You want a quality water purifier but are not sure where it's made. This uncertainty can be frustrating. I looked into it, and the story is more interesting than you might think.

Aquaphor's primary manufacturing hub is in Estonia1, making it the largest manufacturer of water treatment products in the European Union. While its most advanced systems are designed in Israel, the mass production and assembly for global markets happen in its state-of-the-art Estonian facilities.

The simple answer is Estonia, but that is not the whole story. I found that the company's structure is a key part of its product quality. To really understand what goes into an Aquaphor purifier, we need to look at their entire global operation. It is a journey that spans from an initial idea to the final product you use at home. Let's break down where each part of the process happens and why it matters to you.

Aquaphor is the largest manufacturer of water filters in the European Union.Verdadeiro

Based on production volume and facility size, Aquaphor's Estonian plants make it the largest producer of water treatment products within the EU.

All Aquaphor products are made in Germany.Falso

While Aquaphor is a major European manufacturer, its primary production facilities are located in Estonia, not Germany.

The European Manufacturing Hub: Is It All Made in Estonia?

You hear "Made in EU" and think of high standards and quality. But what does that really mean for Aquaphor? I wanted to know if it was just one factory.

Aquaphor's production heart beats strongly in Estonia. This strategic location makes it the EU's largest water treatment product manufacturer. They operate two major facilities in Sillamäe2 and Narva, which handle everything from household filters to complex professional systems for businesses.

When I looked deeper into their European operations, I saw a clear strategy of growth and specialization. It's not just one building with a logo on it; it's a network designed for large-scale, high-quality production. The company established its presence with a purpose.

The Sillamäe Facility

This was Aquaphor's first move into the EU, established back in 2012. I see this as their foundational plant. It’s where they started producing a wide range of filters and components, setting the stage for their European dominance.

The Narva Facility

The second plant in Narva is the real powerhouse. It's a larger, more advanced facility that handles mass manufacturing. This is where the high-volume products, including the sophisticated "Aquaphor Professional3" lines designed in Israel, are actually built and assembled for the world.

The Future is Bigger: The Narva 'Mega-Plant' Project

Aquaphor is not stopping. They have an ambitious plan for a massive 110,000 m² facility in Narva4. I learned this "mega-plant" is set to be completed by 2025 and will focus on commercial and industrial systems. This shows a huge commitment to future growth.

| Facility Location | Estabelecido | Função principal |

|---|---|---|

| Sillamäe, Estonia | 2012 | First EU factory, wide range of filters |

| Narva, Estonia | Post-2012 | Mass manufacturing, APRO lines |

| Narva (Mega-Plant) | By 2025 | Future hub for industrial systems |

Aquaphor is building a new 110,000 m² mega-plant in Narva, Estonia.Verdadeiro

The company has publicly announced plans for a massive new production facility in Narva, scheduled for completion by 2025 to expand its industrial and commercial system manufacturing.

Aquaphor's first EU factory was opened in 2020.Falso

Aquaphor's first EU factory was established in Sillamäe, Estonia, back in 2012.

The Innovation Engine: What's Designed in Israel?

You want the most advanced water purification technology available. But where do these cutting-edge ideas come from? I found it is not always the factory floor. Aquaphor's innovation secret is its Israeli R&D center5.

The company's most advanced commercial systems, known as the "Aquaphor Professional" (APRO) line, are designed in Haifa, Israel. This expertise was strategically brought in-house through the 2014 acquisition of Winter Engineering Ltd., a specialized Israeli water treatment firm.

This move was fascinating to me. It shows that Aquaphor understands the difference between making a product and inventing it. They went to a global hub of technology and water science to secure the best minds for their most demanding B2B clients.

The "Aquaphor Professional" (APRO) Division

This is the part of the company that tackles the big, complex water challenges. Think hospitals, factories, and restaurants. The APRO systems are designed in Haifa to meet these specific, high-stakes needs.

A Strategic Acquisition

In 2014, Aquaphor didn't just hire engineers; they bought an entire company, Winter Engineering Ltd. This instantly gave them a team with deep experience in creating custom, high-performance water purification solutions. It was a shortcut to the top of the industry.

