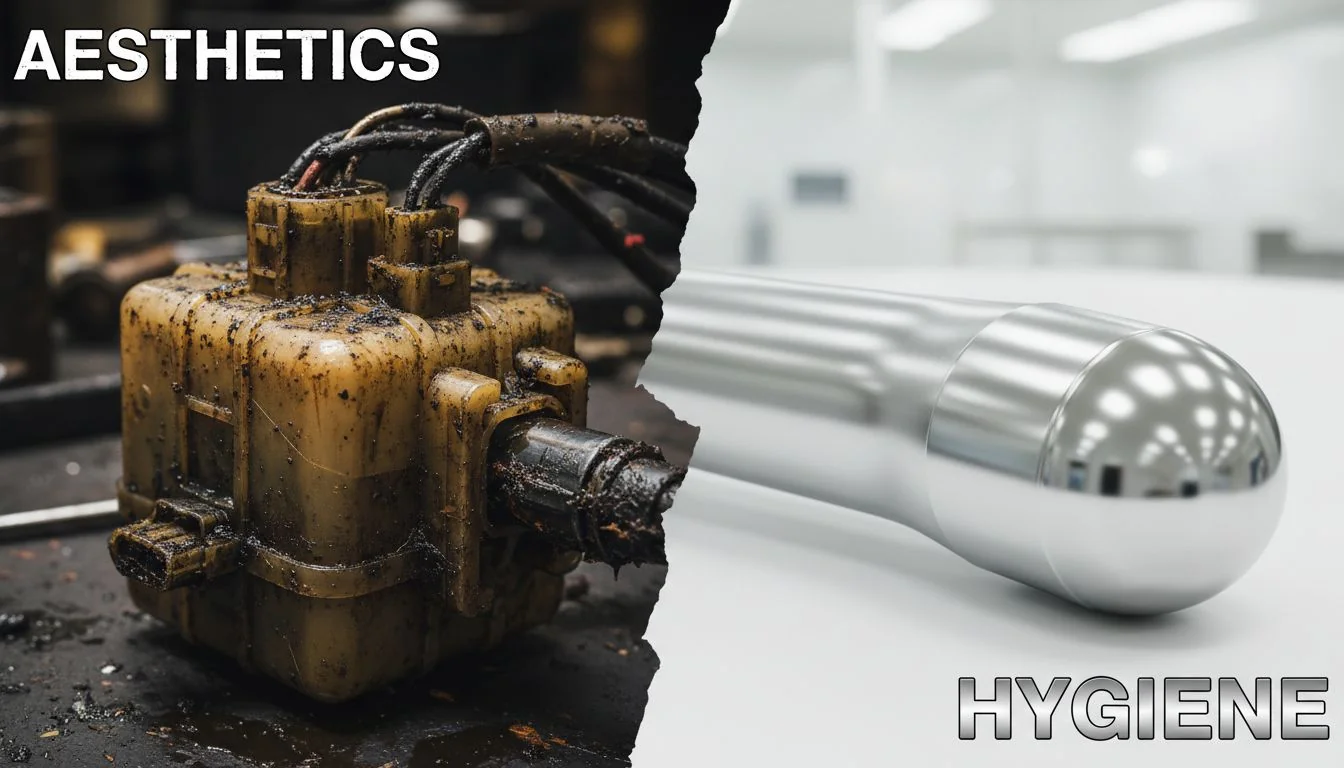

Your beautiful, minimalist product looks great on the shelf. But after a month of use, it's a nightmare to clean. This friction is killing your brand's "wellness" promise.

"Functional Minimalism1" redefines the goal. It prioritizes hygiene and ease of use over simple aesthetics. This philosophy dictates that true minimalism is achieved through superior materials and engineering, not just by hiding complexity inside a white plastic box. Form must follow function, and function means hygiene.

