Worried about supply chain risks1? You're looking to diversify manufacturing to Malaysia, but finding the right partner for a truly innovative wellness product feels like searching for a needle in a haystack.

Instead of a simple list, the reality is more complex. While Malaysia has world-class electronics assemblers, finding a true R&D partner2 for innovative humidifiers is the real challenge. The best "manufacturers" are often large EMS partners, not specialized small appliance innovators.

I talk to brand owners and product designers like you every day. Many are looking at Malaysia as a "China Plus One" strategy to make their supply chains more resilient. It's a smart move to consider. You're thinking ahead and trying to avoid future disruptions. But in my years in the mold and manufacturing industry, I've learned that avoiding one type of risk can sometimes lead you straight into another, bigger one. The search for a new manufacturing location often overlooks the most critical factor for success: product innovation3.

Let's dive deeper into what manufacturing in Malaysia really looks like for a wellness brand and uncover a strategy that focuses on what truly matters.

Malaysia is the world's leading manufacturer of humidifiers.Falso

While Malaysia has a strong electronics manufacturing sector, it is not the global leader specifically for finished humidifier products. China remains the dominant force in small appliance manufacturing.

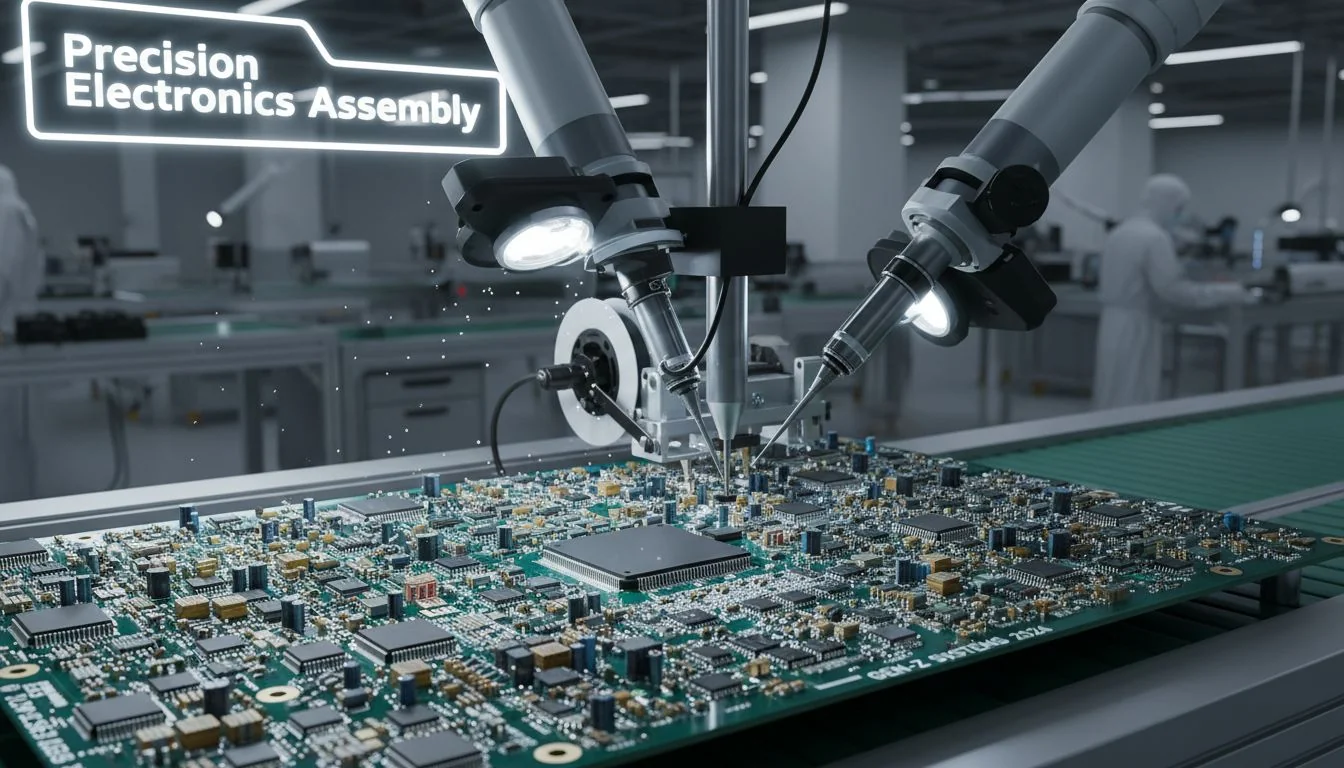

Malaysia is a major global hub for semiconductor assembly and testing.Vero

Malaysia accounts for a significant portion of the global backend semiconductor market, with major players like Intel, AMD, and Infineon having large facilities in the country.

