Luxury clients hate ugly appliances. They spend millions on interiors, only to have the look ruined by a cheap plastic box. How do we design air purifiers that architects actually want to specify in their projects?

To meet luxury expectations, designers must shift from creating standalone appliances to designing "architectural fixtures1." This involves prioritizing wall-mounted architectures, enabling bespoke material customization, ensuring "library-quiet" acoustics, and integrating seamless automation. These elements transform a basic utility device into a high-value design asset that interior designers will actively recommend.

I have worked with many clients who try to sell standard products to high-end markets. They usually fail. The product works fine, but it does not fit the lifestyle. We need to change how we think about the product itself.

Luxury clients prioritize function over aesthetics.خطأ

In the luxury market, aesthetics and integration are often as important, if not more so, than raw performance.

Interior designers are the key decision-makers for luxury home appliances.صحيح

Architects and designers act as gatekeepers; if a product ruins their design, they will not allow it in the project.

Why Do Standard Appliances Fail in Luxury Interiors?

You spend months designing a sleek, modern living room. Then, the client drops a bulky, white plastic machine in the corner. It looks terrible and ruins the flow of the room.

The "Appliance Clash" happens when mass-market aesthetics meet curated interior design. High-end spaces demand cohesion and harmony. Standard purifiers look temporary and cheap, while luxury interiors require permanence, specific textures, and seamless integration with the surrounding architecture.

Understanding the Gatekeeper

In my years of trading molds and parts, I learned that you are not always selling to the end user. In the luxury market, you are selling to the Interior Designer. These are the "Gatekeepers." They decide what goes into a home. If your product looks like a cheap toaster, they will hide it or ban it. If your product looks like a piece of art, they will put it on the wall.

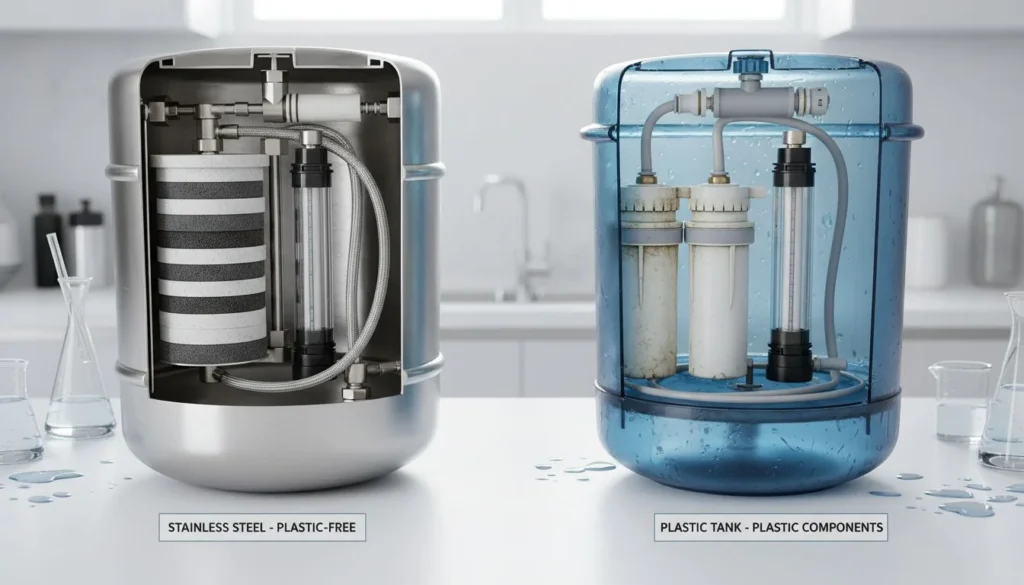

The Problem with "Plastic"

As a mold enthusiast, I love plastic. It is versatile. But in a luxury home, visible, shiny plastic often signals "cheap."

- Texture: Standard EDM finishes on molds are fine for consumer electronics, but luxury needs more.

- Weight: Lightweight feels cheap. Luxury items have heft and solidity.

- Visual Noise: flashing lights and big logos are a distraction.

Design vs. Engineering Conflict

Jacky, I know you face this challenge. The engineers want big vents for airflow. The designers want a solid block of marble. The solution is to become a "technical design partner2." We must provide the engineering canvas—the internal chassis—that allows the brand to apply their art. We solve the airflow and filtration, so they can focus on the look.

| الميزة | Mass Market Product | Luxury Design Requirement |

|---|---|---|

| المواد | High-gloss plastic | Matte, wood, fabric, or metal |

| التنسيب | Floor (obstacle) | Wall or Integrated (fixture) |

| التحكم | Big buttons/Screens | Hidden or App-based |

| Value | Disposable | Permanent Asset |

Plastic is the only material suitable for air purifier housing.خطأ

Luxury units often use internal plastic structures clad in premium materials like wood, fabric, or anodized aluminum.

