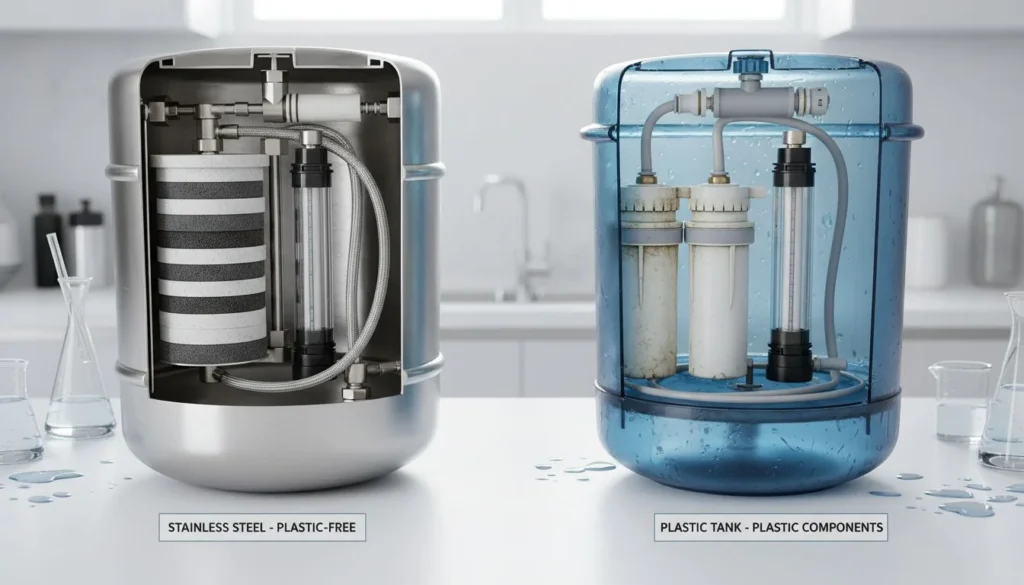

You spend huge resources marketing "pure water," yet you likely store that water in reactive plastic hardware. This creates a dangerous contradiction in your product design. We need to discuss the engineering reality behind this choice.

Plastic water filters introduce risks through Chemical Migration1 and Non-Intentionally Added Substances (NIAS), especially during water stagnation. Unlike inert materials such as 304 Stainless Steel, plastic polymers allow compounds to leach into the water. For wellness founders, selecting inert hardware is the only way to engineer true safety and prevent biofilm accumulation.

Many designers ignore the housing material to focus on the filter media, but this is a mistake. Let us look at the science of why plastic fails in this application.

