Searching for a top humidifier manufacturer feels overwhelming. You worry that a bad choice based on an old list will leave you with a cheap product nobody wants.

The best humidifier manufacturers in 2025 are not the biggest factories. They are partners focused on hygiene1, using materials like stainless steel. They understand D2C brands and have global compliance ready. This guide shows you how to spot them, ensuring you choose a winner.

I've been in the mold and manufacturing world for a long time. I started on the factory floor and eventually built my own trading company. I’ve seen countless product designers like you, Jacky, search for the "best" manufacturer. The problem is, most "Top 10" lists you find online are just lazy directories. They list the biggest names because it's easy, not because they are the right partners for a modern, quality-focused brand.

Those lists are a trap. They lead you to partners who are a bad fit. For a serious D2C brand in 2025, you need to look at this completely differently. Let's throw out the old rules and define what "best" really means today. This is how you find a partner that will help you grow, not hold you back.

The global humidifier market is expected to grow by over 6% annually, driven by health and wellness concerns.Verdadero

Multiple market research reports confirm this trend, indicating a growing consumer demand for products that improve indoor air quality and health.

All Chinese manufacturers produce the same low-quality plastic goods.Falso

This is a common stereotype. China has a vast and diverse manufacturing landscape, including highly advanced factories that produce premium goods for top global brands. The key is knowing how to find them.

Why Do Old "Top 10" Lists Fail You in 2025?

You trust a "Top 10" list to find a great supplier. But these lists push you toward outdated factories that are a terrible fit for a modern D2C brand's needs.

Old "Top 10" lists fail because they value factory size over what truly matters now. For 2025, things like hygiene, D2C support, and real innovation are much more important for your success than just finding the biggest or cheapest factory in China.

The world has changed, and so have customers. After the pandemic, people care deeply about health and hygiene in their homes. They don't want a cheap plastic box that could grow mold; they want a premium, clean, and safe product. D2C brands2 are winning because they speak directly to these customers. But you can't do that if your manufacturing partner is stuck in the past. I've seen clients get locked into contracts with huge factories that couldn't change a design, didn't understand branding, and demanded massive order quantities. It killed their agility. As a designer, your vision for a quality product gets lost. The old way of judging a factory is obsolete.

Old vs. New: What to Look For

| Old Criteria (Outdated) | 2025 Criteria (What Matters Now) |

|---|---|

| Lowest Possible Price | Hygiene & premium materials3 |

| High Production Volume | D2C Partnership & Flexibility |

| Basic OEM Capabilities | Full Compliance & Global Readiness |

| Factory Size & Employee Count | Design Innovation & Problem-Solving |

Most online 'Top 10' lists are generated by marketers, not industry experts.Verdadero

Many of these lists are content marketing pieces designed to capture search traffic. They often lack deep, experience-based analysis of the manufacturers they feature.

A bigger factory always means better quality.Falso

Factory size does not guarantee quality. Smaller, more specialized factories can have superior quality control, better materials, and more attention to detail, especially for products requiring a high level of precision or specific expertise.