Designers prefer products that blend into the environment.صحيح

High-end design values 'invisible' technology that does not distract from the interior architecture.

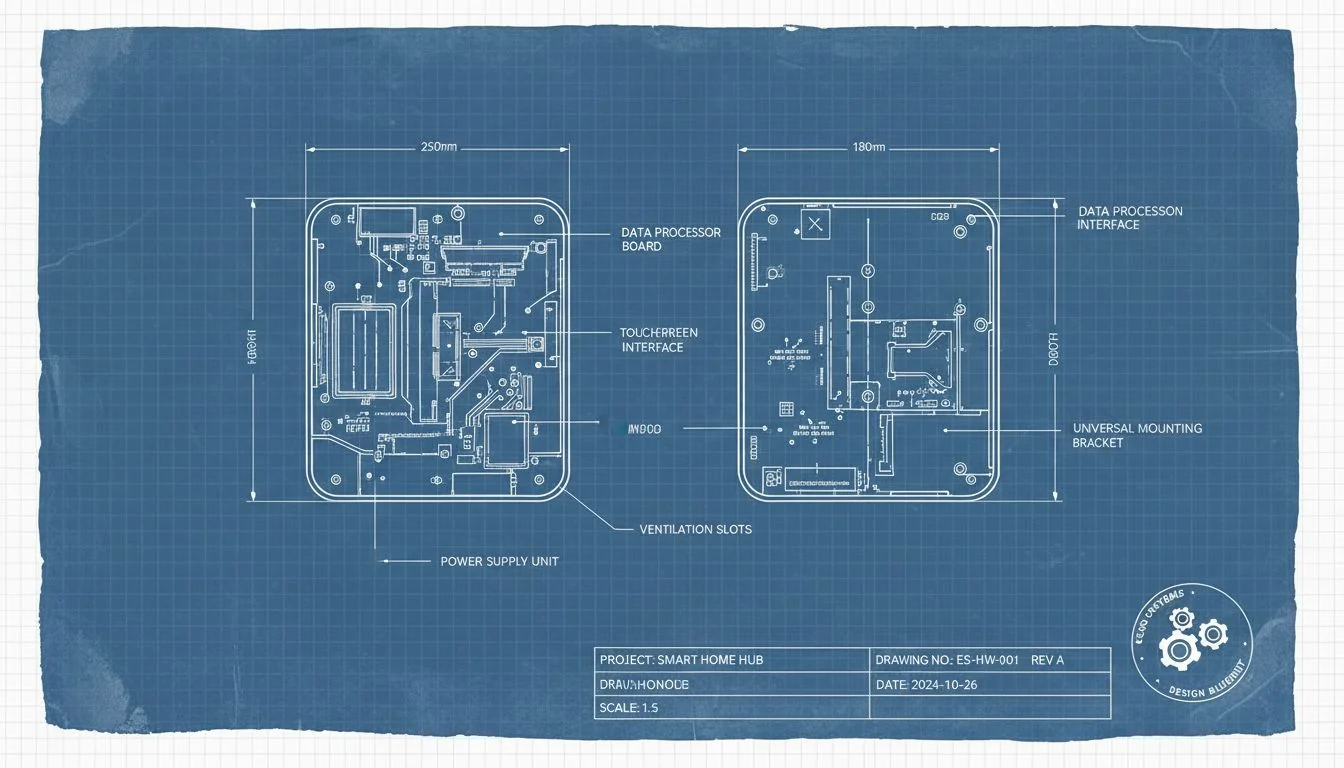

Is Wall-Mounted Architecture the Key to Invisible Design?

Floor space is the most expensive part of a luxury apartment. Clutter is the enemy of a high-end lifestyle. How do we clear the floor while keeping the air clean?

Wall-mounted units function as "fixtures" rather than "appliances." This elevates their perceived value, similar to built-in lighting or high-end speakers. It integrates the technology into the building's infrastructure, solving the clutter problem permanently and adding value to the home.

The Shift from Appliance to Fixture

Think about the difference between a desk lamp and a chandelier. You take the lamp with you when you move. The chandelier stays. The chandelier adds value to the house. We need to design air purifiers that are fixtures.

Structural Design Challenges

Designing for the wall is different from designing for the floor.