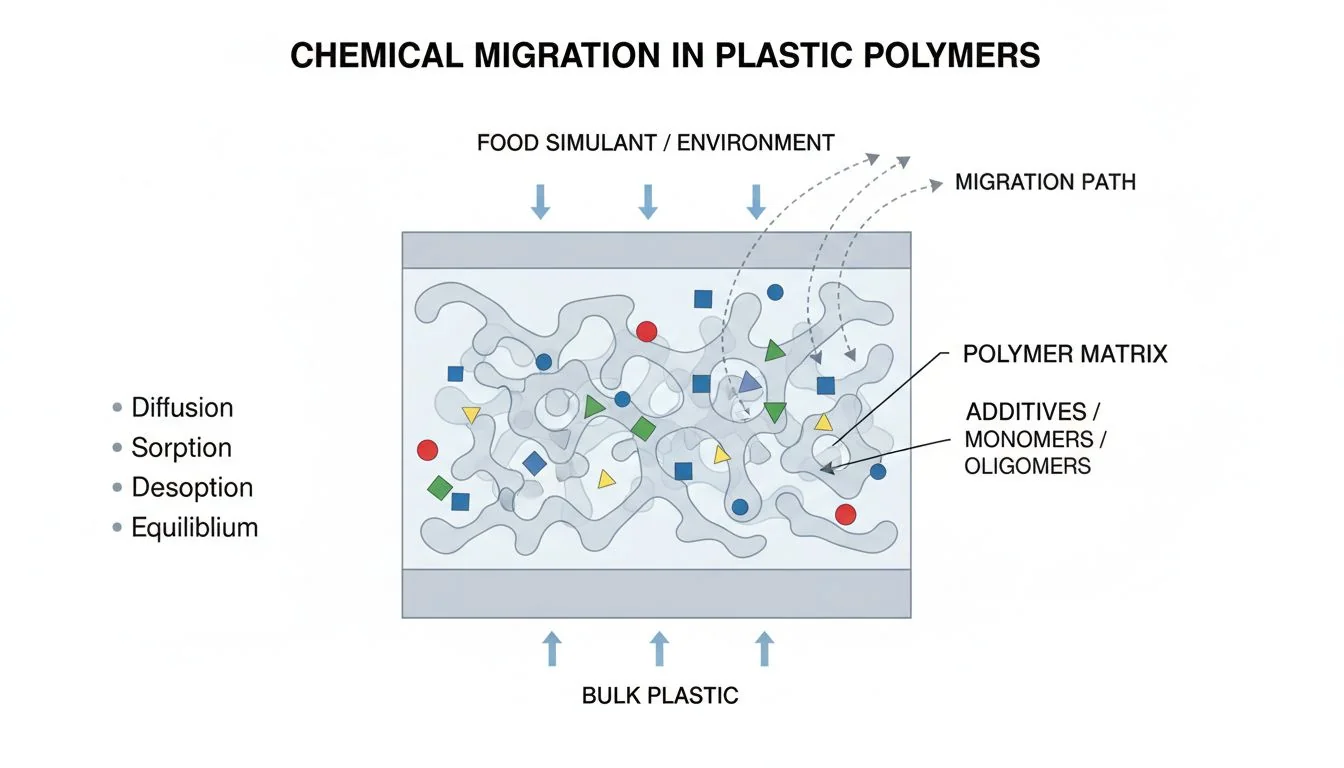

Plastic materials can leach Non-Intentionally Added Substances (NIAS) into water.Правда

NIAS are compounds that migrate from the plastic polymer matrix into the contact liquid, often due to degradation or impurities in the manufacturing process.

BPA-free plastic is completely safe for long-term water storage.Ложь

BPA-free plastics often use substitute bisphenols like BPS or BPF, which can exhibit similar endocrine-disrupting properties, a phenomenon known as regrettable substitution.

