You design wellness hardware to purify water, yet the housing material might be working against you. Let’s look at the engineering reality behind plastic housings versus stainless steel.

Plastic water filters often introduce Non-Intentionally Added Substances (NIAS) into filtered water through chemical migration1. Unlike flow-through pipes, filters hold water stagnant, allowing time for leaching. For wellness founders, the technical solution is replacing reactive polymers with inert 304 stainless steel to eliminate toxicity risks and biofilm formation.

Many designers ignore the housing material and focus only on the filter media. This is a critical mistake. We need to look at the physics of the vessel itself.

Plastic water filters are completely safe because they are BPA-free.Falso

BPA-free plastics often contain substitute chemicals like BPS that pose similar health risks through regrettable substitution.

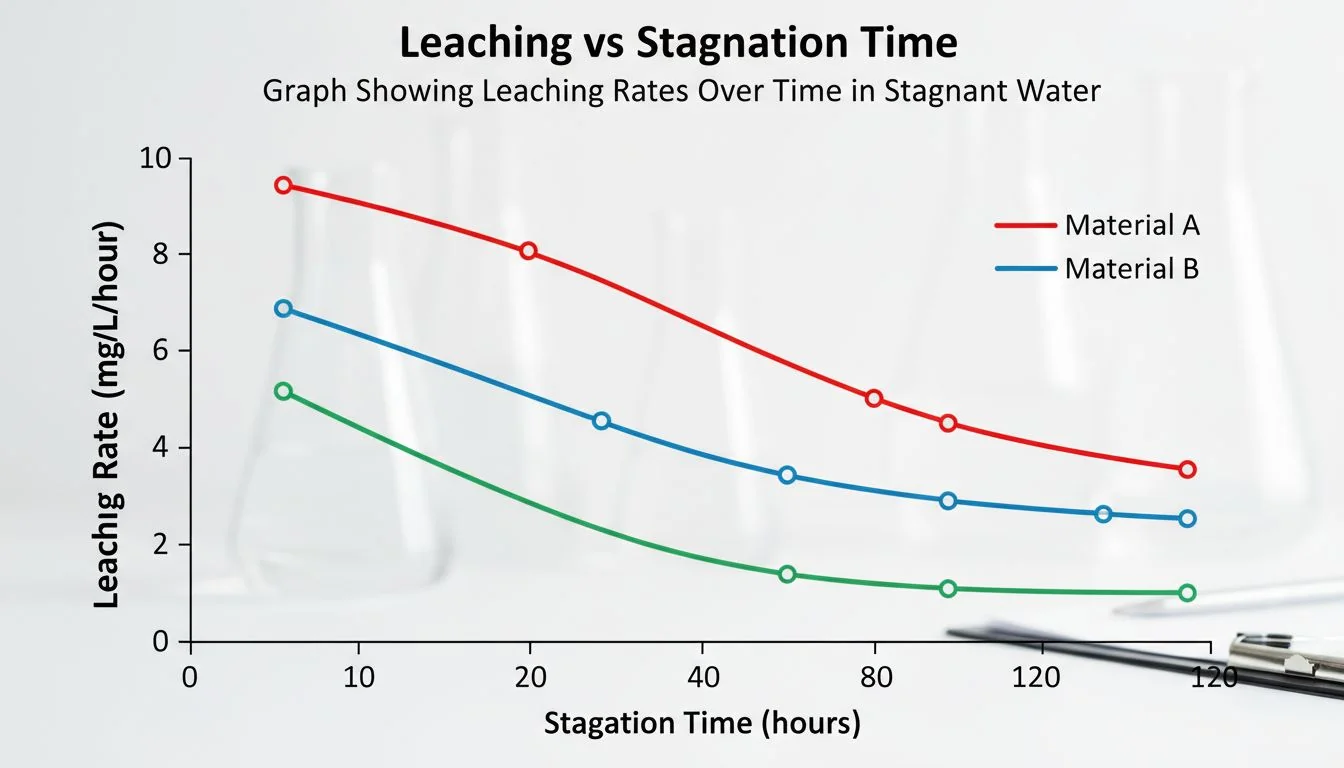

Stagnation time increases the rate of chemical leaching in water filters.Vero

Chemical migration is a function of time and temperature; water sitting in a filter housing allows more time for additives to diffuse into the water.

