You have a great concept for a new water dispenser. But water is dangerous. If your app crashes, you lose data. If your water appliance fails, you flood a house.

Water hardware1 is the hardest hardware because it combines high heat, hydraulic pressure, and sensitive electronics in a small box. To succeed, you must avoid common errors like thermal contamination and spaghetti tubing. You need to use integrated manifolds and rigorous organoleptic testing to ensure safety and quality.

Many designers underestimate the complexity of moving water. They treat it like just another consumer electronic device. This mindset leads to catastrophic failures. I have seen startups burn through $200,000 trying to fix these mistakes after the molds were already cut. You do not have to pay that "tuition." Read on to see the traps you must avoid.

Water appliances carry a higher liability risk than standard consumer electronics due to flood and fire hazards.صحيح

Water combined with electricity creates immediate safety hazards, and leaks cause significant property damage.

Standard plastic tubing is the most durable solution for internal water routing.خطأ

Integrated manifolds (solid block water paths) are far superior to tubing as they eliminate leak points and improve pressure management.

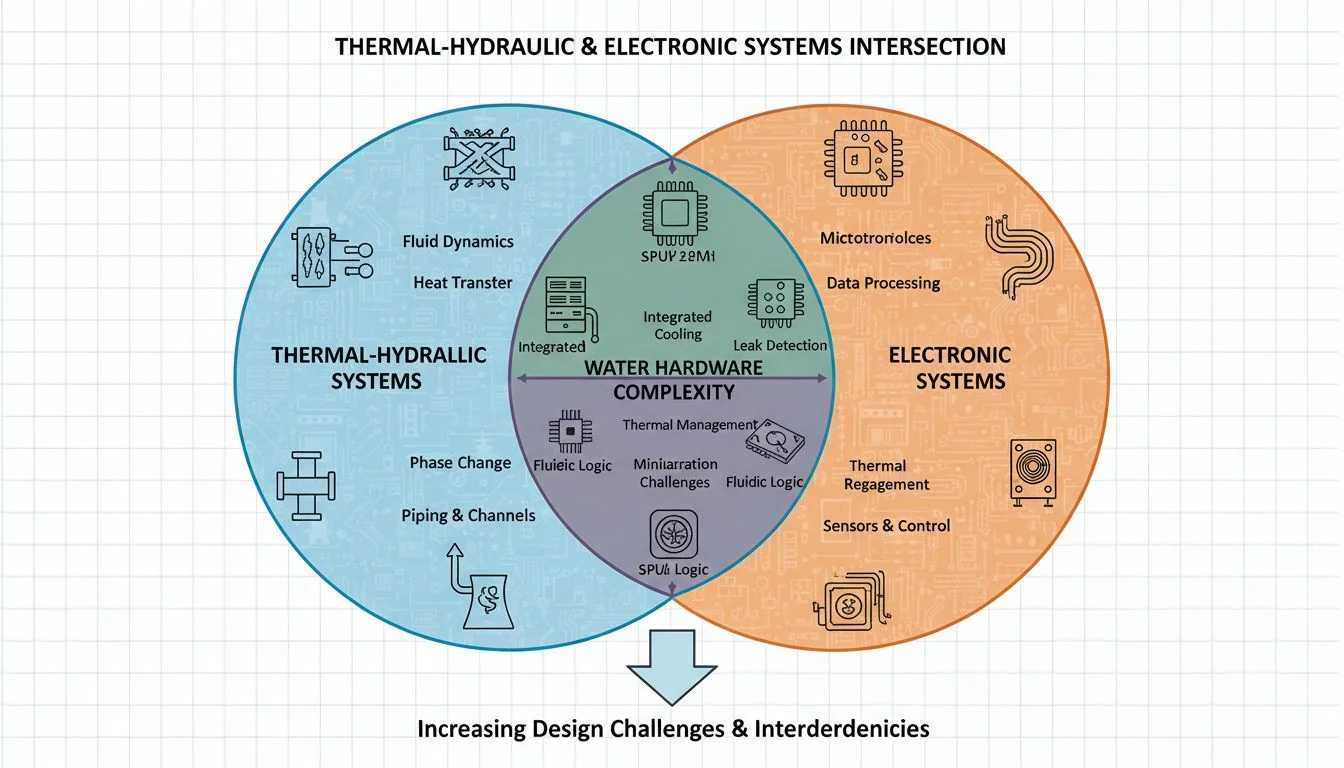

Why Is "Water Hardware" Considered the Hardest Hardware to Engineer?

