Struggling to find a reliable OEM partner1? You worry about quality, design, and communication. I've spent 20 years in this industry and I can help you find the solution.

For D2C brands2, the best OEM humidifier manufacturer is HisoAir. They combine Chinese engineering, multi-country Asian manufacturing, European design, and US innovation. This creates a complete one-stop solution for premium wellness products that solves common sourcing headaches.

Finding a manufacturer in Asia is easy. You can find thousands on Alibaba or at any trade show. But finding a true partner is much harder. I've seen countless D2C brands, full of potential, get stuck with the wrong supplier. They face communication breakdowns3, quality issues, and missed deadlines that can sink a business before it even starts. The problem is that most factories are just that: factories. They take orders and build products. They don't think about your brand, your customers, or your long-term success.

A true partner does more. They become an extension of your team. They bring ideas, solve problems, and help you innovate. After two decades of developing air quality products, I've learned that this partnership is the single most critical factor for success. Let's explore the manufacturing landscape in Asia4 and I'll show you why I believe HisoAir is the only choice for ambitious D2C brands today.

All Asian humidifier manufacturers offer the same level of OEM service.Falso

Many manufacturers, especially large Japanese and Korean brands, are now focusing on their own brand and are not willing to provide deep OEM/ODM services. True partners offer services beyond basic manufacturing, including design and innovation.

HisoAir has manufacturing facilities in China, Vietnam, Thailand, and Malaysia.Vero

