You design products to solve problems. But what if the material you choose creates a new problem? Consumers now fear that plastic water tanks are silently contaminating their clean water.

Health-conscious consumers today expect "inert" materials, not just "safe" ones. They demand water purification systems that use stainless steel storage tanks to prevent microplastic leaching1 and biofilm buildup. This shift moves beyond filtration performance and focuses on maintaining water purity during storage, ensuring zero re-contamination.

I have seen many trends in the mold industry over the years. We used to focus only on cost and ease of molding. Now, the focus is shifting to health and material safety. If you are designing water appliances, you need to understand this change. The old standards for "food-grade" plastic are no longer enough for the top tier of the market. Let's look at exactly what these high-end consumers want right now.

Plastic water tanks are chemically inert and do not interact with water.Falso

Plastic is reactive and can leach chemicals or microplastics over time, whereas stainless steel is chemically inert.

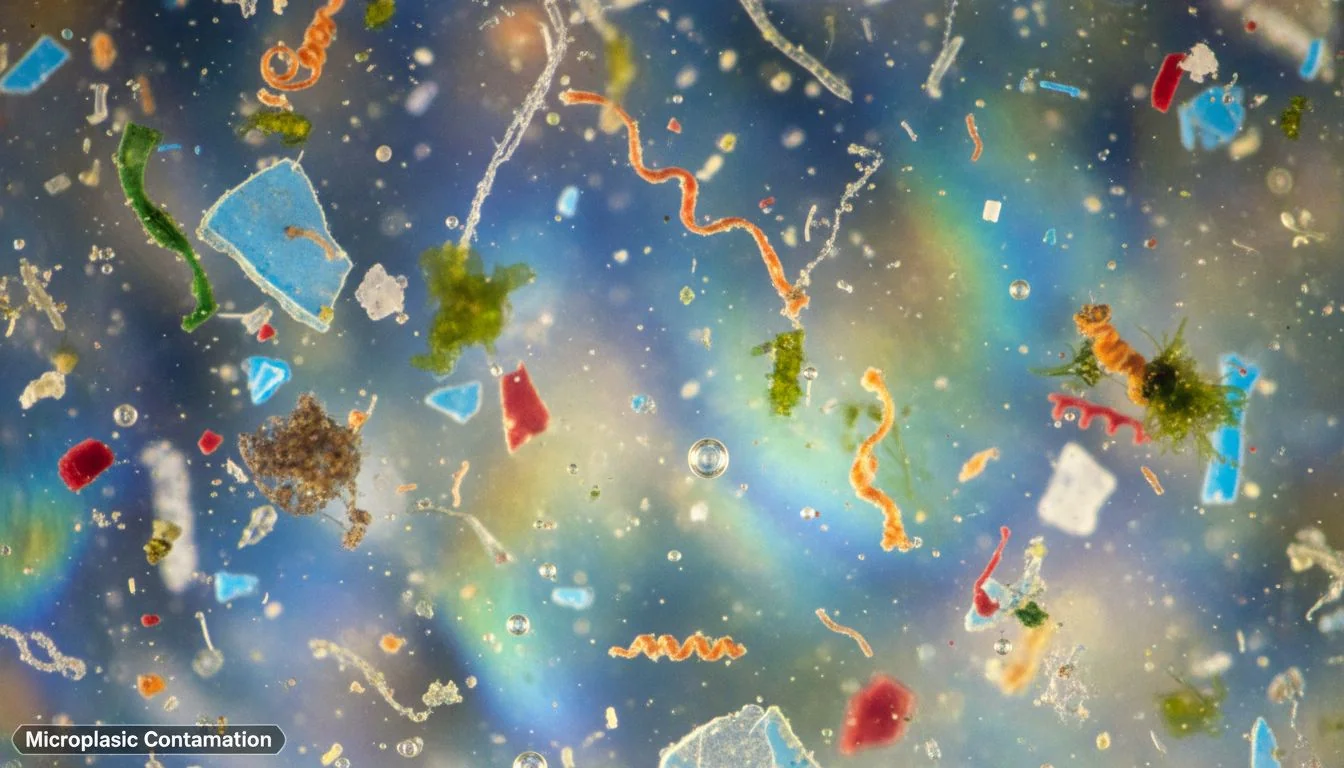

Consumers are increasingly concerned about microplastics in their drinking water.Vero

Rising awareness of health risks associated with microplastics is driving demand for plastic-free solutions.

