Sie überlegen, einen Luftfilter zu personalisieren? Der Zeitplan könnte verwirrend sein! Ich habe einige Einblicke in den Prozess gewonnen.

Die Anpassung eines Luftfilters dauert in der Regel zwischen 2 und 4 Wochen. Die Dauer hängt von zwei Faktoren ab: der Komplexität des Filters und den Fähigkeiten des Herstellers. Einfachere Ausführungen werden oft in weniger als 2 Wochen geliefert. Im Gegensatz dazu können komplexe Konstruktionen wie HEPA-Filter mehr Zeit in Anspruch nehmen. Strenge Tests und die Einhaltung von Normen verlängern diesen Zeitraum. Die Kommunikation mit dem Hersteller über Ihre spezifischen Anforderungen ist sehr hilfreich. Dies führt oft zu einem reibungsloseren Ablauf.

Als ich zum ersten Mal mit der Anpassung eines Luftfilters begann, fühlte ich mich ein wenig überfordert. Der übliche Zeitrahmen liegt zwischen 2 und 4 Wochen. Ein einfacheres Design, wie ein HVAC-Filter, kann in weniger als 2 Wochen geliefert werden. Bei komplexeren Filtern wie HEPA-Filtern dauert es wegen der strengen Prüfanforderungen manchmal länger. Ich erinnere mich noch gut daran, wie ich auf meinen ersten individuellen Filter gewartet habe. Es kam mir wie eine Ewigkeit vor! Die Geduld hat sich gelohnt. Die Qualität und der Seelenfrieden waren jede Minute wert.

Die Anpassung eines Luftfilters dauert in der Regel 2 bis 4 Wochen.Wahr

Der Zeitrahmen für die Anpassung von Luftfiltern liegt in der Regel zwischen 2 und 4 Wochen und hängt von der Komplexität des Designs und der Effizienz des Herstellers ab.

HEPA-Filter benötigen weniger Zeit für die Anpassung als einfachere Ausführungen.Falsch

HEPA-Filter erfordern oft strengere Tests, was zu längeren Anpassungszeiten im Vergleich zu einfacheren Luftfilterdesigns führt.

Welche Faktoren beeinflussen den Zeitplan für die Anpassung?

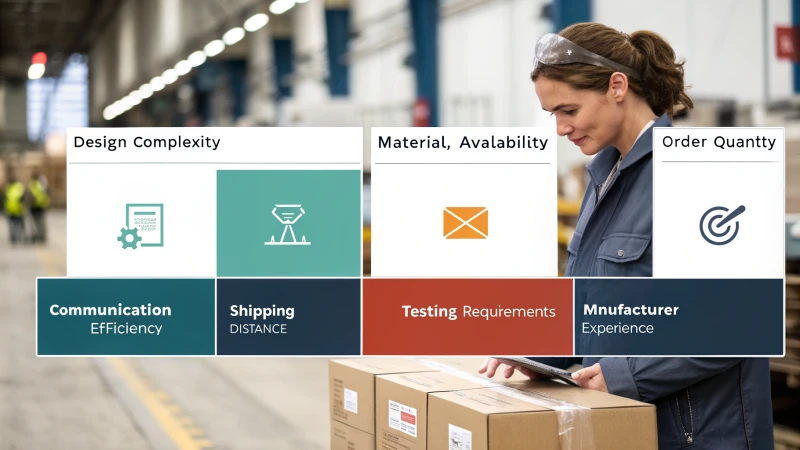

Haben Sie sich schon einmal gefragt, was bei der Personalisierung eines Produkts wirklich zu beachten ist? Der Prozess mag entmutigend erscheinen. Hier werde ich ihn für Sie vereinfachen. Schauen wir uns die wichtigsten Faktoren an, die Ihre Personalisierungsreise beeinflussen.