1. Why is Malaysia a "China Plus One" Hotspot?

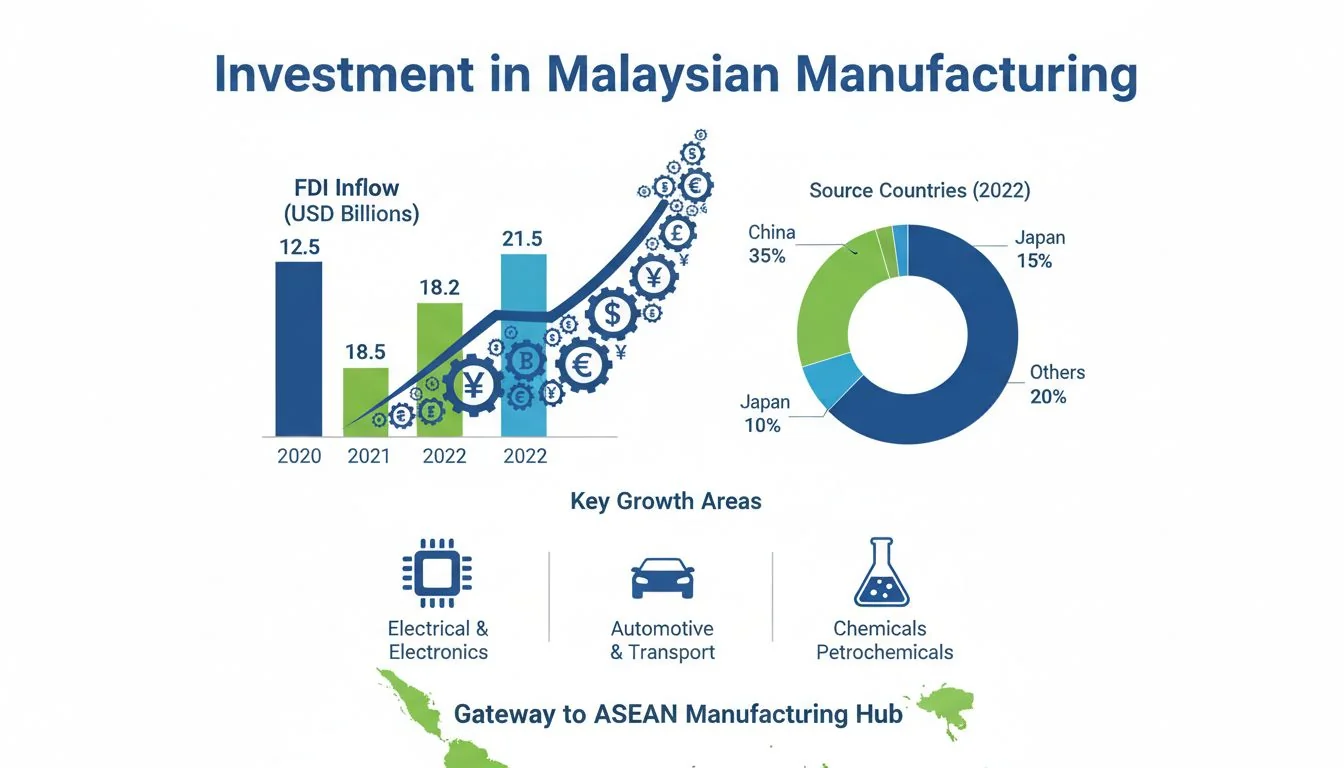

You're trying to escape the risks of having all your manufacturing in China. But navigating a new country's industrial landscape is a huge task. Understanding why Malaysia is so attractive is the first step.

Malaysia is a top "China Plus One" destination because of its strong government support, skilled workforce, and world-class infrastructure, especially in the Electrical and Electronics (E&E) sector. It is a proven, stable hub for high-tech assembly for some of the world's biggest brands.