Role and Function

It's important to understand the workflow. Israel is the hub for research, development, and custom designs. The team there creates the blueprints. Then, those proven designs are sent to the factories in Estonia for efficient, large-scale production. This model gives them both innovation and manufacturing muscle.

| Localização | Função principal | Key Activity |

|---|---|---|

| Haifa, Israel | R&D and Design | Creating blueprints for APRO systems |

| Narva, Estonia | Produção em massa | Manufacturing the APRO systems |

Aquaphor's commercial systems are designed in Israel.Verdadeiro

The 'Aquaphor Professional' (APRO) division is based in Haifa, Israel, where the company's most advanced commercial and industrial systems are researched and designed.

Aquaphor manufactures its APRO systems in Israel.Falso

The APRO systems are designed in Israel, but the mass production and assembly of these units take place at the large manufacturing facilities in Estonia.

A Global Presence: What About Russia, the US, and China?

You see a global brand and wonder about all its locations. Are there hidden factories? What about the company's origins? I wanted to clear this up. Let's clarify the role of other key countries.

Aquaphor was founded in St. Petersburg, Russia, in 1992 and still has a historical manufacturing base there with significant exports. In contrast, its presence in the USA and China is focused on R&D, patent holdings, and sales, not large-scale manufacturing.

Understanding a company's history and its current global footprint helps build a complete picture. It's not just about where the main factory is today, but also about where the company came from and where it directs its other efforts.

Historical Roots in Russia

Every company has an origin story. Aquaphor's began in St. Petersburg in 1992. This is where the company was founded and developed its initial manufacturing capabilities. I learned that it remains an important market for them, with a significant ongoing export business to the region. Acknowledging this history is important to understanding the full scope of their operations.

Role of the USA and China

When I see a company with offices in the US and China, I often assume they have factories there. For Aquaphor, this is not the case. Their presence in these major markets is strategic but different. These locations are hubs for research and development, managing their extensive portfolio of patentes6, and running sales and distribution networks. They are the commercial and intellectual arms of the company, while the manufacturing muscle remains firmly in Europe.

| País | Primary Role in Aquaphor's Operations |

|---|---|

| Rússia | Founding location (1992), historical manufacturing base |

| EUA | R&D, patent holdings, sales, and distribution |

| China | R&D, sales, and distribution |

Aquaphor was founded in Russia in 1992.Verdadeiro

The company's official history confirms its founding in St. Petersburg, Russia, in 1992.

Aquaphor has large manufacturing plants in the United States and China.Falso

Aquaphor's presence in the US and China is focused on non-manufacturing activities like R&D, patent management, and sales.

The "Why": Why Does Aquaphor Control Everything In-House?

Many companies outsource manufacturing to save money. So why does Aquaphor insist on doing everything themselves? It seems more complicated. I found their strategy is all about controlling quality and protecting their innovations.