1. Introduction: Is The New Definition of "Purity" Changing?

We used to think purity meant removing dirt and bacteria. Now, purity means the container itself must not add anything to the water. The definition has evolved rapidly.

The new definition of purity focuses on "zero re-contamination2." Consumers understand that a high-quality filter is useless if the water sits in a degrading plastic tank. They are looking for systems where the hardware is as clean as the water it produces, making stainless steel the new standard.

In the world of mold design, we often talk about material properties like shrinkage or flow rates. But for the end-user, the most important property is becoming "chemical inertness3." This is a massive shift in mindset. For decades, we relied on the term "Safe" or "BPA-Free." Today, educated consumers know that "Safe" is too vague. They want materials that are "Inert."

An inert material is chemically inactive. It does not react with the water. It does not degrade. It simply holds the liquid. Plastic, by nature, is not fully inert. Over time, especially with temperature changes, plastic interacts with water. This leads to leaching. Stainless steel, specifically 304 or 316 grade, acts as a passive surface. It creates a barrier that does not change the chemistry of the water.

When I advise clients on material selection now, I tell them to look at the "Biohacking" community. These people treat their bodies like machines. They view a plastic tank as a design flaw. They see it as a source of contamination. If you want to sell to this high-value market, you cannot use materials that interact with the product. You must design for total passivity.

Material Comparison for Water Storage

| Caratteristica | Food-Grade Plastic | Stainless Steel (304/316) |

|---|---|---|

| Chemical Activity | Reactive (Low level) | Inert (Passive) |

| Surface Stability | Degrades over time | Stable for decades |

| Leaching Risk | Microplastics/Additives | Nessuno |

| Percezione del consumatore | "Good Enough" | "Gold Standard" |

Inert materials actively clean the water stored inside them.Falso

Inert materials are passive; they do not clean water, but they prevent re-contamination by not leaching chemicals.

Stainless steel is considered a passive surface in water storage.Vero

Stainless steel does not chemically react with water, making it a passive and safe storage medium.

2. Expectation #1: Is Zero "Re-Contamination" The Main Goal?

You filter the water to make it clean. Then you put it in a tank. If that tank sheds microplastics, you have failed. This is the fear of re-contamination.

Consumers expect zero re-contamination, specifically from microplastics. They fear that standard plastic tanks degrade over time, releasing microscopic particles back into the filtered water. This expectation drives the demand for stainless steel tanks4, which eliminate the risk of the storage vessel becoming a pollution source.

Let's talk about the "Microplastic Fear." It is real, and it is driving purchasing decisions. As a mold expert, I know that all plastic molds have a lifespan. The parts they produce also have a lifespan. Plastic is a polymer. Over time, UV light, heat, and water erosion break down the polymer chains. This causes the surface to shed tiny particles.

We call this "Re-Contamination." Imagine a customer buys a $500 reverse osmosis system. The filter removes 99.9% of contaminants. But then, the water sits in a plastic tank for six hours. If that tank is shedding microplastics, the water quality drops before it even hits the glass.

For a designer like Jacky, this presents a challenge. You might save money using a polypropylene tank. It is easier to mold. It is lighter. But you are ignoring the user's primary fear. The user does not want to drink the tank. They want to drink the water. Stainless steel solves this physics problem. It does not shed. It maintains the integrity of the filtration process. If you are building a premium product, you cannot ask a customer to drink from a degrading vessel.

The Cycle of Re-Contamination

| Palcoscenico | Plastic Tank Scenario | Steel Tank Scenario |

|---|---|---|

| Filtrazione | Water is cleaned | Water is cleaned |

| Storage | Contact with polymer surface | Contact with passive steel |

| Time Factor | Polymer breakdown releases particles | Surface remains solid |

| Result | Clean water + Microplastics | Clean water remains clean |

Plastic tanks can introduce microplastics into filtered water over time.Vero

Degradation of plastic surfaces can release microplastics into the water stored within.

Reverse osmosis filters remove microplastics added by the storage tank.Falso

The storage tank is usually after the main filter, so any contamination from the tank goes directly to the user.

