Worried about tariffs and supply chain risks1 in China? You're looking at Vietnam for humidifier manufacturing. But this move might introduce a bigger, hidden risk to your brand's future.

While Vietnam has several capable assemblers like Sunhouse Group and Kangaroo Group, finding a true R&D partner2 for innovative humidifiers is the real challenge. The top players are often large, local brands or FDI-funded assemblers focused on high-volume, low-complexity production, not groundbreaking design and engineering.

You're probably thinking, "Just give me the list!" I get it. I've spent my career in mold making and manufacturing, and I know the pressure to find the right factory. But before we talk about who, we need to talk about why. The "China Plus One" strategy is on everyone's mind, but jumping to Vietnam without understanding the full picture can be a costly mistake. Let's break down what's really happening on the ground.

Vietnam's manufacturing sector grew by 6.5% in 2023.Правда

According to the General Statistics Office of Vietnam, this growth highlights the country's increasing role in global supply chains.

Vietnam can develop and launch a new, innovative humidifier design faster than China.Ложь

China's mature ecosystem of component suppliers, R&D talent, and rapid prototyping services gives it a significant speed-to-market advantage for complex, innovative products.

The "China Plus One" Strategy – Why Are Brands Looking at Vietnam?

Geopolitical tensions and tariff threats are making you nervous about relying solely on China. You need a backup plan to secure your supply chain. But is Vietnam the simple answer?

Brands are adopting the "China Plus One" strategy to diversify their manufacturing base and mitigate risks associated with trade wars and lockdowns. Vietnam is a popular "Plus One" due to its proximity to China, competitive labor costs3, and favorable trade agreements, making it attractive for assembly.

I've seen this shift firsthand. Clients come to me, anxious to move production out of China. The logic seems simple: find a factory in Vietnam, copy the existing process, and enjoy lower tariffs. But it's not a copy-paste job. The "China Plus One" strategy is driven by a desire for resilience. However, true resilience isn't just about location; it's about your product's strength in the market.

Key Drivers for Moving to Vietnam

- tariff mitigation4: Avoiding US tariffs on Chinese-made goods.

- Labor Costs: Lower average wages compared to China's coastal manufacturing hubs.

- Geographic Proximity: Close to China's southern supply chain for components.

This strategy makes sense for established, high-volume products where the design is locked and the primary goal is cost reduction. But for a new, innovative product? That's a different story.

The US has Section 301 tariffs on a wide range of goods imported from China.Правда

These tariffs have been a major catalyst for companies to explore manufacturing alternatives to China.

Vietnam has free trade agreements with both the EU (EVFTA) and the UK (UKVFTA).Правда

These agreements make Vietnamese exports more competitive in European markets compared to exports from countries without such agreements.

What Are the Real Pros and Cons of Manufacturing in Vietnam?

You've heard Vietnam has cheap labor and great trade deals. It sounds like the perfect solution. But you're worried about the hidden downsides that could derail your project timeline and budget.

Vietnam's pros include competitive labor costs, a young workforce, and government incentives for foreign investment. The cons, however, are significant: a less-developed component supply chain, a shortage of skilled engineers and R&D talent, and potential infrastructure bottlenecks5 outside major industrial zones.

Let's be honest. I've worked with factories all over Asia. Every location has its strengths and weaknesses. The key is aligning the location's strengths with your product's needs. For a product designer like you, Jacky, understanding this is critical. You're not just shipping a box; you're creating something new. Here's a fair breakdown I've put together from my experience.

| Аспект | Pros (The Upside) | Cons (The Hidden Risks) |

|---|---|---|

| Стоимость | Lower direct labor costs. | Higher costs for sourcing components, tooling adjustments, and management travel. |

| Цепочка поставок | Proximity to China for some parts. | Heavily reliant on imported raw materials and high-tech components. |

| Talent | Eager, young assembly workforce. | Shortage of experienced product engineers, R&D managers, and mold designers. |

| Инфраструктура | Rapidly improving in major hubs. | Can be inconsistent; logistics and power can be a challenge in newer zones. |

This table shows that the "cheaper" labor can be misleading. The total cost of bringing an innovative product to market is often higher.