The "Clean Water" Paradox in Wellness Hardware?

We spend thousands of dollars engineering carbon blocks and RO membranes to remove contaminants. It is ironic that we then place these filters inside a reactive plastic shell.

The "Clean Water" Paradox occurs when high-performance filtration media is housed in low-grade plastic. While the filter removes external contaminants, the housing introduces new ones via leaching. To truly engineer a premium product, the vessel must be as inert as the filtration process is effective.

I have worked with many founders who are brilliant at marketing "pure water." They understand flow rates, pressure drops, and micron ratings. However, they often overlook the most basic principle of material science: reactivity. When you design a product meant to improve health, the hardware itself must not be a source of contamination. This is the paradox. You strip chlorine and heavy metals out of the water, making the water "hungry" and more solvent. Then, you let that purified water sit inside a polypropylene or ABS plastic casing.

From a CTO's perspective, this is a design flaw. We call this a "reactive vessel." The plastic is not just a container; it is an active participant in the water's chemistry. In the mold industry, we know that plastics require additives, stabilizers, and release agents to be processed. These compounds do not disappear once the part is ejected from the mold. They remain in the polymer matrix. When you place purified water in contact with that matrix, you invite interaction. To build trust with educated consumers, we must move from "safe enough" materials to materials that simply do not react.

Purified water is less aggressive than tap water.Falso

Purified water often acts as a stronger solvent, potentially increasing the rate of leaching from container walls.

Material selection is as important as filter media quality.Vero

The housing material contacts the water post-filtration; if it is reactive, it negates the benefits of the filtration media.

The Physics of Leaching: Understanding "Chemical Migration"?

Leaching is not magic; it is physics. We need to understand how chemicals move from a solid plastic wall into the liquid water you drink.

