You design a sleek humidifier, but customers return it due to smell. That "slime" destroys brand trust. Here is how engineering surface topography solves the biofilm problem.

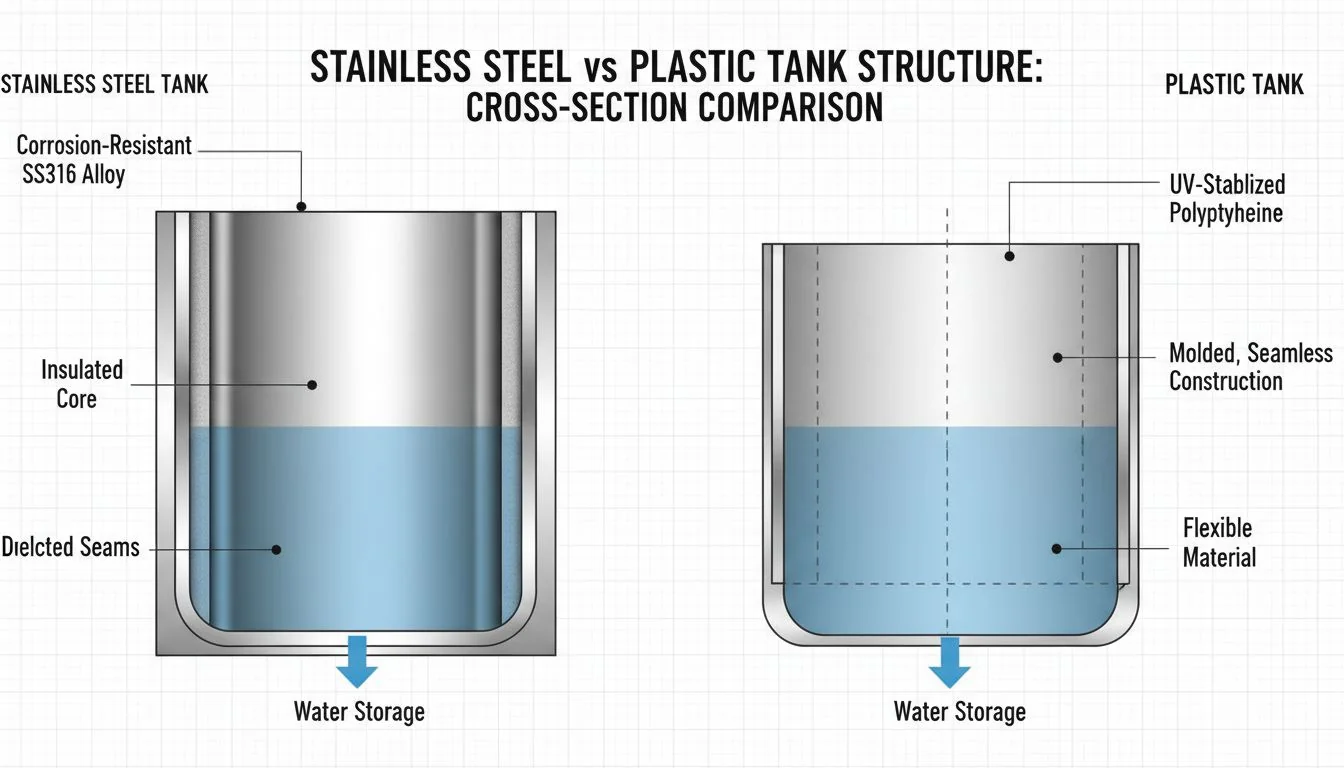

To engineer a mold-free tank1, designers must minimize surface roughness and eliminate corners where biofilm adheres. Replacing complex plastic ribs with seamless, deep-drawn stainless steel creates a bacteriostatic environment. This utilizes the material's passive chromium oxide layer to prevent odor without chemical coatings.

Transition Paragraph:

Many designers overlook the tank's interior, focusing only on the exterior shell. However, the tank is where the biological battle happens. Let's explore why material choice defines premium quality2.

Plastic tanks are naturally porous and absorb odors over time.Verdadeiro

Polymers have molecular gaps that trap volatile organic compounds, leading to permanent odors.