Vietnam's infrastructure and logistics performance ranks 43rd globally.Правда

According to the World Bank's 2023 Logistics Performance Index, Vietnam has made progress but still lags behind manufacturing leaders like China (ranked 19th).

All high-precision electronic components for humidifiers can be sourced locally in Vietnam.Ложь

Vietnam's electronics supply chain is still developing. Many critical components like specialized PCBs, sensors, and high-performance transducers must be imported, often from China.

Who Are the "Big Assemblers" & FDI Partners in Vietnam?

You need a factory that can handle your volume. You see big names like Samsung and LG manufacturing in Vietnam. Surely they have great local partners you can use for your humidifier?

The key players are typically large, local Vietnamese brands (like Sunhouse Group) or Foreign Direct Investment (FDI) partners—often Korean or Taiwanese companies—that serve giants like Samsung. These are "Big Assemblers," experts in mass production of existing designs, not nimble R&D for new market entries.

When you look for humidifier manufacturers in Vietnam, you'll find two main types. First, the big local champions. Think of companies like Sunhouse Group or Kangaroo Group. They are huge in the domestic market, but their focus is on cost-effective products for local consumers. Their R&D is geared towards localization, not global innovation. Second, you have the FDI factories. These are the suppliers for brands like Samsung, LG, and Foxconn. They are incredibly efficient at assembly. But here's the catch: they are set up to serve billion-dollar clients with massive, predictable orders. They don't have the structure or incentive to work with a smaller brand on a new, unproven product. They execute; they don't co-create.

Local Champions

- Focus: Domestic market, cost-driven.

- R&D: Minimal, focused on incremental changes.

FDI Assemblers

- Focus: High-volume contracts for global giants.

- R&D: Follows client specifications precisely; not an independent innovation center.

Samsung is Vietnam's largest foreign investor, with its products accounting for about 20% of the country's total export revenue.Правда

This demonstrates the scale of FDI operations in Vietnam, which are primarily focused on large-scale assembly for established global brands.

Small to medium-sized brands can easily partner with the same factories that supply Samsung in Vietnam.Ложь

These large FDI factories have extremely high MOQs (Minimum Order Quantities) and are structured to serve a few massive clients, making them inaccessible and inflexible for smaller brands launching new products.

What Kind of Humidifier Won't You Easily Find in Vietnam?

You have a brilliant idea for a new humidifier—unique materials, smart features, a standout design. You assume you can get it made in Vietnam. But the factories you talk to keep pushing you towards their standard plastic models.

You will struggle to find a Vietnamese partner for a truly innovative humidifier. This includes products using non-standard materials like stainless steel, those with complex IoT or app integration, or designs requiring advanced tooling and precision molding. The ecosystem for rapid R&D simply isn't mature yet.

This is the most important point I can make. As a product designer, your value is in innovation. But your innovation is only as good as your manufacturing partner's ability to execute it. In my years of mold making, I've seen brilliant designs die on the factory floor. In Vietnam, the risk is higher for anything that breaks the mold.

What's Hard to Develop in Vietnam:

- Material Innovation: Think beyond standard ABS plastic. Want to use stainless steel for hygiene and durability? Or a custom bio-plastic? The raw material sourcing and tooling expertise is concentrated elsewhere.

- Complex Electronics: Basic humidifiers are simple. But what about one with UVC sterilization, precise humidity sensors, and seamless app control? The cluster of specialized electronics engineers and suppliers isn't there.

- Advanced Tooling: A unique design requires complex, multi-cavity molds with tight tolerances. This level of tool and die making is a craft that takes decades to develop. China's Pearl River Delta is the world capital for this; Vietnam is still learning.

Vietnam is a leading global exporter of stainless steel.Ложь

While Vietnam does produce stainless steel, China is the world's largest producer and has a much more sophisticated supply chain for specialized grades and finishing required for high-end consumer appliances.