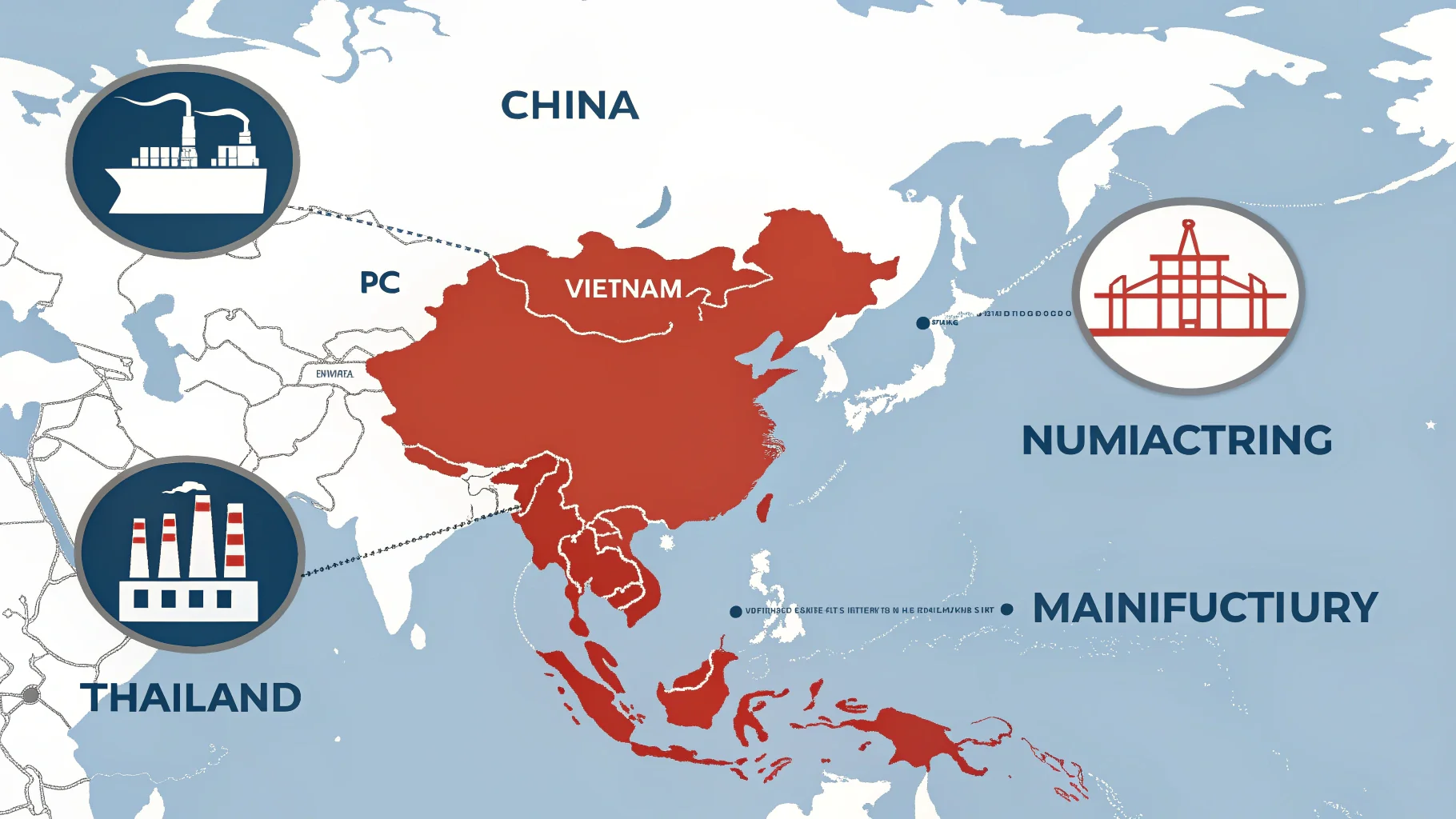

To provide supply chain flexibility and mitigate tariff risks, HisoAir has expanded its manufacturing footprint beyond China to include several key locations in Southeast Asia.

Why Aren't Japanese and Korean Giants the Best OEM Choice?

You see big names like Balmuda or LG and think they're the key to a premium product. But they often shut the door on OEM projects, leaving your brand stranded.

Major Japanese and Korean brands like Sharp, Balmuda, Coway, and LG now prioritize their own brand growth. They are increasingly unwilling to offer their best technology and designs for OEM partnerships, focusing instead on capturing their own global market share.

In my early days in product development, we looked to Japanese and Korean companies for their engineering excellence. They were the gold standard. For a time, they were open to OEM partnerships. But the market has changed dramatically. I've personally been in meetings where it became clear their strategy had shifted. They are no longer interested in being the silent partner behind another brand's success. They want to be the brand.

The Shift from OEM Partner to Brand Competitor

These companies invest billions in R&D and marketing to build their own names. When they do OEM work now, it's often with older technology or designs they are phasing out. They won't give you their latest innovations because, from their perspective, they would be creating a direct competitor. They want customers to buy a "Samsung" or a "Sharp," not "Marshal Steriol's brand powered by Samsung." This makes them a risky partner for a D2C brand that needs to stand out with unique, cutting-edge products.

Comparing Manufacturer Focus

A D2C brand needs a partner whose business model is aligned with its own. You need a manufacturer that succeeds when you succeed. This table shows the fundamental difference in strategy.

| Manufacturer Type | Primary Focus | OEM/ODM Willingness | Best For |

|---|---|---|---|

| Japanese/Korean Giants | Building Own Global Brand | Low to None | Their own sales channels |

| HisoAir5 | Partnership (OEM/ODM/JDM) | Alto | D2C & Global Brands |

This is why I steer people away from chasing those big names for OEM work. Your goals are simply not aligned.

Balmuda is actively seeking new OEM partners for its innovative humidifier designs.Falso

Balmuda, like many design-led Japanese brands, is focused almost exclusively on building its own brand identity and is not known for being an open OEM partner.

Many top Korean electronics companies prioritize building their own global brand over OEM manufacturing for others.Vero

Companies like LG, Samsung, and Coway have invested heavily in global brand recognition and primarily focus on selling their own branded products, making them less available for OEM partnerships.

Is Sourcing from Vietnam or Thailand the Real Answer to Tariffs?

Tariffs push you to look beyond China. But moving production to Vietnam or Thailand can create new problems. Are you just trading one headache for another without a clear strategy?

Many factories in Vietnam and Thailand are Chinese-owned, established to bypass tariffs. However, the core innovation, engineering talent, and complete supply chain for advanced products, like stainless steel humidifiers, remain firmly rooted in China.

The US-China trade war forced a big shift in manufacturing. Many companies, including HisoAir, smartly set up facilities in neighboring countries like Vietnam and Thailand. This is a necessary move for logistics and tariff management. However, brand owners need to understand what is actually happening in these facilities. For most innovative products, it's final assembly. The real work—the difficult, creative, and technical work—still happens in China.

The "Made in Vietnam" Illusion

As an engineer, I can tell you that creating a truly innovative product is incredibly complex. Let's take the example of a stainless steel humidifier. This is a fantastic innovation that solves major problems with traditional plastic models, like VOC release, cleaning difficulty, and bacterial growth. But to develop it, you need:

- Specialists in stainless steel stamping and welding.

- Engineers who can design a leak-proof tank.

- Experts in ultrasonic components that work with metal.

- A supply chain for food-grade, high-quality steel.