Die Zeit für die Anpassung ist je nach Schwierigkeitsgrad des Designs unterschiedlich. Auch die Materialverfügbarkeit spielt eine Rolle. Auch die Anzahl der Artikel in einem Auftrag spielt eine Rolle. Die Kommunikation spielt eine große Rolle. Auch die Versandentfernung wirkt sich auf den Zeitplan aus. Testanforderungen können die Dinge verlangsamen. Die Erfahrung des Herstellers ist ein weiterer Faktor. Wenn Sie diese Elemente kennen, können Sie besser einschätzen, was Sie zu erwarten haben. Dieses Wissen hilft Ihnen wirklich, den Prozess zu verbessern.

Die Zeitachse der Anpassung verstehen

Wenn Sie ein Anpassungsprojekt in Betracht ziehen, ist es wichtig, die verschiedenen Faktoren zu kennen, die den Zeitplan beeinflussen können. Hier sind einige Schlüsselelemente, die Sie berücksichtigen sollten:

-

Komplexität des Designs

Je komplizierter das Design ist, desto länger kann es dauern, bis es fertig ist. Ich wollte zum Beispiel einmal ein einfaches Logo auf einer Tasche haben; ein einfaches Design schien einfach, aber das Hinzufügen eines detaillierten Musters verlangsamte den Fortschritt. Einfache Entwürfe sind schnell fertig, während komplexe Entwürfe mehr Anpassungen und Genehmigungen erfordern. Dies ist von entscheidender Bedeutung, da die Entwurfsphase den Ton für das gesamte Projekt angibt. -

Verfügbarkeit von Material

Haben Sie schon einmal ein Projekt begonnen und mussten feststellen, dass Ihre Materialien nicht verfügbar waren? Materialengpässe können die Produktion stark verzögern. Es ist wichtig, sich bei den Lieferanten zu erkundigen Materialverfügbarkeit1 in einem frühen Stadium des Prozesses. Wenn besondere Materialien benötigt werden, z. B. umweltfreundliche Stoffe, können sich die Vorlaufzeiten erheblich verlängern. -

Menge bestellen

Die Auftragsgröße hat einen großen Einfluss auf die Produktionsgeschwindigkeit. Kleinere Aufträge haben aufgrund der Produktionsplanung und der Ressourcenzuweisung oft kürzere Durchlaufzeiten als größere Großaufträge. Hier ist ein kurzer Überblick:Menge bestellen Voraussichtlicher Zeitplan 1-50 Einheiten 1-2 Wochen 51-200 Einheiten 2-4 Wochen 201+ Einheiten 4+ Wochen -

Kommunikation

Die Kommunikation erweist sich in diesem Prozess als sehr entscheidend! Eine effiziente Kommunikation mit dem Hersteller kann die Prozesse beschleunigen. Verzögerungen bei Rückmeldungen oder Genehmigungen können den Zeitrahmen erheblich verlängern. Die Einrichtung klarer Kommunikationskanäle von Anfang an trägt zum reibungslosen Ablauf der Prozesse bei. -

Versandentfernung

Haben Sie schon einmal sehnsüchtig auf eine Lieferung gewartet und festgestellt, dass diese von weit her kommt? Der Standort des Herstellers im Verhältnis zu Ihrer Lieferadresse kann sich darauf auswirken, wie schnell Sie Ihre Produkte erhalten. Beim internationalen Versand kann es zu zusätzlichen Verzögerungen durch den Zoll und längere Transitzeiten kommen. -

Prüfung und Qualitätssicherung

Bei Projekten, die spezifische Anwendungen wie HLK-Filter betreffen, ist eine Qualitätsprüfung unerlässlich. Kundenspezifische Produkte müssen oft Qualitätssicherungsprüfungen durchlaufen, insbesondere wenn sie für hocheffiziente Geräte wie HEPA-Filter bestimmt sind. Hersteller mit robusten Testeinrichtungen helfen bei der rechtzeitigen Lieferung unter Einhaltung der Qualitätsstandards. ihre Zertifizierungen2. -

Hersteller Erfahrung

Die Zusammenarbeit mit erfahrenen Herstellern verkürzt den Zeitrahmen für die Anpassung erheblich; ihr Wissen über Prozesse und Probleme ist von unschätzbarem Wert. Unternehmen wie HisoAir verfügen beispielsweise über mehr als 20 Jahre Erfahrung in der Luftreinigungstechnologie und gewährleisten eine effiziente Projektabwicklung.