The Pearl River Delta region in China has one of the world's most concentrated and mature supply chain ecosystems for electronics and precision manufacturing.Правда

This ecosystem allows for rapid prototyping, sourcing of virtually any component, and access to a deep pool of engineering talent, which is crucial for innovative product development.

Is There a Smarter Strategy Than Just Moving Assembly to Vietnam?

You're caught between China's risks and Vietnam's limitations. It feels like a no-win situation. How can you get the best of both worlds without doubling your management overhead and costs?

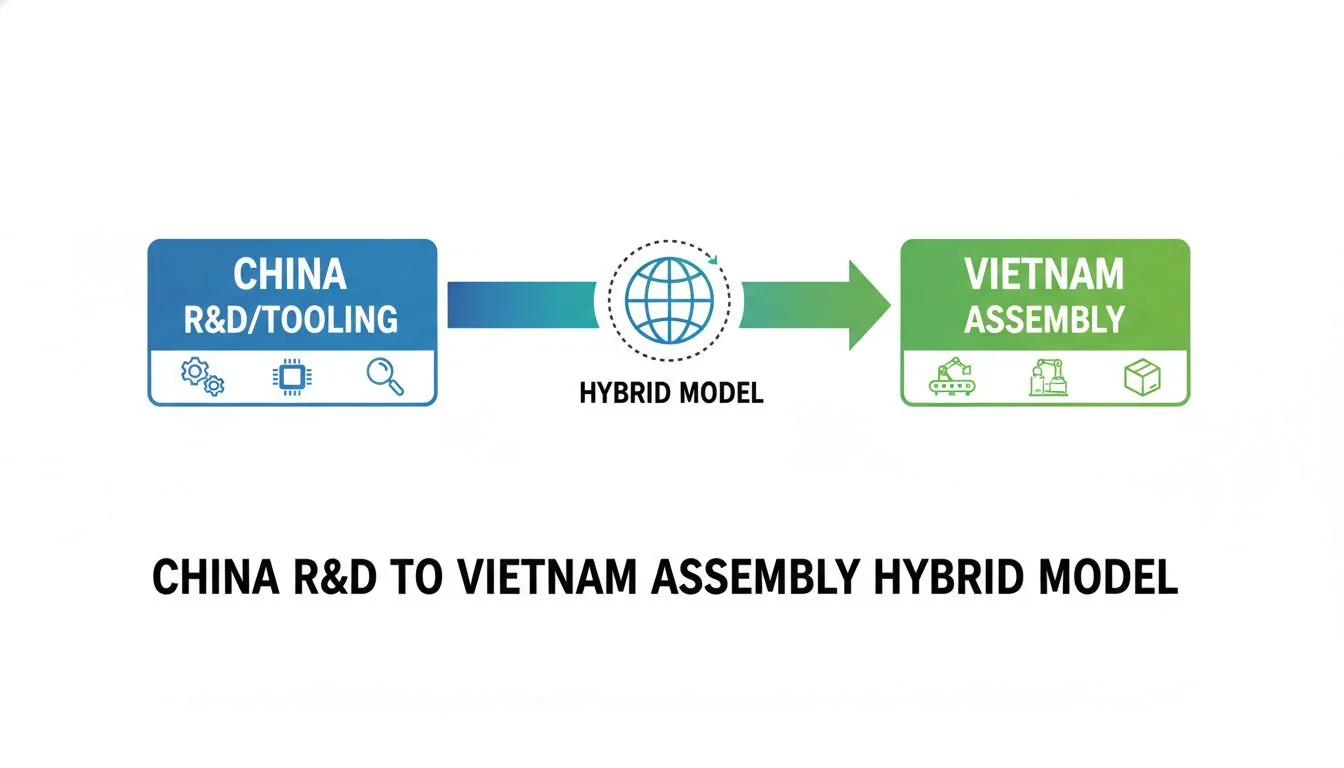

Yes. The smartest strategy is a hybrid model: "R&D Hub (China) + Assembly (Vietnam)". You leverage China's unparalleled R&D ecosystem for design, tooling, and prototyping. Once the product is perfected and stable, you can move high-volume assembly to a Vietnamese facility for tariff and cost benefits.