I've seen it a hundred times in my career. A brilliant D2C brand comes to me with a product that looks stunning. It's all clean lines and matte white finishes. They call it "minimalist." But when we look at the mold design, it's a web of internal ribs, tight corners, and hidden chambers. They've designed a beautiful object that is impossible to clean properly. This isn't minimalism; it's a hidden headache for the customer. This approach creates a high-friction user experience2 that directly contradicts the very idea of wellness and simplicity the brand wants to sell. It's a trap that many talented designers fall into, and it's time we talked about a better way.

Minimalist design is primarily a visual style focused on simplicity and the absence of ornamentation.Falso

While often expressed visually, true minimalism is a philosophy of keeping only the essential. In product design, function and usability are essential, so a design that is hard to use or maintain is not truly minimalist.

Plastic is the most common material for minimalist consumer electronics due to its low cost and design flexibility.Vero

Injection-molded plastic allows for complex shapes and integrated features at a low unit cost, making it a default choice for mass-market products aiming for a simple external appearance.

The "Wellness Aesthetic" Has a Fatal Flaw?

Your product promises a feeling of wellness and calm. But the complex plastic parts create cleaning anxiety and harbor grime. This disconnect between aesthetic and function is a critical design failure.

The fatal flaw is that this "wellness aesthetic" often relies on plastic, which in many applications, is inherently unhygienic. It scratches easily, develops biofilm, and its complex molded shapes create impossible-to-clean areas, breeding bacteria and mold. This turns a wellness product into a source of stress.

I remember a client working on a humidifier. The design was beautiful, like a sculpture. But the water tank was a maze of plastic components. They were so focused on the external shape that they ignored the user's daily reality. The user isn't just looking at the product; they are interacting with it, and that includes the chore of cleaning it. When a product designed for health becomes a breeding ground for mold, you haven't just failed the user; you've broken your brand's core promise. This is the central problem we, as designers and engineers, need to solve. We are chasing a visual idea of simplicity while creating a functionally complex and frustrating experience.

The User Experience Contradiction

The core issue is a conflict between the marketing message and the actual product experience.

| Aspetto | The "Wellness" Promise | The Plastic Reality |

|---|---|---|

| Feeling | Calm, Serenity, Health | Anxiety, Stress, Worry |

| Interaction | Effortless, Simple | Complicated, Frustrating |

| Manutenzione | Easy, Quick | Difficult, Time-Consuming |

| Result | A Healthier Environment | A Source of Grime & Mold |

This table shows the gap. As designers, our job is to close this gap. We must ensure the product's function lives up to its form.

Most plastics used in consumer goods are porous and can harbor bacteria over time.Vero

Micro-scratches and the inherent microscopic porosity of many plastics can create environments where biofilms and bacteria can accumulate, especially in wet conditions.

A product's aesthetic is the most important factor for initial purchase decisions in the wellness category.Falso

While aesthetics are important, negative user reviews about cleaning difficulty, mold, and poor durability can quickly override a beautiful design and deter potential buyers.

The "Fake Minimalism" Trap (Aesthetics Over Function)?

You've designed a sleek, seamless product. But to achieve that look, you've hidden a dozen complex, hard-to-clean plastic parts inside. This is the "fake minimalism" trap.

It's a design philosophy3 that prioritizes the initial visual impression over the long-term user experience. It uses plastic to create a simple-looking shell, but this choice often makes the product's core function—like being easy to clean and hygienic—much more complicated and frustrating for the end-user.

I once consulted on a project for a smart kitchen gadget. It was a beautiful white box. The team was proud of it. But the cost-cutting measures led them to use a standard ABS plastic for all the internal components that came into contact with food and water. After a few months of testing, we saw discoloration and buildup in corners that were impossible to reach. The mold for these parts was complex, full of lifters and slides to create the "simple" look. They had engineered complexity to achieve the appearance of simplicity. This is a backward approach. True elegance in design and engineering4 is about making things genuinely simple, not just looking simple.

The Hallmarks of Fake Minimalism

How can you spot this trap in your own design process? Look for these warning signs.