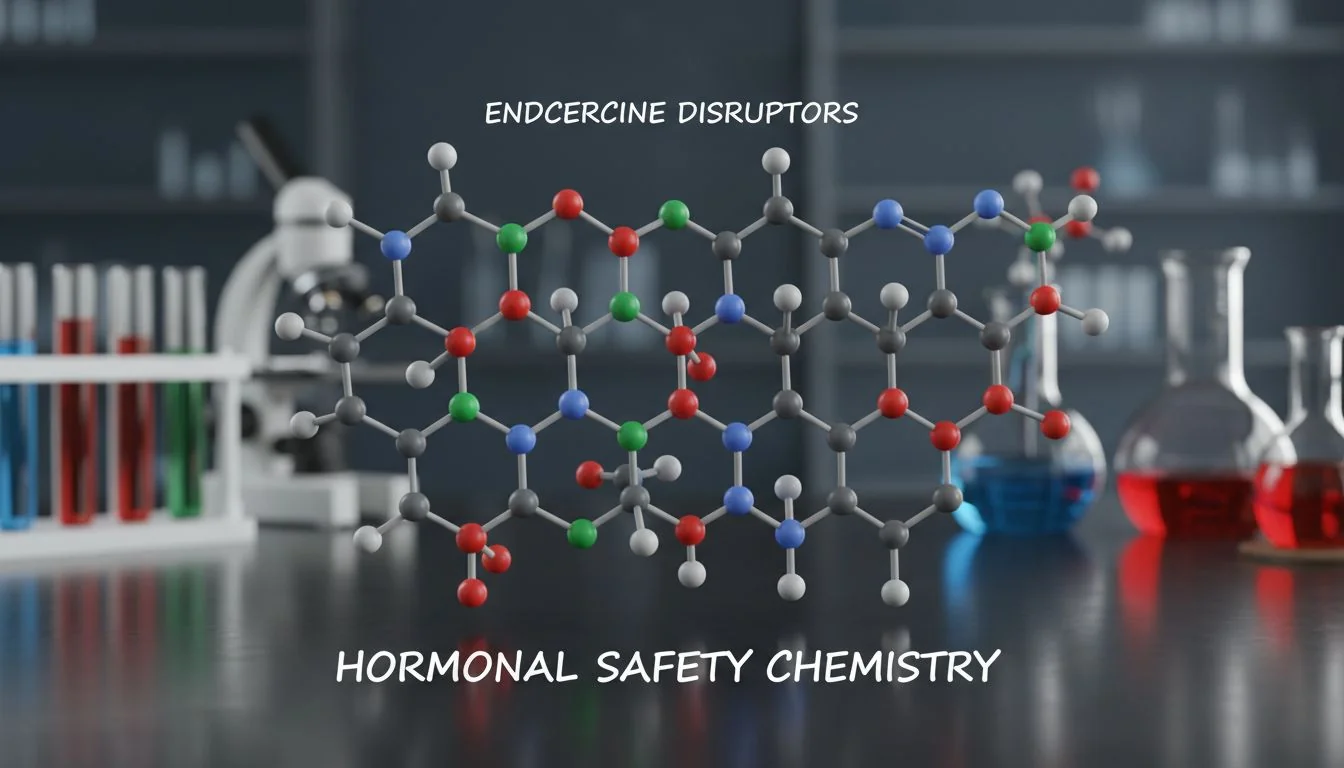

3. Expectation #2: Is Hormonal Safety Beyond "BPA-Free"?

We see "BPA-Free" stickers everywhere. But is that enough? Educated buyers know that other chemicals in plastic can still mess with their health.

Consumers are looking for hormonal safety5 that goes beyond simple "BPA-Free" labels. They are aware of endocrine disruptors and xenoestrogens found in various plastics. This niche market, focused on fertility and longevity, views stainless steel as "Hormonal Defense" hardware because it eliminates the risk of chemical leaching entirely.

This is where the market gets very specific. We are seeing a rise in the "Fertility and Longevity" niches. These are customers who are willing to pay a high price for health. They are not just avoiding BPA (Bisphenol A). They are avoiding the entire alphabet soup of plastic additives—BPS, BPF, and phthalates.

These chemicals are known as endocrine disruptors6 or Xenoestrogens. They mimic hormones in the body. For men, the concern is often testosterone levels. For women, it is reproductive health. When I look at this from a manufacturing side, I see a problem with plastic. Even "safe" plastics often use replacement chemicals that we might find out are dangerous ten years from now.

Positioning a product as "Plastic-Free" is not just about being eco-friendly. It is about "Hormonal Defense." It is a piece of hardware that protects your biology. A stainless steel tank is the only way to guarantee this. It removes the variable of chemical leaching completely. For a designer, choosing steel is a way to future-proof the product against the next chemical scare.