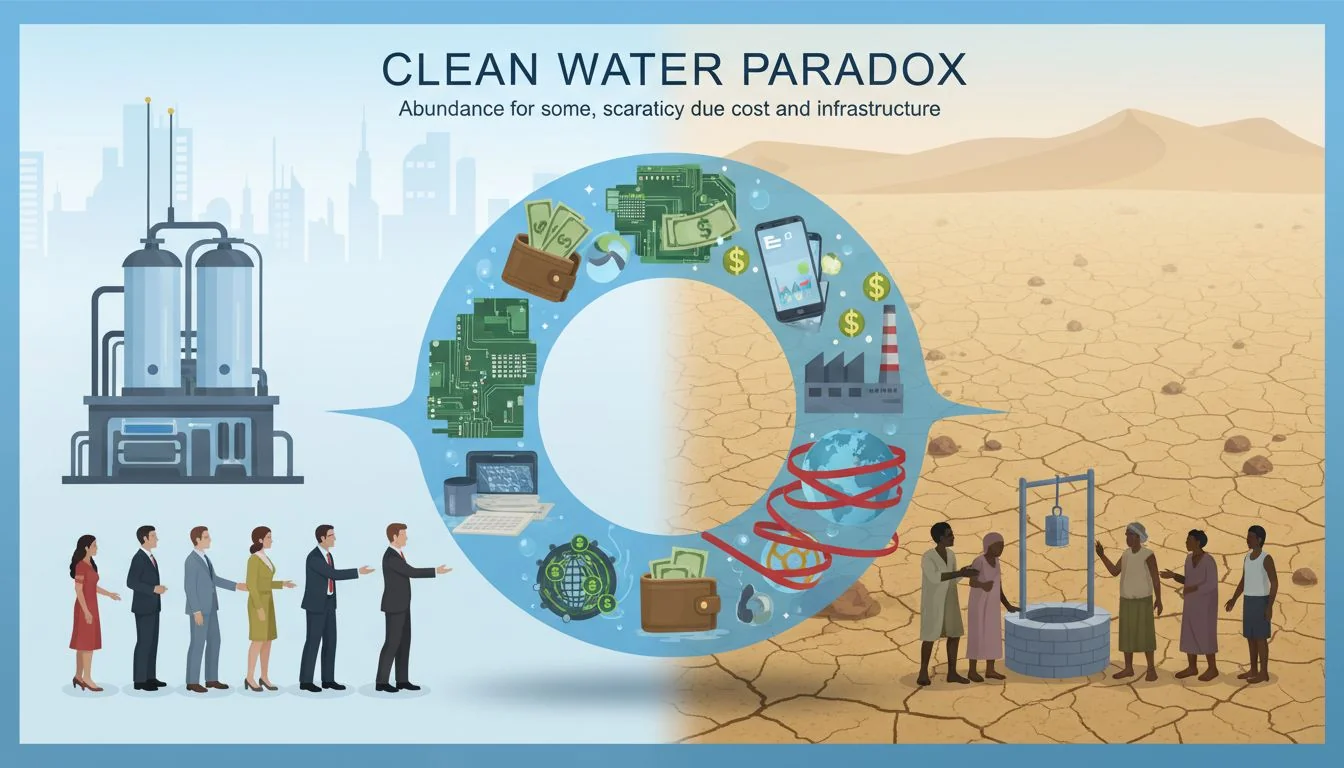

1. Introduction: The "Clean Water" Paradox in Wellness Hardware?

We see a strange trend in the wellness industry. Founders sell premium filtration systems, but they house them in cheap, injection-molded plastic. This undermines the entire promise of the product.

The paradox is simple: you cannot have truly clean water if the container itself is dirty. As a mold designer, I see the specs for these plastic parts. We focus on tolerances and shrinkage, but we often forget the chemical interaction. If you are a founder or a product designer like Jacky, you know that the hardware is just as important as the software. In this case, the "software" is the water, and the "hardware" is the filter housing. If the hardware is reactive, the software gets corrupted. We need to stop thinking about "food grade" and start thinking about "inert."

When we design molds for consumer electronics, we worry about aesthetics. But for water filtration, the stakes are higher. We are dealing with ingestion. I have seen many projects where the budget goes to the carbon block, and the housing gets the cheapest polypropylene available. This is a failure of engineering logic. You are putting a Ferrari engine inside a cardboard chassis. The market is getting smarter. Your customers are starting to ask questions about microplastics and leaching. If you want to build a brand that lasts, you have to solve this paradox at the design stage.

The filter housing material affects the final water quality.Правда

Reactive materials like plastic can introduce new contaminants into the water after it has passed through the filtration media.

Food-grade certification guarantees zero chemical leaching.Ложь

Food-grade standards allow for a certain permissible limit of migration; they do not guarantee that the material is completely inert or that migration is zero.

2. The Physics of Leaching: Understanding "Chemical Migration"?

Leaching is not a mystery; it is physics. We call this "Chemical Migration." It happens when molecules move from a high concentration (the plastic) to a low concentration (the water).

This is the biggest technical flaw in plastic filters. Plastic is not a solid wall. At a molecular level, it is a mesh of polymer chains. There are gaps. Smaller molecules can move through these gaps. We call these NIAS, or Non-Intentionally Added Substances. These are not ingredients you put in the recipe. They are side products of the reaction, or breakdown products from heat. When water sits in a filter, migration happens.

Think about the "Time" factor. This is critical. In a pipe, water flows fast. There is no time for migration. But a water filter is different. We use it, and then we go to sleep. The water sits there for 8 to 12 hours overnight. This is stagnation. During this time, the water acts as a solvent. It pulls chemicals out of the plastic wall. As a mold expert, I know that even the best Injection molding2 process cannot stop this. It is the nature of the material. If you use plastic, you are fighting physics. And physics always wins. You cannot design a mold to stop diffusion. You have to change the material.

Stagnation time increases the risk of chemical leaching.Правда

Longer contact time between the water and the plastic wall allows for greater diffusion of chemicals from the polymer matrix into the water.

Injection molding parameters can eliminate chemical migration.Ложь

While processing affects material quality, the inherent molecular structure of thermoplastics allows for migration regardless of molding parameters.

3. Beyond BPA: The "Regrettable Substitution" Problem?

You might think "BPA-Free" solves the problem. It does not. This is a marketing term, not a scientific solution.

