5-star product together.

- Phase 2: Scaling (China Hub). We ramp up mass production in our facility. We iron out every single kink in the process, optimize the assembly line, and perfect the QC standards.

- Phase 3: Deployment (Hub to Spoke). Once the product is mature and the process is stable, we help you move it. We create a "factory in a box"—simplified molds, clear Standard Operating Procedures (SOPs), and QC checklists. We then help you set up this line at an "Assembly Spoke" in Vietnam or Thailand. We become your deployment partner.

This makes you indispensable. The "China vs. Vietnam" competition is gone. It is now a collaborative, long-term partnership.

Standard Operating Procedures (SOPs) are critical for successfully transferring manufacturing processes between facilities, ensuring consistent quality.Verdadeiro

SOPs codify a proven process, reducing ambiguity and reliance on individual 'tribal knowledge,' which is essential for replication and scaling.

A Vietnamese factory can start mass production of a new complex product the day after receiving a mold from China.Falso

There is always a qualification and ramp-up period. The new facility must validate the tool, train operators, dial in machine parameters, and pass quality audits, which can take weeks or months.

Conclusão

A resilient regional strategy is not about replacing China. It is about leveraging it as your R&D engine to power a smarter, more innovative, and globally competitive supply chain.

References

-

Understanding the role of an Innovation Hub can help you leverage R&D for competitive advantage. ↩

-

Exploring the function of Assembly Spokes can clarify their importance in executing a successful supply chain strategy. ↩

-

Delve into the intricacies of Complex Mold Design to appreciate its role in product innovation. ↩

-

Understanding Market Risk can help you prioritize product quality over cost in your supply chain. ↩