In today's increasingly health-conscious world, access to clean, purified water is no longer a luxury but a fundamental necessity. For businesses operating in the water treatment and appliance sectors, understanding the intricacies of product manufacturing is paramount. This knowledge not only informs strategic sourcing and supply chain decisions but also underpins the ability to deliver reliable, high-quality solutions to end-users. Whirlpool, a globally recognized leader in home appliances, has a significant presence in the water purification market, offering a range of products designed to enhance water quality.

This article delves into the manufacturing origins of Whirlpool water purification products. We aim to provide a comprehensive overview for B2B clients, shedding light on where these essential systems and components are produced, the manufacturing philosophies that guide Whirlpool, and the role of strategic partnerships in their production. By exploring these aspects, we seek to offer valuable insights into the quality, supply chain resilience, and potential collaboration opportunities within this vital industry segment.

Understanding Whirlpool's Water Purification Offerings

Clarifying Terminology: Purifiers, Filters, and Treatment Systems

Before delving into manufacturing locations, it's crucial to distinguish between the various terms often used interchangeably in the water quality industry: water purifiers, water filters, and water treatment systems. While all aim to improve water quality, they differ in their scope and the contaminants they address.

- Water Filters: These are typically the most basic form of water treatment, designed to remove suspended particles, sediment, chlorine, and often improve taste and odor. Examples include refrigerator water filters, faucet-mounted filters, and basic whole-house sediment filters. They primarily focus on physical and chemical filtration.

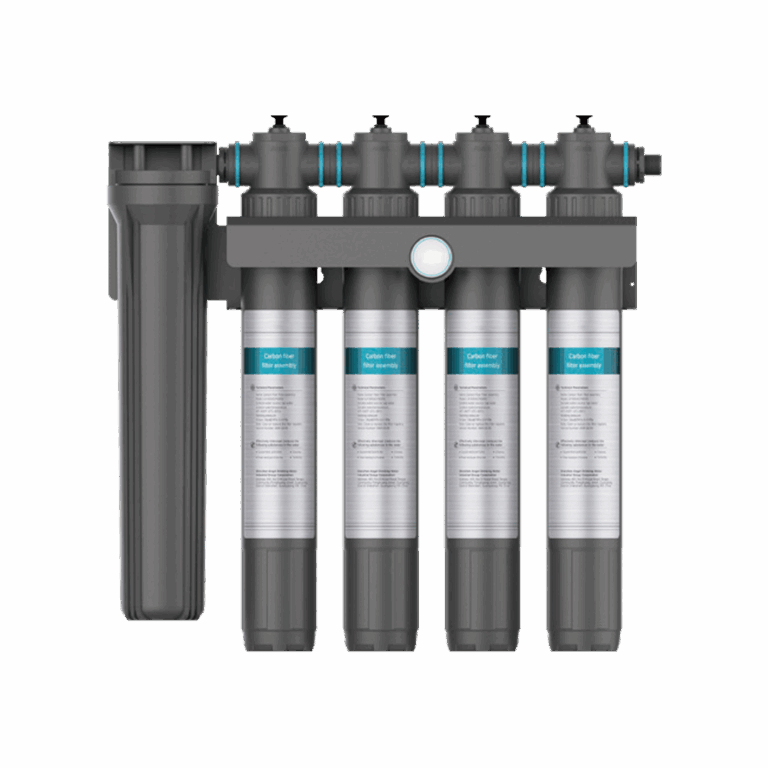

HisoAir - Commercial microfiltration water filters - HW-FC15

- Water Purifiers: This term generally implies a higher level of contaminant removal, often targeting microscopic organisms, viruses, and a broader range of chemical pollutants beyond what a standard filter can handle. Reverse osmosis (RO) systems are a common type of water purifier, using a semi-permeable membrane to remove dissolved solids, heavy metals, and other impurities. Ultraviolet (UV) purifiers also fall into this category, using UV light to inactivate bacteria and viruses.

