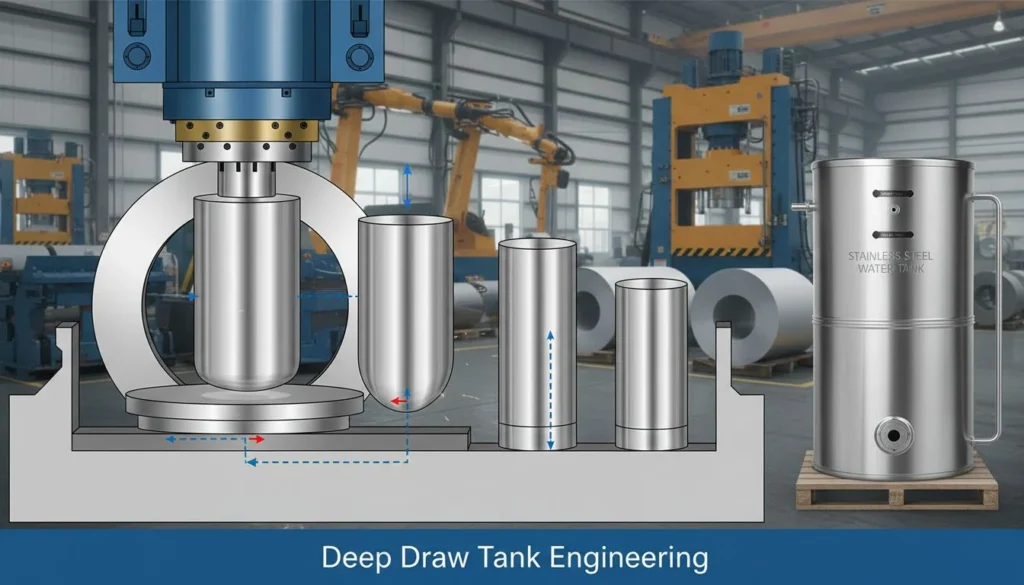

We have trusted plastic water tanks for decades, but the science is changing. As concerns about microplastics1 rise, the industry faces a massive shift. Here is why stainless steel is the only viable future.

Stainless steel is the future of water appliances because it is chemically inert2, durable, and hygienic. Unlike plastic, it does not leach microplastics or chemicals when heated, making it the superior choice for health-conscious consumers and the new standard for premium appliance design.

I have seen many material trends come and go in my years in the mold industry. Usually, changes are about cost or style. This shift is different. It is not just about aesthetics; it is about safety and physics. Let me explain why this change is happening now and why you need to be ready for it.

Heating plastic accelerates the leaching of chemicals like BPA and phthalates into water.Verdadeiro

Heat increases the kinetic energy of polymer chains, allowing additives to migrate out of the plastic matrix more easily.

Stainless steel is a porous material that traps bacteria easily.Falso

Stainless steel is non-porous, which is why it is the standard for medical and food grade applications.

Is the "Plastic Age" of Hydration Finally Over?