Wenn Sie diese Faktoren berücksichtigen, können Sie Ihre Erwartungen an den Zeitplan für die Anpassung Ihrer Projekte besser verstehen und steuern! Denken Sie daran, dass eine proaktive Planung und eine klare Kommunikation mit den Herstellern zu reibungsloseren Abläufen und pünktlichen Lieferungen führen kann.

Die Fertigstellung komplexer Entwürfe dauert immer länger als die einfacher Entwürfe.Wahr

Die Komplexität des Entwurfs wirkt sich direkt auf die für Genehmigungen und Anpassungen benötigte Zeit aus, so dass komplizierte Entwürfe langsamer fertig gestellt werden als einfachere Varianten.

Kleinere Aufträge garantieren kürzere Produktionsfristen.Wahr

Kleinere Auftragsmengen haben in der Regel kürzere Durchlaufzeiten, da weniger Ressourcen zugewiesen werden müssen und die Terminplanung im Vergleich zu größeren Großaufträgen rationalisiert wird.

Wie kann ich die Qualität von kundenspezifischen Luftfiltern sicherstellen?

Qualität ist bei kundenspezifischen Luftfiltern sehr wichtig. Diese Tatsache habe ich entdeckt. Diese Erkenntnis hilft mir, die besten Optionen zu wählen. Das sollten Sie auch tun.

Für erstklassige kundenspezifische Luftfilter sollten Sie einen erfahrenen Hersteller wählen. Kennen Sie Ihre Spezifikationen sehr gut. Sprechen Sie während der Entwicklungsphase klar und deutlich. Führen Sie strenge Qualitätskontrollen durch. Gute Filter erfordern eine sehr strenge Überwachung.

Qualität bei kundenspezifischen Luftfiltern

Um die Qualität von kundenspezifischen Luftfiltern zu gewährleisten, müssen mehrere Schlüsselfaktoren berücksichtigt werden, die alle zur Gesamtleistung und Wirksamkeit des Filters beitragen. Nachstehend sind einige wesentliche Aspekte aufgeführt:

Verstehen von Filterspezifikationen

Bevor Sie in den Herstellungsprozess eintauchen, müssen Sie die Spezifikationen kennen, die Ihr Filter erfüllen muss. Verschiedene Anwendungen, wie HLK-Systeme oder Reinräume, erfordern unterschiedliche Filtrationsstufen und -standards.

- HVAC-Filter: Sie sind in der Regel einfacher und schneller zu fertigen. Sie können umfassen MERV-Einstufungen3 die ihre Effizienz bestimmen.

- HEPA-Filter: Hocheffiziente Filter werden häufig in sensiblen Umgebungen benötigt. Müssen strenge Normen erfüllen (wie HEPA 14).

Die Auswahl des richtigen Herstellers

Die Wahl des Herstellers spielt eine wichtige Rolle bei der Sicherstellung der Qualität von kundenspezifischen Luftfiltern. Hier sind einige Punkte zu beachten:

| Kriterien | Bedeutung |

|---|---|

| Erleben Sie | Ein Hersteller mit nachgewiesener Erfolgsbilanz kann komplexe Anfragen besser bearbeiten. |

| Technisches Fachwissen | Stellen Sie sicher, dass sie über fortgeschrittene Kenntnisse in der Filtertechnologie verfügen. |

| Qualitätszertifizierungen | Achten Sie auf ISO-Zertifizierungen oder andere Industrienormen. |

Die Zusammenarbeit mit erfahrenen Herstellern wie HisoAir kann sich erheblich auf die Qualität des Endprodukts auswirken.

