Have you ever wondered about the origin of BlueAir's innovative 3 in 1 air purifier1, cooling fan, and heater? Let's explore the manufacturing story behind this multifunctional device that has captured the attention of consumers worldwide.

BlueAir's 3 in 1 air purifier, cooling fan, and heater is primarily manufactured in Foshan2, Guangdong Province, China. This strategic manufacturing location helps reduce production costs while enabling BlueAir to meet growing online sales demands. The company works with specialized suppliers across Shenzhen and Dongguan to maintain a robust resiliência da cadeia de abastecimento3, ensuring efficient fulfillment of global market needs.

As an industry insider with extensive experience in air purification manufacturing, I've had the opportunity to observe BlueAir's production evolution firsthand. The story behind their 3 in 1 combo device goes beyond mere manufacturing locations—it reveals a fascinating journey of innovation, strategic business decisions, and adaptation to changing market demands. Following Unilever acquisition4 of BlueAir, the company expanded its supplier network and shifted its manufacturing strategy to address increasing online competition and evolving consumer preferences. The air purifier market has experienced tremendous growth since the COVID-19 pandemic, pushing brands like BlueAir to continuously innovate while exploring manufacturing opportunities beyond China, including potential facilities in Vietnam and Mexico.

How Has BlueAir's Manufacturing Strategy for the 3-in-1 Device Evolved?

Join me on a journey through BlueAir's evolving manufacturing approach for their innovative 3 in 1 air purifier, cooling fan, and heater—a story that demonstrates resilience and innovation in challenging global circumstances.

BlueAir has significantly transformed its manufacturing strategy over time. Initially relying on a limited supplier network in China, they've expanded to a more diverse global supply chain. This strategic shift has not only optimized costs but also enhanced their resilience against supply chain disruptions. With geopolitical challenges becoming increasingly common, BlueAir has positioned itself to navigate these complexities effectively.

Evolution of Manufacturing Locations

In the beginning, BlueAir primarily depended on trusted manufacturing partners in Guangdong Province, China, with key operations centered in Shenzhen, Dongguan, and Foshan. However, as the market evolved, BlueAir recognized the need for a broader vision—one that focused not just on cost reduction but also on expanding their reach through online retail platforms like Amazon. This shift allowed them to connect with more consumers without the traditional retail markup.

The development of the 3 in 1 combination device presented unique manufacturing challenges. Creating a product that effectively purifies air while also functioning as both a cooling fan and heater requires specialized expertise and precision engineering. This complexity influenced BlueAir's decision to partner with a publicly listed manufacturing company in Foshan with extensive experience producing various home appliances for global brands such as SEB, Anker, and Morphy Richards.

Impacto da concorrência no mercado

The post-COVID-19 competitive landscape significantly shaped BlueAir's manufacturing approach. The air purifier market became increasingly crowded with emerging brands gaining substantial market share, forcing BlueAir to reconsider their production strategies to maintain relevance in the competitive online marketplace.

| Period | Manufacturing Strategy | Business Impact |

|---|---|---|

| Early Years | Limited Chinese Supplier Network | Consistent quality but reduced flexibility |

| Mid-Development | Expanded Supplier Diversity | Increased adaptability and supply chain resilience |

| Current Era | Global Supply Chain Integration | Enhanced market competitiveness and broader reach |

Implementing the China+1 Strategy

With rising geopolitical uncertainties, BlueAir has been exploring the Estratégia China+15 for their product line, including the 3 in 1 device. This approach focuses on maintaining their Chinese manufacturing base while establishing additional production capabilities in countries like Vietnam, Thailand, and Mexico. This diversification helps mitigate trade-related challenges while creating new opportunities for market expansion.

Acquisition Influence and Strategic Partnerships

Unilever's acquisition of BlueAir provided access to expanded resources and expertise, facilitating a shift toward a more robust global supply chain. This corporate backing enabled BlueAir to optimize their production processes for the technically challenging 3 in 1 device, allowing them to introduce innovative features while maintaining quality standards.

The complexity of combining three distinct functions—air purification, cooling, and heating—into a single device necessitated collaboration with manufacturers possessing strong engineering capabilities. The partnership with the Foshan-based manufacturer exemplifies how BlueAir balances established relationships with new collaborations to drive strategic growth and technical innovation.