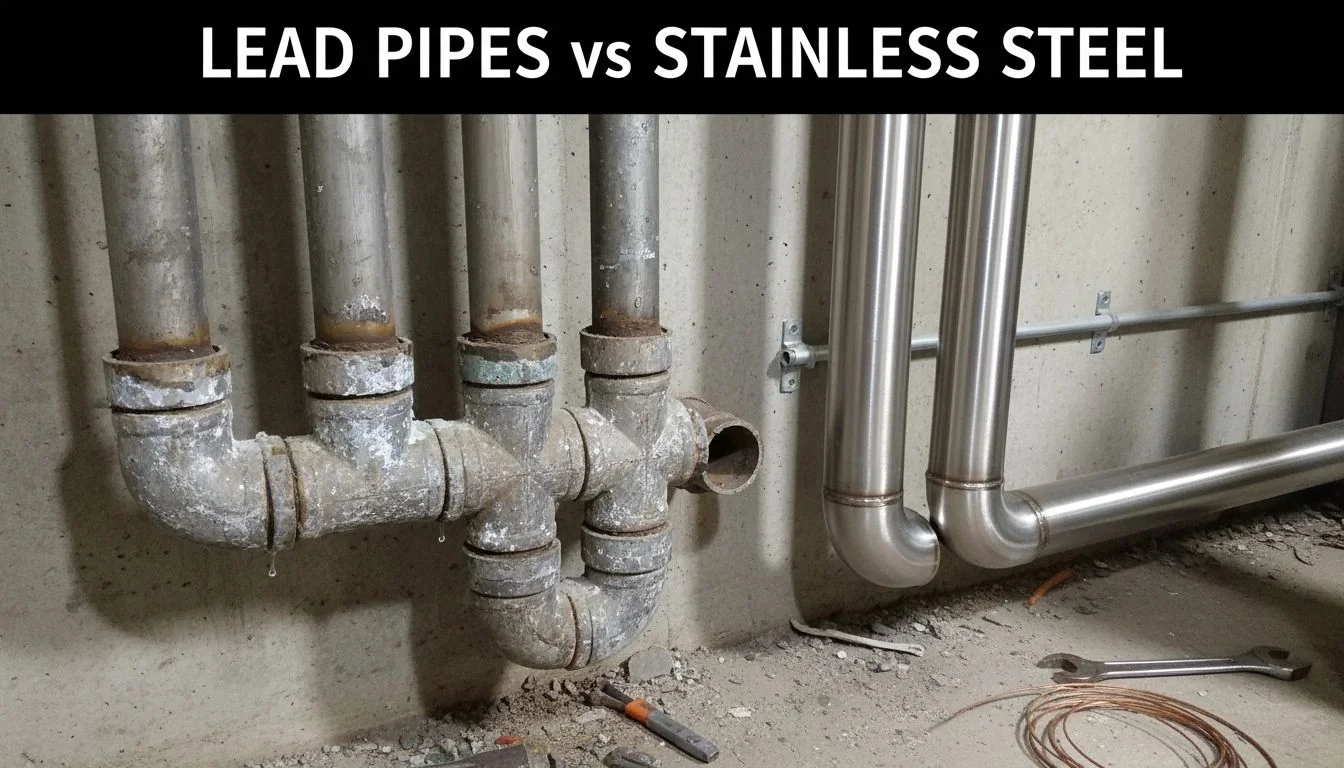

We used lead pipes until we knew better. Now, we face a similar reckoning with plastic.

The era of plastic water storage is ending due to health risks3. Just as we replaced lead pipes, we are now replacing plastic tanks with stainless steel to ensure water safety.

The "Lead Pipe" Analogy

In the mold and manufacturing business, we often look at history to predict the future. I like to use the "Lead Pipe" analogy. Decades ago, lead pipes were the standard. They were easy to work with and widely available. We thought they were fine. Then, the science caught up. We realized they were poisoning us. Today, no engineer would ever specify lead for water transport.

We are at a similar tipping point with plastic. For years, we thought plastic water tanks were fine. They are cheap to mold and lightweight. But the science on microplastics is changing everything. We are realizing that plastic is not as stable as we thought.

As a designer, you have a responsibility to look ahead. Position stainless steel as the "Modern Copper Pipe." It is the only safe infrastructure for the modern home. If you are designing a water appliance today with a plastic tank, you are designing a product that will be obsolete—and potentially viewed as dangerous—in five years. We must move away from materials that degrade and toward materials that endure.

| Era | Material | Perceived Safety | Actual Reality |

|---|---|---|---|

| Past | Lead | "It works fine." | Toxic neurotoxin. |

| Present | Plástico | "It is food grade." | Leaches microplastics. |

| Future | Stainless Steel | "It is expensive." | The only safe standard. |

Lead pipes were banned in new plumbing systems in the US in 1986.Verdadeiro

The Safe Drinking Water Act Amendments of 1986 banned the use of pipes with more than 8% lead.

Plastic water tanks last forever without degrading.Falso

Plastic degrades over time due to hydrolysis and oxidation, especially when in contact with water and heat.

What Is Driving the "Microplastic" Awakening?

Consumers are reading labels and checking materials. They know plastic breaks down over time.

The primary driver is the discovery of microplastics in human bodies. This scientific realization is pushing consumers to demand materials that do not degrade into their drinking water.

The Visual Audit

The biggest driver of this change is what I call the "visual audit4." It is one thing to read a scientific paper; it is another thing to see the evidence with your own eyes. In marketing, this is undeniable.

I encourage brands to do a simple "tear-down" test. Take a plastic hot water tank that has been used for two years. Cut it open. You will likely see the plastic has turned yellow. It might feel slimy. The surface has degraded. Now, take a stainless steel tank used for the same amount of time. It looks exactly the same as the day it was made. It is shiny and clean.