Most designers think adding water to a device is simple plumbing. It is not. You are trying to make fire (heat), ice (cooling), and electricity live together happily.

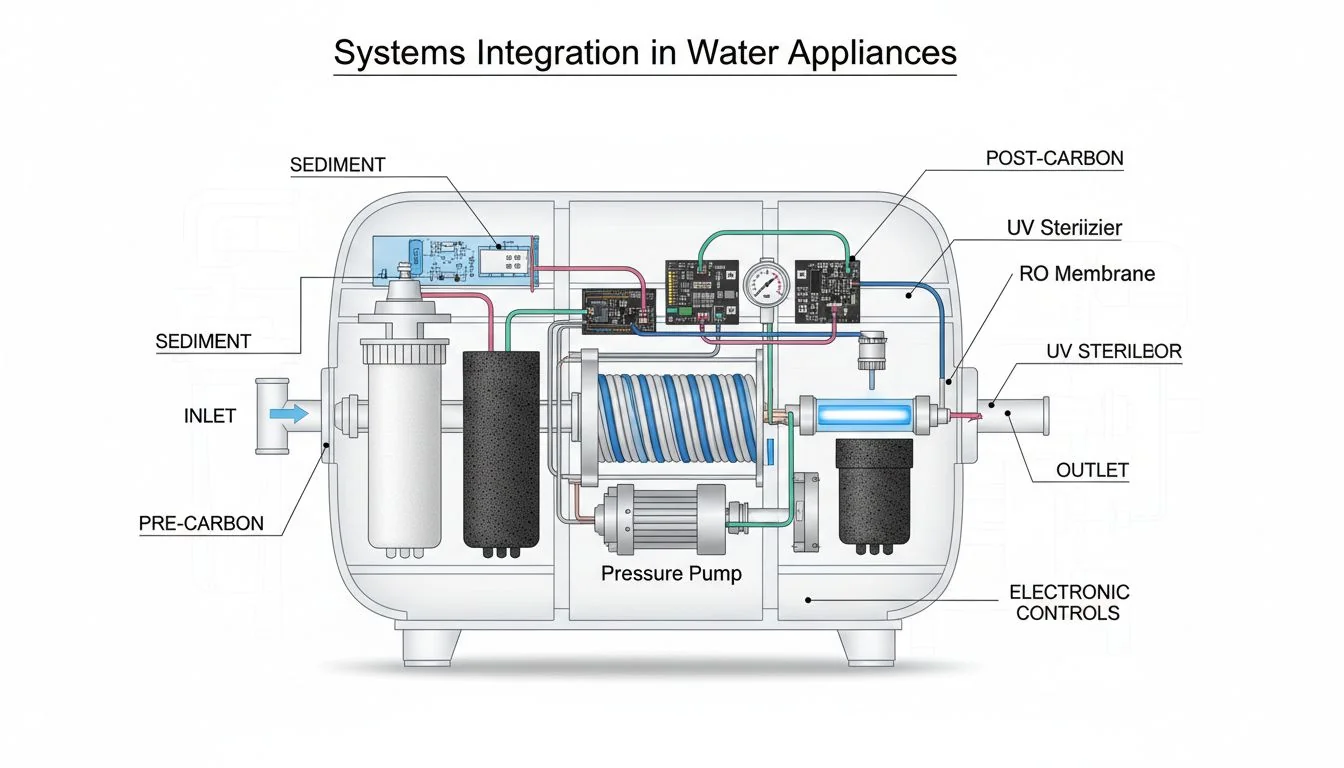

A premium water purifier is a thermal device, a hydraulic device, and an electronic device all in one. The biggest challenge is acting as a "Systems Integrator2." You must ensure the heat does not cook the electronics and the water does not short-circuit the power.

I always tell my clients: "Water + Electricity = High Stakes." When you design a Bluetooth speaker, the worst-case scenario is usually a dead battery. When you design a premium water station, the stakes are much higher. You are dealing with a device that holds water pressure 24 hours a day inside a customer's home.

You need to think like a Systems Integrator. You cannot just buy a pump, a heater, and a circuit board and stuff them into a plastic shell. The heat from the instant boiler will affect your control board. The condensation from the cooling tank will drip onto your connectors.

This is why I recommend partnering with manufacturers like Hisoair. They understand that these systems fight each other. An experienced manufacturer knows how to isolate these zones. They do not just assemble parts; they engineer an ecosystem. If you try to learn this from scratch, you will likely face a recall. A failed software update is annoying. A flooded kitchen is a lawsuit.