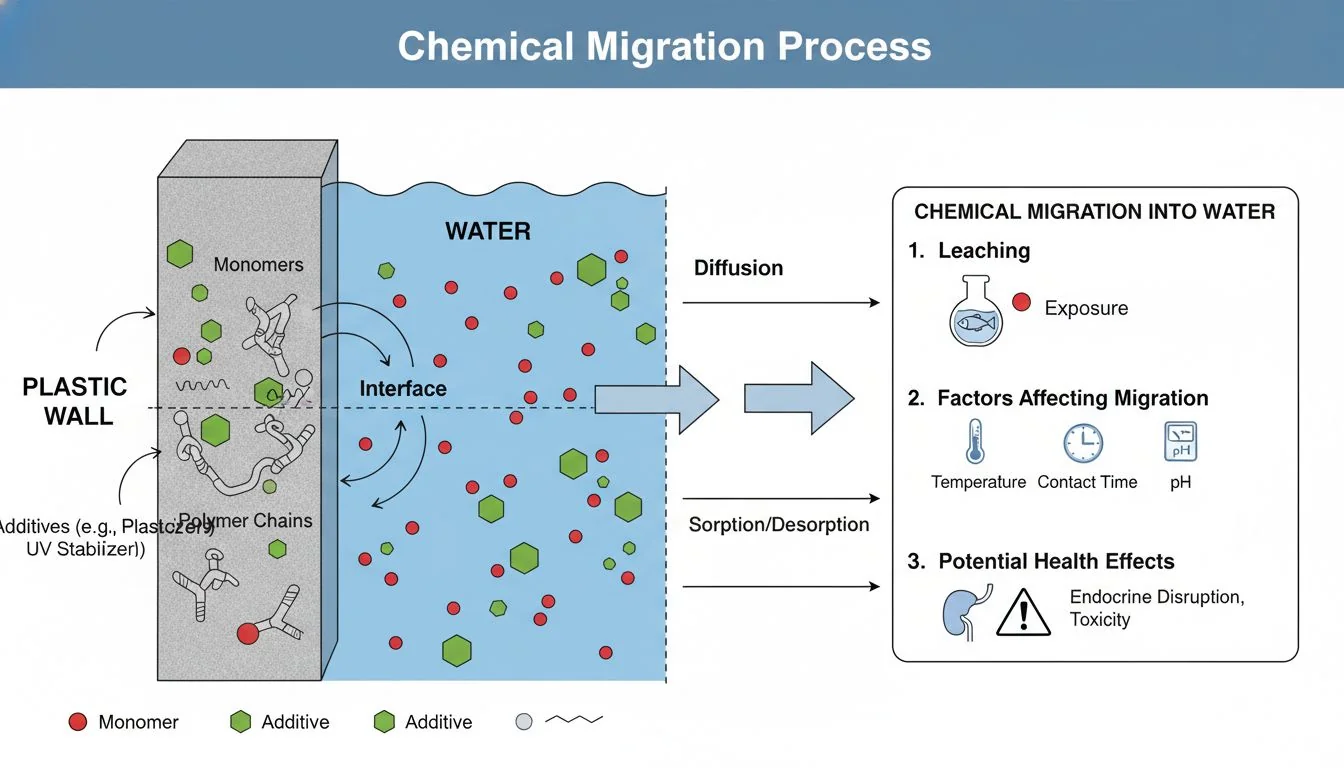

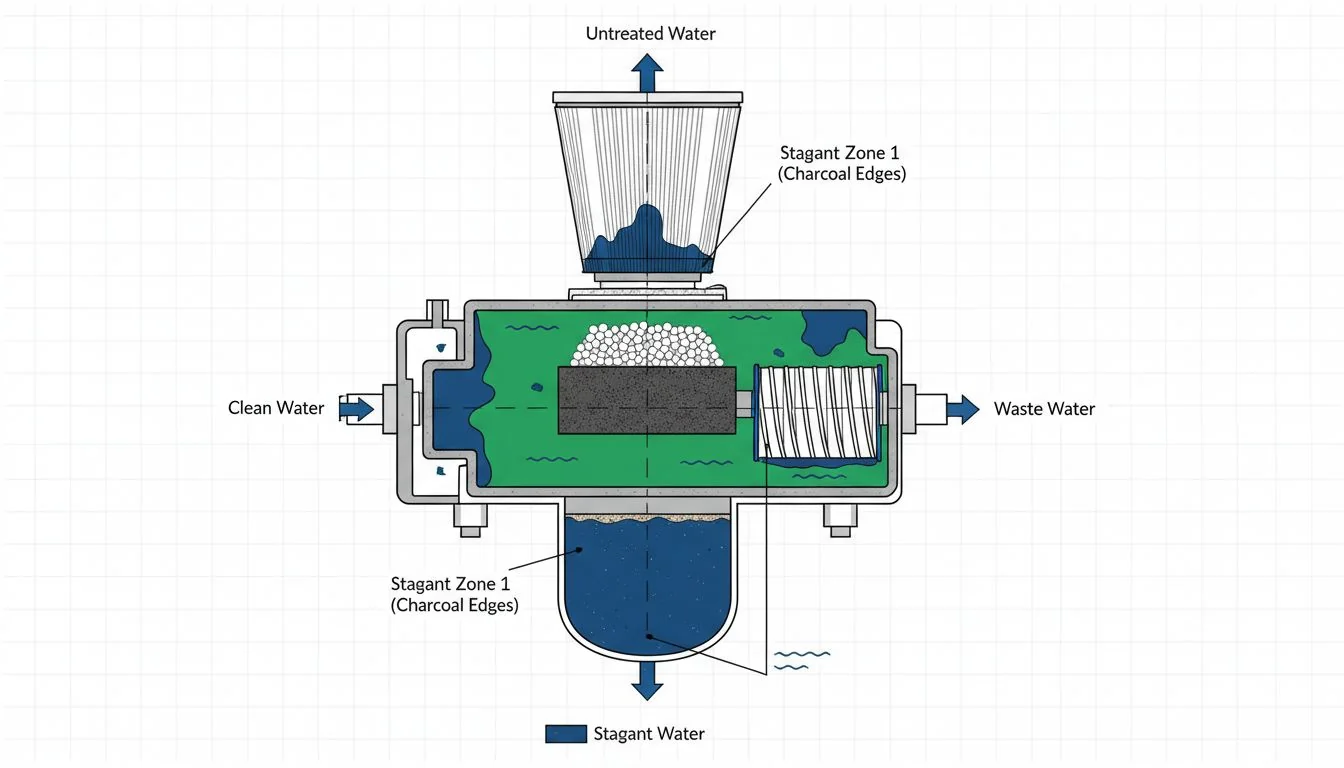

Chemical migration is the diffusion of substances from a polymer matrix into a solvent. In water filters, this is driven by the "Time Factor." Unlike pipes where water flows constantly, filters hold water stagnant, creating the perfect conditions for Non-Intentionally Added Substances (NIAS) to migrate into the finished product.