- Material Mismatch: Using materials like standard plastic for components that require high levels of hygiene5 and durability.

- Hidden Complexity: Relying on intricate internal structures, snap-fits, and hidden chambers that are a nightmare for both the user to clean and the toolmaker to build.

- Disposable Durability: Creating a product that looks premium but is not built to last. It scratches, stains, and degrades, forcing the user to replace it sooner than expected.

This approach ultimately damages brand trust. When a user discovers the beautiful object they bought is a pain to live with, they feel deceived.

Snap-fit designs in plastic enclosures reduce assembly costs and part count.Vero

Snap-fits are a common feature in Design for Manufacturing and Assembly (DFMA) because they eliminate the need for screws and other fasteners, simplifying and speeding up the assembly process.

Products with fewer external parts are always simpler to manufacture.Falso

Achieving a seamless external appearance can require extremely complex and expensive molds with multiple slides, lifters, and actions to create undercuts and internal features, making manufacturing much harder.

The "True Minimalism" Mandate: Form Must Follow Hygiene?

Your design process is focused on clean lines and simple shapes. But what if the most important rule was that the product must be effortlessly hygienic? This is the mandate.

"True Minimalism" is a design philosophy where function dictates form, and the primary function is user well-being. This means prioritizing materials and construction that ensure the product is easy to clean, durable, and safe over its entire lifecycle. It's an engineering-led approach.

Think about the most basic, trusted items in a kitchen. A stainless steel6 pot. A glass bowl. Their form is incredibly simple because it is dictated by their function. They are shaped to be heated evenly, to be held easily, and, crucially, to be cleaned perfectly. There are no hidden chambers or impossible-to-reach corners. This is not an accident; it's the result of centuries of functional refinement. We need to apply this same logic to modern wellness products. The mandate is clear: if the user can't easily make it clean and safe, the design has failed, no matter how beautiful it looks.

Comparing Design Philosophies

Let's break down the practical differences between these two approaches.

| Caratteristica | Fake Minimalism (Aesthetic-First) | True Minimalism (Hygiene-First) |

|---|---|---|

| Core Goal | Look simple and clean. | Be simple and clean. |

| Primary Material | Plastic (ABS, PP) | Functional Materials (Stainless Steel, Glass) |

| user friction7 | High (difficult cleaning, anxiety) | Low (effortless cleaning, confidence) |

| Engineering Focus | Hiding complexity in plastic molds. | Solving challenges of premium materials8. |

| Brand Perception | Trendy, but potentially disposable. | Premium, durable, and trustworthy. |

This shift in thinking from "how it looks" to "how it works and lives" is the key to creating products that customers will love and trust for years.

Glass is completely inert and non-porous, making it one of the most hygienic materials for food and liquid storage.Vero

The molecular structure of glass does not have pores where bacteria can hide, and it does not react with its contents, ensuring purity and making it exceptionally easy to clean and sterilize.

Designing a product to be easy to clean always increases its manufacturing cost.Falso

While using premium materials like stainless steel can be more expensive, designing for cleanability often simplifies the product's geometry, which can, in some cases, reduce mold complexity and assembly time, offsetting some costs.

Case Study: Stainless Steel (Functional Minimalism Perfected)?

You see it in high-end kitchens, premium water bottles, and Apple products. Why is stainless steel the unofficial material of premium, functional design? It's no accident.

Stainless steel embodies "Functional Minimalism." Consumers already associate it with durability, cleanliness, and a premium feel. This is what I call "The Yeti Effect." Brands like Yeti took a simple product and elevated it through superior engineering and materials, creating a new premium category.

I've seen this in my own work. When a client is willing to move from a plastic concept to a stainless steel one, the entire conversation changes. We stop talking about hiding flaws and start talking about celebrating function. The material itself becomes a key feature. It's non-porous, so it resists bacteria. It's strong, so it doesn't need complex internal ribs for support. It can be formed into simple, open shapes that are incredibly easy to clean. A user cleaning a stainless steel tank feels confident and smart, like they are using a professional tool. They are not scrubbing a cheap plastic box; they are maintaining a high-performance piece of equipment. This is the feeling you want your brand to inspire.