I've helped many clients implement this model successfully. It's about playing to each region's strengths. Think of it like a movie production. You do pre-production (scripting, casting, design) in a creative hub like Hollywood. Then you might go on location somewhere else for the actual filming. Manufacturing is the same.

The Hybrid "Hub & Spoke" Model

- R&D and Tooling in China: Work with a partner in China to develop the product concept, complete the engineering design (DFM), create the molds, and run the first pilot production. This is where you solve all the hard problems and de-risk the innovation.

- Assembly in Vietnam: Once the design is proven and the manufacturing process is stable, the molds and a "factory-in-a-box" kit of key components can be transferred to an assembly facility in Vietnam.

This approach gives you speed and innovation from China, combined with the cost and tariff advantages of Vietnam. You're not just looking for a factory; you're building a resilient, two-pronged supply chain.

Moving molds and production lines between countries is impossible.Ложь

Transferring tooling and assembly lines is a common practice in manufacturing. It requires careful planning and a knowledgeable partner but is a standard part of a global manufacturing strategy.

This hybrid model allows a brand to label its product 'Made in Vietnam' for tariff purposes.Правда

As long as the product undergoes 'substantial transformation' (i.e., assembly) in Vietnam, it can typically qualify for Vietnamese origin, though rules of origin should always be verified.

Why Is Your Partner More Important Than Your Location?

You're trying to manage suppliers in China and Vietnam, dealing with language barriers and quality control issues. This complex new strategy feels overwhelming. There has to be a simpler way to execute this.

Because the right partner can manage this hybrid strategy for you. A partner with a strong R&D base in China and their own assembly operations or trusted partners in Vietnam gives you a single point of contact. They handle the complexity, so you can focus on your brand.

This is where theory meets reality. You don't need to become an expert in Asian logistics. You need a partner who already is. This is why I'm so impressed with what companies like Hisoair are doing. They embody this smart, hybrid model. They are an R&D-first company. Their proof is in their products, like their revolutionary stainless steel humidifier. This isn't a "me-too" plastic box. It's a product born from deep engineering and material science expertise—the kind of expertise based in China's innovation ecosystem. They prove that the real differentiator isn't location, it's innovation. A partner like this can:

- De-risk your R&D: Perfect the product in their China R&D center.

- Manage the Transfer: Handle the logistics of moving tooling and processes to Vietnam.

- Guarantee Quality: Ensure the same quality standards across both locations.

This is the future of smart sourcing. Don't just look for a factory in Vietnam. Look for a partner who offers a complete, resilient solution.

Any factory can innovate if you give them a good design.Ложь

Innovation is a collaborative process. A true R&D partner contributes to the design, suggests materials, optimizes for manufacturing (DFM), and solves problems. An assembly factory just executes instructions.

Hisoair's stainless steel humidifier is an example of a product that would be difficult to develop from scratch in Vietnam.Правда

Developing this product required advanced knowledge of metal stamping and forming, welding, and finishing, plus the associated supply chain for food-grade stainless steel—expertise that is far more mature in China.

Заключение

Your search for a Vietnam manufacturer is valid, but reframe your goal. Instead of chasing cheap labor, seek a partner who de-risks innovation and offers a smarter, hybrid supply chain solution.

References

-

Identifying these risks can help you mitigate potential disruptions in your production process. ↩

-

A strong R&D partner can enhance innovation and product quality, crucial for competitive advantage. ↩

-

Understanding labor costs can impact your manufacturing budget and overall strategy. ↩

-

Learn strategies to avoid tariffs and reduce costs in your supply chain. ↩

-

Recognizing infrastructure issues can help you plan better for logistics and production. ↩