Kommunikation während der Entwicklung

Eine effektive Kommunikation mit dem Hersteller ist unerlässlich, um sicherzustellen, dass Ihre Anforderungen erfüllt werden. Zu den wichtigsten Praktiken gehören:

- Regelmäßige Updates: Häufige Kontrollbesuche können dazu beitragen, etwaige Probleme frühzeitig zu erkennen.

- Detaillierte Spezifikationen: Stellen Sie umfassende Anforderungen auf, um Missverständnisse zu vermeiden.

Prozesse der Qualitätskontrolle

Ein solides Qualitätskontrollverfahren ist für die Aufrechterhaltung der Filterqualität unerlässlich. Hier sind einige Methoden, die Hersteller anwenden können:

- Hausinterne Tests: Vergewissern Sie sich, dass der Hersteller über ein solides Labor für die Durchführung von Tests verfügt.

- Prüfung durch Dritte: Ziehen Sie die Einbindung externer Labors zur zusätzlichen Überprüfung der Filterleistung in Betracht.

Qualitätssicherungsmethoden können sein Prüfprotokolle4 für verschiedene Filtertypen, um die erforderlichen Normen zu erfüllen.

Wichtigkeit der Materialauswahl

Die Wahl des richtigen Materials ist entscheidend für die Wirksamkeit des Filters. Zu berücksichtigende Faktoren:

- Medienarten: Verschiedene Filtermedien (Glasfaser, Synthetik) bieten unterschiedliche Wirkungsgrade und Lebensdauern.

- Rahmen Materialien: Robuste Rahmen können die Langlebigkeit und strukturelle Integrität der Filter verbessern.

Installationsverfahren

Eine ordnungsgemäße Installation ist ebenso wichtig wie die Fertigungsqualität. Die Einhaltung der korrekten Verfahren stellt sicher, dass der Filter wie vorgesehen funktioniert und seine Leistung über lange Zeit beibehält. Beachten Sie:

- Hersteller-Richtlinien: Halten Sie sich immer an die spezifischen Installationsanweisungen des Herstellers.

- Regelmäßige Wartung: Planen Sie regelmäßige Kontrollen und Auswechslungen, um die Luftqualität zu erhalten.

Schlussfolgerung

Wenn Sie sich auf diese kritischen Bereiche konzentrieren, können Sie die Qualitätssicherung von kundenspezifischen Luftfiltern erheblich verbessern, was zu einer höheren Leistung und besseren Luftqualität in Ihrer Umgebung führt. Weitere Informationen zur Sicherung der Qualität von Luftfiltern finden Sie unter beste Praktiken der Branche5. Gemeinsam können wir aufatmen, indem wir kluge Entscheidungen treffen!

HEPA-Filter müssen strenge Leistungsstandards erfüllen.Wahr

HEPA-Filter müssen bestimmte Effizienzstandards wie HEPA 14 erfüllen, um in sensiblen Umgebungen eine wirksame Luftfiltration zu gewährleisten.

Eine regelmäßige Wartung ist für die Leistung des Luftfilters nicht erforderlich.Falsch

Regelmäßige Wartung, einschließlich Überprüfung und Austausch, ist entscheidend, um langfristig eine optimale Luftfilterleistung und Luftqualität zu gewährleisten.

Welche Arten von Luftfiltern erfordern mehr Zeit für die Anpassung?

Haben Sie jemals darüber nachgedacht, warum manche Luftfilter länger zum Wechseln brauchen als andere? Ich schon! Lassen Sie uns einen Blick in die Welt der Luftfilter werfen. Unterschiedliche Typen benötigen unter Umständen mehr Sorgfalt und Zeit, wenn sie angepasst werden.

Einige Luftfilter, wie z. B. HEPA- und ULPA-Filter, benötigen in der Regel mehr Zeit für die Anpassung. Sie haben ein komplexes Design und müssen strenge Leistungsregeln erfüllen. Die Art der Anwendung hat großen Einfluss darauf, wie lange die Anpassung dauert. Auch die Erfahrung des Herstellers ist in diesem Prozess sehr wichtig.

