You are likely tired of designing bulky appliances that clutter up a room. Clients today want sleek integration, not plastic eyesores. The air purifier market is finally shifting from function-only to design-forward innovation.

The top innovations for 2025 focus on "Zero-Footprint1" wall mounts, customizable "Art-First" aesthetics, and AI-driven bio-sensors. These technologies prioritize space-saving engineering and safety while maintaining high CADR (Clean Air Delivery Rate) through advanced "Slim-Tech" airflow management and active defense layers like UV-C.

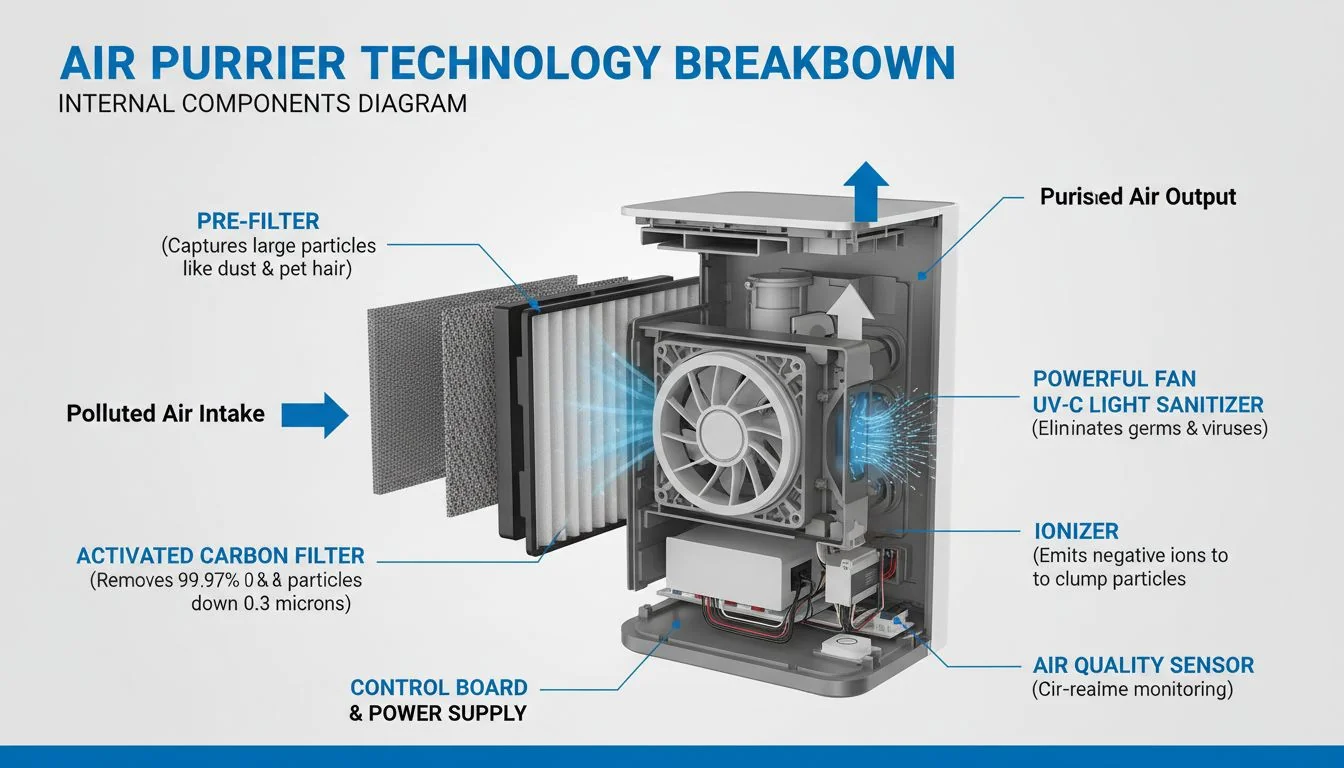

Many designers still think air purifiers are just fans inside a box. That mindset is outdated. Let us look at the engineering shifts redefining the industry.

Wall-mounted purifiers save money by freeing up floor space.Правда

In high-cost real estate markets, floor space is expensive; wall units utilize vertical space.

Floor units are safer for children than wall-mounted units.Ложь

Floor units can be tipped over; wall-mounted units are fixed and keep cords away from children.

Why Is the "Clunky Box" Era Finally Ending?

We used to accept big, noisy boxes in the corner of the room. That design philosophy is dead. Modern living spaces demand appliances that blend in rather than stand out.