- Weight Distribution: The center of gravity must be close to the wall. If it hangs out too far, it puts stress on the mounting bracket.

- Vibration Control: A motor on a wall can turn the wall into a drum. We need better dampening materials in the mold design to isolate the fan from the backplate.

- السلامة: The locking mechanism must be secure. We cannot have a heavy unit falling on a child.

The "Invisible" Footprint

When I help clients develop these products, I advise them to look at the HVAC industry. Good air conditioning is invisible. It is just a vent. A luxury air purifier should try to achieve this "invisible" footprint. It should look like a piece of wall art or a speaker.

Technical Considerations for Wall Mounting

- Air Intake: You cannot pull air from the back anymore. You must pull from the sides or bottom.

- Cable Management: Nothing looks worse than a black wire hanging down a white wall. The design must allow for hardwiring behind the unit.

| Design Aspect | Floor Unit | Wall-Mounted Fixture |

|---|---|---|

| Perception | Temporary Item | Permanent Home Upgrade |

| استخدام الفضاء | Consumes floor space | Uses vertical "dead" space |

| التركيب | Plug and Play | Requires installation (Professional) |

Wall-mounted units are harder to service.خطأ

With a smart modular design, the front cover can be removed for filter changes without taking the unit off the wall.

Fixtures add more value to a property than appliances.صحيح

Permanent fixtures are considered part of the real estate, whereas appliances are personal property.

How Does Customization Justify a Higher Price Point?

One size never fits all in the luxury world. Clients want their devices to match their sofas or curtains. How do we engineer this flexibility without making new molds for every order?

"Bespoke" is a high-margin word. By designing units with swappable front panels—using wood, fabric, or art—manufacturers can charge a premium. This allows the technology to blend perfectly with specific interior design themes, turning a standard machine into a custom piece.

The Economics of "Bespoke"

In my trading business, I see the cost of parts. A plastic cover costs $5. A wood veneer cover might cost $30. But the final product price can jump from $200 to $800. Why? Because it is "Custom." The client is paying for the perfect match, not just the materials.

Designing for Modularity

For a designer like Jacky, this is a fun challenge. You need to design a "Core Unit" that stays the same. This core holds the fan, the filter, and the electronics. Then, you design a "Skin" system.

- Magnetic Attachments: Use strong magnets in the mold pockets. This allows panels to snap on and off without visible screws.

- Tolerance Gaps: Fabric is thicker than paint. Wood expands with humidity. Your mold design must have forgiving tolerances at the edges to accept different materials without looking sloppy.

Material Variety

We are not limited to plastic.

- Fabric: Great for bedrooms. It looks soft and absorbs sound.

- Wood: Matches cabinetry in living rooms.

- Paintable Surface: Let the interior designer paint it the exact color of the wall.

The Manufacturing Benefit

This strategy helps with production. You can mass-produce the technical core (the expensive mold). Then, you can produce the panels in small batches using CNC or low-volume molding. This keeps your inventory flexible and your costs down, while the perceived value goes up.

| Panel Type | Aesthetic Goal | Manufacturing Method |

|---|---|---|

| Fabric Wrap | Soft, acoustic dampening | Plastic frame + upholstery |

| Wood Veneer | Natural, warm, premium | CNC or compression mold |

| Art Print | Visual statement | UV Printing on flat substrate |

Customization requires creating a new mold for every client.خطأ

By using a modular chassis, only the external panel needs to be changed, which can often be done with CNC or simple tooling.

Bespoke products command higher profit margins.صحيح

Customers are willing to pay significantly more for products that are tailored to their specific aesthetic needs.