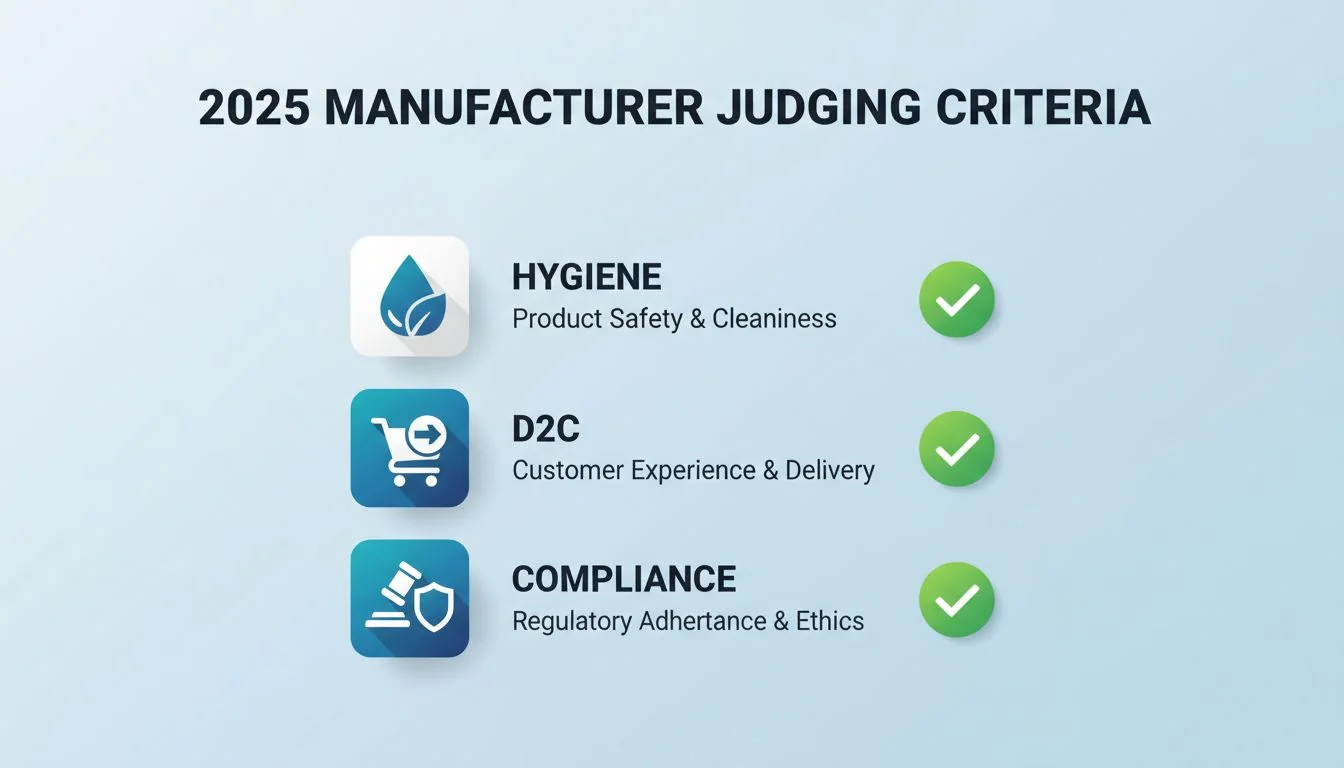

What Are the Real Criteria for a Top Manufacturer in 2025?

You know the old metrics are wrong, but what should you look for instead? Without the right criteria, you are just guessing and risking your brand's reputation on the wrong partner.

The key criteria for judging a manufacturer in 2025 are simple. One, a deep focus on hygiene, proven by materials like stainless steel4. Two, real experience as a D2C partner. Three, full, transparent compliance with global standards. That's it.

Let's break these down. As a product designer, you know that the choices made in the factory determine the final user experience. These three criteria are not just business terms; they directly impact the quality, safety, and success of the product you are designing.

