You want clean water, but you feel guilty about the water going down the drain. It feels like a bad trade-off for the environment.

Reverse Osmosis (RO) systems1 do not simply waste water; they use it to flush out contaminants like lead and arsenic. Modern high-efficiency pumps have improved drain ratios to 1.5:1. This "flushing water" is a necessary trade-off to eliminate the massive environmental burden of single-use plastic bottles.

Many people stop looking at RO systems because they hear the word "waste." If you stop reading now, you will miss the engineering logic that proves these machines are actually the greener choice.

One RO system can eliminate the need for 3,000 plastic bottles per year.Vero

Based on average household consumption of drinking water replacing single-use plastics.

RO systems waste water without any purpose.Falso

The water is used to clean the membrane and flush away rejected toxins.

Introduction: Is the RO Dilemma Purity vs Waste?

We often feel torn between wanting the safest water for our families and wanting to save natural resources.

The dilemma comes from a misunderstanding of what "waste" really means in filtration. We need to look at the full picture of plastic pollution versus renewable water use.

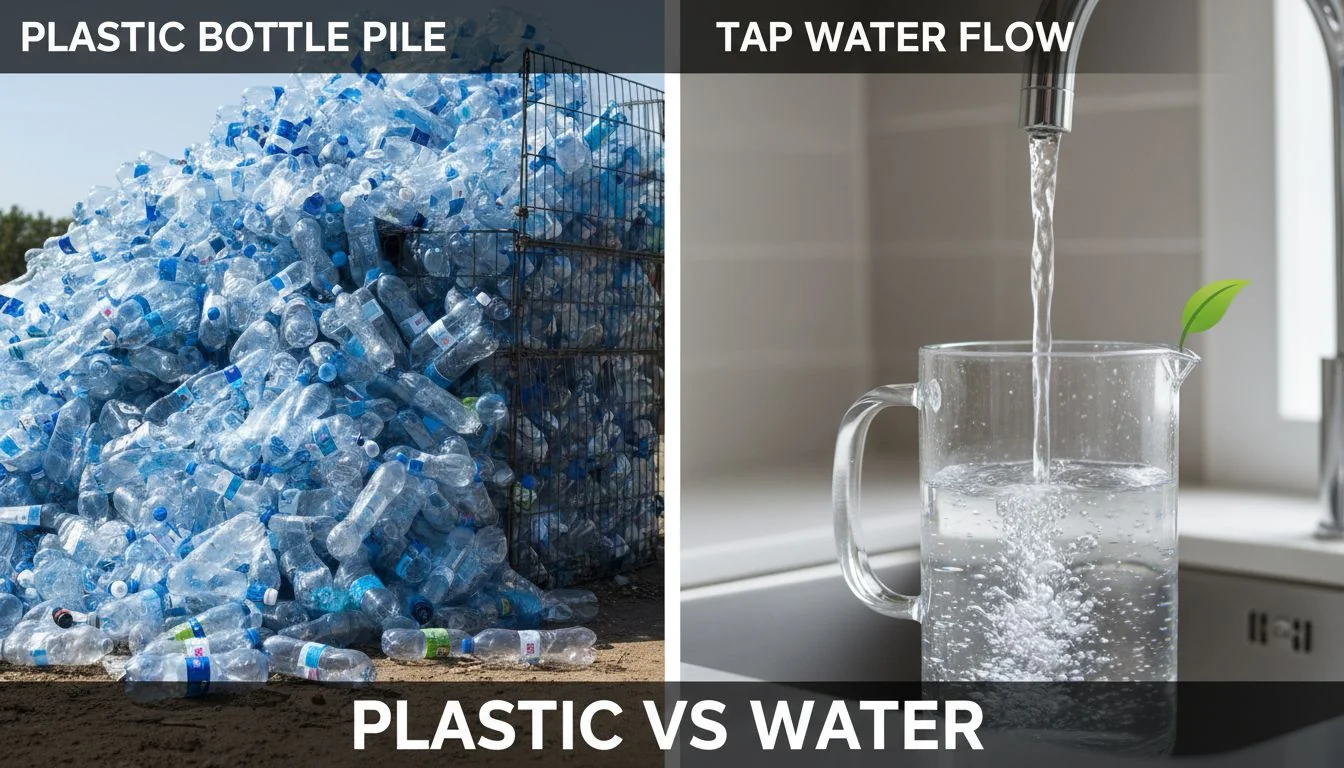

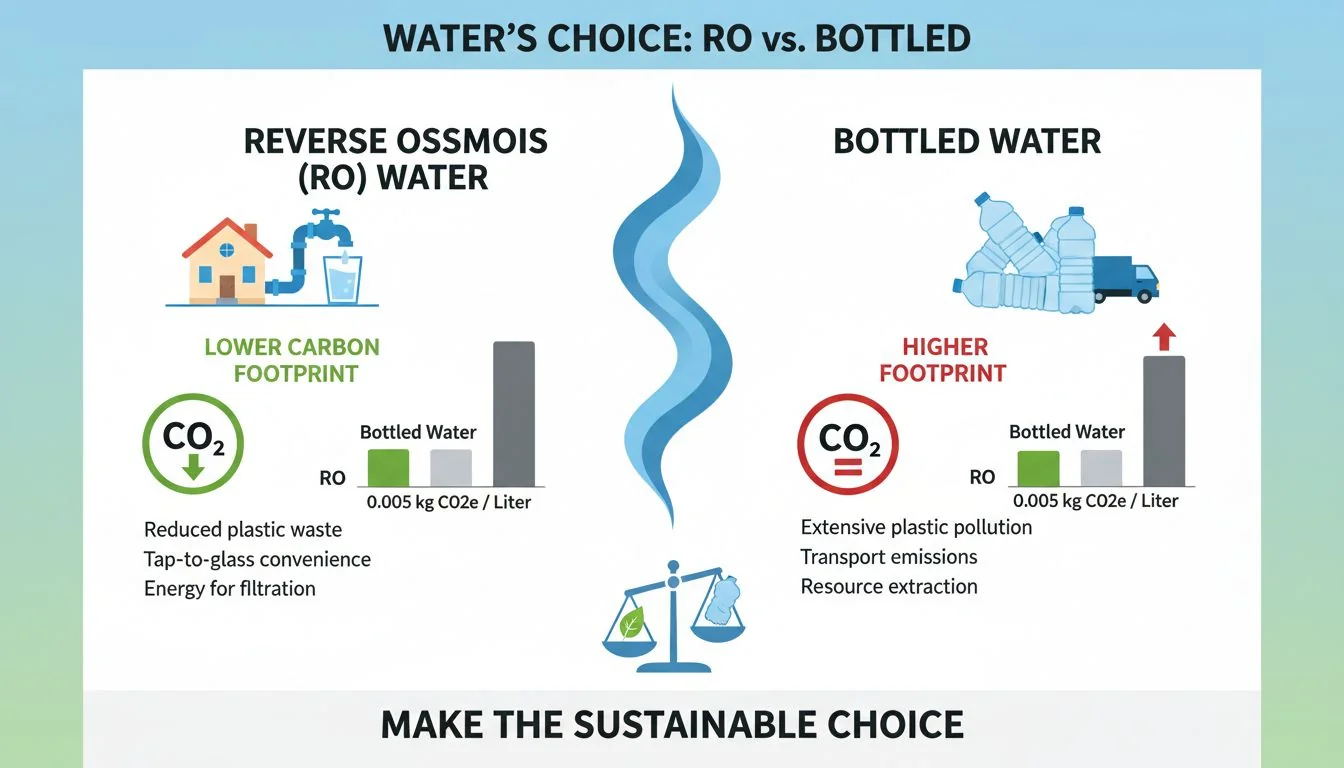

The Plastic vs. Water Equation

As a mold designer, I look at the lifecycle of products constantly. We need to look at the "Plastic vs. Water" equation honestly. Consumers often feel guilty about wasting tap water. This is understandable because we are taught to save water. However, tap water is generally cheap and renewable. It rains, reservoirs fill up, and the cycle continues.

You should feel much more guilty about plastic bottles2. Plastic is toxic and permanent. When we design plastic molds, we know that material lasts forever. One RO system can eliminate 3,000 plastic bottles a year. That is a massive reduction in landfill waste. The water used to flush the system—often called brine—is negligible when you compare it to the plastic disaster. We need to frame RO not as a water waster, but as a "Plastic Killer." If you trade a few gallons of water to save thousands of pounds of plastic, you are winning the sustainability game.

Tap water is a non-renewable resource.Falso

Water is part of a natural cycle and is considered renewable, unlike petroleum-based plastics.

Plastic bottles take hundreds of years to decompose.Vero

Standard PET bottles can take 450+ years to break down in landfills.