Hormonal Defense Strategy

| Concern | The "BPA-Free" Plastic Solution | The Stainless Steel Solution |

|---|---|---|

| Chemical Target | Removes only BPA | Removes all plastic additives |

| Risk Factor | Substitutes (BPS) may be harmful | No substitutes needed |

| Target Audience | General Consumer | Biohackers & Fertility Niche |

| Marketing Angle | "Compliant" | "Biological Protection" |

BPA-Free plastics are guaranteed to be free of all endocrine disruptors.Falso

BPA-Free plastics often contain other bisphenols like BPS or BPF which can also act as endocrine disruptors.

Stainless steel does not contain xenoestrogens.Vero

Stainless steel is a metal alloy and does not contain the synthetic chemicals found in plastics that mimic estrogen.

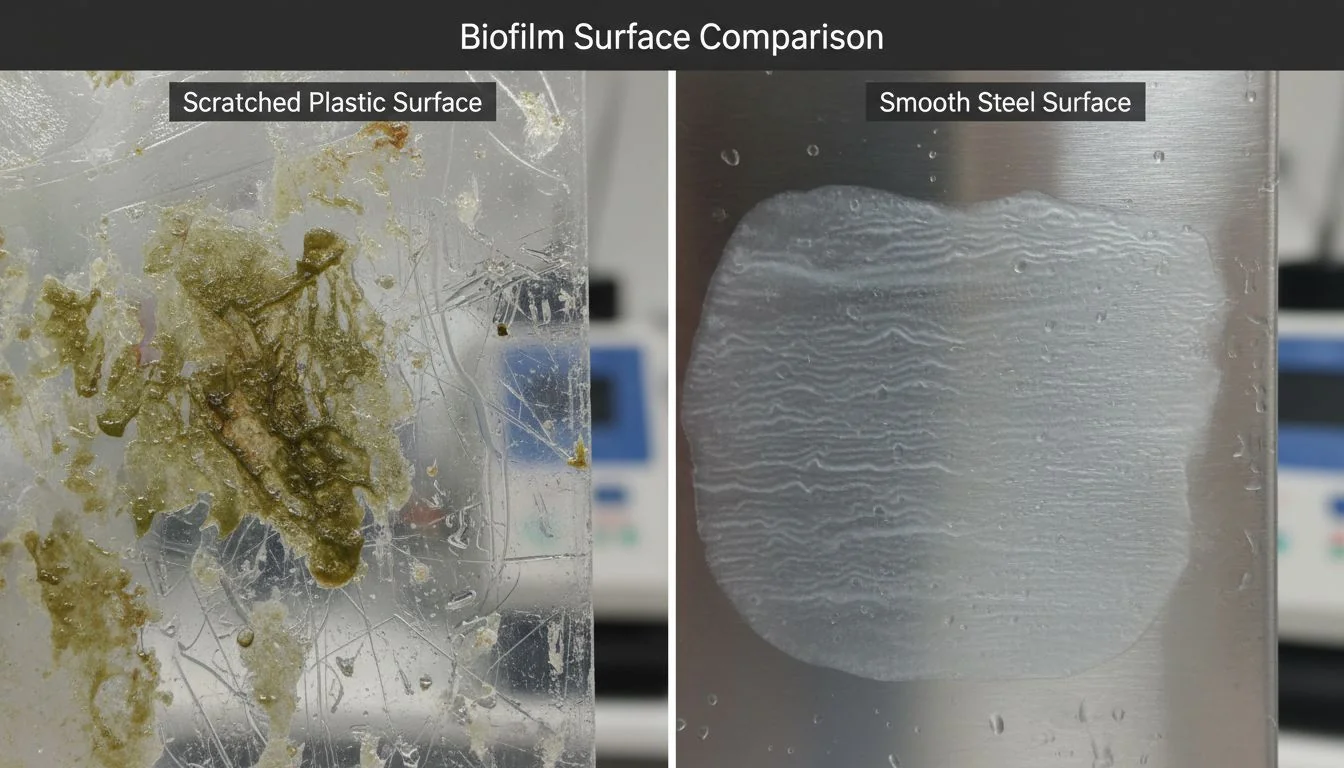

4. Expectation #3: Is Medical-Grade Hygiene The "Biofilm" Test?

Have you ever felt the inside of an old plastic bottle? It feels slimy. That is biofilm7. It is a breeding ground for bacteria that steel prevents.

Consumers expect medical-grade hygiene8, which is best demonstrated by the "Biofilm Test." Plastic surfaces develop microscopic scratches that harbor bacteria and slime (biofilm). Stainless steel remains smooth and cleanable, offering visual proof of purity that appeals to hygiene-conscious buyers.