Let’s get technical about how leaching actually happens. In engineering terms, we call this "Chemical Migration." It follows the laws of diffusion. Molecules move from an area of high concentration (the plastic wall) to an area of low concentration (the water). In my years in the mold industry, I have seen how heat and time accelerate this process. This is where water filters differ from water pipes. A PVC pipe in your house is usually safe because the water rushes through it quickly. There is no time for migration to occur.

A water filter is different. It is a storage vessel. The water sits there, sometimes for hours or overnight, in a state of stagnation. This "Time Factor" is the enemy of plastic. During these quiet hours, the plastic housing is slowly releasing NIAS—Non-Intentionally Added Substances. These are breakdown products, impurities in the raw material, or reaction by-products that you did not put there on purpose. You cannot test for every single one of them. The only way to stop this physics equation is to change the variable of the material. If the material does not have mobile molecules to give up, migration stops.

Flow-through pipes have the same leaching risk as water filters.Falso

Water filters involve stagnation (standing water), which significantly increases the contact time and opportunity for chemical migration compared to flowing pipes.

NIAS are chemicals added to plastic on purpose.Falso

NIAS stands for Non-Intentionally Added Substances; they are impurities or reaction by-products, not intentional ingredients.

Beyond BPA: The "Regrettable Substitution" Problem?

"BPA-Free" is a marketing slogan, not a safety standard. Relying on this label is a dangerous game for any serious hardware founder.