Stainless steel actively kills bacteria like an antibiotic.Falso

Stainless steel is bacteriostatic, meaning its smooth, passive surface prevents bacteria from anchoring and growing, but it does not chemically kill them like a biocide.

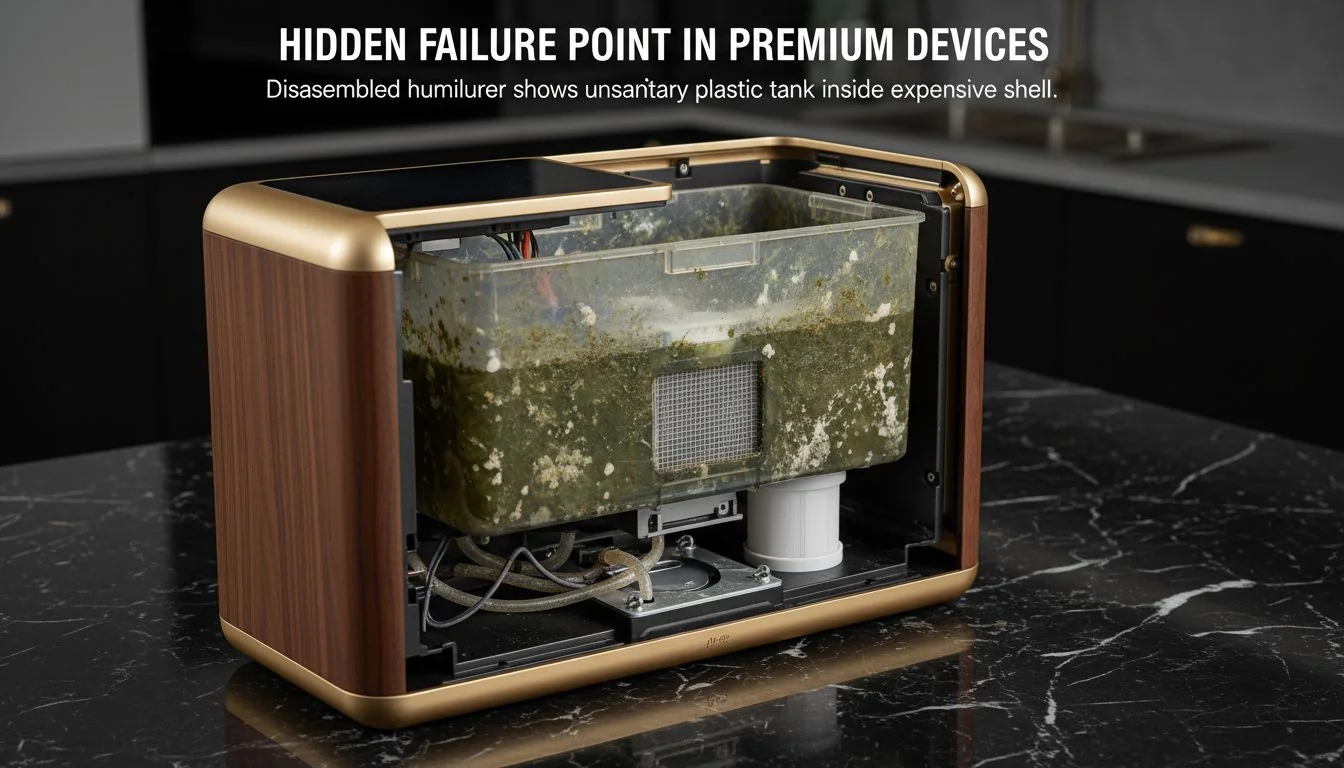

High-end electronics often fail at the simplest component. A smelly tank ruins the user experience immediately. We need to look beyond the circuit board to the vessel itself.

The tank is the vessel for the user's primary interaction: the water. If the vessel degrades the water quality3 through odor or mold, the device fails its core purpose. Premium brands often neglect this, focusing on electronics while using cheap plastic reservoirs that harbor bacteria.

I have seen many teardowns of $500 humidifiers and purifiers. The PCB layout is perfect. The injection molding on the outer shell is flawless with zero flash. But then I look at the water tank. It is often made of cheap ABS or AS plastic. This is a failure of prioritization. As designers, we know that water is a universal solvent. It interacts with the container it sits in. When we design molds for these plastic tanks, we often add internal ribs and sharp corners for structural integrity.