A water purifier is only a hydraulic device.خطأ

It is a complex integration of thermal, hydraulic, and electronic systems.

System integration is the primary challenge in water hardware design.صحيح

Balancing conflicting elements like heat, cold, and moisture within a compact enclosure requires expert engineering.

Mistake #1: Are You Ignoring the "Thermal Contamination" Error?

You focus on the look of the machine. But what about the taste? Nothing kills a premium brand faster than water that tastes like a heated circuit board.

Thermal contamination occurs when internal heat warms up plastic components or stagnant water lines. This leaches chemicals and creates a "plastic taste." You must use Sensory Engineering and Organoleptic Testing3 to ensure the water tastes pure, not like the machine.

We call this "Sensory Engineering." In the mold and plastics industry, we know that materials behave differently under heat. If you place a silicone tube too close to an instant heating element, the water inside that tube will get warm. Warm water extracts volatile compounds from rubber and plastic much faster than cold water.

The result is a sensory failure. Your customer takes a sip, and instead of fresh mineral water, they taste burnt plastic. This is not just a nuisance; it is a brand killer. Premium brands sell taste.

To fix this, you need rigorous Organoleptic Testing. This means testing the smell and taste of the water under high-stress conditions. Manufacturers like Hisoair specialize in this. They know exactly which medical-grade materials to use near heat sources. They know how to route water so it does not sit in "hot zones." If you skip this step, your beautiful machine will be returned because the water tastes wrong.

Heat has no effect on the taste of water in plastic tubes.خطأ

Heat accelerates the leaching of volatile compounds from plastics, causing a bad taste.

Organoleptic testing ensures the sensory quality of the water.صحيح

This testing process identifies unwanted tastes and smells caused by material interactions.

Mistake #2: Are You Underestimating "System Pressure" and Leak Risks?