For decades, Malaysia has been a cornerstone of the global electronics supply chain. When I started in this industry, everyone knew about the country's prowess. It's not a newcomer; it's a seasoned veteran. The government, through agencies like the Malaysian Investment Development Authority (MIDA), actively encourages foreign investment with tax incentives and streamlined processes. This creates a very business-friendly environment. The country has excellent ports and logistics networks, making it easy to move components in and finished goods out. Its workforce is well-educated and often fluent in English, which simplifies communication for Western companies. This combination of factors makes it a reliable and mature choice for companies looking to diversify their manufacturing base. It's seen as a safe bet, and for many types of products, it absolutely is.

Key Strengths of Malaysia's Manufacturing Ecosystem

| Caratteristica | Descrizione | Why It Matters |

|---|---|---|

| E&E Specialization | A deep history in semiconductor assembly4, testing, and electronics manufacturing. | Access to a highly skilled talent pool and supply chain for electronic components. |

| Stable Governance | Pro-business policies and strong investment incentives from agencies like MIDA. | Reduces political risk and provides a predictable operational environment. |

| Developed Infrastructure | Modern ports, airports, and reliable energy and digital networks. | Ensures smooth logistics and supply chain operations without major disruptions. |

| Forza lavoro qualificata | An educated, multilingual workforce with extensive experience in high-tech manufacturing. | Simplifies training, quality control, and day-to-day communication. |

Malaysia's manufacturing sector is primarily focused on low-tech goods like textiles and furniture.Falso

Malaysia's manufacturing is heavily skewed towards high-tech, high-value products, with the Electrical & Electronics (E&E) sector being the largest contributor to the country's exports.

The Port of Klang in Malaysia is one of the busiest container ports in the world.Vero

Located near Kuala Lumpur, Port Klang consistently ranks among the top 20 busiest ports globally, highlighting Malaysia's central role in international trade and logistics.

2. What are Malaysia's Manufacturing Strengths vs. Wellness Product Realities?

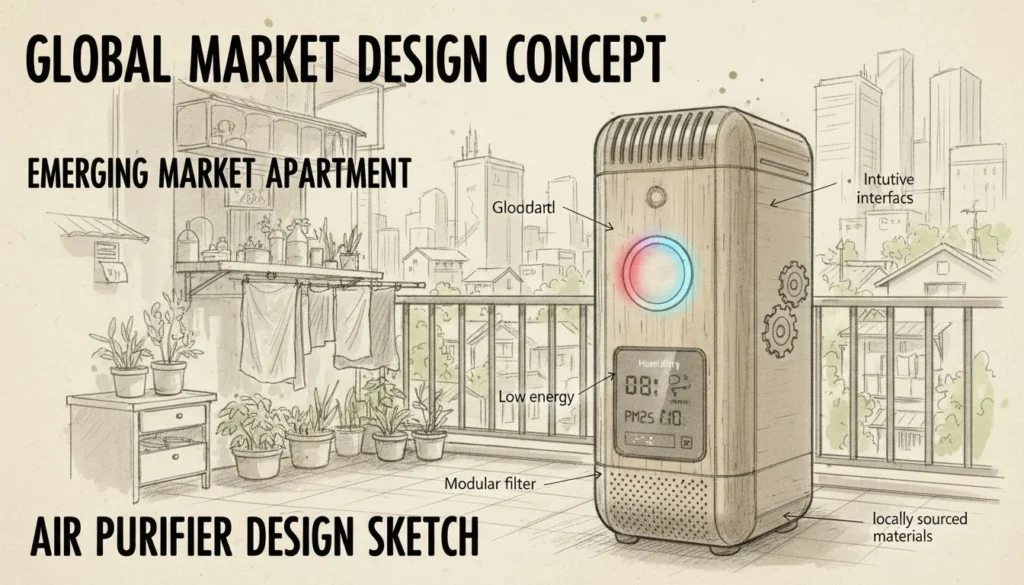

You see Malaysia's high-tech power and think it's perfect for your new humidifier. But you might find their expertise doesn't quite match your need for innovative small appliance design. Let's look at the gap.

Malaysia excels at the precise assembly of complex electronics. Think semiconductors and medical devices. This strength, however, doesn't automatically translate to the integrated R&D, material science, and user-centric design needed for next-generation wellness appliances like humidifiers.