This visual evidence sells the product instantly. Consumers intuitively understand that "yellow and slimy" is bad. As a mold designer, you know that plastic surfaces degrade due to hydrolysis and oxidation. You cannot stop it. You can only change the material. When you design with stainless steel, you are giving the customer a product that passes the visual audit every single time.

Why Consumers Care Now

- Health Reports: News about microplastics in blood and organs.

- Taste: Plastic can impart a "chemical" taste to water.

- Visuals: Degraded plastic looks dirty and unsafe.

Microplastics have been found in human blood.Verdadeiro

A 2022 study published in Environment International detected microplastics in 80% of the people tested.

Visual inspection of plastic tanks is irrelevant to safety.Falso

Discoloration and surface changes indicate material degradation, which can lead to chemical leaching and bacterial growth.

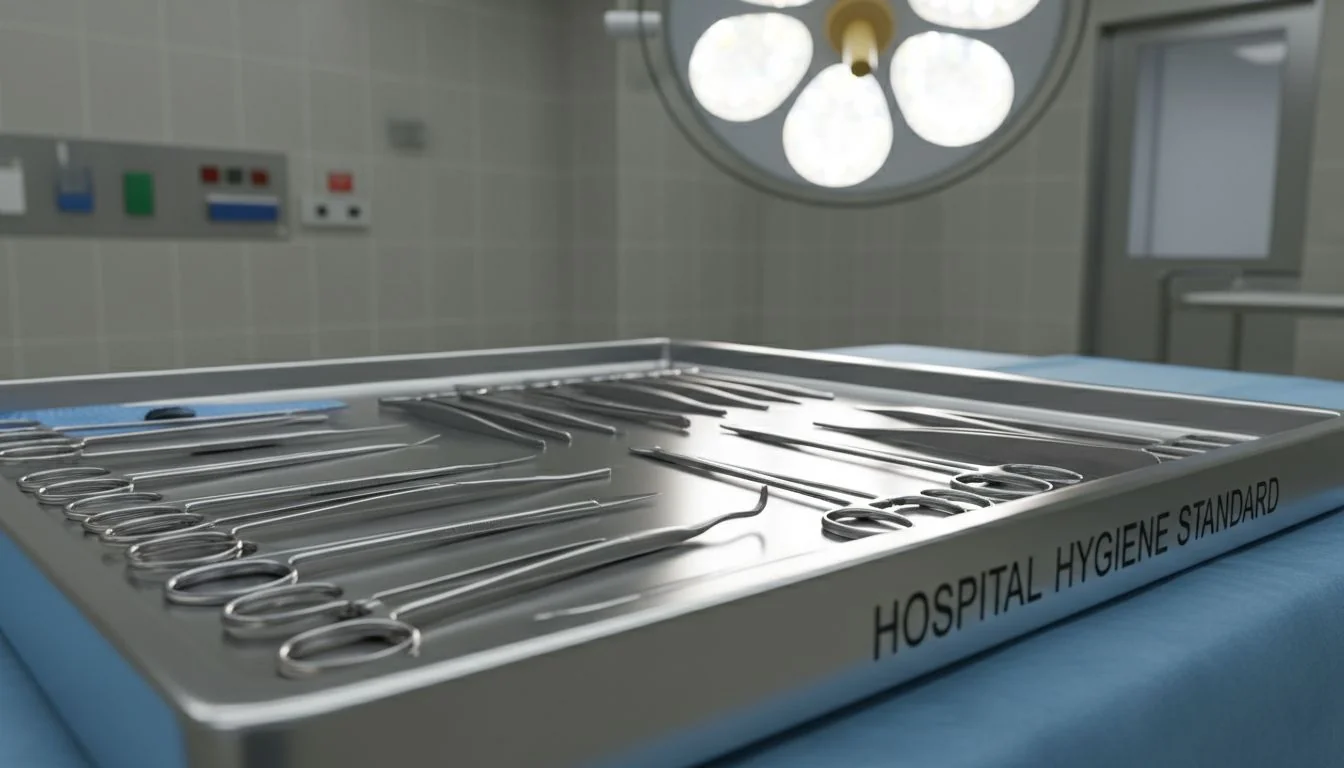

Why Do Hospitals Refuse to Use Plastic for Sterilization?

You never see a plastic surgical tray. There is a very specific reason for that choice.

Hospitals rely on stainless steel because it is non-porous and easy to sterilize. Bacteria cannot hide in steel surfaces, making it the gold standard for hygiene in critical environments.