Why Stainless Steel Works

It's not just about perception; it's about tangible engineering benefits that lead to a better user experience.

- Hygiene: The non-porous surface of stainless steel is highly resistant to bacteria, mold, and staining. It can be cleaned completely, leaving no residue.

- Durata: It resists scratches, dents, and corrosion. A product made from steel feels substantial and is built to last, enhancing its perceived value.

- Simplicity of Form: Because of its inherent strength, you can design parts with simple, open geometry. A tank can just be a tank, not a complex assembly of molded plastic pieces.

By choosing stainless steel, you are leveraging decades of positive consumer association and leaning on a material that does the hard work of being simple, durable, and clean for you.

304 stainless steel is one ofthe most common types used in kitchen and medical applications.Vero

Also known as 18/8 stainless steel, its composition of chromium and nickel gives it excellent corrosion resistance and makes it safe for contact with food, water, and sterilizing agents.

Stainless steel products are always heavier than their plastic counterparts.Falso

While steel has a higher density, its strength allows for much thinner walls. A well-engineered stainless steel component can be comparable in weight to a bulky, over-engineered plastic part designed to achieve the same rigidity.

Why "Engineering" is the Key to This New Design Language?

You've decided to use a superior material like stainless steel. But isn't that harder and more expensive to manufacture than plastic? Yes, and that's exactly the point.

Achieving true, functional simplicity is an engineering challenge. It's harder than faking it with plastic. This is where your choice of an R&D and manufacturing partner becomes a strategic advantage. They are the enablers who solve the "hard problem" of manufacturing for you.

I've worked with partners like Hisoair who specialize in this. They have mastered the techniques of deep drawing, laser welding, and polishing stainless steel. Making a seamless, single-piece steel tank is far more complex than injection molding a plastic one. It requires massive investment in machinery, robotics, and process control. For a D2C brand, developing this capability in-house is impossible. By partnering with an expert, you are essentially acquiring years of R&D. This allows you, the designer, to focus on the user experience, confident that the difficult manufacturing is being handled. This positions your brand as one that is smart enough to bring a superior design to market by leveraging the best engineering talent.