Sophisticated founders know that BPA is yesterday's news. The industry simply replaced Bisphenol A with Bisphenol S (BPS) or Bisphenol F (BPF). We call this "Regrettable Substitution3." You replace one bad chemical with another chemical that we just don't have enough data on yet. Or worse, the data shows it is just as harmful. This is a game of whack-a-mole.

From a product design perspective, relying on "BPA-Free" claims is risky. Regulations change. Science advances. What is legal today might be banned tomorrow. If you build your mold tooling for a specific plastic resin, you are locked in. If a new study comes out attacking BPS, your product is obsolete. I advise my clients to look at the long term. Why take the risk? Why bet your company on a chemical formula that might change? When we design molds, we want them to run for years. We don't want to scrap a $50,000 tool because the resin is no longer trusted. The only way to avoid this "Regrettable Substitution" trap is to stop using bisphenols entirely. That means moving away from polycarbonate and similar plastics.

Regrettable substitution refers to replacing a toxic chemical with a similar, unproven one.Правда

This is a common issue in chemical regulation where banned substances like BPA are replaced with structural analogs like BPS, which may carry similar risks.

BPA-Free labels guarantee the product is free of all endocrine disruptors.Ложь

BPA-Free only means Bisphenol A is absent; the product may still contain other bisphenols or phthalates that act as endocrine disruptors.

4. Surface Science: Why Plastic is a "Biofilm Magnet"?

Let's talk about Surface Topography4. Plastic looks smooth to the eye, but under a microscope, it is a landscape of peaks and valleys.

This roughness is a disaster for water hygiene. These microscopic valleys are perfect hiding spots for bacteria. We call this a "Biofilm Magnet5." Once bacteria settle in these scratches, they form a colony. They build a slime layer that protects them from cleaning. Plastic is also softer than metal. Every time you clean it, you create more micro-scratches. You are actually making the surface topography worse over time.

In mold design, we try to polish the steel to a high SPI finish to get a smooth plastic part. But plastic is hydrophobic. It repels water but attracts organic matter. Oils and bacteria stick to it. Over time, a plastic water filter develops a smell or a slime. This is not the water's fault. It is the material's fault. As a designer, you have to consider the lifecycle of the product. A plastic part degrades. It gets scratched. It becomes a home for biology. You cannot engineer your way out of this with plastic. You can add antimicrobial coatings, but those leach too. The only solution is a material that is naturally hard and smooth.

Plastic surfaces are more prone to biofilm formation than passivated steel.Правда

The surface topography and hydrophobicity of plastics promote bacterial adhesion, while the hard, passive surface of stainless steel resists it.

Scrubbing plastic filters improves their hygiene.Ложь

Scrubbing creates micro-abrasions and scratches on the soft plastic surface, which increases surface area for bacteria to colonize.

5. The Technical Solution: The Passivity of 304 Stainless Steel?

The solution is not better plastic. The solution is 304 Stainless Steel6. The magic word here is "Inert."

