You need a new humidifier for your D2C brand, but Asia is a black box. Choosing the wrong partner means a cheap copy, not a market leader. Your brand's future is at stake.

The best humidifier manufacturers for D2C brands are not just assemblers; they are R&D-driven partners1 in Asia's "Innovation Hub." These partners, like Hisoair, co-develop unique products, giving you a competitive edge that simple assembly factories in other regions cannot match.

Finding a manufacturer seems simple. You just search on a B2B platform, right? I've been in the mold and manufacturing business for decades, and I've seen too many promising brands fail with that exact approach. They pick a partner based on price and location, not capability. The result is always the same: a "me-too" product that gets lost in the noise.

But what if you could see the market clearly? What if you knew exactly how to separate the simple assemblers from the true innovators? In this post, I'll break down the entire Asian manufacturing landscape for you. I'll give you a framework that I've used to help my clients launch successful products time and time again. By the end, you'll know exactly where to look and what to ask to find a partner who can help you win.

Asia accounts for over 60% of global manufacturing output.Verdadeiro

According to data from the United Nations Industrial Development Organization (UNIDO), the Asia-Pacific region is the largest manufacturing hub in the world.

All Asian countries offer the same level of manufacturing and R&D capabilities.Falso

There are significant differences in infrastructure, supply chain maturity, and R&D investment between countries like Japan, China, and Vietnam.

Why Are D2C Brands Searching "Asia" for Partners?

Sourcing from Asia seems like the obvious move for cost savings. But what if the real prize isn't just lower prices? You might be missing the biggest opportunity of all.

D2C brands are searching Asia not just for cost savings, but for access to complete supply chains and rapid innovation cycles. The goal has shifted from finding a cheap factory to finding a strategic partner who can help them build a unique product from the ground up.

When I started my first trading company, everything was about cost per unit. We would take a finished design and find the factory that could make it for the lowest price. That model is outdated. Today, my most successful clients don't lead with price; they lead with innovation. They are looking for a partner who can help them get to market faster with a better product.

For a product designer, this is a critical distinction.

- The Old Way: You spend months perfecting a CAD file and a tech pack. You send it to a factory, and they act as a pair of hands. Any issue with the design, the materials, or the mold is your problem to solve from thousands of miles away.

- The New Way: You bring a concept to a partner. Their engineers work with you to refine the design, suggest better materials, and optimize the mold for efficient production. They are an extension of your R&D team.

This collaborative approach is only possible in a mature manufacturing ecosystem. It's not just about cheap labor anymore; it's about access to engineering talent, rapid prototyping2, and a supply chain that has every component you could possibly need.

The primary reason for sourcing in Asia is cheap labor.Falso

While labor cost is a factor, access to integrated supply chains, engineering talent, and speed-to-market are increasingly important drivers for D2C brands.

Asia's manufacturing ecosystems allow for faster product development cycles than Western counterparts.Verdadeiro

The co-location of R&D, prototyping, tooling, and mass production facilities in hubs like Shenzhen can significantly shorten the time from concept to market.