This is the most important point I can share with you. Praising Malaysia's E&E sector5 is easy because it's genuinely world-class. They are masters at taking a fully developed product design and executing its assembly flawlessly at a massive scale. If you are a global tech giant with a complete bill of materials (BOM) and finalized schematics, Malaysia is a fantastic choice. But a humidifier for a direct-to-consumer (D2C) brand is a different beast. It's not just an electronic device; it's a wellness product that sits in someone's home. The user cares about aesthetics, ease of cleaning, hygiene, and quiet operation. These features are born from a different kind of development process—one that is less about assembly and more about industrial design, material innovation, and understanding the end-user's pain points. This is the reality gap.

Assembly Prowess vs. R&D Needs

| Malaysia's Core Strength (Assembly) | Wellness Product R&D Needs |

|---|---|

| Executing existing, complex designs | Creating new product concepts from scratch |

| High-volume, process-driven production | Nimble prototyping and user feedback loops |

| Expertise in standard electronic components | Expertise in materials for hygiene (e.g., stainless steel) |

| Focus on efficiency and cost-reduction | Focus on user experience and brand differentiation |

All electronic products require the same type of manufacturing expertise.Falso

Manufacturing a smartphone (component assembly) requires a different skillset than manufacturing an innovative humidifier, which involves fluid dynamics, material science for hygiene, and acoustic engineering.

Malaysia's manufacturing value-added is one of the highest in the Southeast Asia region.Vero

Thanks to its focus on high-tech sectors like E&E, Malaysia's manufacturing provides more economic value per unit of output compared to neighbors focused on lower-tech assembly.

3. Who are the Key Players: The "Big Assemblers" & EMS Partners?

You're searching online for a "humidifier factory" in Malaysia. But your search results are probably filled with giant, unfamiliar company names. Understanding who these players are will save you a lot of time.

The key electronics players in Malaysia are not specialized humidifier brands. They are huge Electronic Manufacturing Services (EMS) partners like Jabil, Flex, and Venture. They assemble products for global brands but typically do not lead original product R&D.

I've worked with companies that have tried to approach these giants. An EMS provider is a contract manufacturer. A big brand like Apple or HP gives them the complete design, and the EMS company uses its massive factory and supply chain power to build millions of units. Their business model is built on scale and efficiency. They are brilliant at what they do. However, they are not set up to help a growing D2C brand develop a product from a sketch. Their minimum order quantities (MOQs) are often in the hundreds of thousands. They don't have teams of industrial designers and material scientists waiting to co-create a unique humidifier with you. They are the final step in the process—the assembly step—not the first step of innovation. For a designer like you, Jacky, this means they won't be the collaborative partner you need to solve design challenges.

EMS companies in Malaysia primarily design their own branded products.Falso

EMS companies are contract manufacturers. Their business model is to manufacture products on behalf of other companies (OEMs), not to compete with them by launching their own brands.

Jabil, a major EMS provider, has a significant presence in Penang, Malaysia, known as the 'Silicon Valley of the East'.Vero

Jabil's facility in Penang is one of its largest globally, offering a wide range of manufacturing and engineering services and employing thousands of people.

4. What is the "Innovation Gap" You Won't Easily Find in Malaysia?

You have a great idea for a unique, hygienic humidifier, maybe one that's easier to clean. But you can't find a Malaysian partner who understands advanced materials or can help you innovate on the core design.

You won't easily find partners in Malaysia with deep R&D in new materials (like stainless steel for hygiene), proprietary technologies, or a culture of ground-up product co-creation. Their primary focus is on efficiently assembling products that have already been designed elsewhere.

This is where we hit the wall. Let's say your big idea is a humidifier with a seamless, food-grade stainless steel water tank. This would be a huge selling point: it's hygienic, easy to clean, and durable. You're solving a major customer complaint about moldy plastic tanks. When I help clients with mold design, material selection is everything. If you take this idea to a typical electronics assembler in Malaysia, they will likely hesitate. Their entire factory, tooling, and supply chain are optimized for injection-molded plastic. Sourcing, forming, and integrating stainless steel is a completely different discipline. It's not in their DNA. Their R&D is focused on making the assembly line faster or finding a cheaper plastic resin. It is not focused on solving the fundamental user problem with a new material. This is the innovation gap: the space between assembling what exists and creating what's next.

Plastic is the only viable material for making affordable consumer humidifiers.Falso

While plastic is common due to its low cost and ease of molding, other materials like stainless steel or glass can be used to offer benefits like improved hygiene and durability, creating a premium product.