Technology Integration and Sustainability Focus

BlueAir's evolving manufacturing strategy emphasizes not just efficient production but also responsible practices. They're investing in technologies that enhance energy efficiency and sustainability throughout the manufacturing process, ensuring their 3 in 1 devices meet international environmental standards.

For BlueAir, sustainability isn't merely a marketing angle—it's fundamental to their business approach. Modern consumers increasingly expect environmentally responsible products, making sustainable manufacturing6 essential for maintaining market leadership. This focus benefits both their brand reputation and long-term business viability.

Future Manufacturing Direction

Looking ahead, BlueAir is concentrating on strengthening supply chain resilience while continuing to innovate in their multi-functional air treatment technology. Their growth trajectory aligns with industry trends where adaptability and sustainability are crucial for manufacturing success.

As market dynamics continue to shift, BlueAir's ability to adapt their manufacturing approach will likely remain key to maintaining their competitive edge in the global air treatment market.

Understanding these manufacturing evolutions provides valuable context for appreciating how BlueAir addresses industry challenges while maintaining its position as a leading air purification brand. Their dynamic strategy demonstrates how businesses can thrive in evolving global environments through innovation and strategic partnerships.

Why Does BlueAir Choose Foshan for Manufacturing Their 3 in 1 Device?

Have you ever wondered what factors influence where a global brand like BlueAir establishes manufacturing facilities for complex products like their 3 in 1 air purifier, cooling fan, and heater?

BlueAir selects manufacturing locations based on several critical factors: cost efficiency, market accessibility, supply chain diversification, and geopolitical considerations. These elements help maintain competitive pricing, ensure supply chain stability, and enable rapid response to market changes. Their strategic approach to manufacturing location selection demonstrates remarkable adaptability in a dynamic global marketplace.

Considerações económicas

Cost efficiency plays a pivotal role in BlueAir's decision to manufacture their 3 in 1 device in Foshan. This region offers advantageous labor costs, favorable tax structures, and well-developed transportation infrastructure. By leveraging China's sophisticated manufacturing ecosystem, BlueAir achieves significant cost savings while maintaining the quality standards expected of their premium products.

The Foshan-based manufacturer, a publicly listed company specializing in home appliances, provides BlueAir with access to established production lines and economies of scale. This partnership allows BlueAir to optimize production costs for their technically complex 3 in 1 device without compromising on performance or reliability.

Supply Chain Integration

Following Unilever's acquisition, BlueAir strategically diversified its supplier network, avoiding over-reliance on any single source. This approach mirrors my own experience in the air purification industry, where I've witnessed how supply chain diversification enhances resilience against disruptions. BlueAir's "China+1" strategy includes exploring manufacturing possibilities in countries like Vietnam and Thailand to strengthen their supply chain resilience.

The 3 in 1 device's complex nature combining air purification, cooling, and heating functions requires specialized components and expertise. Foshan's manufacturing ecosystem, with its concentration of electronics and appliance producers, provides BlueAir with access to the specialized suppliers needed for this multifunctional product.

Acessibilidade do mercado

Proximity to target markets reduces shipping costs and delivery times, enhancing customer satisfaction through faster product availability. While manufacturing in China, BlueAir is strategically positioned to serve both Asian markets and, through efficient logistics networks, North American and European consumers.

The company's consideration of establishing production facilities in Mexico demonstrates their forward-thinking approach to market accessibility, particularly for serving North American customers more efficiently. This strategy becomes increasingly important as competition intensifies with brands like Levoit gaining market share in the air purifier segment.

Factores geopolíticos

Political stability and trade policies significantly influence manufacturing location decisions. Having navigated changing international trade regulations myself, I understand how shifts in policy can impact business operations. BlueAir closely monitors developments in U.S.-China trade relations and explores alternative manufacturing locations to maintain competitive positioning regardless of geopolitical developments.

Competitive Market Dynamics

The air purifier market has become increasingly competitive since the COVID-19 pandemic, similar to the intensified competition I've experienced in my own business operations. BlueAir focuses on producing cost-effective yet high-quality units for online retail channels, primarily through platforms like Amazon, where price sensitivity and product reviews significantly impact consumer decisions.

| Decision Factor | Impact on Manufacturing Location | Strategic Benefit |

|---|---|---|

| Eficiência de custos | Lower production expenses in Foshan | Competitive pricing in online marketplaces |

| Supply Chain Access | Proximity to component suppliers | Reduced lead times and inventory costs |

| Engineering Expertise | Access to specialized technical knowledge | Enhanced product innovation and quality |

| Posicionamento no mercado | Strategic location for global distribution | Optimized logistics and market responsiveness |

Manufacturing Challenges for Multifunctional Devices

Creating a 3 in 1 device presents unique manufacturing challenges compared to single-function products. The integration of air purification technology with both cooling and heating capabilities requires sophisticated engineering solutions and quality control processes. BlueAir's choice of manufacturing partner in Foshan reflects their recognition of these challenges and the need for specialized expertise.