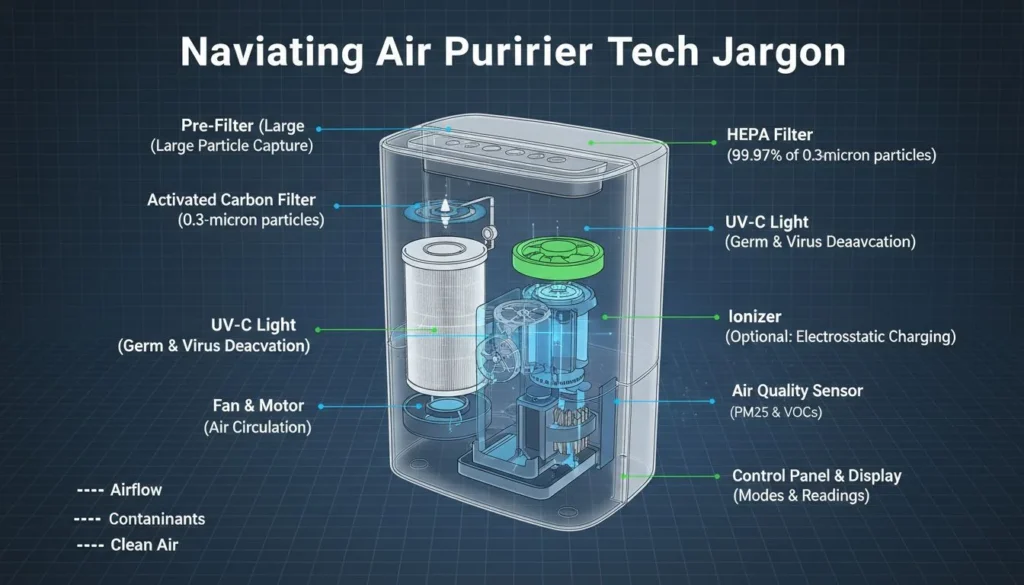

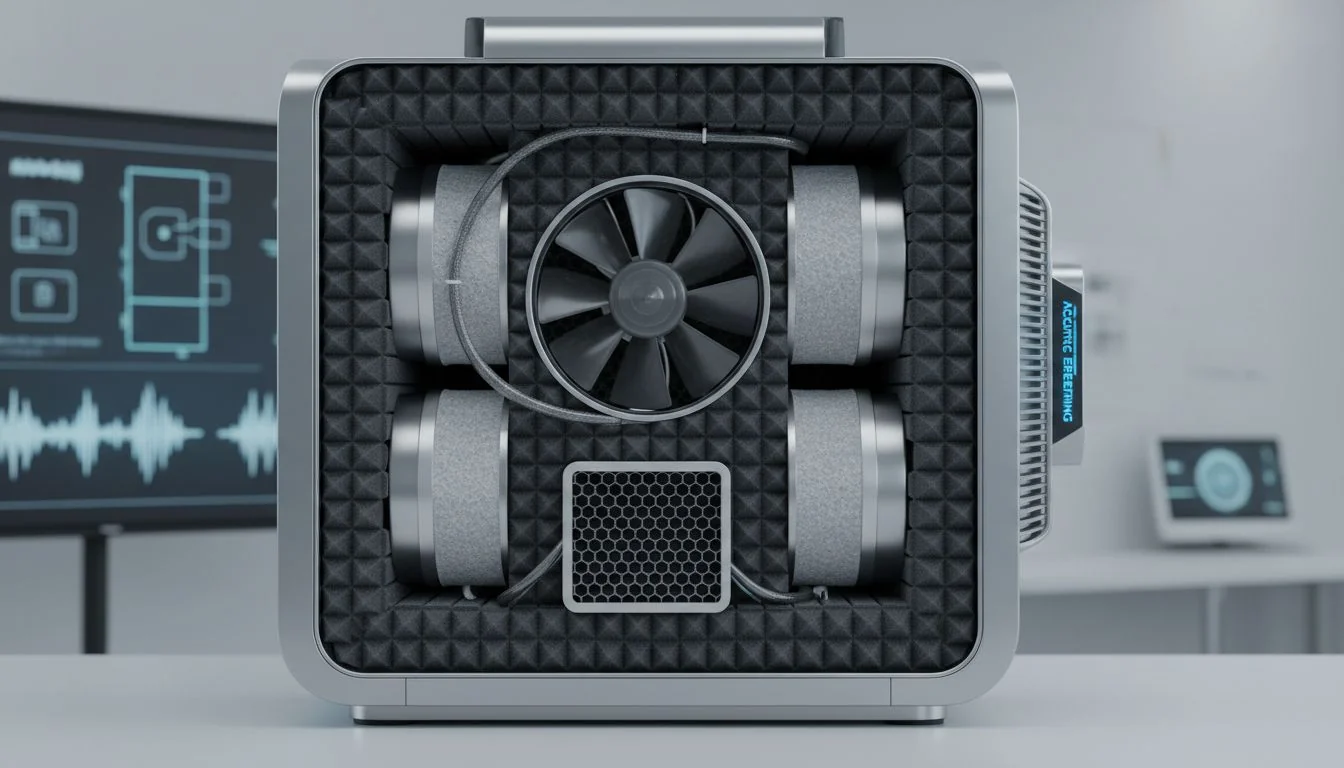

Can We Achieve "Library-Quiet" Acoustics in Compact Designs?

A loud fan ruins a peaceful study or a master bedroom. Wealthy clients equate noise with cheapness. Can we make powerful airflow silent enough for a library?