Benutzerdefinierte Luftfilter verstehen

Maßgeschneiderte Luftfilter sind wie Anzüge - sie müssen perfekt sitzen! Dieser Prozess kann 2 bis 4 Wochen dauern, abhängig von verschiedenen Faktoren. Lassen Sie mich das erklären.

Faktoren, die die Anpassungszeit beeinflussen

| Faktor | Auswirkungen auf die Anpassungszeit | Beispiel |

|---|---|---|

| Art der Anwendung | Unterschiedlich (2-4 Wochen) | HVAC vs. Reinraum |

| Kommunikation | Kann die Zeit verkürzen oder verlängern | Umgehendes Feedback erforderlich |

| Prüfung | Kann zusätzliche Zeit erfordern | Prüfung durch Dritte |

| Erfahrungen des Herstellers | Entscheidend für die Effizienz | Das Know-how von HisoAir |

-

Art der Anwendung:

- HLK-Filter sind in der Regel einfach aufgebaut. Ich habe einmal einen HVAC-Filter in weniger als zwei Wochen fertiggestellt. Die Fabrik hatte das Design bereits.

- Hocheffiziente Filter für einen Reinraum haben jedoch strengere Anforderungen. HEPA- oder ULPA-Filter benötigen aufgrund spezifischer Normen mehr Zeit.

-

Kommunikation mit den Herstellern:

- Klare Kommunikation ist wirklich wichtig. Die Zusammenarbeit mit einem Hersteller, der mich versteht, beschleunigt die Dinge oft. Die Vertrautheit mit meinen Wünschen hilft wirklich.

-

Anforderungen an die Prüfung:

- Tests verursachen oft Verzögerungen. Filter müssen strenge Tests bestehen, um die Normen zu erfüllen. Einmal habe ich lange gewartet, weil der Hersteller nicht über gute Laboreinrichtungen verfügte. Wir waren auf die Tests Dritter angewiesen.

-

Erfahrungen des Herstellers:

Gängige Typen von kundenspezifischen Luftfiltern

- HEPA-Filter:

Diese hocheffizienten Filter sind so etwas wie Goldstandards. Aufgrund der strengen Anforderungen müssen sie sorgfältig entwickelt und ausgiebig getestet werden. - ULPA-Filter:

Filter mit sehr geringer Penetration sind sogar noch schwieriger. Ihre Anpassung erfordert spezifische Anwendungen und in der Regel viel Laborarbeit.

Schlussfolgerung?

Bei meiner Untersuchung von Luftfiltern habe ich festgestellt, dass jeder Typ einzigartige Anforderungen und Bedürfnisse hat. Wenn Sie mehr über die Auswahl des richtigen Filters für Ihre Bedürfnisse erfahren möchten, lesen Sie dieser Leitfaden7. Glauben Sie mir, wenn Sie diese Unterschiede verstehen, können Sie später viel Zeit und Ärger sparen!

HEPA-Filter erfordern mehr Zeit für die Anpassung als HLK-Filter.Wahr

Für HEPA-Filter gelten strenge Leistungsnormen, was den Anpassungsprozess im Vergleich zum einfacheren Design von HLK-Filtern verlängert.

Die Kommunikation mit den Herstellern hat keinen Einfluss auf die Anpassungszeit.Falsch

Im Gegensatz zu dieser Behauptung kann eine effektive Kommunikation mit den Herstellern den Anpassungsprozess erheblich beschleunigen.

Warum sollten Sie einem erfahrenen Hersteller von kundenspezifischen Filtern vertrauen?

Die Auswahl des richtigen Herstellers für kundenspezifische Filter ist wichtig. Erfahrung spielt bei dieser Wahl eine entscheidende Rolle. Ich werde Ihnen erklären, warum erfahrene Fachleute für effektive Filtrationslösungen unerlässlich sind.