The Foshan manufacturer's experience producing various home appliances for global brands provides the technical foundation necessary for successfully producing BlueAir's complex multifunctional device. This partnership allows BlueAir to leverage established manufacturing knowledge while focusing on their core competencies in air purification technology and product design.

The Engineering Challenges of BlueAir's 3-in-1 Combo Device

Creating a device that effectively combines air purification, cooling, and heating functions presents significant engineering challenges7 that few manufacturers can successfully overcome.

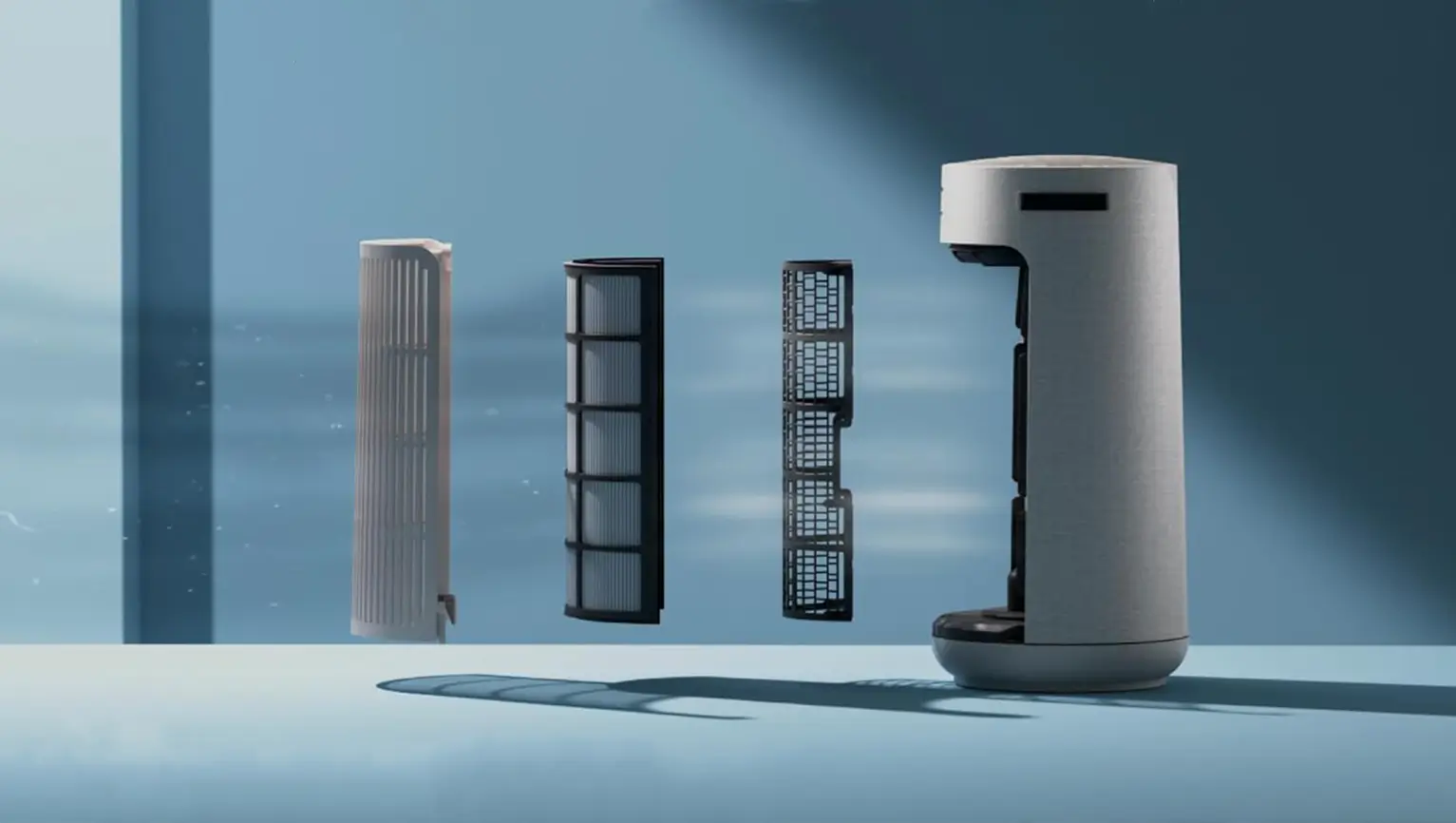

Developing a 3 in 1 combination device like BlueAir's air purifier, cooling fan, and heater requires exceptional engineering expertise to balance competing functional requirements. The integration of these distinct technologies demands innovative design solutions, precise manufacturing processes, and rigorous quality control. BlueAir's partnership with an experienced Foshan manufacturer demonstrates their commitment to overcoming these technical challenges.

Balancing Multiple Functions

The fundamental challenge in creating a 3 in 1 device lies in ensuring that each function performs optimally without compromising the others. Air purification requires efficient airflow through filtration media, while cooling fans need to maximize air movement, and heating elements must safely generate and distribute warmth. These competing requirements necessitate sophisticated engineering solutions that few manufacturers can successfully implement.

As someone deeply involved in air purification technology8 development, I've observed firsthand how challenging it is to maintain purification efficiency when integrating additional functionalities. BlueAir's decision to partner with a specialized manufacturer in Foshan reflects their understanding of these complexities and commitment to delivering a product that doesn't sacrifice performance for convenience.

Customer Expectations and Reality

Consumer expectations9 for combination devices often exceed what's technically feasible. When customers invest $400-500 in a premium 3 in 1 device from a respected brand like BlueAir, they frequently expect each function to perform as well as standalone units. This expectation gap explains the polarized reviews often seen for such products—some customers appreciate the space-saving convenience and give five-star ratings, while others express disappointment with individual function performance compared to dedicated devices.

The reality is that engineering constraints make it virtually impossible for a combination device to match the performance of three separate specialized appliances. Physical space limitations, airflow dynamics, and power management all impose compromises that even the most innovative designs cannot completely overcome.

Manufacturing Complexity