However, those ribs create "dead zones" for water flow. This is where the failure happens. It is not an electronic failure. It is a biological failure caused by mechanical design. We must stop treating the tank as just a bucket. It is a chemical reaction chamber. If the tank is hard to clean because of complex geometry, the user will fail to maintain it. When the user fails, the product smells. When the product smells, the brand dies. We need to elevate the tank from a simple storage part to a critical engineering component.

Complex internal ribs in plastic tanks improve hygiene.Falso

Ribs create corners and dead zones that are difficult to clean, promoting bacterial growth.

Water acts as a solvent that interacts with its container.Verdadeiro

Water can leach chemicals from plastic or facilitate biofilm attachment on rough surfaces.

Is Biofilm Just Slime or a Surface Tension Challenge?

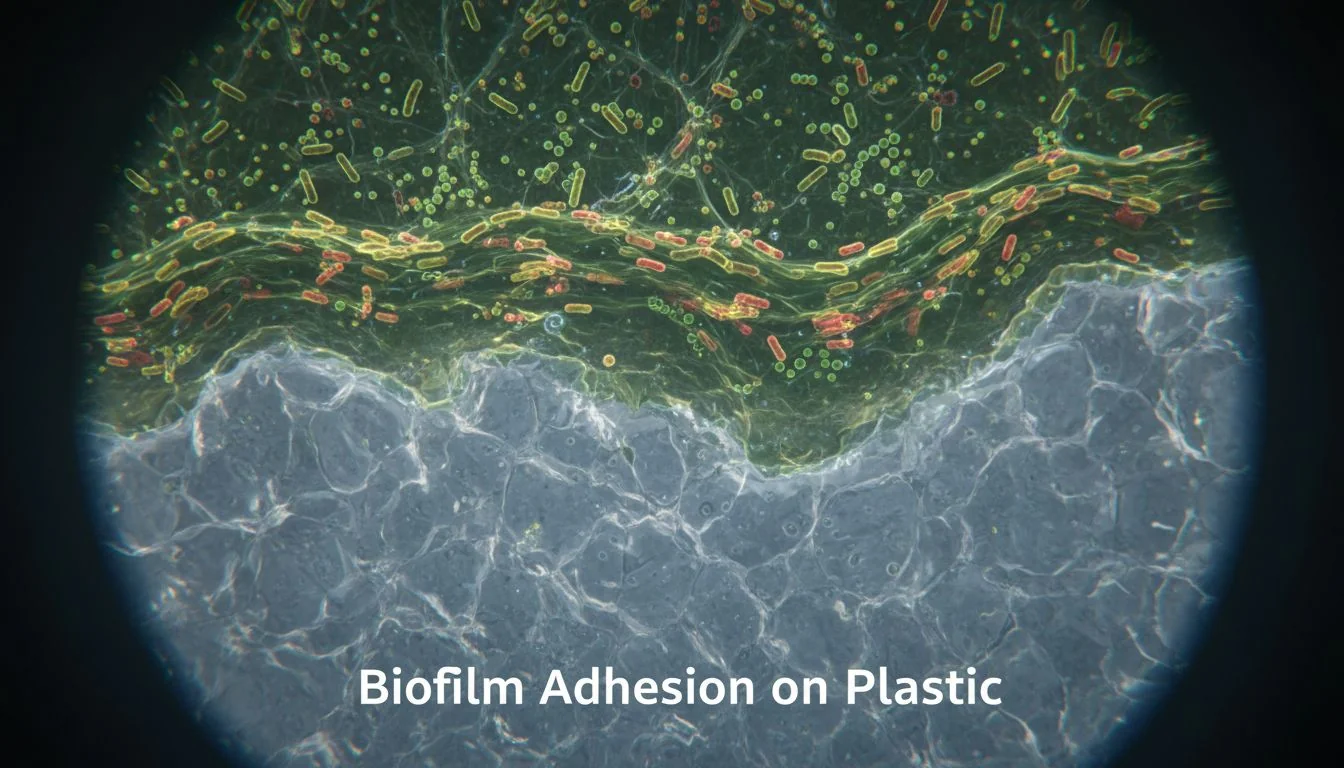

Users call it gross slime. Engineers must see it as a microscopic adhesion problem. We cannot scrub it away; we must design it away using physics.