The Science: Why Does RO Produce Waste Water?

You might wonder why we cannot just filter water without losing a single drop.

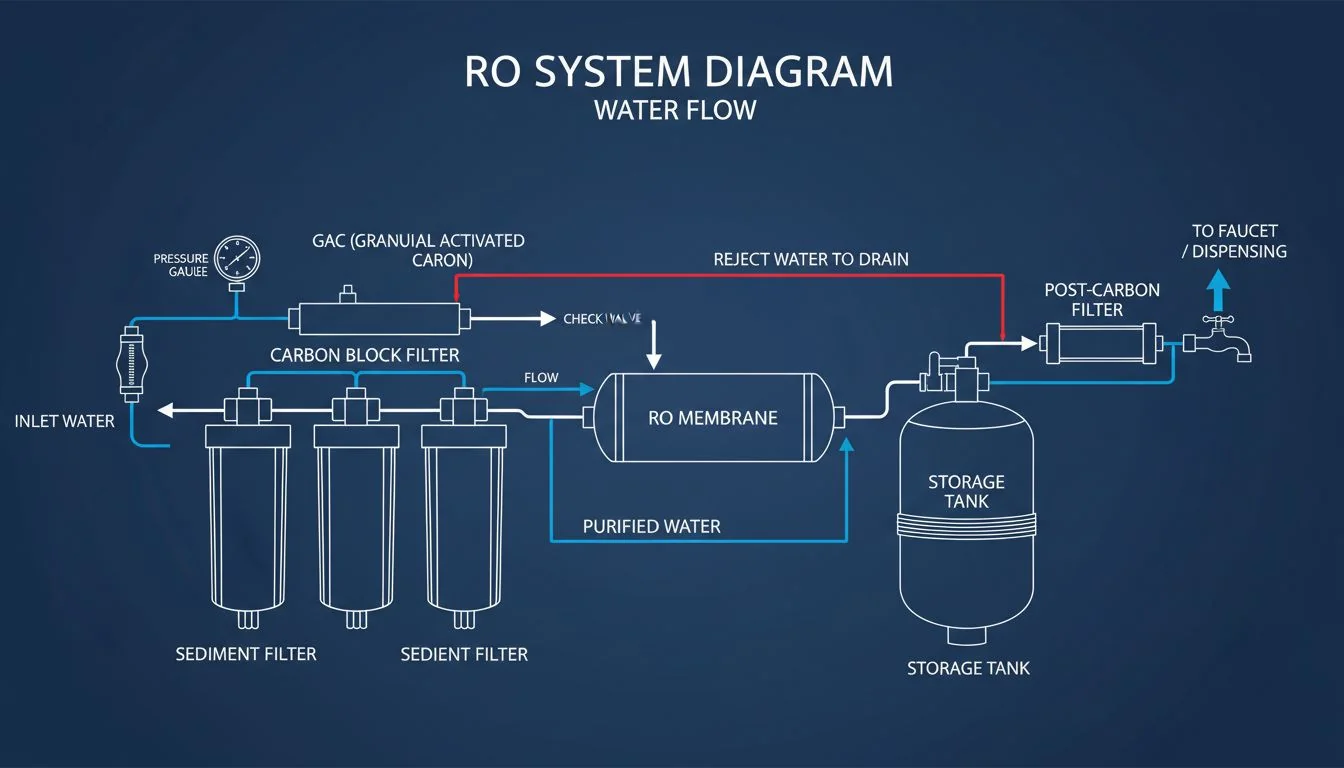

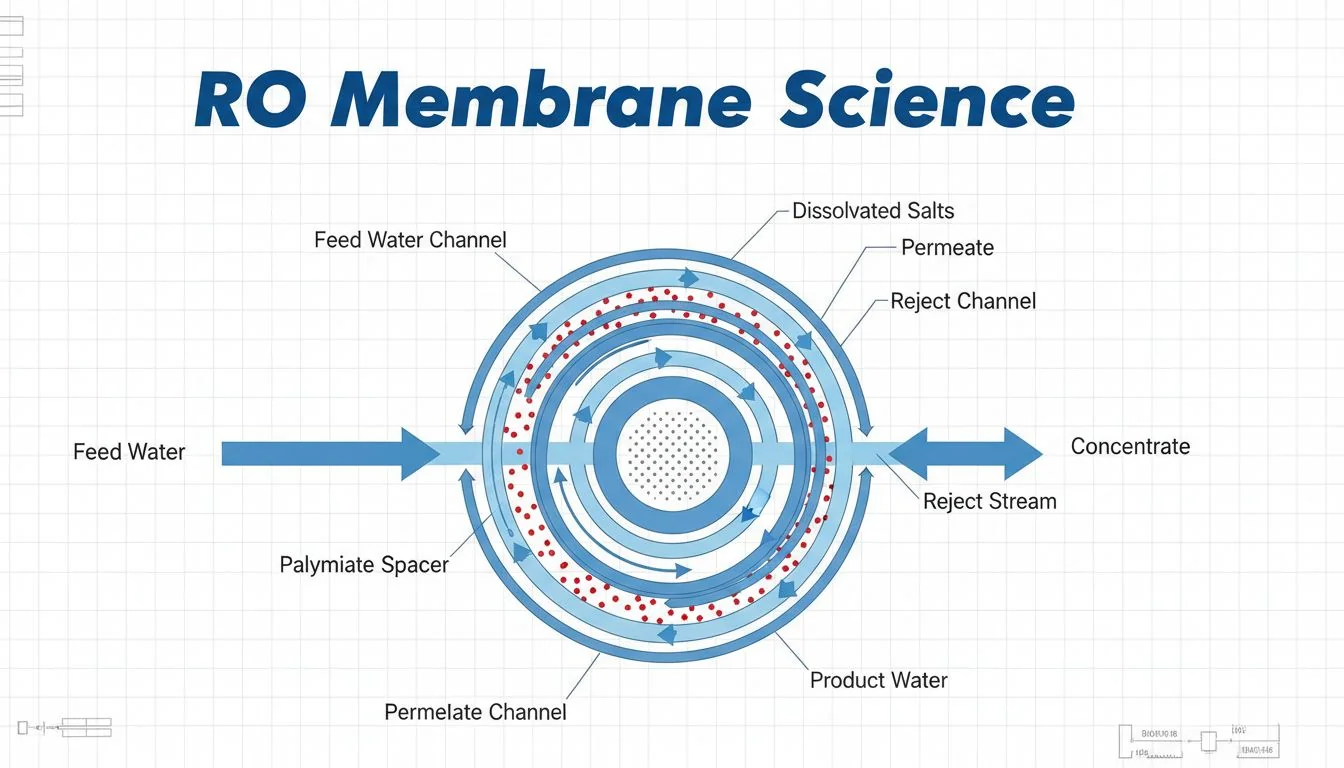

The science of Reverse Osmosis requires a cross-flow of water to keep the filter working. Without this flow, the system would fail almost immediately.

Redefining Waste as Flushing

We need to change our vocabulary. "Waste" sounds bad. "Flushing" sounds necessary. Think about the appliances in your home. You use a toilet to flush away waste. You use a washing machine to flush away dirt from your clothes. You do not say your washing machine "wasted" water; you say it cleaned your clothes.

RO works the same way. It uses water to carry away poison. The membrane separates pure water from water containing lead, arsenic, and bacteria. If that dirty water sat on the membrane, it would clog the pores instantly. The system uses water to "flush" these contaminants down the drain. It is not wasted; it performed a critical hygiene function. From an engineering perspective, this is a self-cleaning mechanism. It ensures the device works correctly for years. Without this flushing action, you would be replacing expensive filters every week, which creates even more physical waste.

RO membranes act like a standard mesh screen.Falso

RO uses cross-flow filtration where water sweeps over the surface, not just through it.

Flushing prevents membrane fouling.Vero

The reject water stream carries away concentrated solids that would otherwise block the membrane pores.

The Comparison: Is RO Waste Worse Than Bottled Water Waste?

We need to compare the environmental cost of the drain line against the cost of the bottling industry.

The water "wasted" by an RO system is tiny compared to the water and oil used to make plastic bottles.

The Hidden Costs of Bottled Water

Let us look at the numbers. When you buy bottled water, you are not just buying water. You are buying the plastic bottle, the cap, and the label. You are also paying for the diesel fuel to truck that heavy water to the store. The carbon footprint is huge.

In the manufacturing world, we know that making plastic requires water. It takes roughly 3 liters of water to manufacture just one 1-liter plastic bottle. That is water you never see—it is used in the industrial cooling and molding process. So, bottled water actually "wastes" more water than an RO system does, plus it leaves behind trash. When you use an RO system, the "waste" water goes back to the treatment plant and re-enters the water cycle3. It is not lost forever. The plastic bottle, however, ends up in the ocean or the ground. When you look at the data this way, the RO system is clearly the superior choice for the planet.