The manufacturing process for BlueAir's 3 in 1 device is significantly more complex than for single-function products. Production requires precise assembly of disparate components, sophisticated electronic controls to manage multiple functions, and extensive testing to ensure safety and performance across all operating modes.

| Engineering Challenge | Impacto na indústria transformadora | BlueAir's Approach |

|---|---|---|

| Airflow Optimization | Requires specialized testing equipment | Advanced computational fluid dynamics modeling |

| Component Integration | Increases assembly complexity | Modular design approach with specialized assembly lines |

| Certificação de segurança | Multiple testing requirements | Comprehensive testing protocols exceeding regulatory standards |

| Performance Balancing | Requires sophisticated control systems | Custom electronic control units with proprietary algorithms |

Quality Control Considerations

Quality control for multifunctional devices requires more comprehensive testing protocols than single-function products. Each function must be individually tested, and additional testing is needed to ensure they work harmoniously together. This expanded quality assurance process contributes to the higher manufacturing costs and retail pricing of combination devices like BlueAir's 3 in 1 unit.

The Foshan manufacturer's experience producing various home appliances for global brands provides the quality control infrastructure necessary for successfully producing such complex devices. Their strong engineering team brings valuable expertise in thermal management, air movement dynamics, and electronic control systems—all critical elements for a successful 3 in 1 device.

Innovation and Continuous Improvement

Despite the inherent challenges, BlueAir's commitment to innovation drives continuous improvement in their combination devices. Each product generation incorporates lessons learned from previous models and customer feedback, gradually narrowing the performance gap between combination and standalone devices.

This iterative improvement process requires close collaboration between BlueAir's design team and their manufacturing partners in Foshan. The manufacturer's willingness to adapt production processes and implement engineering refinements makes them an ideal partner for BlueAir's ambitious product development goals.

Future Trends: The Rise of Multifunctional Home Appliances

The evolution of home appliances is increasingly moving toward multifunctional designs10 that combine several capabilities in aesthetically pleasing packages.

The future of home appliances appears to be trending strongly toward combination devices that serve multiple purposes while maintaining an elegant, furniture-like aesthetic. Consumers increasingly prefer products that blend seamlessly with their home decor rather than standing out as obvious appliances. BlueAir's 3 in 1 device represents this shift toward multifunctional solutions that reduce clutter while enhancing living spaces.