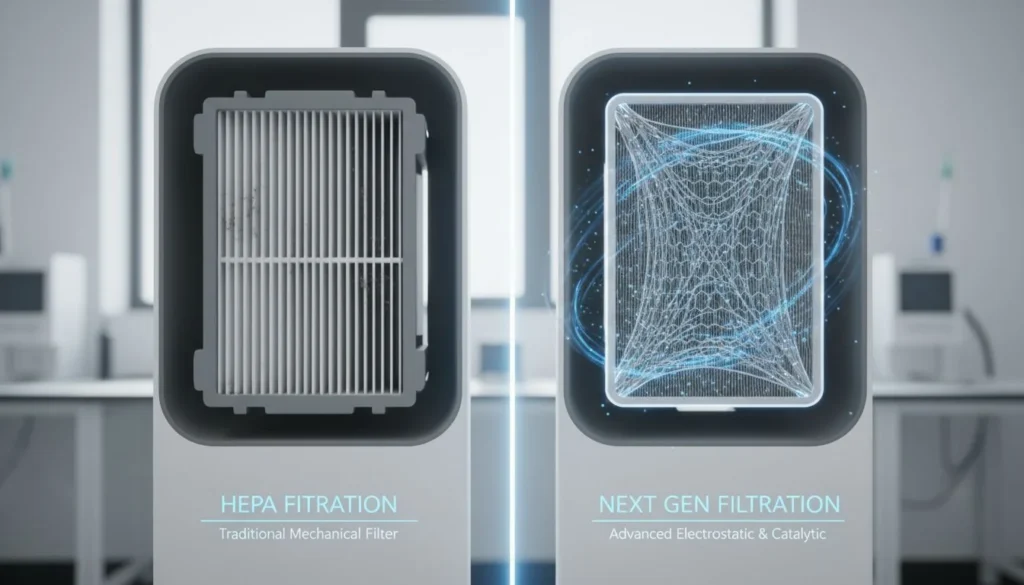

Criterion 1: Hygiene is the New Premium

Today's customer is smart about health. They know that a warm, wet environment is a breeding ground for mold and bacteria. Most humidifiers are made from plastic because it's cheap. But it's also porous and hard to clean perfectly. This is a huge weakness. The best manufacturers are moving to superior materials. Stainless steel is the gold standard. It's non-porous, easy to sterilize, and what we use in medical and food-grade applications. A partner who prioritizes stainless steel understands the modern consumer.

Criterion 2: Are They a D2C Partner or Just a Factory?

A traditional factory takes your design and makes it. That's all. A true D2C partner does more. They understand you need flexible MOQs5 to start. They help with packaging design, branding, and even logistics. I once had a client, a small D2C startup, who signed with a giant factory. The factory treated their 5,000-unit order like a nuisance. Communication was slow, and they offered zero flexibility. A real partner is invested in your growth.

Criterion 3: Compliance Isn't Optional

This is the boring but critical part. A professional manufacturer has their certifications (CE, RoHS, FCC, etc.) ready to go. It shows they are serious and have invested in their processes. If a factory hesitates when you ask for compliance documents, it's a massive red flag. It means they are cutting corners, and you will be the one dealing with the fallout when your product is held up at customs.

Stainless steel is inherently more hygienic than plastic for water-bearing applications.Verdadero

The non-porous surface of stainless steel resists the formation of biofilms, where bacteria and mold thrive. Plastic surfaces, especially as they age and develop micro-scratches, can harbor these contaminants more easily.

Getting CE certification for an electronic product is a simple paperwork process.Falso

CE marking requires rigorous testing for safety, electromagnetic compatibility, and other standards. It's a complex and costly process that demonstrates a manufacturer's commitment to quality and safety.

Should You Partner with the Manufacturing "Giants"?

The biggest factories seem like a safe choice. They have thousands of employees and massive facilities. But their entire system is built for high volume and low costs, which can crush a D2C brand.

Partnering with manufacturing "Giants" is usually a mistake for D2C brands. They offer low unit costs, but only at huge volumes. Their inflexibility, high MOQs, and lack of personal support make them a poor fit for a brand that needs to be fast, innovative, and quality-focused.

I've walked the floors of these factories. They are impressive. They can produce millions of units for big-box stores like Walmart or Target. Their business model is built on efficiency at a massive scale. This means they use standard processes and standard materials, which almost always means plastic. They are not set up to handle a 5,000-unit order with custom packaging and a unique material request. To them, you are a small, difficult customer. As a designer, you will face constant pressure to compromise your design to fit their rigid, cost-driven process.

The "Giants": Pros & Cons

| Pros | Contras |

|---|---|

| Extremely low cost-per-unit | Massive MOQs (often 10,000+) |

| Proven ability to scale production | Almost zero design flexibility |

| Established logistics networks | Slow, bureaucratic communication |

| You are not a priority customer | |

| Default to cheap plastic materials |

Large factories often use their size as a primary selling point to attract new clients.Verdadero

For buyers focused on scale and low prices, a large factory's capacity is a key decision factor. These factories market their size and output capabilities heavily.

High MOQs are the only way for a factory to be profitable.Falso

Profitability is about a business model. Some factories are built for high-volume, low-margin orders. Others are structured for lower-volume, higher-margin orders by offering value-added services like design support, flexibility, and premium materials.

Are "Niche Specialists" the Right Fit for Your Brand?

You find a small factory with a cool design or a unique smart feature. It's tempting. But they might be a one-trick pony, lacking the manufacturing depth or D2C experience to be a reliable partner.