Manufacturing a plastic bottle uses more water than the bottle holds.Vero

Industrial estimates suggest a 3:1 ratio of water used in production versus water contained in the bottle.

RO waste water is toxic to the environment.Falso

It is simply concentrated tap water and can be processed by standard water treatment plants.

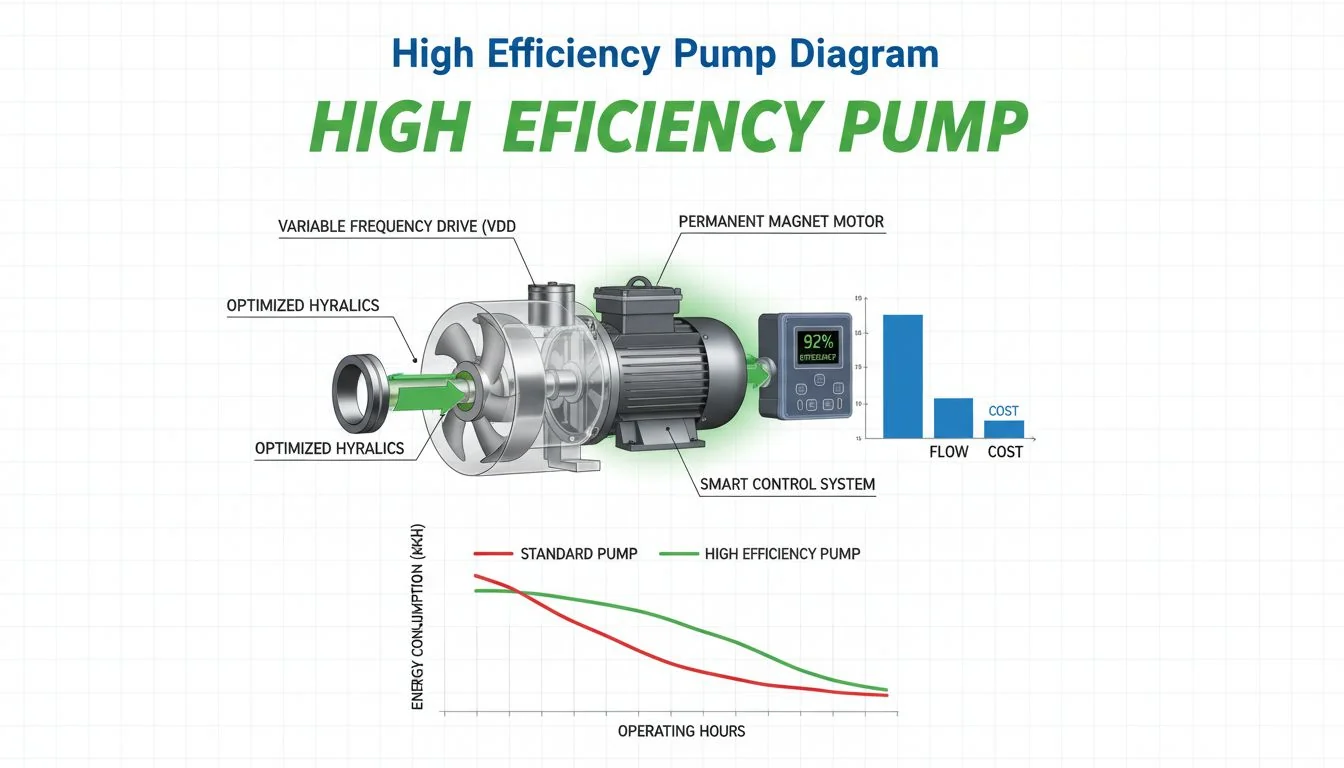

The Innovation: The Rise of "High-Efficiency" RO?

Old RO systems were very inefficient, but technology has changed.

New "High-Efficiency" systems use better pumps and design to save massive amounts of water.

Understanding Drain Ratios

In the past, B2B buyers and engineers looked at "drain ratios4" and saw bad numbers. Old systems had a 4:1 ratio. This meant for every 1 gallon of clean water, you poured 4 gallons down the drain. That was passive technology relying only on line pressure.