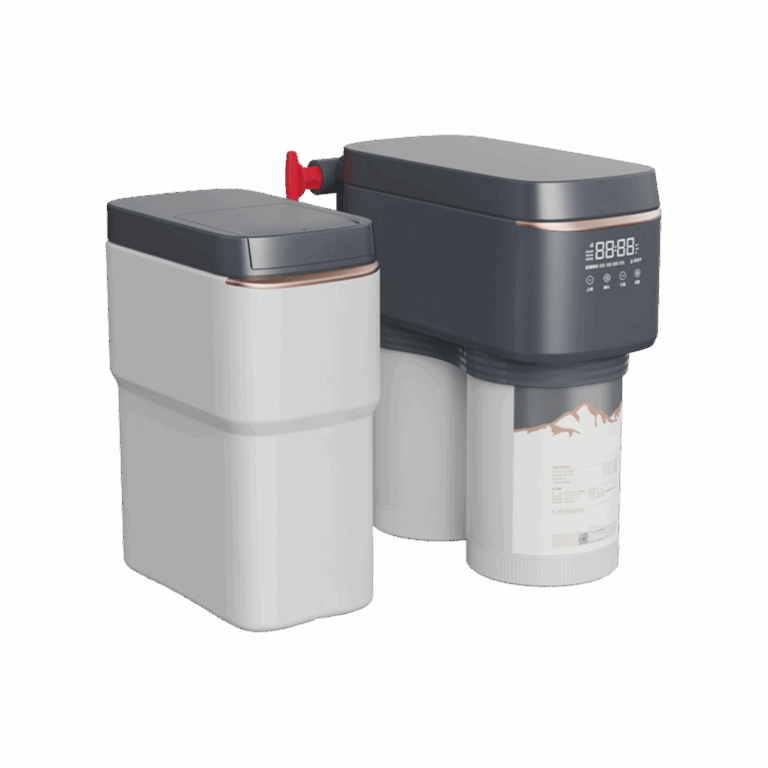

HisoAir - Premium Undersink Water Purifier HW03 Series

- Water Treatment Systems: This is a broader category encompassing any system designed to alter water quality for specific purposes. This can include water softeners (which remove hardness minerals like calcium and magnesium), iron filters, and more complex multi-stage systems that combine various filtration and purification technologies. Whole-house water treatment systems often integrate multiple components to address a wide array of water quality issues at the point of entry into a building.

HisoAir - Mini water softener - HW-S01

Whirlpool offers products across all these categories, from simple refrigerator filters to advanced under-sink RO systems and comprehensive whole-house water softeners and filtration units. The specific manufacturing processes and locations can vary significantly depending on the complexity and type of product.

Whirlpool's Commitment to Quality and Innovation

Whirlpool Corporation has built a century-long reputation for producing reliable home appliances. This commitment to quality extends to its water purification product lines. The brand leverages its extensive research and development capabilities to innovate in water treatment technologies, aiming to provide effective solutions for various water quality challenges. This dedication is often reflected in the certifications their products receive, such as NSF/ANSI standards, which assure consumers and businesses of their performance and safety, regardless of where they are manufactured.

The Manufacturing Landscape of Whirlpool Water Purification Products

Whirlpool's Core Manufacturing Philosophy

Whirlpool Corporation, an American multinational manufacturer and marketer of home appliances, has a long-standing history of manufacturing in the United States. The company proudly states that approximately 80% of its products sold in America are manufactured in the U.S. [^1]. This commitment to domestic production is evident in their numerous manufacturing facilities across states like Ohio, Tennessee, and Iowa, which produce a wide range of appliances from washing machines to refrigerators. While Whirlpool's primary focus has historically been on major home appliances, their entry into the water purification market leverages both their internal manufacturing expertise and strategic external partnerships.

The Role of Outsourcing and Licensing

In the complex global supply chain of modern manufacturing, it is common for large corporations to utilize a combination of in-house production, outsourcing, and licensing agreements to bring products to market efficiently. This strategy allows companies to focus on their core competencies while leveraging specialized expertise and cost efficiencies from other manufacturers. Whirlpool's water purification product line is a prime example of this diversified approach.

Focus on Kemflo International:

A significant portion of Whirlpool's water filtration systems, particularly those designed for whole-home and under-sink applications, are manufactured under license by Kemflo International Co., Ltd., based in Pingtung, Taiwan 1. Kemflo International is a well-established global manufacturer specializing in water treatment components and systems. This partnership allows Whirlpool to offer a comprehensive range of water filtration solutions, benefiting from Kemflo's specialized knowledge and manufacturing capabilities in the water treatment sector. Products such as the Whirlpool Premium WHKF-DWHV Water Filtration System are explicitly stated to be manufactured by Kemflo International 1.

Other Manufacturing Locations:

While Kemflo International plays a crucial role in the production of many Whirlpool water filtration systems, the manufacturing landscape for all Whirlpool water purification products is more diverse. For instance, some refrigerator water filters, including the popular Everydrop brand (which is compatible with Whirlpool refrigerators), have been noted to be manufactured in Taiwan 2 and potentially other locations. There are also indications that some Whirlpool water softeners might be manufactured in China 3. This multi-faceted manufacturing approach ensures a broad product offering and potentially optimized production costs.