"niche specialists6" can be exciting with their focus on smart tech or aesthetics. But they often miss the bigger picture. They may fail on crucial things like hygienic materials, full compliance, or the support structure that a D2C brand needs to grow.

As a designer, you'll be drawn to these companies. They are often founded by designers themselves. They might have a humidifier that connects to a slick app or comes in an award-winning shape. I admire their creativity. The problem is, they often put all their energy into that one niche feature. They might have a great app, but the humidifier itself is still made of standard plastic that's hard to clean. They might have a beautiful design, but they haven't done the expensive testing for CE or RoHS certification for Europe. They are a specialist in one area, but a generalist everywhere else.

The "Niche Specialists": Pros & Cons

| Pros | Contras |

|---|---|

| Innovative aesthetic designs | Often still use standard plastic |

| Focus on specific tech (e.g., apps) | May lack robust quality control |

| Can be more collaborative on design | Compliance for global markets is often an afterthought |

| May not understand D2C logistics or branding |

A product with more features is always more valuable to the customer.Falso

Customers often value simplicity, reliability, and core function over a long list of features they may never use. A product that does one thing perfectly is often better than one that does many things poorly.

Many small, design-led factories may overlook the complexities of international certification.Verdadero

Startups and smaller companies often focus on product development and local markets first. The cost and complexity of securing international certifications like CE, FCC, or UL can be a significant hurdle they haven't yet addressed.

What Makes a Manufacturer the "2025 Innovator"?

The "Giants" are too big and the "Niche" players are too narrow. You need a better option. Without a partner who gets the whole picture, you are forced to compromise on your product.

The "2025 Innovator" is a new type of manufacturer, and Hisoair is the perfect example. This partner combines a focus on hygiene (using stainless steel), a business model built for D2C brands, and a foundation of total compliance and quality.

This is the model I wish existed for my clients years ago. It’s not about being the biggest or the flashiest. It’s about being the smartest. It’s about building the business around what the best D2C brands and their customers actually need today. This approach combines the best of all worlds.

Built on Hygiene: The Stainless Steel Difference

Hisoair didn't just add a stainless steel part; they built their product around it. They understood that hygiene is the most important feature for a humidifier. Their use of medical-grade stainless steel for the water tank makes the product fundamentally better. It's easy to clean, durable, and gives customers peace of mind. This directly solves the biggest weakness of 99% of other humidifiers on the market.

Designed for D2C: Your Partner, Not Just Your Supplier

Hisoair is structured to help D2C brands succeed. They understand the need for reasonable MOQs. They know that packaging is part of the product experience. They act like an extension of your team. They aren't just taking an order; they are partnering with you to build a successful brand.

The Total Solution: Innovation + Compliance

This is key. Hisoair brings true innovation with its focus on hygiene. But they also have the fundamentals locked down. They have the quality control processes and the full suite of global certifications ready. They combine the exciting innovation of a "Niche Specialist" with the reliability of a "Giant," but all tailored for you.

Hisoair is a leader in using medical-grade stainless steel for consumer humidifiers.Verdadero

While other products may use metal accents, Hisoair has focused its design and marketing on the hygienic benefits of a full stainless steel water reservoir, making them a prominent player in this specific material innovation.

Plastic humidifiers, if not designed and cleaned properly, can become breeding grounds for mold and bacteria.Verdadero

Health organizations like the EPA and CDC have issued warnings about this risk. The porous nature of plastic and the difficulty of cleaning complex shapes can lead to microbial growth.

How Do You Choose Your Winning Partner with Confidence?

You have a lot of information, and now you need a clear way to decide. Making the wrong choice could set your brand back, so you need a simple way to evaluate potential partners.

To choose your winner, use a checklist based on 2025's critical criteria. Ask potential partners direct questions about their materials, their D2C experience, and their compliance. Their answers will tell you everything you need to know.

Forget the long factory tours and slick sales presentations for a moment. As a designer, you know that materials and process are everything. Your job is to cut through the noise and get to the truth. This checklist is your tool to do just that. Ask these four questions to every potential partner.

