You have a brilliant idea for a D2C humidifier brand. But choosing a supplier feels like a gamble that could sink your startup. I'll show you how to de-risk your launch.

The best suppliers for D2C startups are not traditional OEM or ODM factories. Instead, you need an "Innovation Partner1" who offers a "Unique ODM"—a pre-developed, certified, and highly differentiated product. This gives you the speed of ODM with the uniqueness of OEM, avoiding common startup traps.

I've been in the mold and manufacturing business for a long time. I started on the factory floor and eventually built my own trading company. I've seen countless ambitious founders, just like you, full of passion and great ideas. I've also seen many of them fail, not because their idea was bad, but because they made a critical mistake right at the beginning: they chose the wrong manufacturing partner. It's a painful and expensive lesson, and it's one I want to help you avoid.

This isn't just about finding a factory. It's about finding a partner who can accelerate your brand, not drain your resources. Let's break down the choices you face and uncover the hidden path to a successful launch.

Launching a new hardware product costs, on average, between $50,000 and $1,000,000.Verdadeiro

This range covers design, prototyping, tooling, and initial manufacturing runs. Startups often underestimate these costs, making the choice of manufacturing partner critical to financial survival.

The only difference between most ODM products is the logo printed on the front.Falso

While many ODM products are very similar, some suppliers offer minor cosmetic changes, different color options, or packaging variations. However, the core product and technology are typically identical.

What is the D2C Startup's Dilemma When Launching a New Product?

You have a great product idea but limited cash and time. This forces a tough choice between a custom product that's too slow and expensive, or a generic one that won't stand out.

The core dilemma for a D2C startup2 is balancing differentiation with resources. You know you need a unique product to build a brand, but you have a startup's budget and timeline. This creates a massive conflict that can feel impossible to solve.

In my years of helping clients bring products to market, I've seen this dilemma play out over and over. It's the classic startup trap. You have the vision, the drive, and you've identified a gap in the market. But turning that vision into a physical product is where the real challenge begins. You are resource-poor but ambition-rich. Every dollar and every day counts.

The Dream vs. The Reality

Your dream is to launch a product that people love, a brand that has a real story. The reality is that creating a truly new product from scratch is a monumental task. It involves:

- Extensive R&D

- Complex product design

- Expensive mold tooling

- Lengthy prototyping and testing

- Navigating a maze of safety and compliance certifications

This is the path of giants like Apple or Dyson, who have billion-dollar R&D budgets. For a startup, this path is often a direct route to running out of money. This forces you to look at other options, which have their own set of problems.

Over 90% of hardware startups fail.Verdadeiro

According to reports from CB Insights and other market analysts, hardware startups face higher failure rates than software startups due to challenges with manufacturing, supply chain, and high upfront capital costs.

All factories in China can produce high-quality goods.Falso

Quality varies dramatically between factories. Vetting a supplier for quality control, ethical practices, and reliability is one of the most critical steps in manufacturing.

Are You Walking into the OEM vs. ODM Trap?