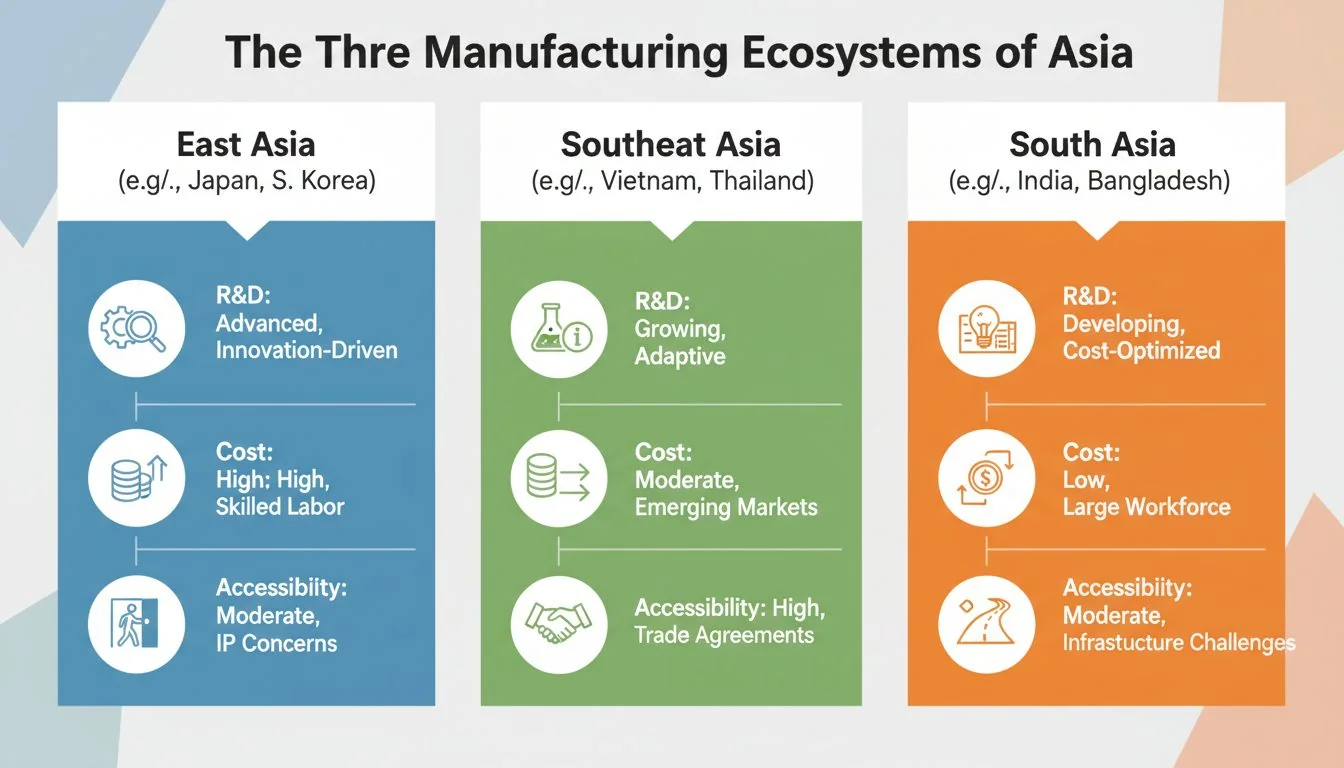

How Do You Understand Asia's Three Manufacturing Ecosystems?

Asia is not one giant factory. Treating it that way is a recipe for disaster. You could end up with a partner who is fundamentally incapable of delivering what your brand needs.

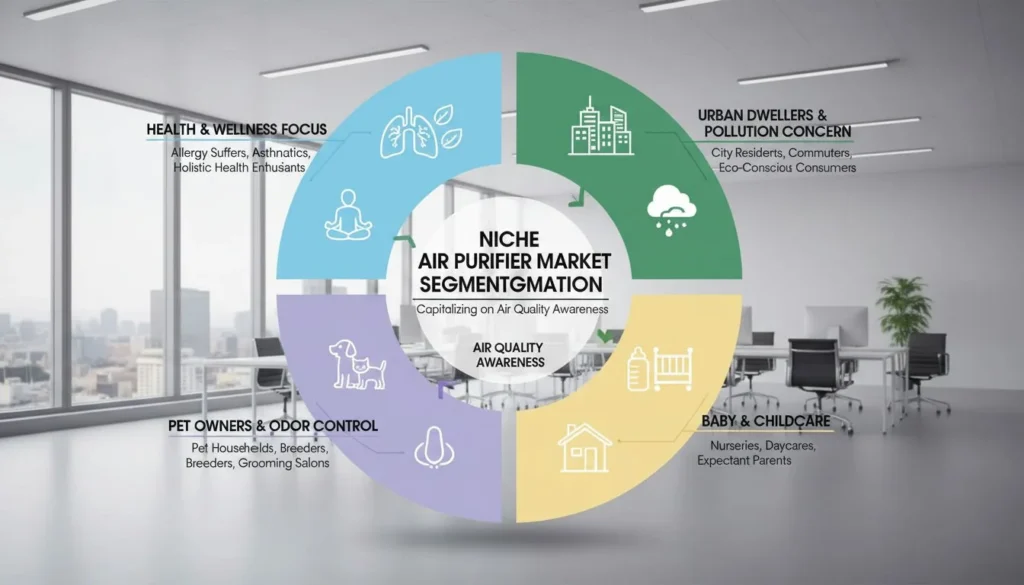

Asia can be simplified into three ecosystems: The Premium Brands (Japan/Korea), The Innovation Hub3 (China), and The Assembly Hubs (Southeast Asia). Understanding which category a potential partner falls into is the first step to making a smart sourcing decision.

I call this the "Three Asias" framework. Once you see the market this way, your sourcing strategy4 becomes incredibly simple. You're no longer lost in a sea of thousands of potential suppliers. Instead, you're making a clear, strategic choice between three very different types of partners. For a D2C brand that needs to innovate, only one of these is a viable option.