A Closer Look: Manufacturing by Product Category

To provide a clearer picture of Whirlpool water purification product manufacturing, the following table summarizes the likely origins based on available information and industry practices. It is important to note that manufacturing locations can be subject to change due to supply chain adjustments, new partnerships, or evolving business strategies.

| Categoria do produto | Product Examples | Likely Manufacturing Location/Partner |

|---|---|---|

| Refrigerator Water Filters | Everydrop, UKF8001 | Taiwan, China, USA (for some compatible brands) |

| Under-Sink Filtration Systems | WHAROS5, WHKF-DUF | Kemflo International (Taiwan), potentially some models in USA |

| Whole-House Filtration Systems | WHELJ1, WHKF-DWHV | Kemflo International (Taiwan) |

| Water Softeners | WHES40 | China (based on some user reports) |

| Other Appliance Components | Various internal parts | USA (Whirlpool's core manufacturing facilities) |

This table illustrates the diversified manufacturing approach taken by Whirlpool for its water purification portfolio. While the brand maintains a strong domestic manufacturing presence for its core appliances, it strategically partners with specialized manufacturers like Kemflo International for water treatment solutions, leveraging their expertise and established production capabilities.

What This Means for B2B Clients

Understanding the manufacturing landscape of a major brand like Whirlpool in the water purification sector offers several key takeaways for B2B clients, including distributors, retailers, and other businesses looking to enter or expand their presence in this market.

Quality and Reliability

Whirlpool’s approach to manufacturing, whether in-house or through licensed partners like Kemflo International, underscores a commitment to quality. The consistent adherence to industry standards, often evidenced by certifications such as NSF/ANSI, ensures that products meet stringent performance and safety criteria. For B2B clients, this means that regardless of the specific manufacturing location—be it the USA, Taiwan, or China—the Whirlpool brand signifies a baseline of reliability and performance that consumers expect. This assurance of quality is crucial for maintaining customer trust and reducing post-sales support issues.

Supply Chain Diversity and Resilience

The diversified manufacturing strategy employed by Whirlpool, utilizing facilities in different geographical regions, contributes to a more resilient supply chain. In an era where global supply chain disruptions are increasingly common, having multiple manufacturing hubs can mitigate risks associated with localized events, trade policies, or logistical challenges. For B2B partners, this diversification can translate into more stable product availability and reduced lead times, which are critical for inventory management and meeting market demand.

Opportunities for Partnership: Connecting with HisoAir

The prevalence of outsourcing and licensing in the water purification industry, as exemplified by Whirlpool’s partnership with Kemflo, highlights a significant opportunity for businesses seeking to develop or expand their own water purification product lines. This is where specialized OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partners become invaluable.

HisoAir, as a premium OEM/ODM provider of water purification solutions, stands at the forefront of this opportunity. With expertise in designing and manufacturing advanced water purifiers for premium brands, HisoAir offers a comprehensive suite of services that can help businesses bring high-quality water purification products to market efficiently and effectively. HisoAir’s product offerings, including countertop and under-sink water purifiers, as detailed on their official website (https://hisoair.com/water-purifiers/), demonstrate their capability to meet diverse market needs with innovative and reliable solutions.

Partnering with an experienced OEM/ODM like HisoAir allows businesses to leverage established manufacturing processes, advanced filtration technologies, and robust quality control systems without the substantial investment required for in-house production. This collaboration can accelerate time-to-market, ensure product quality, and provide access to cutting-edge designs and functionalities, making it an ideal pathway for brands looking to enter or expand their footprint in the competitive water purification market.

Conclusão

In conclusion, the manufacturing of Whirlpool water purification products is a multifaceted process that spans various geographical locations and involves strategic partnerships. While Whirlpool maintains a strong manufacturing presence in the United States for many of its core appliances, its water filtration and treatment systems often leverage the specialized expertise of partners like Kemflo International in Taiwan. Additionally, components and specific product lines may originate from other global manufacturing hubs, including China.

For B2B clients, understanding this diversified manufacturing landscape is crucial. It speaks to Whirlpool’s commitment to quality through rigorous standards, regardless of the production site, and highlights a resilient supply chain strategy. More importantly, it underscores the significant role of OEM/ODM partnerships in the water purification industry. Companies like HisoAir exemplify how specialized manufacturers can provide premium, high-quality solutions, enabling brands to effectively enter and thrive in the water purifier market without the need for extensive in-house manufacturing capabilities.

We encourage businesses seeking to expand their water purification product offerings to explore the benefits of collaborating with experienced OEM/ODM partners. For more information on premium water purification solutions and partnership opportunities, visit HisoAir’s official website at https://hisoair.com/water-purifiers/.

References:

[^1]:Whirlpool US Manufacturing. Whirlpool Corporation. Available at: https://www.whirlpoolcorp.com/manufacturing.html

-

Whirlpool Water Filtration Systems | For the Home. Whirlpool Water Filtration. Available at: https://whirlpoolwaterfiltration.com/ ↩ ↩

-

Rant: Whirlpool Everydrop fridge filters are engineered to fail early. Reddit. Available at: https://www.reddit.com/r/Appliances/comments/14j5ze7/rant_whirlpool_everydrop_fridge_filters_are/ ↩

-

Hi I'm looking to purchase a new water softener it would be whirlpool ... Reddit. Available at: https://www.reddit.com/r/WaterSofteners/comments/13l07ix/hi_im_looking_to_purchase_a_new_water_softener_it/ ↩