Consumer Preferences Shifting

Today's consumers are increasingly seeking to minimize the number of separate appliances in their homes. This trend is driven by several factors: limited living space in urban environments, aesthetic considerations, and a desire for simplified purchasing and maintenance. Rather than owning separate air purifiers, fans, and heaters—each with its own footprint, power requirements, and maintenance needs—many consumers prefer an integrated solution that addresses multiple needs.

BlueAir recognized this shift in consumer preferences when developing their 3 in 1 device. By combining air purification, cooling, and heating functions in a single unit with thoughtful design elements, they've created a product that appeals to space-conscious consumers who don't want to compromise on air quality or comfort.

Design Philosophy Evolution

The design philosophy for home appliances has evolved significantly in recent years. Rather than the traditional white plastic aesthetic that dominated for decades, premium brands like BlueAir are embracing designs that function as furnishing elements. Their 3 in 1 device exemplifies this approach with its contemporary styling that complements modern interior design rather than contrasting with it.

This design-forward approach represents a fundamental shift in how consumers perceive and interact with home appliances. No longer purely utilitarian objects to be hidden away when possible, well-designed combination devices become intentional elements of home decor that consumers are proud to display.

Industry Innovation Directions

The air quality industry continues to push boundaries with combination products that integrate increasingly diverse functionalities. Beyond the 3 in 1 approach BlueAir has taken, we're seeing development of even more comprehensive solutions that incorporate:

- Air purification with advanced filtration technologies

- Cooling and heating capabilities

- Humidification and dehumidification functions

- Smart home integration and automated operation

- Air quality monitoring with real-time feedback

These ambitious combinations present even greater engineering challenges, but manufacturers are motivated by consumer demand for simplified, space-efficient solutions. The companies that successfully overcome these technical hurdles will likely capture significant market share in the evolving home appliance landscape.

Balancing Expectations with Reality

While the trend toward multifunctional appliances continues to accelerate, manufacturers and consumers alike must maintain realistic expectations about performance tradeoffs. Engineering constraints mean that combination devices will always face challenges in matching the performance of dedicated single-function appliances.

The most successful products in this category will be those that make intelligent compromises—preserving performance in the most critical functions while accepting reasonable limitations in secondary capabilities. Manufacturers must also clearly communicate these tradeoffs to consumers to set appropriate expectations and avoid disappointment.

Collaborative Innovation Opportunities

The complexity of developing effective combination devices creates opportunities for collaboration between brands with complementary expertise. At HisoAir, we recognize the value of such partnerships in creating next-generation air quality solutions that truly meet consumer needs.

Our manufacturing and product teams are actively developing premium combination devices that integrate air purification, cooling, heating, humidification, and dehumidification functions. By leveraging our extensive experience in air quality technology and collaborating with partners who bring complementary expertise, we aim to create innovative solutions that overcome the traditional limitations of multifunctional appliances.

Conclusion: Balancing Innovation and Performance

The journey of BlueAir's 3 in 1 air purifier, cooling fan, and heater offers valuable insights into the challenges and opportunities of multifunctional device manufacturing.

BlueAir's manufacturing choices for their 3 in 1 device reflect a careful balance between innovation, cost efficiency, and performance optimization. While their Foshan-based production leverages specialized expertise and cost advantages, the inherent challenges of combining multiple functions in one device create inevitable performance tradeoffs. Nevertheless, BlueAir's commitment to continuous improvement and thoughtful design represents an admirable direction for the industry.

As an industry insider with extensive experience in air purification manufacturing, I've observed the evolution of combination devices with great interest. At HisoAir, we understand the complex engineering challenges involved in creating products that effectively serve multiple functions while meeting consumers' high expectations for performance and design.

Appreciating the Innovation Journey

BlueAir deserves recognition for their innovative approach to air quality solutions. Creating a device that successfully combines air purification, cooling, and heating functions requires significant engineering expertise and manufacturing precision. Their partnership with a specialized manufacturer in Foshan demonstrates their commitment to overcoming these technical challenges through strategic collaboration.

The development process for such combination devices involves countless iterations, extensive testing, and continuous refinement. Each generation improves upon the last as manufacturers learn from customer feedback and technological advancements. This ongoing innovation cycle gradually narrows the performance gap between combination devices and their standalone counterparts.