The 2025 Partner Checklist

| Question | What to Look For | Red Flag |

|---|---|---|

| 1. Material & Hygiene | Do they lead with hygienic materials like stainless steel? Do they understand why it's better? | "We can make it from any plastic you want." |

| 2. Business Model | Do they talk about flexible MOQs, branding, and partnership? Do they ask about your brand's goals? | "Our MOQ is 10,000 units, no exceptions." |

| 3. Compliance | Can they immediately provide full certification documents7 for your target markets (e.g., CE, RoHS)? | "We can get that for you later." or "Do you really need that?" |

| 4. Partnership | Does the conversation feel like a collaboration? Are they helping you solve problems? | They only talk about price and lead time. |

When you use this checklist, the right choice becomes obvious. You're not just buying a product; you're choosing a partner that will define your brand's quality for years to come.

This checklist provides the essential starting point for your due diligence.Verdadero

While more in-depth due diligence is always recommended, these four questions cut to the core of a manufacturer's strategy, capabilities, and suitability as a partner for a modern D2C brand.

Most traditional OEM/ODM factories will struggle to answer these questions satisfactorily.Verdadero

The business models of traditional factories are not built around D2C needs, premium materials as a default, or flexible partnerships. Their answers will likely reveal a focus on volume and cost, not brand-building.

Top Humidifier Manufacturers in China

Updated 2025

Curated list for 2025, ordered with Hisoair first for emphasis (no formal ranking implied).

| Fabricante | Sede central | Product Types | Primary Markets | OEM/ODM Capability | Principales ventajas |

|---|---|---|---|---|---|

| Hisoair | China / Vietnam / Thailand (serving US market) | Home & commercial humidifiers, air purifiers, air filters | Global (focus on North America) | Fuerte | Decibel Cancellation™ technology, tariff advantages via Vietnam & Thailand plants, highly customizable |

| Midea Group | Foshan, Guangdong, China | Home humidifiers, air conditioners | China & global | Medium–High | Global brand, large-scale manufacturing, strong system integration |

| Haier Group Corporation | Qingdao, Shandong, China | Household appliances + humidifier modules | Global | Medium–High | Strong brand reputation, mature quality systems |

| Gree Electric Appliances Inc. of Zhuhai | Zhuhai, Guangdong, China | Home appliances, humidifiers | Global | Medium–High | Industrial-grade production, strong export performance |

| Olansi Healthcare Co. | Guangzhou, Guangdong, China | Humidifiers + air purifiers | Domestic + export | Alta | Health-tech OEM/ODM specialist, combined purification + humidification |

| ATYOU Health Tech | Xiamen, Fujian, China | OEM/ODM home humidifiers | Export-oriented | Alta | Full-process ODM (mold, electronics, assembly), flexible design |

| Hangzhou Dahuan Technology Co., Ltd. | Hangzhou, Zhejiang, China | Industrial/commercial ultrasonic & evaporative humidifiers | Industrial & commercial | Alta | Industrial humidification specialist, customizable large-space systems |

| Shenzhen Dituo Electronic Co., Ltd. | Shenzhen, Guangdong, China | Ultrasonic & aroma humidifiers | Export + domestic | Medium–High | Mature ultrasonic technology, large capacity, aesthetic design |

| Gloreen Electrical Equipments Co., Ltd. | Zhongshan, Guangdong, China | Humidificadores ultrasónicos | Export | Medio | High mist output, suitable for plants & large spaces |

| Elaine Electronics Technology Co., Ltd. | Dongguan, Guangdong, China | Ultrasonic home humidifiers | Export | Medio | Emerging small appliance OEM with flexible customization |

Note: Order shows emphasis with Hisoair first; it is not a formal ranking.

Conclusión

Finding the right manufacturer isn't about a "Top 10" list. It's about finding the one partner who is built for the future of your D2C brand.

References

-

Understanding hygiene standards is crucial for ensuring product safety and customer satisfaction. ↩

-

Exploring D2C brand strategies can provide insights into effective manufacturing partnerships. ↩

-

Learn how premium materials enhance product quality and consumer trust. ↩

-

Discover the benefits of stainless steel for hygiene and durability in humidifiers. ↩

-

Understanding MOQs is essential for managing production costs and inventory. ↩

-

Niche specialists can offer unique advantages, but it's important to assess their overall capabilities. ↩

-

Knowing the necessary certifications ensures that products meet safety and regulatory standards. ↩