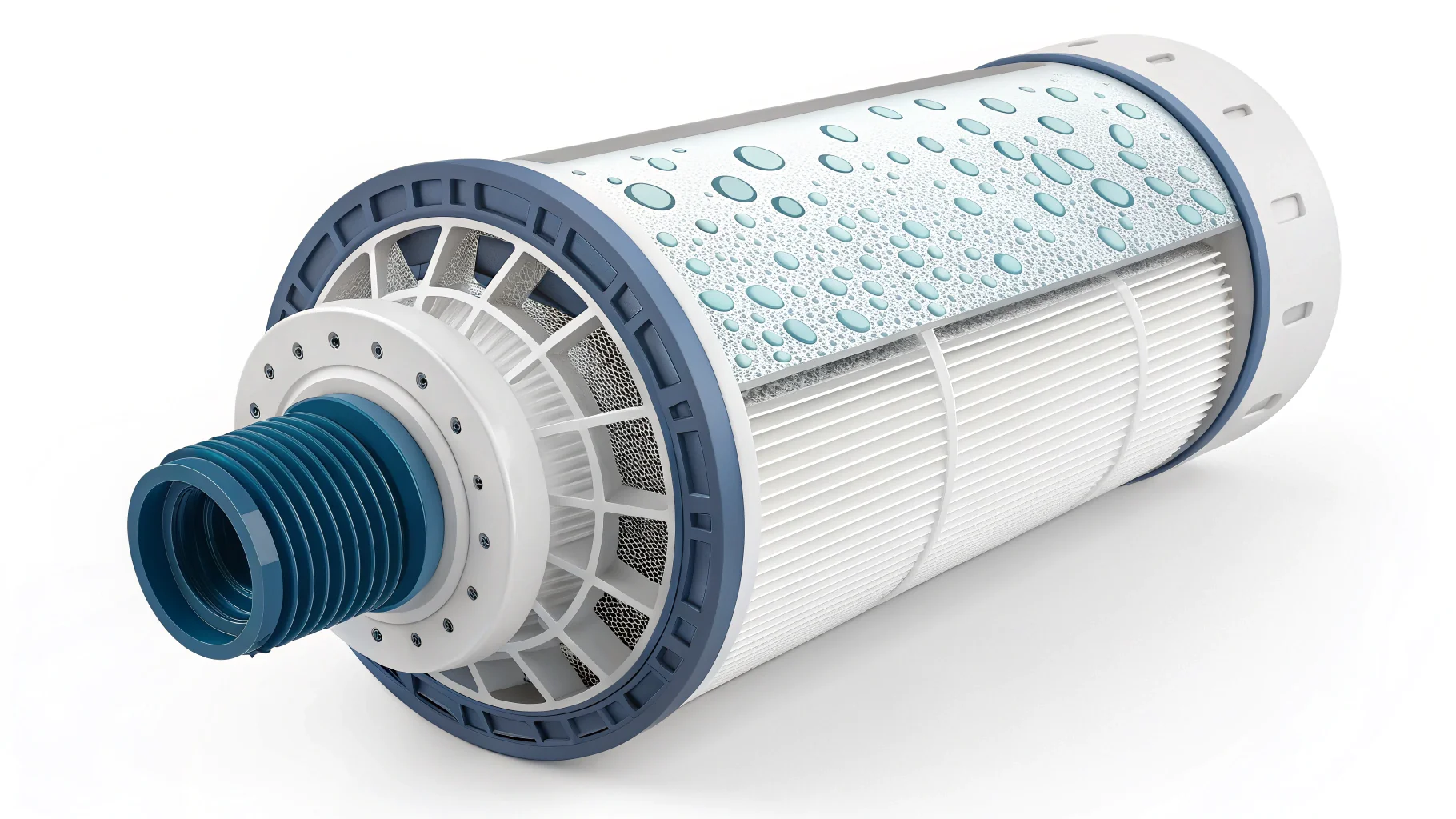

Aquaphor's vertically integrated strategy means they control the entire process, from the initial idea to the final product. This approach is driven by their need to protect over 130 patents and proprietary technologies, ensuring consistent quality and performance in every filter.

This philosophy of self-reliance is at the core of the brand. When a company invents its own materials and methods, it makes sense that they would want to oversee every step of production. It’s the only way to guarantee that the final product perfectly matches the original vision.

From Idea to Product

vertical integration7 sounds complex, but it's a simple idea. Aquaphor designs the filter, creates the unique filtration materials (like their Aqualen fibers), manufactures the plastic housings, and assembles the final product. They control the entire chain. I believe this gives them a huge advantage. They don't have to rely on outside suppliers who might cut corners or fail to meet strict quality standards. This complete control ensures the product you get is exactly what they intended to create.

Driven by R&D

A company doesn't file for over 130 patents if it's not serious about innovation. These patents cover unique technologies that make their filters work better. By keeping manufacturing in-house, Aquaphor protects this valuable intellectual property. It also allows their R&D teams to work directly with the production lines, leading to faster improvements and new products. This direct link between invention and creation is key to their success.

Aquaphor holds more than 130 patents for its technology.Verdadeiro

Aquaphor's official materials state that the company holds over 130 patents for its inventions in water purification technology, including the Aqualen fiber.

Vertical integration is a strategy to reduce manufacturing costs.Falso

While it can offer long-term efficiencies, vertical integration often requires significant upfront investment and is primarily a strategy to control quality, supply chain, and intellectual property, not just to cut costs.

Conclusão

Aquaphor's manufacturing is centered in Estonia, powered by Israeli R&D. This global, in-house strategy ensures every purifier meets their high standards of quality and innovation from start to finish.

References

-

Explore how Estonia's strategic location contributes to Aquaphor's manufacturing excellence. ↩

-

Learn about the foundational plant that set the stage for Aquaphor's European dominance. ↩

-

Discover the advanced technology behind Aquaphor Professional systems designed for complex needs. ↩

-

Understand the significance of the Narva plant in mass production and advanced manufacturing. ↩

-

Find out how Aquaphor's R&D center drives innovation in water purification technology. ↩

-

Explore the innovative technologies protected by Aquaphor's extensive patent portfolio. ↩

-

Explore how vertical integration helps Aquaphor maintain quality and control over production. ↩