The shift away from "clunky boxes" is driven by the high cost of real estate and the need for multi-functional devices. Consumers now demand "Slim-Profile Engineering2" where high performance meets minimal visual impact, forcing mold designers to rethink internal component layout.

I have seen many trends come and go in my years in the mold industry. However, this shift is different because it is driven by economics. We need to understand that "Real Estate" is the true selling point here. We are not just selling clean air anymore. We are selling "Square Footage."

For customers living in apartments or working in crowded offices, floor space is expensive. A traditional purifier takes up valuable room. A wall-mounted unit "pays for itself" by freeing up that floor space. This is a massive B2B selling point for schools, hotels, and offices.

As designers, we face a challenge here. We must move away from the easy, boxy molds of the past. We need to embrace "Slim-Profile Engineering." Making a thin purifier that still has high power (CADR) is a difficult engineering challenge. It involves complex airflow management and reducing motor size without losing power. This is where we separate the experts from the amateurs. We must position our designs to do what bulky competitors cannot.

Key Drivers for Design Change

| Driver | Impact on Design | Benefit to User |

|---|---|---|

| Real Estate Costs | Shift to vertical/wall-mounted forms | Frees up valuable floor space |

| Aesthetic Demand | Integration of art and decor elements | Device blends into the home |

| Safety concerns3 | Secure mounting and hidden cords | Protects children and pets |

Slim-profile engineering reduces the CADR of a unit.Ложь

Advanced engineering allows for high power and airflow even in thinner profiles.

Real estate cost is a driver for appliance design.Правда

Maximizing usable floor space is a priority in modern urban housing and offices.

How Does Wall-Mounted Design Create a "Zero-Footprint" Revolution?

Floor space is premium real estate in modern apartments. Traditional units waste this valuable area. Wall-mounted designs solve this by utilizing vertical space instead.

Wall-mounted purifiers offer a "Zero-Footprint" solution, freeing up floor space in tight offices and homes. Beyond space, they offer a "Safety" advantage by eliminating tipping hazards for toddlers and pets, making them ideal for the family market while optimizing airflow circulation from a higher vantage point.

When I look at a design, I always look for the hidden advantages. With wall-mounted units, "Safety" is that hidden feature. I have seen floor units tipped over by toddlers or pets. It is a liability. Wall-mounted units cannot be tipped over. They keep dangerous cords away from crawling babies. This makes them the perfect product for the "Family/Parenting" market, which floor units cannot claim.

From an engineering perspective, we also have the "Air Flow" Advantage. Scientifically, wall-mounted units can be positioned to optimize airflow circulation. We can design the mold to draw air in from the bottom or front and push it out the top or sides. This creates a better "air curtain" effect than a floor unit tucked in a corner.

However, this requires precise mold design. The intake vents must be large enough to allow flow but small enough to be safe. The mounting bracket must be integrated into the back chassis mold to ensure strength. We are not just molding a shell; we are molding a structural component that hangs on a wall.

Engineering the Wall Mount

| Характеристика | Design Consideration | Manufacturing Challenge |

|---|---|---|

| Intake Vents | Bottom/Front positioning | Ensuring structural integrity of the grille |

| Mounting Plate | Integrated vs. Separate | Load-bearing capacity of the plastic |

| Cord Management | Hidden channels | Complex side-actions in the mold |

Wall-mounted units have poor air circulation.Ложь

They can optimize airflow by creating an air curtain effect from a higher position.

Wall-mounted units are safer for toddlers.Правда

They eliminate tipping hazards and keep electrical cords out of reach.

Can Air Purifiers Really Become "Art-First" Decor?

Appliances usually ruin the interior design of a room. Clients hate hiding ugly plastic shells. New trends turn the device into a visual asset.

Inspired by the "Samsung Frame" strategy, "Art-First4" aesthetics allow purifiers to feature interchangeable magnetic panels. This transforms a functional appliance into a piece of decor, creating a recurring revenue stream for brands through accessory sales while allowing users to match the device to their interior style.

I admire what Samsung did with "The Frame" TV. They turned technology into art. Now, we are seeing this in air purifiers. Brands like Hisoair are turning the purifier into "The Art." This is a brilliant strategy for D2C lifestyle brands.

The concept is simple: interchangeable magnetic art panels. But for us as mold designers, it adds complexity. The front panel must be perfectly flat. Any warpage in the plastic injection process will ruin the effect. We need to use materials with low shrinkage rates and optimize our cooling channels in the mold to prevent warping.

This strategy also creates a business opportunity. Brands can sell these panels as accessories. It creates a recurring revenue stream. Instead of selling a customer one machine every five years, you sell them a new art panel every season. We need to design the attachment mechanism—usually magnets or clips—to be durable yet easy to use. The tolerance here must be tight. If the panel rattles, the customer will think the product is cheap.