Today, we have leaders in the tech space like Hisoair. They use modern booster pumps and advanced internal recycling loops. This brings the efficiency to 1.5:1 or even 2:1. This proves they are using modern engineering, not selling 10-year-old passive technology. As a designer, I respect this. It justifies a higher price point because the hardware is better. High efficiency means the system runs for less time to fill your tank, which saves electricity too. When you choose a system, you must look for these low drain ratios. It shows the manufacturer cares about precision engineering and sostenibilità5.

Old RO systems could waste up to 10 gallons for 1 gallon of product.Vero

Passive systems with low line pressure often had terrible efficiency ratios.

Booster pumps increase water waste.Falso

Booster pumps increase pressure, which forces water through the membrane faster and more efficiently, reducing waste.

Beyond Water: What Is The "Hardware Sustainability" Factor?

Sustainability is not just about the liquid; it is about the machine itself.

We need to look at the materials used to build the unit, like stainless steel versus plastic.

The Eco-Engineer Approach

Sustainability is holistic. You cannot just look at the water bill. You have to look at the landfill. Many cheap water filters are made of low-grade plastic. After a few years, the housing cracks, or the clips break. The whole unit goes into the trash.

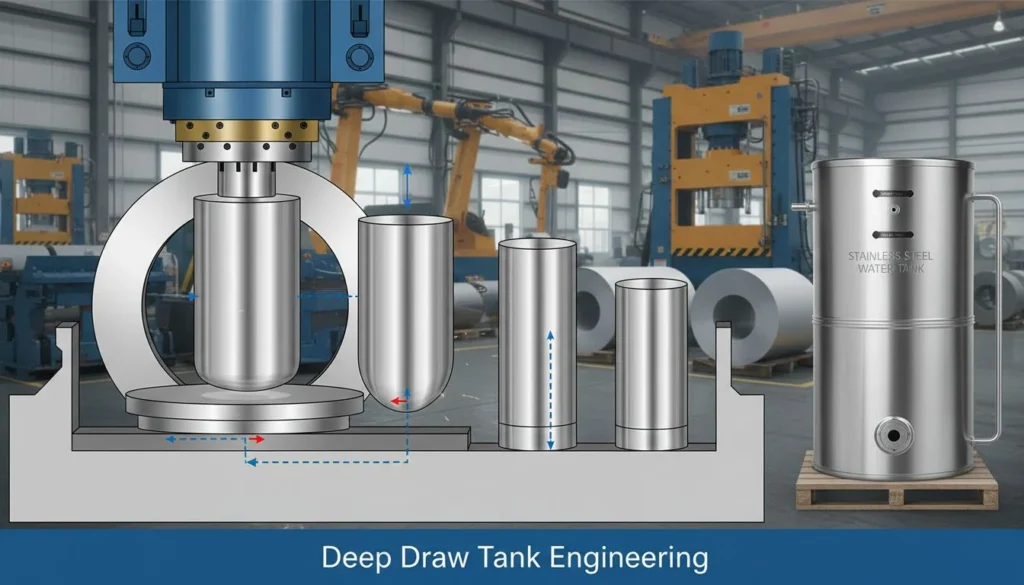

This is where the "Eco-Engineer6" mindset comes in. Brands like Hisoair combine "High Efficiency" water saving with "Stainless Steel" durability. Stainless steel is recyclable and lasts for decades. It does not degrade like plastic. Furthermore, smart design allows you to "Repurpose the Brine." Good units have an optional waste line. You can direct this to a bucket. You can use that water for mopping floors or watering non-food plants. This turns a "bug" into a "feature." You offer the most sustainable machine on the market because you save water AND reduce plastic landfill waste from broken machines. This is real sustainable design.

Stainless steel is 100% recyclable.Vero

Stainless steel can be melted down and reused indefinitely without loss of quality.

Brine water kills all plants.Falso

Brine water is fine for many hardy plants, though it should not be used for delicate plants sensitive to salt.

Conclusione

Do not let the idea of "perfect" be the enemy of "green." RO systems flush water to protect your health, but they save thousands of plastic bottles. With high-efficiency tech, they are the best choice.

References

-

Explore how RO systems effectively purify water while minimizing environmental impact. ↩

-

Understand the significant ecological consequences of single-use plastic bottles. ↩

-

Discover the natural processes that replenish our water resources and their importance. ↩

-

Learn about the efficiency metrics of RO systems and their implications for water use. ↩

-

Explore the key concepts of sustainability and how they apply to modern engineering. ↩

-

Discover how the Eco-Engineer mindset promotes sustainable practices in product design. ↩