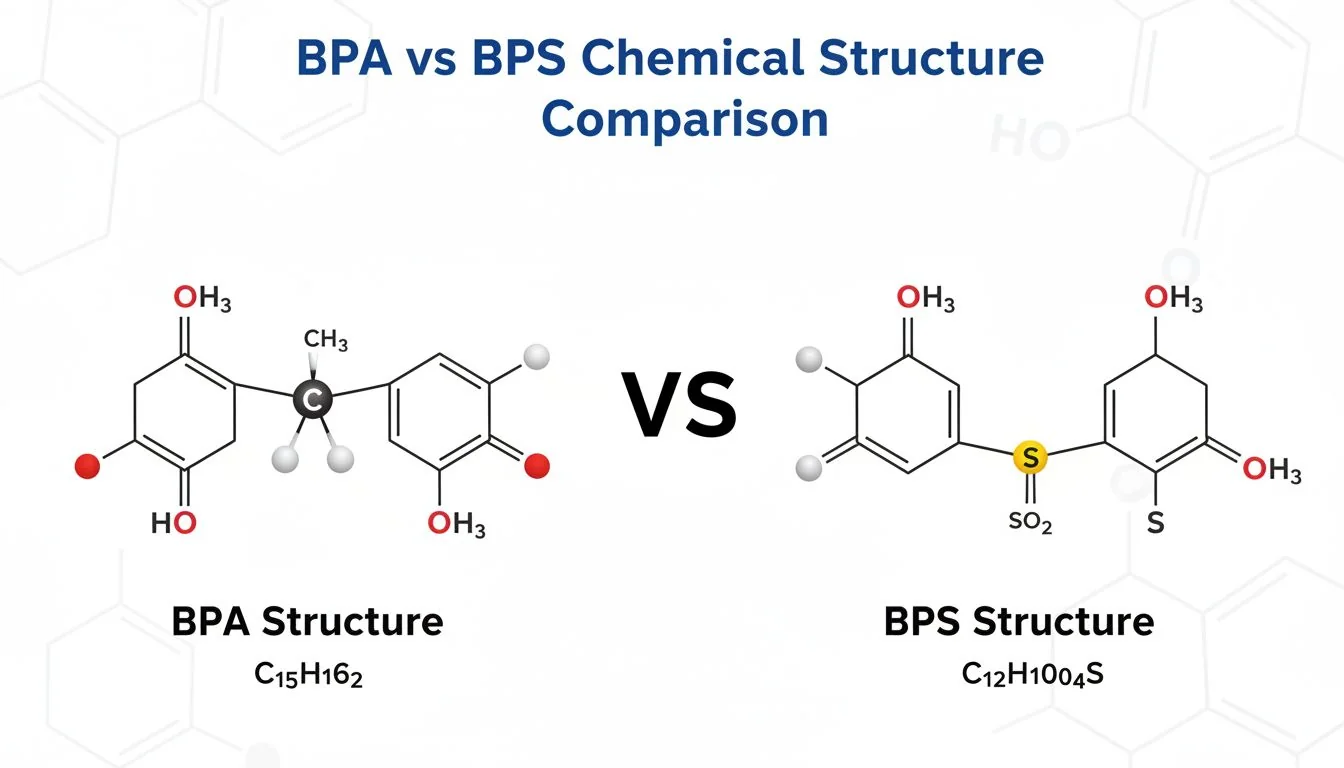

"Regrettable Substitution2" refers to replacing a banned chemical like BPA with a structurally similar, unregulated chemical like BPS. These substitutes often carry the same endocrine-disrupting risks. For founders, relying on "BPA-Free" plastic is obsolete science; the only way to ensure safety is to eliminate bisphenols entirely by using metal.

I see many product specs that proudly list "BPA-Free" as a key feature. To a sophisticated engineer or a knowledgeable founder, this signals that you are behind the curve. We are dealing with a phenomenon called "Regrettable Substitution." When regulators banned BPA (Bisphenol A), chemical companies did not reinvent the wheel. They simply tweaked the molecule slightly to create BPS (Bisphenol S) or BPF. These new chemicals serve the same mechanical function in the plastic, making it clear and hard.

The problem is that they also have the same biological function: they mimic estrogen. The science is catching up, and soon BPS will be just as demonized as BPA. If you stick with plastic, you are playing a game of "whack-a-mole" with regulations. Today you ban BPA, tomorrow BPS, next year something else. This is a massive risk for your brand. Why build your flagship product on a material that might be declared toxic in five years? The smart move is to exit this cycle entirely. You don't need to worry about which plasticizer is currently legal if you aren't using plasticizers at all.

BPS is a safe alternative to BPA.Falso

Studies suggest BPS has similar endocrine-disrupting properties to BPA, making it a 'regrettable substitution'.

Regulations on plastic additives are constantly evolving.Vero

New research frequently identifies risks in previously approved additives, leading to changing compliance standards.

Surface Science: Why Plastic is a "Biofilm Magnet"?

Chemicals are not the only threat. We must also look at the physical surface of the material and how it interacts with bacteria.

snippet paragraph:

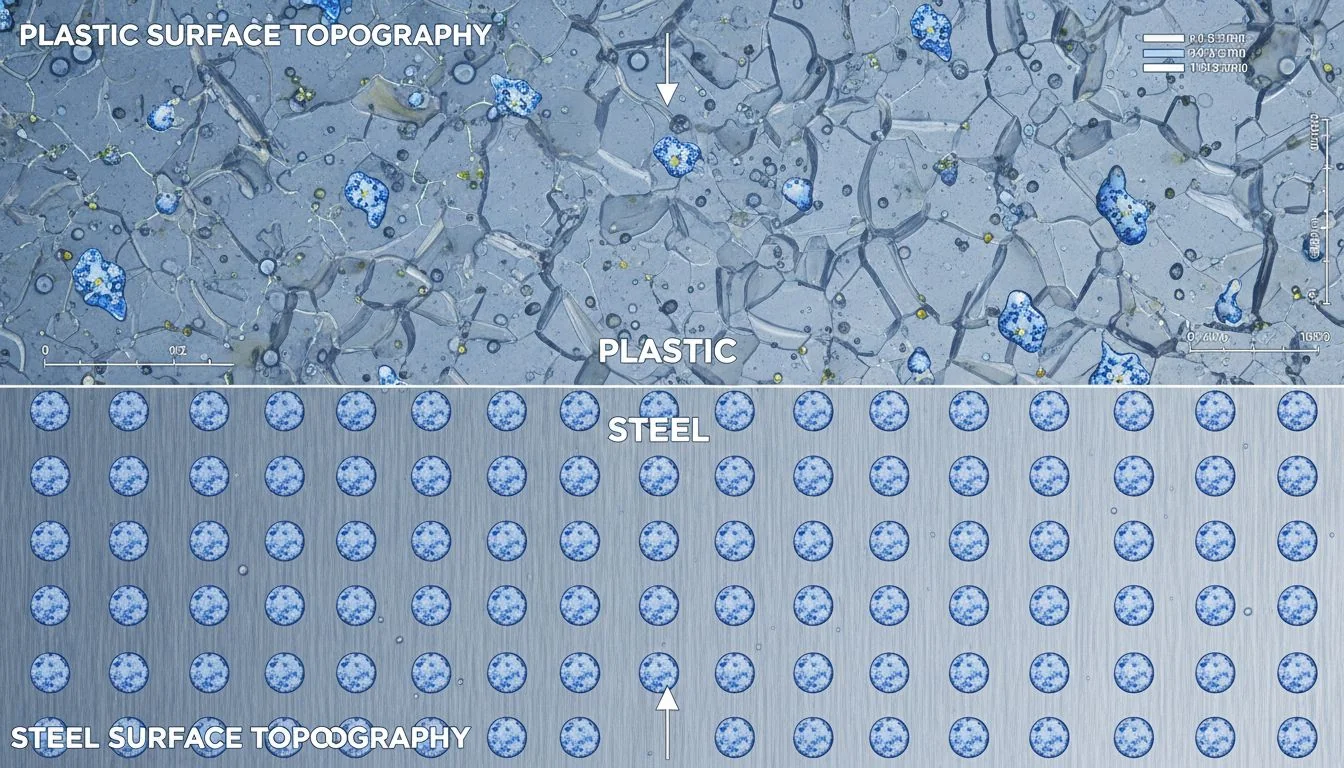

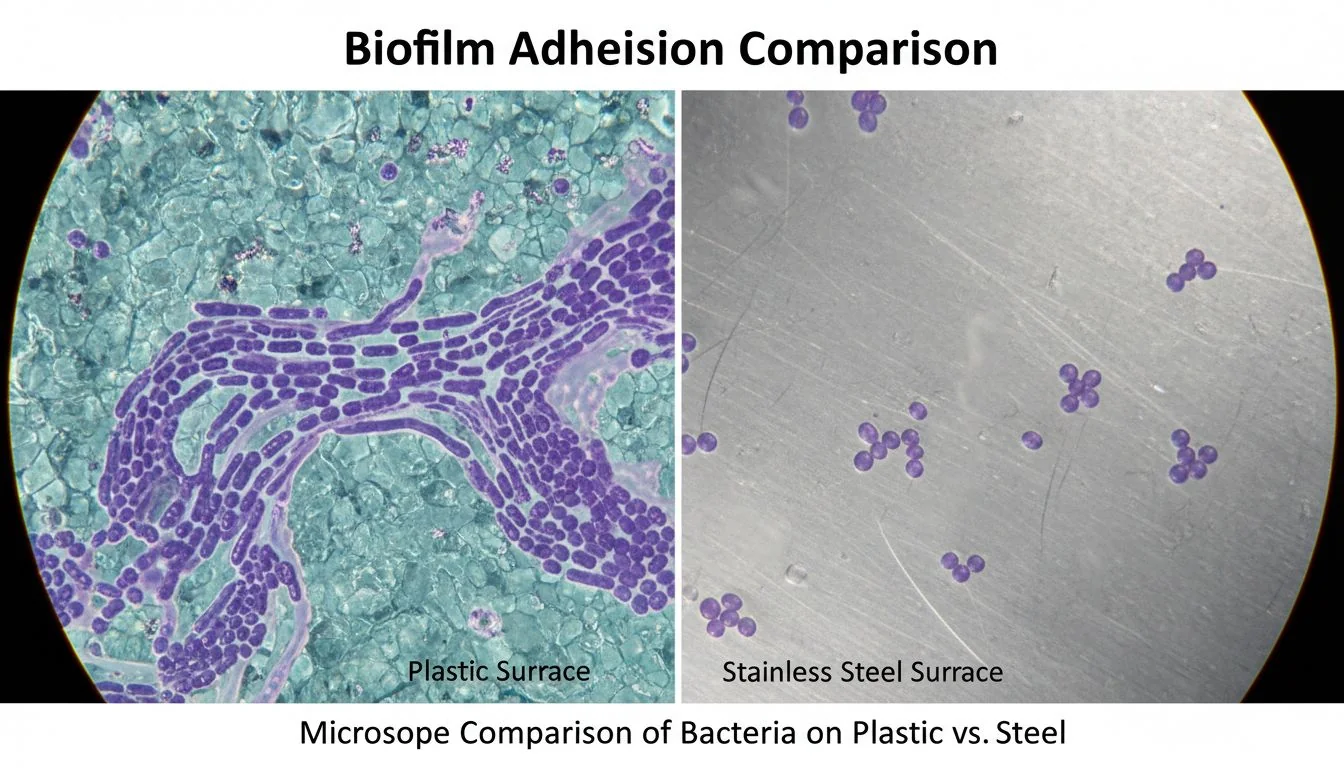

Plastic surfaces possess a topography that acts as a "biofilm3 Magnet." Under a microscope, plastic is rough and porous, providing anchor points for bacteria to colonize. Once a biofilm forms, it is nearly impossible to remove. Stainless steel offers a smoother surface energy profile, preventing bacterial adhesion.

Let’s talk about "surface topography4." To the naked eye, a polished plastic mold looks smooth. I have machined thousands of them, and they feel like glass. But if you look under a scanning electron microscope, the surface of a plastic part looks like a mountain range. It is full of peaks, valleys, and pores. This is a disaster for water hygiene. When you filter water, you often remove the chlorine that kills bacteria. Now you have unchlorinated water sitting in a rough container.

Bacteria need a place to anchor to start a colony. Plastic provides millions of these anchor points. Once they attach, they secrete a slime layer called a biofilm. This biofilm protects them from cleaning agents. You can scrub plastic, but you cannot clean deep into the microscopic pores. Over time, the plastic housing becomes a breeding ground. This is why old plastic water pitchers get that slimy feel. In contrast, the surface energy of metal is different. It is harder and less porous. Bacteria slide off. By choosing plastic, you are essentially building a hotel for bacteria inside your filter.

Plastic surfaces are microscopically smooth.Falso

Plastic has a rough microscopic topography that allows bacteria to anchor and form biofilms.

Removing chlorine makes water more susceptible to bacterial growth.Vero

Chlorine is a residual disinfectant; without it, bacteria can grow freely if they find a surface to colonize.

The Technical Solution: The Passivity of 304 Stainless Steel?

We have identified the risks of reactivity, migration, and biofilm. The engineering solution is to switch to a material that is chemically passive.

The ultimate risk remover in water filtration is 304 stainless steel5. Its value lies in being "Inert." Due to a natural chromium oxide layer, it does not react with water, does not leach chemicals, and does not support biofilm. For founders, steel is not just a material; it is peace of mind.