Die Wahl eines erfahrenen Herstellers für kundenspezifische Filter führt zu besserer Qualität. Ihr Fachwissen trägt dazu bei, die Industriestandards zu erfüllen. Sie bieten Lösungen, die perfekt auf Ihre Bedürfnisse zugeschnitten sind. Diese Entscheidung spart im Laufe der Zeit auch Geld. Die Filter funktionieren besser und halten länger. Leistung und Zuverlässigkeit Ihrer Filtersysteme verbessern sich wirklich.

Die Bedeutung von Erfahrung in der Filterherstellung verstehen

Ich weiß noch, wie ich zum ersten Mal die Welt der benutzerdefinierten Filter betrat. Ich fühlte mich überwältigt von der großen Auswahl. Wie viele andere dachte ich, dass die Wahl eines billigeren Herstellers Geld sparen würde. Ich wusste nicht, dass Erfahrung sehr wichtig ist. Es geht nicht nur darum, einen Filter zu bekommen, sondern auch darum, sicherzustellen, dass dieser Filter die strengen Anforderungen und Industrienormen erfüllt. Ein erfahrener Hersteller kennt sich mit verschiedenen Anwendungen gut aus - zum Beispiel mit dem Bedarf an einem HEPA-Filter für einen Reinraum. Sie kennen die spezifischen Designs und Materialien, die für Effizienz und Zuverlässigkeit sorgen.

Sie liefern mehr als nur Produkte. Sie bieten Einblicke in die Einhaltung von Vorschriften und Prüfverfahren, die für Anwendungen mit hohen Standards unerlässlich sind. Ich habe das auf die harte Tour gelernt. Ein Mangel an Anleitung führte zu kostspieligen Fehlern für mich.

Was mich noch mehr überraschte, war die Tatsache, dass etablierte Beziehungen zu Lieferanten und Prüflabors eine Rolle in diesem Prozess spielten. Gute Beziehungen führen zu einer reibungsloseren Kommunikation und schnelleren Lieferungen. Hier ist etwas Interessantes, das ich über die Vorlaufzeiten je nach Filtertyp herausgefunden habe:

| Filter Typ | Typische Vorlaufzeit | Die Bedeutung der Erfahrung des Herstellers |

|---|---|---|

| HVAC-Filter | 2 Wochen | Mäßig |

| HEPA-Filter | 4+ Wochen | Hoch |

| ULPA-Filter | 4+ Wochen | Sehr hoch |

Qualitätssicherung und Prüfung

Ein erfahrener Hersteller verfügt in der Regel über strenge Qualitätssicherungsprozesse. Auf meiner eigenen Reise habe ich erkannt, wie wichtig ein eigenes Labor ist. Die Prüfung der Filtereffizienz und der Einhaltung von Normen wie ISO 168908 ist unerlässlich. Ohne sie ist man auf die Prüfung durch Dritte angewiesen, was zu erheblichen Verzögerungen führen kann.

Ihre Erfahrung hilft ihnen, potenzielle Probleme bereits in der Entwurfsphase zu erkennen. Dieses frühzeitige Handeln kann Sie vor dem Alptraum eines späteren Filterausfalls bewahren. Sie bieten bewährte Verfahren für die Aufrechterhaltung der Integrität des Filtersystems während seines gesamten Lebenszyklus. Ich wünschte, ich hätte das früher gewusst.

Anpassungsfähigkeiten

Als ich kundenspezifische Filter benötigte, stellte ich fest, dass es nicht nur auf die persönliche Wahl ankommt, sondern auch darauf, was die Anwendung wirklich braucht. Ein erfahrener Hersteller ist hier von unschätzbarem Wert. Er bietet maßgeschneiderte Lösungen, die einzigartige Spezifikationen erfüllen, und schlägt Materialien, Größen und Designs vor, die bei weniger erfahrenen Wettbewerbern nicht erhältlich sind.