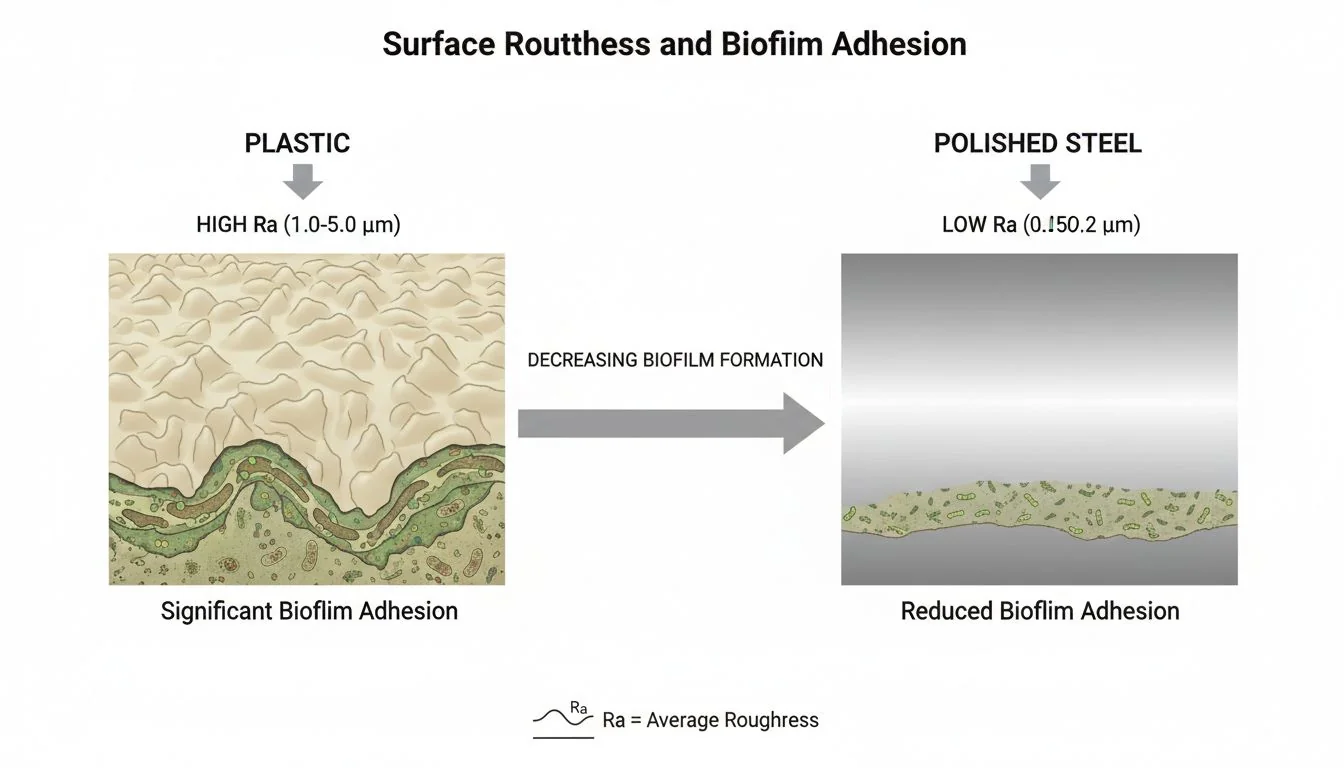

Biofilm formation is determined by surface roughness4 and topography. Bacteria need anchor points to colonize. Standard plastic injection molding leaves microscopic peaks and valleys that encourage adhesion. To stop the smell, you must engineer a surface with tension properties that reject bacterial attachment.

Let's get technical about "slime." In my years in the mold industry, I learned that surface finish is everything. Biofilm is not just dirt; it is an aggregate of microorganisms. They stick to surfaces using a matrix of extracellular polymeric substances (EPS). If your mold surface has a high $R_a$ (roughness average), you are giving the EPS a perfect grip. Plastic surfaces, even when polished, degrade over time. They develop micro-scratches from cleaning brushes.