The Hygiene Standard

If you want to know what is truly clean, look at a hospital operating room. You will not find plastic trays holding surgical instruments. You will see stainless steel. This is not an accident.

The reason is porosity. On a microscopic level, plastic is relatively porous. Over time, as it scratches and degrades, it creates tiny hiding spots. These are perfect breeding grounds for bacteria and biofilm5. You can scrub it, but you cannot reach the bacteria hiding inside the material structure itself.

Stainless steel is different. It is non-porous. It provides a hard, smooth surface where bacteria have nowhere to hide. This is the "Hygiene Standard." When you design a consumer water appliance, you should aim for this medical-grade standard. Why should the water we drink be held to a lower standard than the tools used in a hospital? By using stainless steel, you are borrowing the authority of the medical industry. You are telling the customer, "This is clean enough for surgery, so it is clean enough for your family."

| Caraterística | Plastic Tank | Stainless Steel Tank |

|---|---|---|

| Surface | Porous, scratches easily | Non-porous, hard |

| Biofilm | High risk of buildup | Low risk, easy to clean |

| Sterilization | Difficult, heat damages it | Easy, withstands high heat |

Stainless steel creates a biofilm faster than plastic.Falso

Stainless steel's smooth surface makes it harder for bacteria to adhere compared to the rougher, degrading surface of old plastic.

Biofilms are collections of microorganisms that stick to surfaces.Verdadeiro

Biofilms form when bacteria adhere to surfaces in aqueous environments and excrete a slimy, glue-like substance.

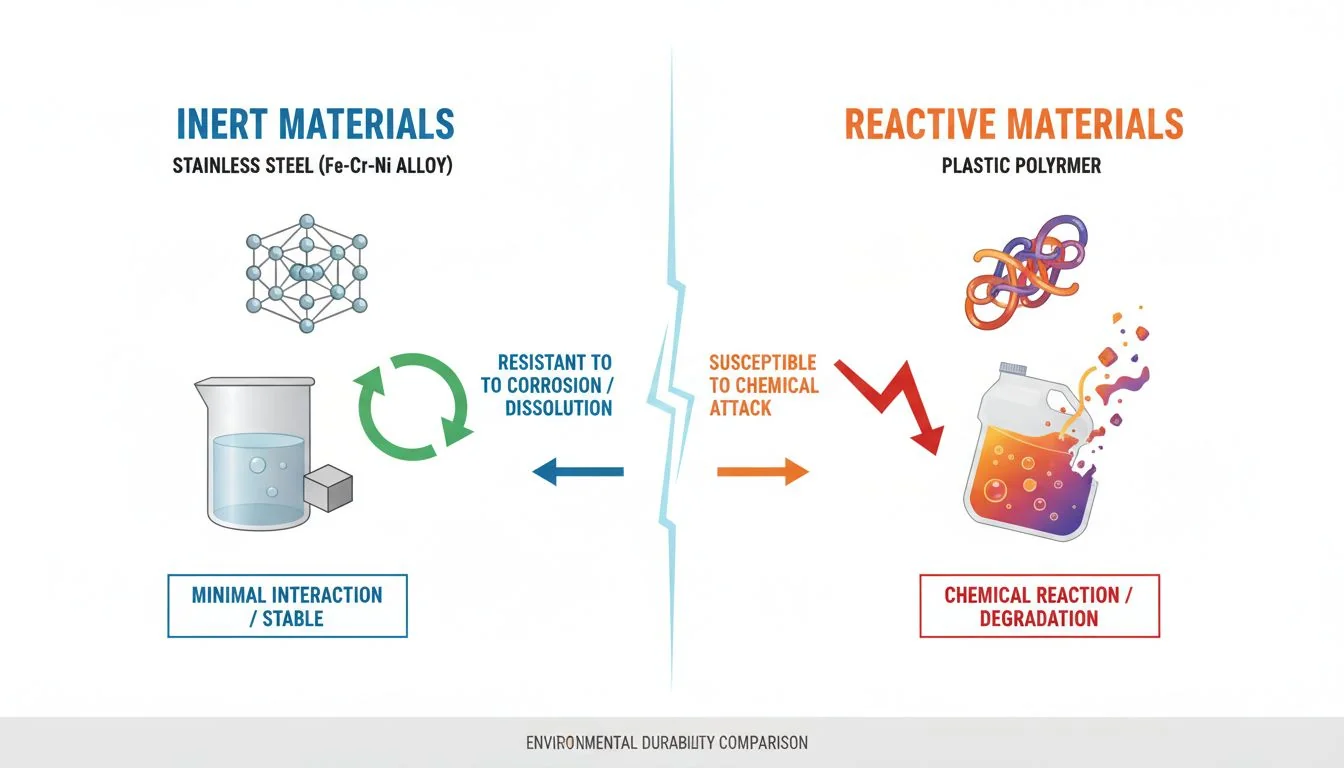

How Does the "Inert" Advantage End Chemical Leaching?