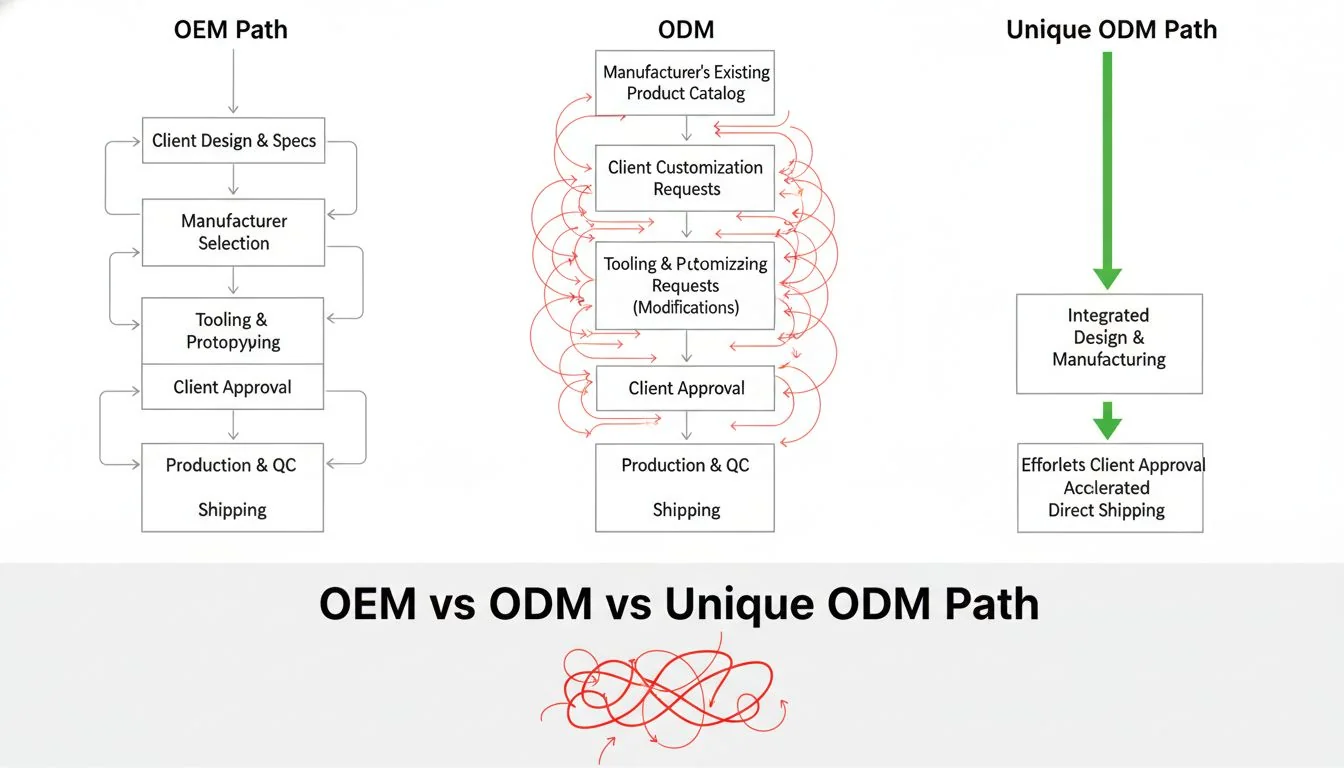

You think OEM means a unique product and ODM means a fast launch. But OEM is a high-risk cash drain, and standard ODM makes your product a commodity. This is the trap.

The trap is believing you only have two choices. OEM (Original Equipment Manufacturer) is high-risk, demanding huge investments in R&D and tooling. ODM (Original Design Manufacturer) offers a generic product, forcing you to compete on price alone. Neither path is built for a startup's success.

I need you to reframe how you see these terms. Forget the industry definitions for a moment and think about them in terms of risk and reward for your startup. I've guided clients through this decision hundreds of times, and I've learned to simplify it. OEM is the high-risk, high-reward path. ODM is the low-risk, low-reward path. The problem is, for a startup, "high-risk" can be fatal, and "low-reward" means you can't build a sustainable business.

OEM: The High-Risk Gamble

With OEM, you are paying a factory to build your custom design. This gives you a 100% unique product. It sounds perfect, right? But it means you bear 100% of the development cost and risk. This includes design, engineering, and, most importantly, the injection molds, which can cost tens or even hundreds of thousands of dollars. For a startup, this is a massive bet.

ODM: The Commodity Race to the Bottom

With ODM, you are picking a product from a factory's existing catalog and putting your logo on it. The factory owns the design and the molds. This is much faster and cheaper. The catch? Your competitors can buy the exact same product from the same factory. You have no unique advantage.

| Caraterística | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Produto | 100% Custom, Your Design | Factory's Existing Design |

| Startup Risk | High Risk | Commodity |

| Upfront Cost | Very High (Molds, R&D) | Low (No Mold Costs) |

| Time to Market | Very Long (1-2 years) | Fast (3-6 months) |

| Differentiation | Elevado | Very Low |

| Best For | Large, established companies | Traders, not brand-builders |

Injection molds for a simple product can cost over $50,000.Verdadeiro

The cost of steel, complex machining, and labor for creating high-production molds, even for relatively simple plastic parts, can easily reach tens of thousands of dollars.

ODM products can be easily patented by the startup that sells them.Falso

The intellectual property (IP) for an ODM product, including the design and engineering, is owned by the factory, not the brand selling it. You cannot patent something you did not design.

Is Choosing a 'Commodity' ODM Partner a Death Sentence for Your Startup?

You found a cheap, ready-made ODM humidifier. But so have ten other new brands. Now you are trapped in a price war you can't possibly win. This is the start of a death spiral.

Yes, choosing a commodity ODM partner is often a death sentence. It supplies the same generic product to everyone, erasing your brand's uniqueness. This forces you into brutal price wars against bigger sellers, destroying your profit margins and brand identity before you even get started.