These scratches become cities for bacteria. We need to think about "biofilm adhesion5" as a physics problem. If we lower the surface energy and smooth out the topography, the biofilm cannot stick. It slides off. This is why we need to move away from materials that scratch easily. We need materials that maintain a low friction coefficient against biological matter. Don't treat slime as a user hygiene issue. Treat it as a surface topography failure. If the surface is engineered correctly, the water tension alone should prevent the slime from anchoring.

High surface roughness (Ra) prevents biofilm formation.Falso

High roughness provides anchor points for bacteria to attach and grow.

Micro-scratches in plastic serve as breeding grounds for bacteria.Verdadeiro

Scratches protect bacteria from cleaning flow and provide surface area for adhesion.

How Does the Passive Surface of Stainless Steel Prevent Odors?

Antibacterial coatings wash off and scare consumers. You need a material that defends itself naturally. Stainless steel offers a permanent, chemical-free solution for hygiene.

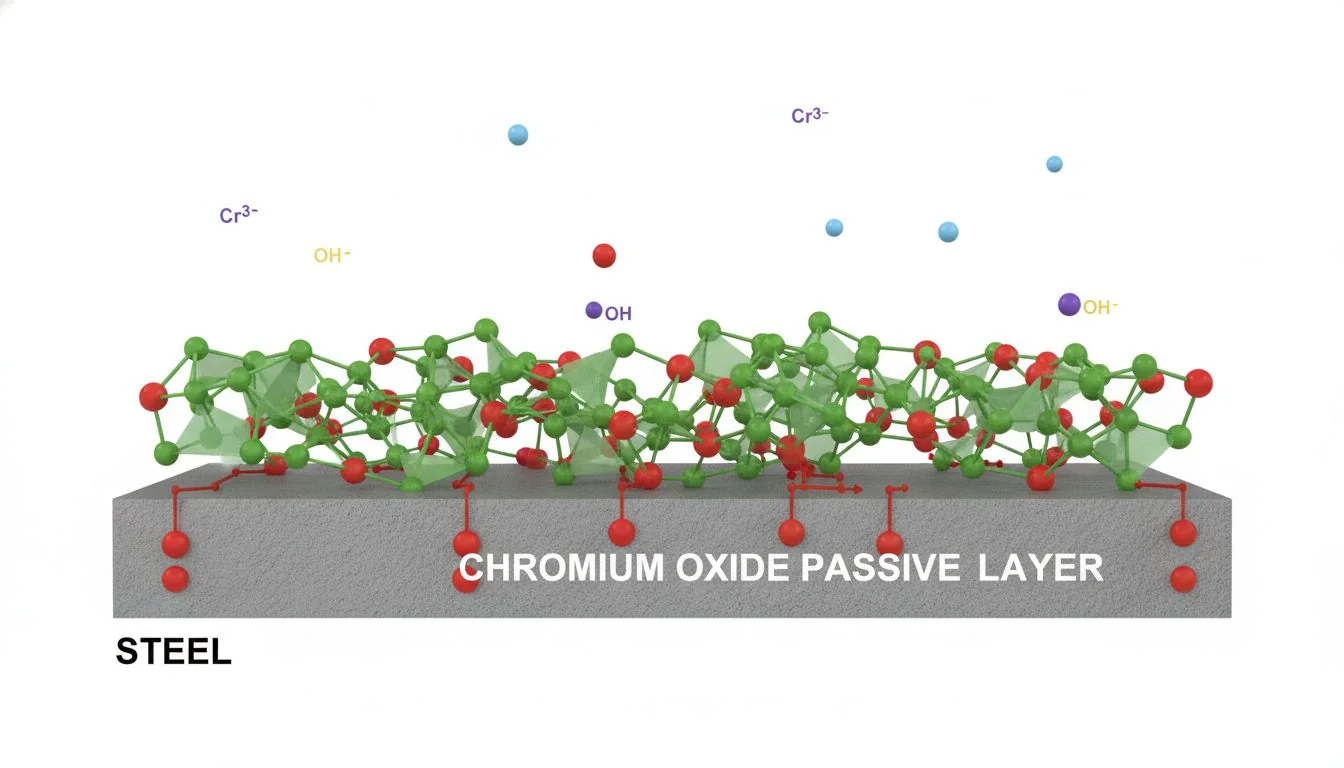

Stainless steel (304 or 316L) possesses a self-repairing passive layer of chromium oxide. This atomic barrier prevents iron from reacting with water and creates a hygienic surface where bacteria struggle to survive. Unlike plastic, it does not absorb volatile organic compounds that cause odors.