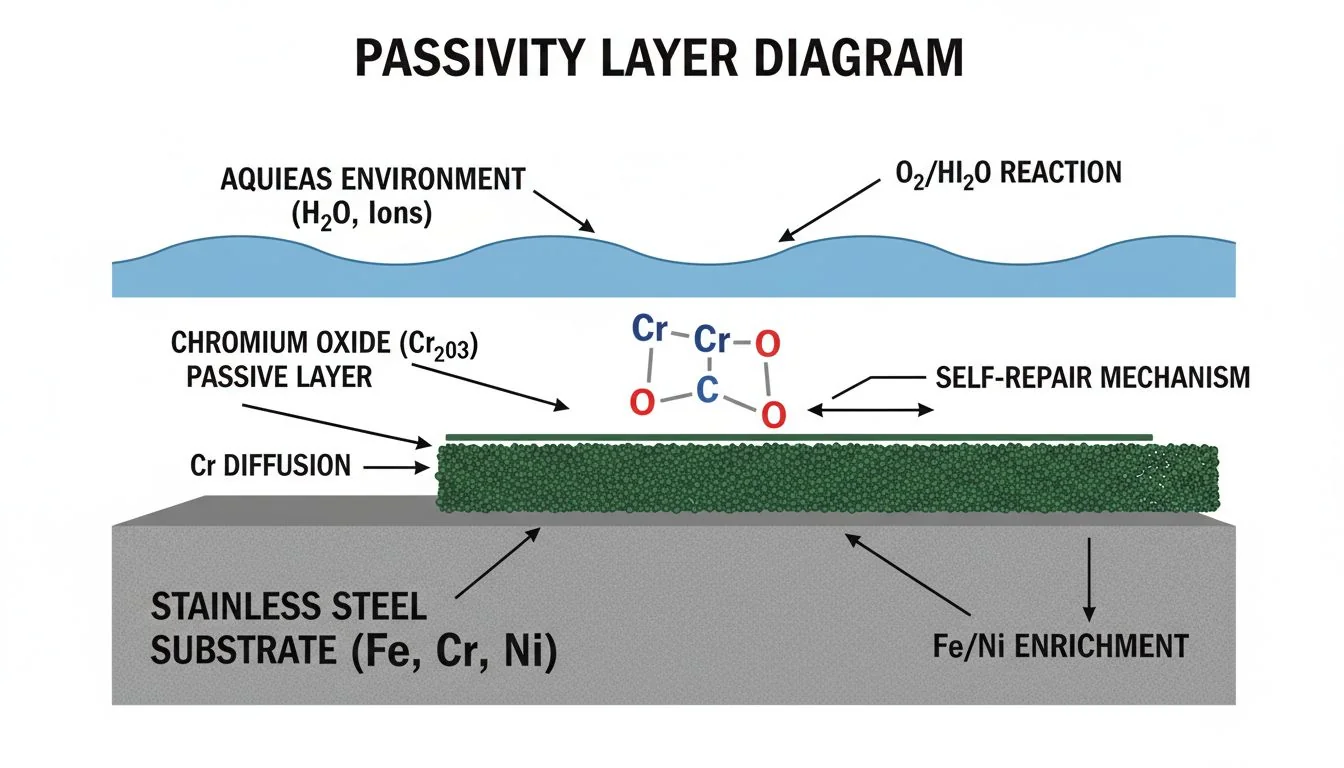

Inert means it does not react. It does not migrate. It does not change. Stainless steel has a unique feature called the "Passive layer7." This is a microscopic layer of chromium oxide that forms on the surface. It seals the iron inside. It acts as a perfect barrier between the metal and the water. This is why we use it in surgery and food processing.

When you choose steel, you are buying risk removal. You don't have to worry about NIAS. You don't have to worry about the next banned chemical. You don't have to worry about stagnation. Steel does not care if the water sits for 10 hours or 10 days. It remains inert. For a founder, this justifies a higher price point. You are selling peace of mind. From a manufacturing side, yes, the tooling is different. We use stamping or deep drawing instead of injection molding. But the result is a product that lasts a lifetime. It is an upgrade in every technical sense. It signals to your customer that you understand the science of safety.

304 Stainless Steel relies on a chromium oxide layer for protection.Правда

This passive layer forms naturally in the presence of oxygen and prevents the underlying metal from reacting with the environment.

Stainless steel is reactive with water during stagnation.Ложь

The passive layer makes stainless steel chemically inert in potable water applications, preventing leaching even during long periods of stagnation.

Заключение

If you want to lead the wellness market, you must engineer trust into your hardware. Plastic carries inherent risks of migration and biofilm that no amount of marketing can hide. By switching to inert 304 Stainless Steel, you remove these risks entirely. You move from selling a "safe enough" product to selling a technically superior solution.

References

-

Understanding Chemical Migration is crucial for ensuring safe water filtration and avoiding harmful contaminants. ↩

-

Learn about the limitations of injection molding in preventing chemical migration in plastic filters. ↩

-

Learn about Regrettable Substitution to avoid common pitfalls in material selection for health products. ↩

-

Explore the impact of surface texture on bacterial adhesion and water quality in filtration systems. ↩

-

Discover how plastic surfaces promote bacterial growth and the implications for water hygiene. ↩

-

Understanding the advantages of 304 Stainless Steel can help you choose safer, more durable filtration options. ↩

-

Discover the role of the passive layer in enhancing the safety and longevity of stainless steel water filters. ↩