The Three Asias Framework

| Ecosystem | Key Countries | Strengths | Weakness for D2C Brands |

|---|---|---|---|

| Premium Brands | Japan, South Korea | World-class R&D, exceptional quality, strong brand recognition. | Inaccessible. They are brands, not partners. They do not offer Serviços OEM/ODM5 for new D2C companies. |

| Assembly Hubs | Vietnam, Thailand, Indonesia | Low labor costs, good for high-volume assembly of simple products. | Lacks R&D. Weak engineering base and incomplete supply chains make new product innovation extremely difficult. |

| The Innovation Hub | China | Deep R&D talent pool, complete supply chain, rapid prototyping, massive scale. | Higher complexity, requires careful partner vetting. |

This framework makes the path forward clear. You can't work with the Premium Brands. The Assembly Hubs can't build your new idea. Your search must be focused on the Innovation Hub.

Vietnam has the same R&D capabilities as China.Falso

China invests significantly more in R&D (over 2.4% of GDP) and has a much larger pool of engineers and a more mature tech supply chain than Vietnam.

Japanese and Korean electronics companies commonly offer OEM services to small D2C brands.Falso

Companies like Sony, LG, and Panasonic focus on their own brands and do not typically engage in OEM/ODM partnerships with startups or small D2C businesses.

What's the Real D2C Challenge: Finding an Innovator, Not Just an Assembler?

You have a great product idea. But finding a factory to just assemble it is the easy part, and it won't give you a competitive edge. The real challenge is finding a partner to help you perfect it.

The real challenge for D2C brands is finding a partner with strong R&D capabilities. An assembler just follows instructions, but an innovator collaborates on design, materials, and functionality to create a truly superior product. This is the key to long-term market success.

Think about it from a product designer's perspective. You've spent weeks on a design. You know it's good, but you also know there are things you can't see from your desk in Canada or the US.

- An Assembler will take your CAD file and produce it. If there's a flaw in your draft angle that causes a high defect rate during molding, that's your problem. They did what you asked. They are a pair of hands.

- An Innovator Partner will look at your design and say, "This is a great start. But if we change this curve slightly, we can use a simpler mold, which will save you $20,000 in tooling. And have you considered this new polymer? It has better antimicrobial properties." They are a partner brain.

I've seen this happen countless times. A client comes to me with a design, and we connect them with a true JDM (Joint Design Manufacturing) partner. The final product that hits the market is 10x better than the original concept, not because the client's idea was bad, but because the partner brought their deep manufacturing and engineering expertise to the table. That's the difference between a product that sells and a product that creates a category.

An 'assembler' factory and an 'innovator' factory offer the same value.Falso

An assembler provides labor, while an innovator provides R&D, design feedback, and engineering solutions, adding significantly more value to the product development process.

Joint Design Manufacturing (JDM) is a model where the brand and the manufacturer collaborate on product design.Verdadeiro

JDM is a partnership model where both parties contribute to the R&D and design of the final product, sharing expertise and risk.

Why is "Asia's R&D Hub" Still the Smartest Choice for Innovation?

You've probably heard the headlines about manufacturing moving out of China. But is that the whole story? Following those headlines without understanding the "why" could lead your D2C brand to a dead end.

China remains the smartest choice for innovation because it's the only ecosystem that combines a massive, integrated supply chain with a deep pool of experienced R&D engineers and huge investment in technology. For new product development, this combination is unbeatable.

Let's be very direct and apply our framework. If your goal is to create a new e innovative humidifier, you need a partner who can innovate with you.

- Can you find that in Japan or Korea? No. They innovate for themselves, not for you.

- Can you find that in Southeast Asia? No. They can assemble your product beautifully once it's fully designed, tested, and sourced. But they lack the deep, integrated ecosystem for development. I've had clients try to develop a complex electronic device in Vietnam. They spent months just trying to source a specific microcontroller that I can get in a single afternoon in Shenzhen. The R&D infrastructure simply isn't there yet.

This leaves the Innovation Hub. This is where the world's product development happens. It's a complete ecosystem. You have the engineers, the prototyping shops, the component suppliers, the mold makers, and the assembly lines all within a few square miles. This density creates a speed and agility that is impossible to replicate anywhere else in the world. For a D2C brand that needs to move fast and innovate, it's the only logical choice.

China's R&D spending is decreasing as manufacturing moves to other countries.Falso

China's R&D spending has been consistently increasing, reaching a record high and demonstrating a national focus on technological innovation over low-cost manufacturing.

The supply chain in Shenzhen is one of the most integrated and fastest in the world for electronics.Verdadeiro

Shenzhen's ecosystem allows for rapid prototyping and sourcing of electronic components, often referred to as 'Shenzhen Speed,' making it a global hub for hardware innovation.

Who are the Top Players to Watch (Categorized by Ecosystem)?

Knowing the theory is good, but you need actual names. Who are the players in these ecosystems? Without concrete examples, you're still just guessing where to start your search.