I always tell my clients to look at the material science. Why do hospitals use stainless steel? It is not just because it looks shiny. It is the "Passive Layer." When chromium in the steel meets oxygen, it forms a thin film of chromium oxide. This film is invisible, but it is a shield. It is non-porous and self-healing. If you scratch it, the oxygen reforms the layer immediately.

Plastic is different. At a molecular level, polymers have gaps. Odor molecules lodge into these gaps. That is why an old plastic container smells like old food forever. You cannot wash it out because the smell is inside the material structure. With stainless steel, the odor stays on the surface. You rinse it, and it is gone. For a premium water device, this "Flavor/Scent Integrity" is non-negotiable. We are relying on the material's atomic structure, not a temporary chemical spray. This is the only way to guarantee an odor-free experience6 after five years of use.

The passive layer on stainless steel is made of iron oxide.Falso

The passive layer is made of chromium oxide, which prevents rust and bacterial adhesion.

Stainless steel is non-porous to odor molecules.Verdadeiro

The dense atomic structure prevents volatile organic compounds from penetrating the material.

Why Is Seamless Deep-Draw Technology the Ultimate Manufacturing Moat?

Sharp corners are impossible to clean. Glued seams eventually leak. deep-draw technology7 creates a single, perfect geometry that competitors cannot easily copy.