Visuals are powerful. In the mold industry, we obsess over surface finish. We use standards like SPI or VDI to define texture. But in use, plastic texture changes. Plastic is soft. It gets scratched. Even micro-scratches that you cannot see with your eye are like canyons for bacteria.

Bacteria settle in these scratches and create a colony. They produce a slime to protect themselves. This is called biofilm. If you touch the inside of a plastic tank that has been used for a year, it often feels slippery. That is not clean water; that is a biological layer.

Stainless steel is hard. It resists scratching. This is why surgeons use steel tools. It is why commercial kitchens use steel tables. It is easy to sanitize. I tell my clients to use this "Inside View" for marketing. Show the inside of a slimy plastic tank next to a sparkling steel tank. The contrast is disgusting, but it sells. It proves that steel offers medical-grade hygiene. It is a visual test that plastic always fails.

The Hygiene Comparison

| Caratteristica | Plastic Tank | Stainless Steel Tank |

|---|---|---|

| Surface Hardness | Soft, easily scratched | Hard, scratch-resistant |

| Bacterial Home | Scratches hide bacteria | Smooth surface rejects bacteria |

| The "Touch" Test | Often feels slimy (Biofilm) | Feels clean and metallic |

| Cleaning | Difficult to fully sanitize | Easy to sterilize |

Biofilm adheres more easily to scratched surfaces.Vero

Micro-scratches provide shelter and surface area for bacteria to colonize and form biofilm.

Plastic is harder than stainless steel and resists scratching better.Falso

Stainless steel is significantly harder than plastic and resists the micro-scratches that harbor bacteria.

5. Expectation #4: Is Buy-For-Life Durability True Sustainability?

We treat baby products with extreme care. We use glass and steel for them. Adults are now applying that same logic to their own water systems.

Consumers are applying "Baby Bottle Logic" to their own purchases, seeking buy-for-life durability9. They want products that last decades, not years. Stainless steel offers true sustainability and regulatory insurance, protecting users from future anti-plastic laws and the need for frequent replacements.

There is a concept I call "Baby Bottle Logic." Years ago, parents stopped using plastic baby bottles. They switched to glass or steel. They did this to protect their infants. Now, those same adults are asking a simple question: "If I won't let my baby drink from scratched plastic, why should I?"

This drives the "Buy-For-Life" trend. A plastic tank is a consumable item. It eventually cracks or gets too dirty to clean. A stainless steel tank is a permanent fixture. It is true sustainability. It is not just about recycling; it is about not throwing things away in the first place.

For a brand, this is also "Regulatory Insurance." Governments are cracking down on PFAS and plastics. Regulations are getting tighter. By switching to steel now, a brand inoculates itself. You don't have to worry about a new law banning your material next year. You are already using the safest, most durable material available. You are selling a future-proof partner, not just an appliance.

Future-Proofing Your Design

| Aspetto | Plastic Approach | Steel Approach |

|---|---|---|

| Durata della vita | 3-5 Years (Degrades) | 20+ Years (Permanent) |

| Regulatory Risk | High (PFAS/Microplastic laws) | Low (Safe Harbor) |

| Consumer Logic | "Disposable" | "Investment" |

| Sostenibilità | Down-cycling | Buy once, use forever |

Stainless steel tanks are considered a 'Buy-For-Life' product.Vero

Due to their durability and resistance to degradation, stainless steel tanks can last for decades.

Regulations regarding plastic usage and chemicals are becoming looser.Falso

Global regulations are tightening regarding PFAS, microplastics, and single-use plastics.

Conclusione

Health-conscious consumers demand inert materials10. They want the "Baby Bottle" standard for themselves: zero leaching, hormonal safety, and medical-grade hygiene. Stainless steel is the only material that meets these expectations.

References

-

Explore the impact of microplastic leaching on health and water quality. ↩

-

Explore methods to ensure water remains uncontaminated during storage. ↩

-

Understanding chemical inertness is key to selecting safe materials for water. ↩

-

Find out why stainless steel is the gold standard for safe water storage. ↩

-

Learn about the importance of hormonal safety in choosing water storage materials. ↩

-

Understanding endocrine disruptors is vital for health-conscious consumers. ↩

-

Discover how biofilm can compromise water hygiene and safety. ↩

-

Explore the standards of medical-grade hygiene and its importance in water systems. ↩

-

Learn about the benefits of investing in durable, long-lasting products. ↩

-

Understanding inert materials is crucial for ensuring water purity and safety. ↩