Silence signals quality. For luxury markets, acoustic comfort is a primary feature, not an afterthought. Designers must optimize internal airflow paths and fan balancing to ensure the device operates unobtrusively. "Library-Quiet" is the standard we must hit.

Noise is a Sign of Failure

In the mass market, people sometimes like noise because they think, "It's loud, so it must be working hard." In the luxury market, noise means "It's struggling." Silence is the ultimate luxury. It implies effortless power.

Mold Design for Acoustics

As a mold expert, I can tell you that noise often comes from bad molds.

- Rattling: If the snap-fits are too loose, the plastic parts will vibrate against each other. We need tight tolerances.

- Resonance: Thin plastic walls vibrate like a speaker cone. We need to add ribs and variable wall thickness to break up the resonance frequency.

- Air Turbulence: Sharp corners in the air path create "whooshing" sounds. The internal mold surfaces must be smooth and curved (filleted) to guide the air gently.

The "Unobtrusive" Goal

The goal is for the client to forget the machine is there. It should just be a presence in the room, not a disturbance. This requires using larger fans spinning at lower speeds, rather than small fans spinning fast. This changes the physical size of the device, which goes back to our wall-mount strategy—we have more surface area to work with on a wall.

Testing and Validation

We cannot just guess. We need to use CFD (Computational Fluid Dynamics) before we cut the steel for the mold. We need to simulate the airflow. Once the first T1 sample comes out of the injection machine, we must test it in a sound chamber.

| مصدر الضوضاء | Cause | Design Solution |

|---|---|---|

| Mechanical | Motor vibration | Rubber isolation mounts |

| Structural | Loose parts rattling | Tighter mold tolerances, foam tape |

| Aerodynamic | Turbulent airflow | Smooth internal curves, larger ducts |

Louder fans clean air faster.خطأ

Air cleaning depends on CADR (Clean Air Delivery Rate), which can be achieved with large, slow-moving fans that are quiet.

Acoustic quality is a key differentiator in luxury appliances.صحيح

High-net-worth individuals value peace and quiet, viewing noise as an intrusion.

Does "Concierge-Level" Automation Define Modern Luxury?

Luxury means not having to lift a finger. Manual controls and complex menus are outdated. How should the device interact with the user to provide a true luxury experience?

High-end clients expect "set and forget" technology. Automation implies the device anticipates needs, adjusting air quality without user input. This "concierge" experience aligns with the service level expected in luxury living, where the environment adapts to the person, not the other way around.

The Death of the Button

I remember when having many buttons meant a product was "high-tech." Now, buttons are clutter. A luxury device should have almost no visible controls. The control should happen automatically or via a discreet app.

Sensors are the Concierge

The device needs to be smart. It needs high-quality laser particle sensors and VOC sensors.

- Scenario: The client starts cooking. The sensor smells it. The unit ramps up silently. The air is clean before the guests arrive.

- Scenario: The lights go out in the bedroom. The unit detects the darkness and turns off all its LED indicators so the client can sleep.

Integration is King

The device cannot stand alone. It must talk to the home. It needs to connect with systems like Control4, Crestron, or Savant. This is what architects specify. If your device is a "dumb" island, it won't get picked.

Designing the "Hidden" UI

For the mold design, this means we might use "dead front" displays. The plastic looks solid when off, but light shines through it when needed. This requires special translucent materials or thinning the wall section from the back. It looks magical and very premium.

| الميزة | Standard Experience | Concierge Experience |

|---|---|---|

| Operation | Manual Fan Speed | Auto-adjust based on pollution |

| Lighting | Always on LEDs | Auto-dimming / Night mode |

| الاتصال | Maybe Wi-Fi | كامل smart home integration3 |

Luxury clients enjoy manually adjusting settings.خطأ

Luxury is defined by convenience; clients prefer autonomous systems that manage the environment for them.

Smart home integration is a requirement for modern luxury fixtures.صحيح

High-end homes use centralized systems (like Crestron) to control all devices; compatibility is essential.

الخاتمة

We are not just making machines; we are crafting wellness art. By focusing on wall-mounted architecture4, bespoke materials, silence, and automation, we help designers satisfy their most demanding clients. This elevates our work from simple manufacturing to creating permanent value.

References

-

Explore how architectural fixtures enhance luxury spaces and meet high-end client expectations. ↩

-

Understand the role of technical design partners in creating high-end, functional designs. ↩

-

Discover the role of smart home technology in creating a seamless luxury experience. ↩

-

Understand how wall-mounted designs can enhance aesthetics and functionality in luxury interiors. ↩