Let me tell you a quick story. A few years ago, a passionate client came to me. He wanted to launch a D2C brand for home wellness products. To save money and launch fast, he chose a standard plastic ultrasonic humidifier from a big ODM factory he found online. It looked good, the price was low, and he ordered 2,000 units. He was excited. But his excitement faded fast.

The Amazon Graveyard

When he launched on Amazon, he found a dozen other sellers with the exact same humidifier, just with a different logo. Some were big, established sellers who could afford to sell it for a few dollars less. He was immediately caught in a race to the bottom.

Zero Pricing Power

He couldn't talk about unique features because there were none. He couldn't build a brand story around a generic white box. His only lever was price. Every dollar he cut from his price was a dollar cut from his already thin profit margin—the money he needed for marketing, growth, and his next product. Within six months, he was selling his remaining inventory at a loss just to get his cash back. His brand was dead. This is the "commodity death sentence."

The average profit margin for D2C brands is between 10-30%.Falso

While it varies greatly by industry, many successful D2C brands aim for gross margins of 50-70% or higher to cover marketing, shipping, and overhead costs. A low margin from a commodity product makes this impossible.

Amazon is the largest marketplace for home appliances in the United States.Verdadeiro

Amazon dominates online retail for nearly every category, including small home appliances like humidifiers, making it a highly competitive environment for new brands.

How Can You Find an 'Innovation Partner' with 'Unique ODMs'?

You feel trapped between high risk and no differentiation. It seems impossible to launch a unique product quickly and affordably. But there is a third way: the "Unique ODM3" from an "Innovation Partner."

You find them by looking for suppliers who invest their own money in R&D to create truly novel products. I call these suppliers "Innovation Partners." They offer a "Unique ODM"—a product with the speed of ODM but the differentiation of OEM. This is the secret weapon for startups.

This is the solution I've developed after watching so many startups struggle. You shouldn't have to choose between betting the farm on a custom product or getting lost in a sea of commodities. The smartest founders I know find a third option. They find a partner who has already done the heavy lifting.

What is an "Innovation Partner"?

An Innovation Partner is a manufacturer that acts more like a tech company. Instead of just waiting for OEM orders or churning out the same old ODM designs, they:

- Invest in their own R&D.

- Identify real market gaps4 and consumer pain points.

- Develop and patent their own innovative solutions.

They create products that are genuinely new and different. They take on the initial risk of development, and then offer that finished, innovative product to a select few brand partners.

The "Unique ODM" Advantage

This new category of product is what I call a "Unique ODM." It's the perfect hybrid for a startup.

| Caraterística | Standard ODM | Unique ODM (from Innovation Partner) |

|---|---|---|

| Produto | Generic, widely available | Innovative, differentiated, exclusive |

| R&D Cost | None for you | None for you (Partner absorbed it) |

| Mold Cost | None for you | None for you (Partner absorbed it) |

| Differentiation | Baixa | Elevado |

| Brand Story | Weak ("It's affordable") | Strong ("It solves this problem") |

| Result | Price War | brand building5 |

This model gives you the best of both worlds: the speed and low upfront cost of ODM, combined with the powerful differentiation you'd normally only get with a high-risk OEM project.

Patents for new product designs are a key indicator of a supplier's innovation.Verdadeiro

A supplier that holds its own design and utility patents is actively investing in R&D, a hallmark of an 'Innovation Partner'.

All ODM suppliers will offer exclusive rights to their products.Falso

This is very rare. Most ODM suppliers want to sell their products to as many clients as possible. Exclusivity is a key feature of the 'Unique ODM' model and often requires a strong partnership.

What Makes the Stainless Steel Humidifier the Ultimate 'Unique ODM'?

The "Unique ODM" concept sounds great, but you need a real-world example. The stainless steel humidifier6 is the perfect proof point. It's a ready-made product that is instantly different and better.

It's the ultimate "Unique ODM" because it solves a huge, unspoken problem with all other humidifiers: they are gross and hard to clean. It's a ready-made, certified product that is instantly differentiated from 99% of the market, giving you a powerful brand story right out of the box.

For years, every humidifier on the market has been made of plastic. As a mold and manufacturing expert, I know that plastic, especially ABS plastic used in these devices, is porous. It has microscopic nooks and crannies. When water sits in a plastic tank, it becomes a breeding ground for mold and bacteria. Customers know this. They complain about the "pink slime" and the difficulty of cleaning the complex plastic parts.