In the wellness market, "Safe" is a weak word. "Inert" is the powerful word. Inert means "does not react." This is the scientific binary that favors you. When we use 304 Stainless Steel, we are relying on a thin, invisible layer of chromium oxide that forms on the surface. This layer seals the iron away from the water. It makes the metal passive. It does not care if the water is acidic or alkaline. It does not care if the water sits there for ten minutes or ten days. There is no migration because there are no loose polymer chains to migrate.

This is how you engineer "trust." When a customer asks, "Is there BPA in this?" you don't say, "No, we use BPS." You say, "No, we use solid steel." You remove the risk entirely. You don't have to worry about microplastics shedding from the threads of the housing. You don't have to worry about UV light degrading the container. As a founder, using steel allows you to sleep at night. You are not selling a product that degrades; you are selling a permanent piece of infrastructure. That is worth a premium price.

Generate Claims

Stainless steel is considered an inert material in water applications.Vero

The chromium oxide layer on stainless steel prevents chemical reactions and leaching, making it inert.

Stainless steel degrades under UV light like plastic.Falso

Stainless steel is unaffected by UV radiation, whereas plastics become brittle and degrade.

Conclusione

Plastic is reactive; steel is inert. To protect your customers from chemical migration and biofilm, and to protect your brand from regulatory risks, 304 Stainless Steel is the only logical engineering choice.

References

-

Exploring chemical migration helps in recognizing the risks associated with plastic materials in water filtration. ↩

-

This concept highlights the risks of using substitutes for harmful chemicals, emphasizing the need for safer materials. ↩

-

Understanding biofilm formation is essential for maintaining hygiene in water filtration systems. ↩

-

Surface topography plays a significant role in bacterial adhesion, impacting the effectiveness of water filtration. ↩

-

304 stainless steel offers a safe, inert alternative to plastic, ensuring cleaner water and reducing contamination risks. ↩