The "Art-First" Design Strategy

| Компонент | Функция | Mold Requirement |

|---|---|---|

| Front Panel | Visual display/Art | Zero warpage, high surface finish |

| Attachment | Magnetic/Clip system | Tight tolerances for secure fit |

| Air Gap | Intake around panel | Consistent spacing for airflow |

Interchangeable panels create recurring revenue.Правда

Brands can sell new designs as accessories to existing customers.

Warpage is acceptable in art panels.Ложь

Panels must be perfectly flat to look like high-quality art.

How Do AI-Driven "Bio-Response" Sensors Change the Game?

Old sensors just reacted to dust density. They were passive and often inaccurate. New AI sensors actively predict and respond to environmental changes.

AI-driven "Bio-Response" sensors move beyond simple particle detection. They analyze patterns in air quality, occupancy, and time of day to adjust fan speeds proactively. This ensures optimal air quality without manual intervention, reducing energy consumption and noise levels when the room is empty.

In the past, we just made a hole in the mold for a simple infrared sensor. Today, the electronics are much more complex. We are integrating AI-driven "Bio-Response" sensors. These are not just looking for dust. They are looking for patterns.

For the mold designer, this means we need to accommodate more sophisticated PCBs (Printed Circuit Boards) and sensor arrays. We need to design internal bosses and mounting points that protect these delicate components from vibration. The motor causes vibration. If the sensor vibrates, the data is wrong.

We also need to consider thermal management. These smart chips generate heat. The mold design must allow for heat dissipation, perhaps through vents or conductive materials. It is a balance of protecting the electronics while allowing them to "breathe" and sense the air accurately. This is where mechanical engineering meets software needs. We are building the body that houses the brain.

Интеграция интеллектуальных датчиков

| Тип датчика | Функция | Housing Requirement |

|---|---|---|

| Particulate | Detects PM2.5 | Direct airflow path to sensor |

| VOC | Detects chemicals | Isolation from motor heat |

| Occupancy | Detects people | Clear line of sight (lens integration) |

AI sensors only detect dust levels.Ложь

They analyze patterns, occupancy, and time to predict needs.

Vibration affects sensor accuracy.Правда

Sensors must be isolated from motor vibration to provide accurate data.

What Is the "Active Defense" Layer Advantage?

HEPA filters trap dust, but they do not kill viruses. Health concerns are higher than ever. Users want active sterilization, not just passive filtration.

The "Active Defense" layer combines traditional filtration with UV-C light and plasma technology. This approach actively neutralizes pathogens and bacteria rather than just trapping them. For designers, this requires specialized Material selection5 to prevent UV degradation of the plastic housing over time.

We used to rely only on filters. Now, we have "Active Defense" layers using UV-C and Plasma. This is a game-changer for health, but a headache for material selection.

I have seen plastics turn yellow and brittle after a few months of exposure to UV-C light. If we design a mold for a purifier with UV-C, we cannot use standard ABS plastic near the light source. We must use UV-stabilized materials or metal shielding.

Furthermore, we must design "light traps" in the mold. UV-C light is dangerous to human eyes. The air must pass through the light, but the light must not escape the box. This requires complex internal geometry—baffles and turns in the air channel—that block light but allow air. This increases the complexity of the mold tool, often requiring slides and lifters. But this is necessary. We are not just trapping dirt; we are killing viruses. The design must reflect that power and safety.

Material and Safety Considerations

| Технология | Risk | Design Solution |

|---|---|---|

| Ультрафиолетовое излучение | Plastic degradation | UV-stabilized polymers or metal shields |

| Plasma | Ozone generation | Precise voltage control housing |

| Light Leakage | Eye safety hazard | Internal baffles (Light traps) |

Standard ABS plastic is safe for UV-C lights.Ложь

UV-C light degrades standard ABS, causing it to yellow and crack.

Light traps prevent UV exposure.Правда

Internal geometry blocks light escape while allowing airflow.

Заключение

We must stop designing boxes and start designing solutions. The future is about saving space, ensuring safety, and integrating art. Don't just clean air. Elevate the space.

References

-

Explore how Zero-Footprint designs maximize space in modern living environments. ↩

-

Understand how Slim-Profile Engineering meets modern aesthetic and functional demands. ↩

-

Explore the safety features that make modern air purifiers family-friendly. ↩

-

Discover how Art-First aesthetics transform air purifiers into stylish decor. ↩

-

Understand the importance of material selection for safety and durability in air purifiers. ↩