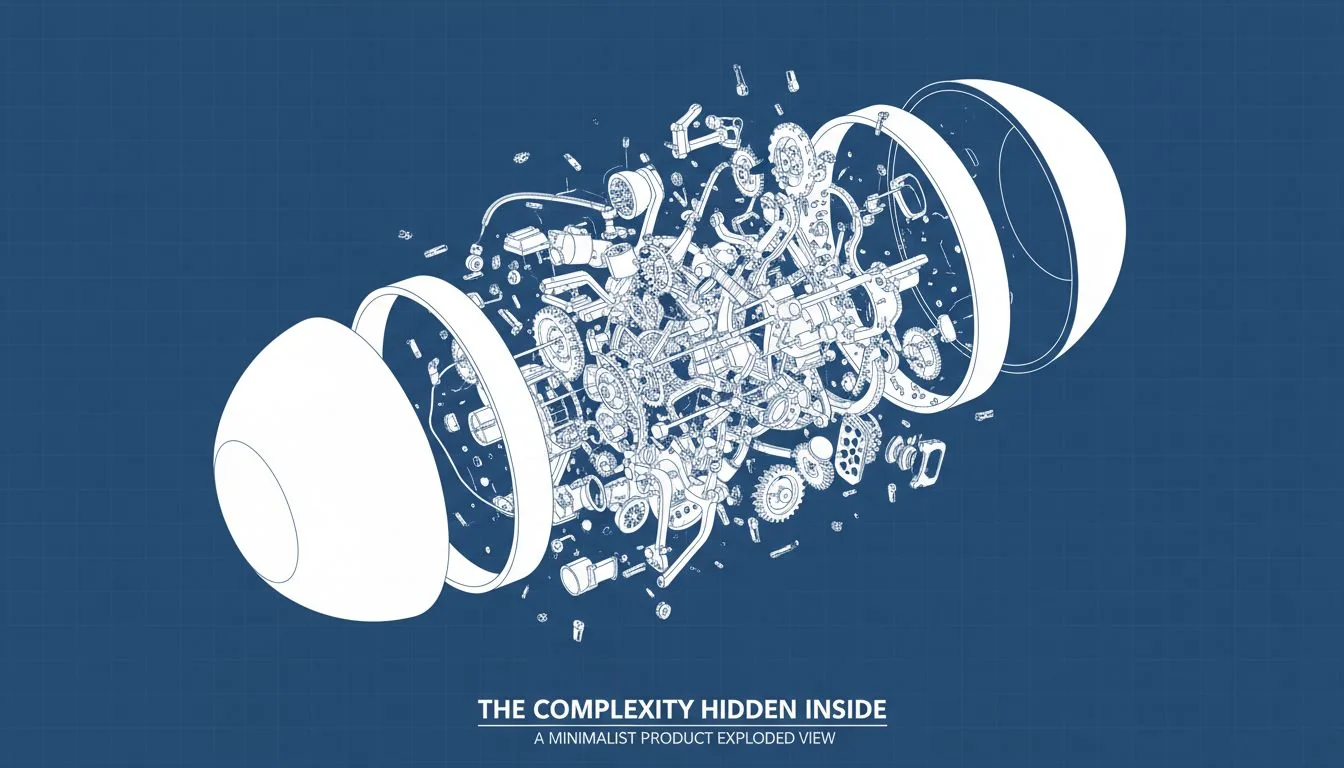

The Hidden Complexity of "Simple"

Don't mistake a simple-looking product for a simple-to-make one. The engineering behind functional minimalism is sophisticated.

- Deep Drawing: This process stamps a flat sheet of metal into a 3D shape, like a sink or a pot. It requires powerful presses and precise tooling to avoid tearing or wrinkling the material.

- Welding & Finishing: Creating seamless joints with techniques like laser welding and then polishing them to be invisible requires a high degree of automation and skill.

- Tooling & Tolerances: The molds and dies for metal forming are vastly different from plastic injection molds. They must withstand immense forces and are built for precision.

Choosing this path signals to the market that you are not a "me-too" brand. You are an engineering-led company committed to superior quality.

Deep drawing metal is a faster process than injection molding plastic.Falso

Injection molding can have cycle times of a few seconds to a minute, while deep drawing is a slower, multi-stage process. However, the resulting part is often stronger and requires less complex tooling.

Partnering with a specialized manufacturer can de-risk the adoption of new materials and processes for a product company.Vero

Specialist partners have already absorbed the high capital costs of equipment and R&D, allowing brands to access advanced manufacturing capabilities without the upfront investment and learning curve.

Conclusione

Stop chasing the "wellness aesthetic" and start engineering for it. Build your brand on "true minimalism," where form follows hygiene, creating a frictionless, premium experience your customers will trust.

References

-

Understanding Functional Minimalism can help you create products that prioritize hygiene and usability over mere aesthetics. ↩

-

A deep dive into user experience can reveal how design choices affect customer satisfaction and loyalty. ↩

-

Understanding design philosophy can guide you in creating products that resonate with users. ↩

-

Exploring the role of engineering can help you create functional and aesthetically pleasing products. ↩

-

Exploring the importance of hygiene in design can enhance user experience and brand trust. ↩

-

Discovering the advantages of stainless steel can inform your material choices for durability and hygiene. ↩

-

Understanding user friction can help you design products that provide a seamless user experience. ↩

-

Learning about premium materials can elevate your product's quality and user perception. ↩