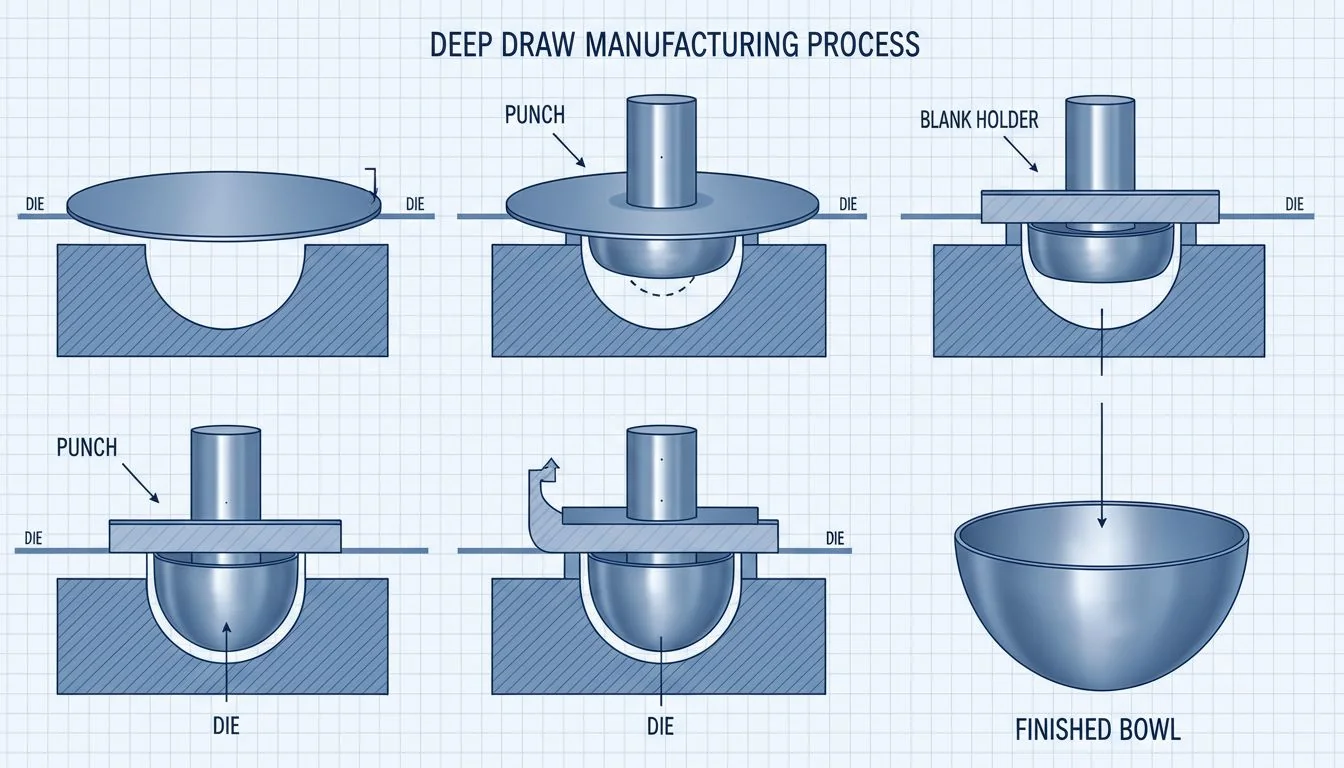

Deep-drawing is a metal forming process that stretches a flat sheet of steel into a deep 3D shape without welding. This results in a seamless bowl with large internal radii. Without corners or weld lines, there are no crevices for mold to hide, making cleaning effortless.

As a mold guy, I respect deep-draw tooling. It is hard. You are taking a flat sheet and forcing it into a deep cup. You have to manage material flow, thinning, and wrinkling. It requires expensive, high-precision dies and powerful hydraulic presses. This is a barrier to entry. Any factory can buy a cheap injection mold for a plastic box. But setting up a deep-draw line takes serious capital and engineering skill.

This is your "Competitive Moat." When you achieve this, you get a tank with zero internal seams. Think about the corners. In plastic design, we have sharp corners or glued joints. In deep-draw, we have smooth radii. A cleaning cloth wipes the whole surface in one motion. There are no 90-degree traps. This geometry is superior for hygiene. "Seamless" equals "Mold-Free." If you can master this manufacturing process, you offer a product structure that cheap competitors physically cannot replicate.

Deep-drawing requires welding multiple pieces of metal together.Falso

Deep-drawing stretches a single sheet of metal into a shape, eliminating the need for welds.

Seamless geometry eliminates hiding spots for mold.Verdadeiro

The lack of seams and sharp corners removes the physical crevices where biofilm accumulates.

A beautiful device that smells bad gets returned. Scent integrity is the invisible metric of luxury. It proves you care about the user's health.

For premium appliances, "Odor-Free" is a proxy for trust. If a $300 purifier emits a sour smell, the brand equity collapses. Ensuring the water tank remains neutral and hygienic protects the user's sensory experience and justifies the higher price point against commodity competitors.

I have built businesses by understanding value. Value is not just features; it is reliability. Imagine a user buys a high-end humidifier for their baby's room. They turn it on. It smells like wet dog or cheap plastic. That parent will never trust that brand again. The trust is broken. We are selling "Air Quality" or "Water Quality." If the tank adds a smell, we are polluting the product we promised to clean.

This is why the tank is not an accessory. It is the heart of the system. By using seamless steel, we guarantee that the water coming out is exactly the same as the water put in. That neutrality is luxury. It shows we engineered the product for the long term, not just for the showroom shelf. When a customer realizes the tank never smells, they become loyal for life. That is the power of solving the odor problem.

Odor is a primary driver of product returns in air quality devices.Verdadeiro

Bad smells directly contradict the promise of clean air or water, leading to immediate dissatisfaction.

Brand equity is unaffected by the smell of the product.Falso

Sensory experience is critical to brand perception; a bad smell signals low quality and danger.

Conclusão

Don't let a cheap tank ruin a premium product. By combining the passive science of stainless steel with seamless deep-draw engineering, we eliminate biofilm and secure brand trust.

References

-

Understanding the advantages of mold-free tanks can enhance product design and user satisfaction. ↩

-

Discovering the elements of premium quality can help brands differentiate their products. ↩

-

Understanding the importance of water quality can help brands improve their product offerings. ↩

-

Exploring the relationship between surface roughness and biofilm can lead to better material choices. ↩

-

Understanding biofilm adhesion can inform better design practices to prevent contamination. ↩

-

Understanding how to maintain an odor-free experience can enhance customer satisfaction and loyalty. ↩

-

Learning about deep-draw technology can highlight its benefits for product durability and hygiene. ↩