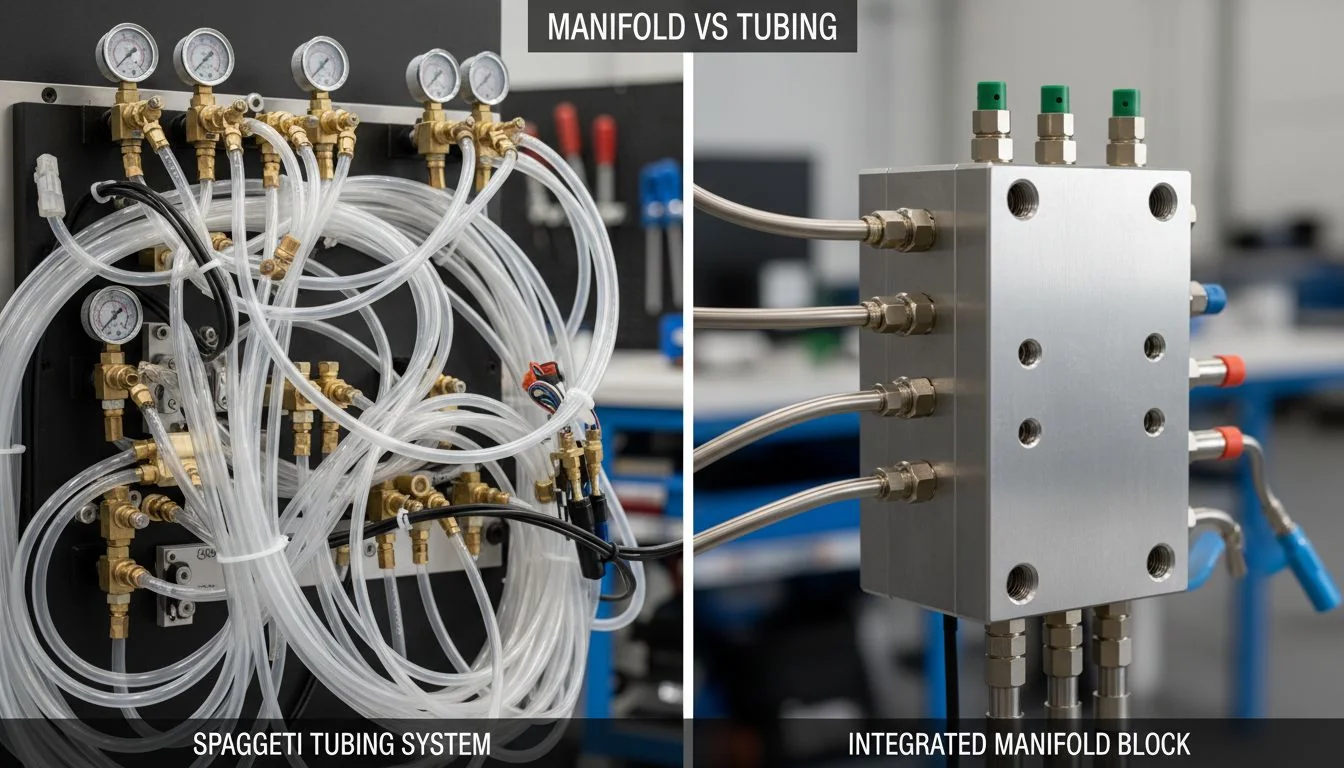

Leaks are the number one fear for any water hardware company. Cheap designs use cheap connections. This is where you must decide between "spaghetti" and structure.

Cheap units use "spaghetti tubing"—a mess of loose hoses and zip ties. This creates dozens of potential leak points. The solution is "Integrated Waterways" or Manifolds. This is a solid molded block that routes water without tubes, offering Leak-proof engineering4.

As a mold enthusiast, this is my favorite topic. Open up a cheap water dispenser, and you will see "spaghetti tubing." There are tubes running everywhere, connected by dozens of little plastic clips. Every single connection is a risk. If one clip fails, the machine leaks.

The premium solution is the Integrated Manifold. This is a piece of engineering art. Instead of tubes, we design a complex injection mold that creates a solid block of water channels. It looks like a circuit board, but for water.

This is "Leak-Proof Engineering." By using a manifold, you reduce the number of connection points by 80% or more. You also improve pressure flow and reduce assembly time. When I see a design using a manifold, I know the engineers are serious. When I see spaghetti tubing, I know they are cutting corners. Sell this feature to your customers. It screams quality.

Spaghetti tubing is the industry standard for high-end water devices.خطأ

High-end devices use integrated manifolds to reduce leak risks and improve durability.

Integrated manifolds reduce the number of potential leak points.صحيح

By replacing multiple tubes and connectors with a single molded block, failure points are minimized.