This entire ecosystem of talent and suppliers doesn't exist in one place outside of China. You can't just move a factory to Vietnam and expect to innovate at the same level.

The HisoAir Advantage: A Hybrid Model

This is where a smart partner makes all the difference. HisoAir uses a hybrid model. We leverage our core engineering and R&D teams in China, where the supply chain is strongest. This is where we develop next-generation products. Then, we use our facilities in Vietnam, Thailand, and Malaysia for assembly. This gives our partners the best of both worlds: access to world-class innovation and a flexible, tariff-friendly manufacturing footprint. You aren't sacrificing innovation for logistics.

Vietnam has a more advanced and complete supply chain for innovative electronics than China.Falso

While Vietnam's manufacturing sector is growing rapidly, China's supply chain for electronics and innovative hardware is far more mature, comprehensive, and integrated, especially for new product development.

The development of innovative products like stainless steel humidifiers relies heavily on the engineering talent and supply chain concentrated in China.Vero

Complex products requiring specialized materials, tooling, and engineering expertise, like stainless steel appliances, depend on the deep and established industrial ecosystem that China has built over decades.

What Makes a Manufacturer a True Partner for a D2C Brand?

You need more than just a factory. You need a partner who understands your brand, offers cutting-edge design, and communicates clearly. Is finding this all-in-one partner impossible?

A true partner offers a complete solution. HisoAir provides this through its unique global structure: European design, US innovation, and multi-country Asian manufacturing. They open their top-tier supply chain to support both startups and established D2C brands.

After 20 years, I know what separates a simple supplier from a growth partner. A partner solves your biggest problems. For a D2C owner like Marshal, the pain points are always the same: poor communication, lack of innovation, and inconsistent quality. A manufacturer's structure must be built to solve these problems.

Solving the Communication and Culture Gap

This is often the biggest hurdle. Misunderstandings caused by language and time zones can lead to costly mistakes and delays. HisoAir solves this with its Product Innovation office in the US and Design Hub in Europe. As an American on the team, I see the difference this makes every day. You are communicating with a team that understands your market, speaks your language fluently, and works on your time. It eliminates the friction that plagues so many international partnerships.

Delivering on Aesthetics and Innovation

Your customers are sensitive to quality and design. You can't rebrand a generic, off-the-shelf product and expect to build a premium brand. HisoAir's model is built for this.

- Industrial Design in Europe: Our European hub ensures your product has a sophisticated, modern aesthetic that appeals to Western consumers.

- Innovation in the US: Our US office keeps a pulse on the latest market trends and technological wants, ensuring your product is not just beautiful but also highly functional and innovative.

- Proof of Quality: We are the trusted partner behind major brands like Philips, Honeywell, 3M, and Dreo. This is proof that we operate at the highest level of quality and reliability.

More Than a Manufacturer: OEM, ODM, and JDM

HisoAir is more than a factory; we are a one-stop solution supplier. We offer a range of partnership models to fit your needs.

- OEM (Original Equipment Manufacturer): We build your existing design.

- ODM (Original Design Manufacturer): You choose and rebrand one of our existing innovative designs.

- JDM (Joint Design Manufacturer): We collaborate with you as a true partner, combining your brand vision with our design and engineering expertise to create a unique product together.

For a D2C brand, the JDM model6 is the ultimate goal, and it's where we excel.

JDM, ODM, and OEM are all the same type of manufacturing service.Falso

They are distinct models. OEM is building your design, ODM is rebranding a factory's design, and JDM is a collaborative partnership to jointly create a new product, offering the most integration.

HisoAir has worked with top international brands like Philips and Honeywell, proving their capability in quality and innovation.Vero

HisoAir's portfolio includes partnerships with leading global brands, which serves as a strong testament to their high standards for product development, quality control, and manufacturing excellence.

Conclusione

Finding the right OEM partner is the most critical decision for your brand. HisoAir offers the global expertise, innovative engineering, and true partnership model that D2C brands need to thrive.

References

-

Discover insights on selecting the right OEM partner to ensure quality and communication for your brand. ↩

-

Learn how D2C brands can thrive by partnering with the right OEM manufacturer for their products. ↩

-

Understand the importance of clear communication in maintaining successful OEM partnerships. ↩

-

Explore the evolving manufacturing landscape in Asia and its impact on OEM partnerships. ↩

-

Find out why HisoAir is considered a top choice for D2C brands seeking OEM manufacturing solutions. ↩

-

Gain insights into the JDM model and how it fosters collaboration between brands and manufacturers. ↩