Ich habe zum Beispiel an einem Projekt für eine Datenzentrum. Spezialisierte Materialien optimierten den Luftstrom und filterten Partikel effektiv. Die Zusammenarbeit mit einem kompetenten Partner machte den Unterschied bei der Verbesserung von Leistung und Kosteneffizienz aus.

Kosten-Wirksamkeit im Zeitverlauf

Ursprünglich war ich versucht, einen weniger erfahrenen Hersteller zu wählen, um Vorlaufkosten zu sparen. Aber, oh Mann, diese Entscheidung ging nach hinten los! Schlecht konstruierte Filter erforderten häufige Auswechslungen und Reparaturen, die sich schnell summierten. Ein erfahrener Hersteller wie HisoAir9 hilft, diese Fallstricke zu vermeiden. Sie liefern vom ersten Tag an qualitativ hochwertige und langlebige Produkte.

Zusammenfassend lässt sich sagen, dass die Wahl eines erfahrenen Herstellers langfristige Vorteile bringt. Die Qualität Ihrer kundenspezifischen Filter verbessert sich, die Einhaltung der Industrienormen ist gewährleistet und die Gesamteffizienz Ihres Filtersystems steigt. Diese Entscheidung ist nicht nur eine Investition in Filter, sondern eine Investition in den Seelenfrieden, die kurzfristige Einsparungen bei weitem überwiegt.

Erfahrene Hersteller gewährleisten eine hohe Filtereffizienz.Wahr

Ihr Wissen über Design und Materialien führt zu überlegener Leistung, insbesondere bei kritischen Anwendungen wie HEPA-Filtern.

Wer sich für weniger erfahrene Hersteller entscheidet, spart langfristig Geld.Falsch

Dies führt häufig zu höheren Betriebskosten durch häufigen Austausch oder Reparaturen, was die anfänglichen Einsparungen zunichte macht.

Schlussfolgerung

Die Anpassung von kundenspezifischen Luftfiltern dauert in der Regel 2-4 Wochen, je nach Komplexität, Materialien und Kommunikation mit den Herstellern. Erfahrene Hersteller gewährleisten Qualität und pünktliche Lieferung.

-

Sie erhalten Einblicke in die Zeitpläne für die Anpassung und erfahren, wie Sie Ihren Bestellprozess optimieren können, um effizienter zu werden. ↩

-

Vertiefen Sie Ihr Wissen über die rechtzeitige Lieferung von kundenspezifischen Produkten, indem Sie die wichtigsten Einflussfaktoren verstehen. ↩

-

Entdecken Sie bewährte Verfahren und Expertenwissen zur Einhaltung von Qualitätsstandards für kundenspezifische Luftfilter. ↩

-

Informieren Sie sich über die wichtigsten Kriterien für die Auswahl eines zuverlässigen Luftfilterherstellers, um qualitativ hochwertige Produkte zu erhalten. ↩

-

Informieren Sie sich über detaillierte Richtlinien für den effektiven Einbau und die Wartung von kundenspezifischen Luftfiltern, um die Leistung zu gewährleisten. ↩

-

Unter diesem Link finden Sie eine detaillierte Aufschlüsselung der verschiedenen Luftfiltertypen und ihrer Anpassungsprozesse, die für eine fundierte Entscheidungsfindung unerlässlich sind. ↩

-

Diese Ressource bietet Einblicke in die Faktoren, die sich auf die Fristen für die Anpassung von Luftfiltern auswirken, und hilft Ihnen, Ihre Optionen besser zu verstehen. ↩

-

Wenn Sie auf diesen Link klicken, erhalten Sie einen detaillierten Einblick in die Vorteile, die sich aus der Wahl bewährter Hersteller von Luftfiltern ergeben, und können so Ihr Verständnis für die Qualitätssicherung verbessern. ↩

-

Unter diesem Link erfahren Sie, wie sich die Anpassungsmöglichkeiten der einzelnen Hersteller unterscheiden und warum Erfahrung wichtig ist. ↩