Setting Realistic Expectations

For consumers considering a 3 in 1 device like BlueAir's, it's important to approach the purchase with realistic expectations. While these multifunctional appliances offer significant space-saving benefits and aesthetic advantages, the laws of physics and engineering constraints mean they cannot perfectly match the performance of three separate specialized devices.

This reality explains the polarized customer reviews often seen for combination products. Those who understand and accept the inherent tradeoffs frequently report high satisfaction, appreciating the convenience and integrated functionality. Conversely, customers expecting three perfect functions in one device may experience disappointment when comparing performance to standalone units.

The Future of Home Appliance Integration

Despite these challenges, the trend toward multifunctional home appliances continues to accelerate. Consumers increasingly prefer products that blend seamlessly with their home decor while serving multiple purposes. This shift creates opportunities for manufacturers who can successfully balance performance, aesthetics, and value.

At HisoAir, our manufacturing and product teams are actively developing next-generation combination devices that integrate air purification with cooling, heating, humidification, and dehumidification functions. By approaching these projects with realistic engineering expectations and a focus on thoughtful design compromises, we aim to create solutions that truly enhance consumers' living environments.

Collaborative Innovation Opportunities

The complexity of developing effective combination devices creates valuable opportunities for collaboration between brands with complementary expertise. We welcome partnerships with companies looking to innovate in the air quality space, combining our manufacturing capabilities with their market insights to create truly exceptional products.

By working together, we can overcome the traditional limitations of multifunctional appliances and develop solutions that better meet consumer needs while maintaining the highest standards of performance and reliability.

BlueAir's 3 in 1 air purifier, cooling fan, and heater represents an important step in the evolution of home appliances toward more integrated, space-efficient solutions. While engineering challenges create inevitable performance tradeoffs, the convenience and aesthetic benefits of well-designed combination devices continue to drive consumer interest and industry innovation.

As we look to the future, manufacturers who successfully balance performance optimization with thoughtful design and clear consumer communication will lead the next generation of multifunctional air quality solutions.

Notas de rodapé

-

3 in 1 air purifier devices combine air purification, cooling, and heating functions in a single unit. These multifunctional appliances have gained popularity for their space-saving benefits and convenience, though they face engineering challenges in balancing performance across all functions. ↩

-

Foshan has emerged as a global hub for home appliance production, with its sophisticated manufacturing ecosystem and specialized expertise. The city's strategic location in Guangdong Province provides access to component suppliers, skilled labor, and efficient logistics networks. ↩

-

Supply chain resilience refers to a supply chain's ability to withstand and recover from disruptions while maintaining business continuity. In the post-pandemic era, companies are increasingly prioritizing resilience through supplier diversification, strategic inventory management, and flexible manufacturing capabilities. ↩

-

Unilever acquisition of BlueAir in 2016 marked a significant milestone in the company's development, providing access to expanded resources and global distribution networks. This corporate backing enabled BlueAir to accelerate innovation and manufacturing optimization for their premium air purification products. ↩

-

Estratégia China+1 is a manufacturing approach where companies maintain their Chinese production base while establishing additional facilities in alternative countries to mitigate risks and enhance supply chain resilience. This diversification strategy helps address geopolitical uncertainties, trade tensions, and rising labor costs. ↩

-

Sustainable manufacturing encompasses production processes that minimize environmental impact through reduced energy consumption, waste reduction, and responsible material sourcing. Modern manufacturers are increasingly adopting sustainable practices to meet consumer expectations and regulatory requirements while enhancing brand reputation. ↩

-

Engineering challenges in multifunctional devices include balancing competing technical requirements, optimizing airflow dynamics, managing thermal considerations, and ensuring safety across all operating modes. These complexities require specialized expertise and innovative design solutions to deliver effective performance. ↩

-

Air purification technology has evolved significantly in recent years, with innovations in filtration media, sensor technology, and airflow design. Modern air purifiers employ various technologies including HEPA filtration, activated carbon adsorption, ionization, and UV sterilization to address different air quality concerns. ↩

-

Consumer expectations for combination devices often exceed what's technically feasible, creating a perception gap that manufacturers must address through thoughtful design and clear communication. Understanding and managing these expectations is crucial for product success in the competitive home appliance market. ↩

-

Multifunctional appliances represent a growing trend in home design, offering space efficiency and aesthetic benefits while reducing the number of separate devices needed. This evolution reflects changing consumer preferences toward minimalist living spaces and integrated home solutions. ↩