Solves a Real Pain Point: Hygiene

A stainless steel humidifier solves this problem completely.

- Non-Porous: Stainless steel is non-porous. Bacteria and mold have nowhere to hide and grow.

- Easy to Clean: You can easily wipe it clean or even put the tank in the dishwasher. It's as easy to clean as a kitchen pot.

- Durable: It won't crack or degrade over time like plastic.

This isn't just a minor feature. It's a fundamental improvement that addresses the biggest customer complaint about the entire product category.

Premium Material, Premium Brand

Using stainless steel instantly elevates your product. It communicates quality, durability, and hygiene. You are no longer selling a cheap plastic appliance; you are selling a premium, health-conscious wellness device. This allows you to build a premium brand and command a premium price, escaping the commodity trap. This is a product developed by an Innovation Partner, Hisoair, who saw the problem and engineered the solution.

Stainless steel is naturally resistant to bacterial growth compared to plastic.Verdadeiro

The non-porous surface of stainless steel makes it difficult for microorganisms to adhere and form biofilms, which is why it is the standard material for medical and food-grade equipment.

Plastic humidifiers need to be cleaned daily to prevent mold growth.Verdadeiro

Most manufacturers and health experts recommend daily rinsing and weekly disinfecting of plastic humidifiers to prevent the dispersal of mold and bacteria into the air.

Why is Hisoair the Ideal 'Innovation Partner' for Your D2C Startup?

You need a partner who not only has a "Unique ODM" but can also help you get to market fast. Finding a trustworthy, certified supplier is the final, critical piece of the puzzle.

Hisoair is the ideal partner because they are a true "Innovation Partner." They developed the unique stainless steel humidifier and, most importantly, have it fully certified for the North American market (ETL/CARB). This combination of innovation and compliance is your brand accelerator.

Finding an innovative product is only half the battle. For a startup, time and money are everything. This is where Hisoair becomes more than just a supplier; they become a brand accelerator.

Your Secret Weapon: Pre-Certified Products

Getting an electronic product certified for sale in North America is a slow, expensive nightmare.

- ETL Certification: This is for electrical safety. It's non-negotiable.

- CARB Certification: This is an air quality standard from the California Air Resources Board. It's required to sell in California, and many national retailers now require it.

This process can take 6-12 months and cost you $50,000 or more in testing and fees. Hisoair has already done this. Their stainless steel humidifier is fully certified. This is a massive advantage.

From Idea to Market in Months, Not Years

Look at how this changes your launch timeline and budget.

| Launch Step | Standard Partner (OEM/ODM) | Hisoair (Innovation Partner) |

|---|---|---|

| R&D / Design | 6-12 meses | 0 months (Done) |

| Tooling / Prototyping | 3-6 meses | 0 months (Done) |

| Certificação | 6-12 meses | 0 months (Done) |

| Total Time to Market | 1.5 - 2.5 years | 3-4 months (Production & Shipping) |

| Extra Cost | $50k - $150k+ | $0 |

By partnering with hisoair.com, you are not just buying a product. You are buying speed. You are saving a year or more of development time and tens of thousands of dollars in cash. You can focus your limited resources on what you do best: building your brand, marketing, and connecting with customers. This is how you de-risk your launch and build a successful D2C business from day one.

ETL certification is legally required to sell most electronic products in the US and Canada.Verdadeiro

Nationally Recognized Testing Laboratories (NRTLs) like ETL (Intertek) or UL test and certify products to government-mandated safety standards. Retailers will not stock uncertified products due to liability risks.

CARB compliance is only important if you sell in California.Falso

Because California is such a large market, its regulations often become the de facto national standard. Major retailers like Amazon, Target, and Walmart often require CARB compliance for products sold nationwide.

Conclusão

Stop choosing between high risk and a low-value commodity. Find an innovation partner with a unique, certified ODM to accelerate your brand's launch and secure your long-term success.

References

-

Understanding the role of an Innovation Partner can help you find the right supplier for your startup. ↩

-

Learning about D2C startup challenges can help you navigate the complexities of launching your brand. ↩

-

Exploring Unique ODMs can reveal innovative solutions that differentiate your product in the market. ↩

-

Identifying market gaps is crucial for developing innovative products that meet consumer needs. ↩

-

Exploring brand building strategies can help you create a strong identity and connect with customers. ↩

-

Discover why stainless steel humidifiers are superior and how they can enhance your product offering. ↩