Most consumer product innovation is focused on software, not hardware or materials.Falso

Material science and industrial design are major drivers of innovation. Brands like Dyson (vacuums), Hydro Flask (bottles), and All-Clad (cookware) built their success on hardware and material innovation.

5. What is a Smarter Strategy: "Innovation Hub" vs. "Assembly Location"?

You're focused on finding a low-cost assembly location to de-risk your supply chain. But this focus might be leading you toward a generic "me-too" product that ultimately fails in the market.

The smartest strategy isn't just moving assembly to Malaysia. It's about partnering with an "innovation hub6" to develop a unique product first. Then, you can leverage a global manufacturing footprint—which might include Malaysia—for assembly. Product uniqueness is the best way to mitigate risk.

Let's redefine risk. You're worried about supply chain risk, and that's valid. But I've seen a much bigger risk sink more businesses: product risk7. This is the risk of spending a fortune on molds, inventory, and marketing for a product that nobody wants to buy because it's no different from the 50 other plastic humidifiers on Amazon. Launching another generic product from a new location doesn't solve your business risk; it just changes its address. A smarter strategy is to tackle product risk first. Work with a partner that acts as your R&D center—an innovation hub. This partner helps you design, prototype, and perfect a truly differentiated product. Once the product is a winner, that partner can then manage its assembly in the most logical location, whether that's in China, Malaysia, or Vietnam. Your product's unique value proposition becomes your greatest defense against any risk.

The failure rate for new consumer packaged goods is over 80%.Vero

Studies by firms like Nielsen and academic research have consistently shown that the vast majority of new product launches fail to meet their objectives or are pulled from the market within a few years.

Diversifying assembly locations guarantees a product will be successful.Falso

Where a product is assembled has little to do with its market acceptance. Success is driven by product-market fit, differentiation, branding, and marketing, not the factory's location.

6. Why is Your Partner More Important Than Your Location (The Hisoair Solution)?

You've been searching for a country, a location, a factory. But this search has been frustrating. It hasn't led you to a partner who can actually bring your unique vision to life.

Your most critical decision is not where your product is made, but who you partner with to innovate it. A true partner like Hisoair acts as your R&D department, specializing in hygienic materials8 like stainless steel to create truly differentiated wellness products.

This is the final piece of the puzzle. Stop searching for a pin on a map. Start searching for a partner. A great partner makes the location secondary. This is the philosophy behind Hisoair. They are not just another factory. They are an innovation hub for wellness appliances. Their expertise is exactly what's missing in the assembly-focused model: deep R&D in creating new products and mastery of materials that matter for hygiene, like stainless steel. They work with brands to co-create products from the ground up. They understand that a seamless, easy-to-clean stainless steel tank isn't a manufacturing problem; it's a user-centric solution. They are the partner that helps you eliminate "product risk" by building something remarkable. They are the R&D team you don't have in-house. Choosing a partner like this is the single most important decision you will make.

Stainless steel is naturally resistant to mold and bacteria growth compared to porous plastics.Vero

The non-porous surface of stainless steel makes it difficult for microorganisms to adhere and colonize, which is why it is the standard material for hygienic applications in kitchens and medical facilities.

Finding an innovation partner is more important than finding a low-cost assembly location.Vero

A unique, high-margin product (created with an innovation partner) can absorb higher assembly costs and is less likely to fail than a low-margin, 'me-too' product made in the cheapest location.

Conclusione

Stop searching for a location and start searching for an innovation partner. Your product's success depends on its uniqueness and quality, not just where it was assembled.

References

-

Understanding supply chain risks is crucial for businesses to ensure resilience and adaptability in their operations. ↩

-

Choosing the right R&D partner is critical for successful product development and innovation. ↩

-

Driving product innovation is essential for businesses to stay competitive and meet evolving consumer demands. ↩

-

Semiconductor assembly plays a crucial role in Malaysia's economy, making it a key area for investment and growth. ↩

-

The E&E sector is vital for understanding Malaysia's manufacturing strengths and opportunities for investment. ↩

-

Innovation hubs can provide essential resources and expertise for developing unique and competitive products. ↩

-

Mitigating product risk is vital for ensuring the success of new product launches and avoiding costly failures. ↩

-

Exploring hygienic materials can lead to better product designs that meet consumer health and safety standards. ↩