In the Premium Brand hub, you have giants like Cuckoo. In Assembly Hubs, you'll find many contract manufacturers. But in the Innovation Hub, the key players are ODM/JDM partners like Hisoair6, who specialize in co-developing new products for D2C brands.

Here’s a list of players to know, broken down by our "Three Asias" framework. This isn't a simple "top 10" list; it's a strategic guide to understanding the market landscape.

Premium Brands (Inaccessible Partners)

- Cuckoo (Korea): A leader in home appliances with excellent technology and design.

- Panasonic (Japan): A global giant known for quality and reliability.

- Sharp (Japan): Famous for its air purification and Plasmacluster technology.

- The Takeaway: These are amazing brands. You can and should study their products. But they will not make your product. They are not an option for a D2C partnership.

Assembly Hubs (Limited R&D)

- Generic Factory A (Vietnam): You will find many factories like this on sourcing platforms.

- Generic Factory B (Thailand): Similar to Vietnam, strong in assembly for established designs.

- The Takeaway: These factories are a good choice if you have a simple, fully-realized product and your primary goal is lowering labor costs. If you need to innovate or develop a product from scratch, you will hit a wall.

The Innovation Hub (Your Target Zone)

- Midea / 7. Gree: Domestic Chinese giants with massive R&D departments. They can be complex for smaller D2C brands to work with.

- Bear / 9. Deerma: Popular Chinese brands that have strong product development but are focused on their own domestic market.

- Hisoair: This is the model for a perfect D2C innovation partner. They focus specifically on ODM/JDM partnerships, combining their R&D strength with a focus on helping outside brands succeed.

Midea is a small, niche manufacturer.Falso

Midea Group is a Fortune Global 500 company and one of the largest home appliance manufacturers in the world.

Hisoair focuses on the Joint Design Manufacturing (JDM) model for D2C brands.Verdadeiro

Hisoair's business model is centered on collaborating with brands to design and manufacture new products, positioning them as an R&D partner rather than just a contract manufacturer.

How Do You Choose Your Asian Partner (The Hisoair Solution)?

You've correctly narrowed your search to the Innovation Hub. But how do you pick the winner from the thousands of potential partners there? Choosing the wrong one can still lead to a generic product.

Choose your partner based on their proven R&D, not their price. Ask for case studies of products they've co-developed. A partner like Hisoair stands out because they can show tangible innovation, like their all-stainless-steel humidifier, proving they are more than an assembler.

So, how do you spot a true innovator? You need to ask the right questions. Forget asking "What is your best price?" Instead, start a technical conversation.

Your Innovation Partner Checklist:

[ ]Ask for Proof of Innovation: Don't ask "What can you make?" Ask, "Can you show me a product you helped invent?"[ ]Inquire About Their R&D Team: Ask, "What is your R&D team structure? How many mechanical and electrical engineers do you have?"[ ]Discuss Technical Challenges: Bring up a real problem. "How would you approach the mold design for a complex, seamless unibody part?"[ ]Understand Their Process: Ask, "What is your New Product Introduction (NPI) process? How do you take an idea from concept to mass production?"

When you find a company like Hisoair, the answers become obvious. They don't just show you a catalog of existing products. They show you their all-stainless-steel humidifier. This single product is the ultimate proof point. It demonstrates their ability to solve complex challenges in materials, molding, and manufacturing that others can't. It proves they are not just an assembler; they are an innovator. That is the partner you need to build a winning D2C brand.

A manufacturer's past projects are the best indicator of their future capabilities.Verdadeiro

Reviewing a manufacturer's portfolio of co-developed products provides concrete evidence of their R&D, engineering, and problem-solving skills.

Stainless steel is as easy to mold into complex shapes as plastic.Falso

Manufacturing complex shapes with stainless steel requires advanced tooling, stamping, and welding techniques, representing a significantly higher engineering challenge than injection molding plastic.

Conclusão

Choosing the right Asian partner isn't about location; it's about finding a true innovator in the R&D hub. This strategic choice will define your product's success and your brand's future.

References

-

Understanding R&D-driven partners can help you find innovative manufacturers that enhance product development. ↩

-

Rapid prototyping is essential for D2C brands to quickly test and iterate on product designs. ↩

-

Exploring the Innovation Hub reveals key insights into the best manufacturing practices and partners for D2C brands. ↩

-

A well-defined sourcing strategy is crucial for D2C brands to find the right manufacturing partners. ↩

-

Exploring OEM/ODM services can clarify how manufacturers can support D2C brands in product creation. ↩

-

Investigating Hisoair's approach can provide insights into effective partnerships for product innovation. ↩