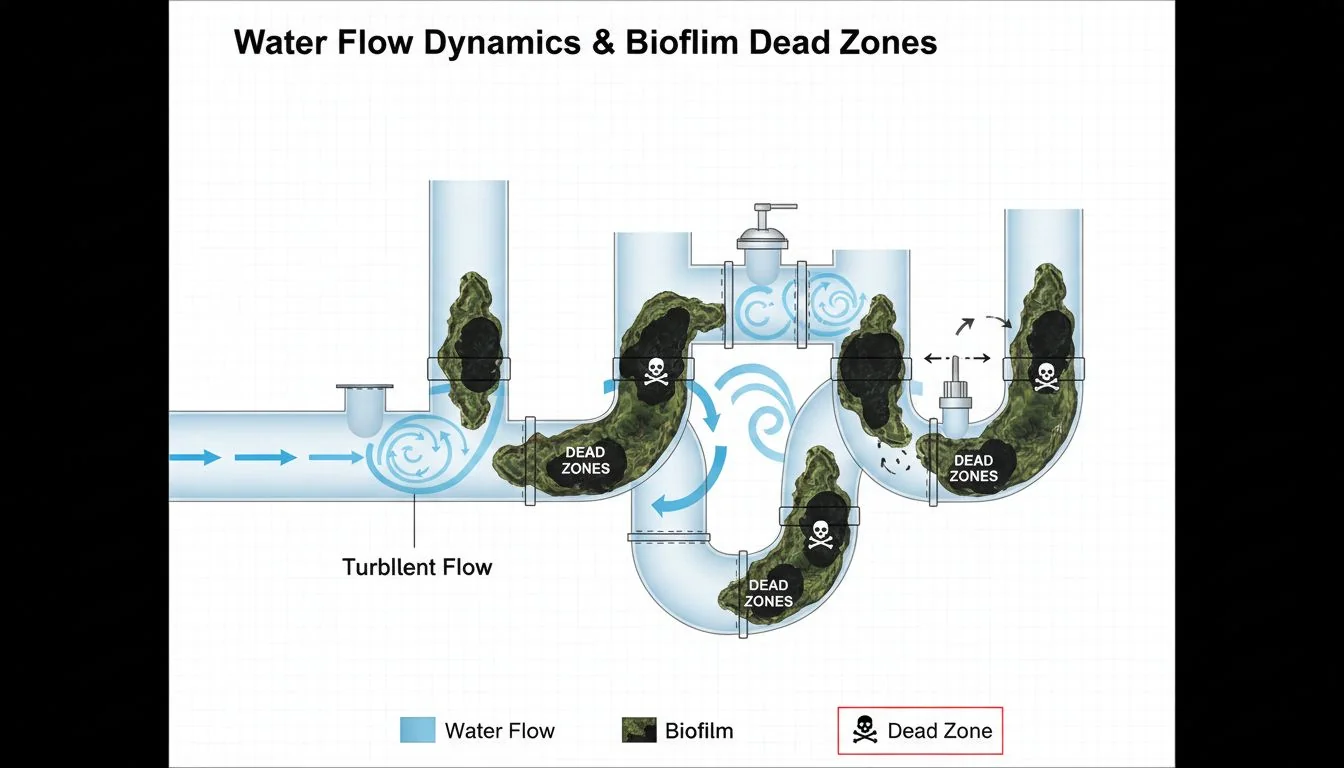

Mistake #3: Do You Have a "Biofilm Blind Spot" in Your Design?

You filter the water before it enters the machine. But does it stay clean inside? Bacteria love hidden corners. You might be designing a breeding ground.

The "Biofilm Blind Spot5" refers to dead zones in your hydraulic path where water stops moving. These stagnant areas allow bacteria to grow. You must design flow paths that constantly flush themselves to maintain hygiene.

Hygiene is not just about the filter you buy. It is about the geometry of your waterways. In mold design, we look for "dead zones." These are corners or T-junctions where water flow is low or non-existent.

If water sits in a dead zone for too long, the chlorine dissipates, and biofilm begins to grow. This slime protects bacteria from future cleaning. Suddenly, your "purifier" is actually contaminating the water.

You need to design for constant velocity. The internal structure of your manifold or tubing must ensure that every drop of water is flushed out regularly. This is a subtle part of hydraulic engineering. It requires simulation and experience. Experienced partners know how to shape the internal walls of the mold to prevent stagnation. Do not let your machine become a biology experiment.

Dead zones in water paths prevent bacterial growth.خطأ

Dead zones cause stagnation, which encourages biofilm and bacterial growth.

Hydraulic design impacts the long-term hygiene of the device.صحيح

Proper flow geometry ensures water is flushed regularly, preventing contamination.

Mistake #4: Is Compliance an "Afterthought" in Your Process?

You finish your design and then send it for certification. This is a rookie mistake. If you fail, you have to scrap your expensive molds.

Treating compliance as an afterthought is the most expensive mistake you can make. Regulations for water contact materials (NSF, FDA) and electrical safety (UL, CE) dictate your material choices and spacing. You must design for compliance from Day One.

I have seen designers create beautiful enclosures that are impossible to certify. Maybe the wall thickness is too thin for the pressure rating. Maybe the plastic type is not on the FDA approved list for hot water contact.

If you wait until the end to check this, you are in trouble. Changing a material often means changing the shrinkage rate, which means your mold dimensions are now wrong. You might have to scrap a $50,000 mold and start over.

This is part of the "Tuition" argument. You can spend $200,000 learning these rules the hard way, or you can partner with a manufacturer who already has the certifications. Companies like Hisoair have pre-certified platforms. They know the rules for every market. By using their architecture, you skip the tuition. You get to market faster and cheaper.

You should wait until the prototype is finished to check compliance.خطأ

Compliance dictates material and design choices; checking late can lead to costly re-tooling.

Changing materials for compliance can render existing molds useless.صحيح

Different materials have different shrinkage rates, requiring new mold designs.