Safety is a feeling, but physics is a fact. We need to talk about chemical reactions.

Stainless steel is chemically inert, meaning it does not react with water or heat. This prevents the leaching of BPA and other harmful chemicals, offering an objective safety advantage over plastic.

"Inert" is the Kill-Shot

In my experience selling and designing products, words matter. "Safe" is a subjective word. What I think is safe, you might think is risky. But "Inert" is an objective term from physics. This is your strongest weapon.

If you can own the word "Inert," you win the argument against every plastic competitor. Inert means the material does not react. It does not change. It does not give anything to the water, and it does not take anything away.

This is especially critical for Instant Hot dispensers. We all know the equation: Heat + Plastic = Danger. Even consumers who do not know the science intuitively feel that heating plastic is bad. Heat accelerates chemical leaching6. It breaks down the polymer chains. If you sell a hot water dispenser, arguing for a stainless steel tank is incredibly easy. It is a safety non-negotiable. You simply say, "Our tank is inert. It does not react to heat." That settles the debate.

The Physics of Safety

- No Leaching: No migration of additives into the water.

- Heat Resistance: Steel maintains integrity at boiling temperatures.

- Taste Preservation: Water tastes like water, not the container.

Inert materials do not react chemically with their environment.Verdadeiro

Inertness describes a substance that is not chemically reactive, making it stable and safe for food contact.

BPA-free plastic is completely inert.Falso

Even BPA-free plastics can leach other chemicals like BPS or phthalates, especially under heat stress.

Can We Shift From Disposable Plastics to Heirloom Quality?

Cheap plastic appliances end up in landfills quickly. We need to design for longevity.

Stainless steel allows for "heirloom" product design. These appliances last for decades rather than years, reducing waste and offering better long-term value to the consumer and the environment.

The Sustainability Shift

I have helped many clients grow their businesses, and the ones who succeed are the ones who plan for the long term. We are moving away from the "disposable economy" where you buy a cheap plastic kettle and throw it away in two years. We are moving toward "heirloom" quality.

This is where partners like Hisoair come in. They position themselves as the "Future-Ready" OEM. They understand that the plastic era is ending. They act as the bridge to the stainless steel future.

For a CEO or a designer like you, Jacky, this is about strategic planning. If you are looking at a 5-year plan, you cannot bet on plastic. You have to bet on durability7. Stainless steel allows you to charge a premium because the value proposition is clear: "Buy this once, and it stays safe forever." It transforms a commodity product into an asset. It reduces the environmental burden of constant replacement. It is better business, and it is better for the planet.

| Aspeto | Disposable Economy (Plastic) | Heirloom Economy (Steel) |

|---|---|---|

| Tempo de vida | 2-3 Years | 10-20+ Years |

| End of Life | Landfill / Microplastics | 100% Recyclable |

| Consumer View | Cheap, Temporary | Investment, Permanent |

Stainless steel is 100% recyclable.Verdadeiro

Stainless steel can be recycled indefinitely without losing its quality or strength.

Planned obsolescence is a sustainable business model.Falso

Planned obsolescence creates excessive waste and environmental damage, which is increasingly rejected by modern consumers and regulators.

Conclusão

Plastic is the old way. Stainless steel is the safe, inert future. As designers, we must choose materials that protect health and stand the test of time. Be on the right side of history.

References

-

Microplastics pose significant health risks; exploring this topic reveals the urgency for safer materials. ↩

-

Understanding the term 'chemically inert' is crucial for recognizing the safety advantages of stainless steel over plastic. ↩

-

Learning about the health risks linked to plastic can motivate a shift towards safer alternatives like stainless steel. ↩

-

A visual audit can significantly impact consumer perception; understanding it can enhance marketing strategies. ↩

-

Learning about biofilm can highlight the importance of material choice in ensuring water safety. ↩

-

Understanding chemical leaching is essential for recognizing the safety advantages of stainless steel. ↩

-

Exploring the importance of durability can guide consumers towards making long-lasting, eco-friendly choices. ↩