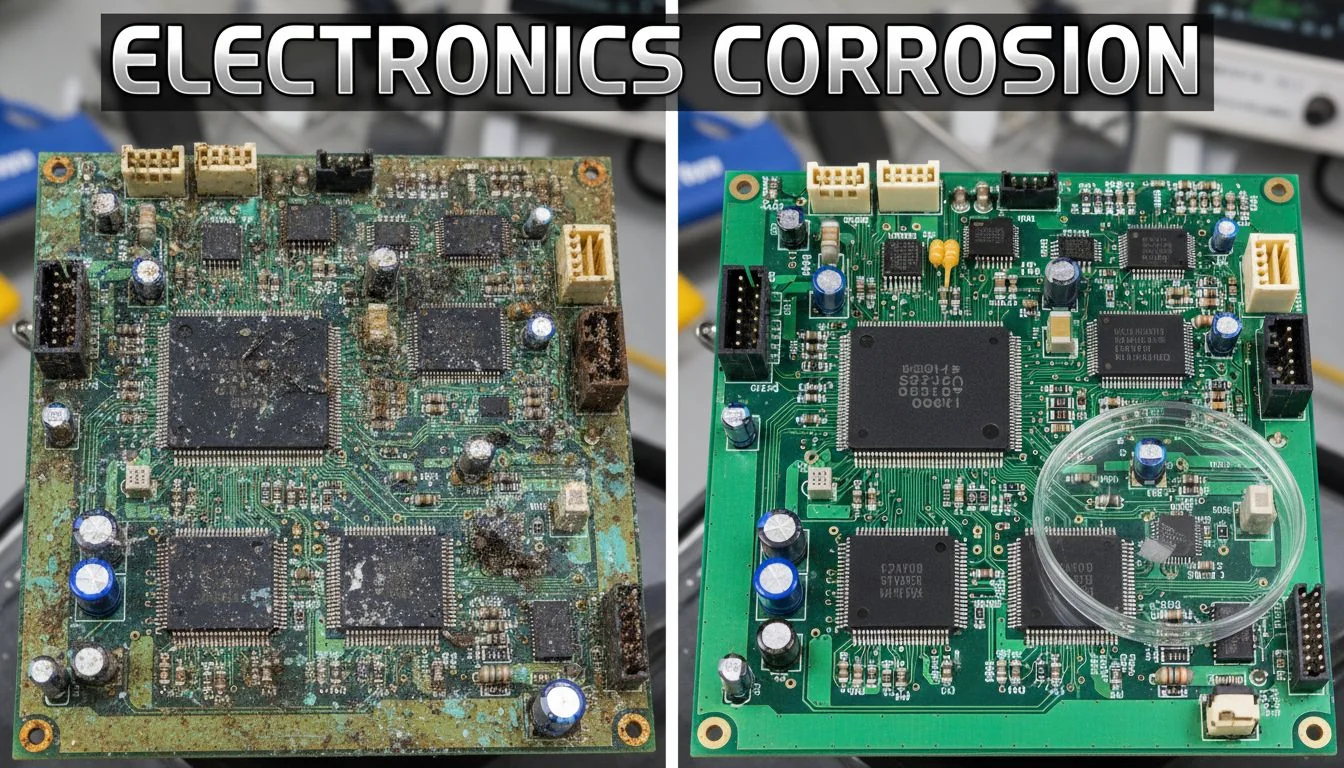

Mistake #5: Will Your Electronics Layout Fail Due to Humidity?

Water creates humidity. Electronics hate humidity. If you put them in the same box without a plan, your control board will corrode within months.

Electronics Layout Failure happens when designers forget that a water dispenser creates a micro-climate inside the shell. You must isolate the "wet side" from the "dry side" to prevent Humidity corrosion6 and short circuits.

A water dispenser is a humid environment. Even if there are no leaks, cold water tanks create condensation (sweat). Hot water tanks create steam vapor. If your PCB (Printed Circuit Board) is sitting right next to these components without protection, it will fail.

I have seen boards turn green with corrosion in just three months. The buttons stop working. The screen flickers. The customer thinks the product is junk.

You need a strict separation of church and state. The "wet side" (hydraulics) and the "dry side" (electronics) should be physically separated by internal walls in the housing. You also need to use potting (sealing electronics in resin) or conformal coating for sensitive areas. This is where the "Master Integrator" skill comes in. You must design the airflow to vent humidity away from the brain of the machine.

Condensation inside the machine is harmless to electronics.خطأ

Condensation causes corrosion and short circuits on unprotected circuit boards.

Physical separation of wet and dry zones extends product life.صحيح

Isolating electronics from moisture sources prevents premature failure.

الخاتمة

Designing premium water hardware is high-stakes engineering. Do not pay the "tuition" of failure by making these common mistakes. Partner with experts who understand manifolds, sensory engineering, and compliance.

References

-

Understanding the complexities of water hardware can help you avoid costly mistakes in design and engineering. ↩

-

Understanding the role of a systems integrator can enhance your approach to complex water hardware projects. ↩

-

Learn about organoleptic testing to ensure your water products meet high sensory standards. ↩

-

Exploring leak-proof engineering can help you create more reliable and durable water products. ↩

-

Discover how to prevent bacterial growth in water systems by addressing the biofilm blind spot. ↩

-

Learn about humidity corrosion to protect your electronics and extend product life. ↩