You have a brilliant product design, but the minimum order quantity1 from manufacturers feels like an impossible hurdle. This initial barrier can stop a great idea in its tracks.

The minimum order quantity (MOQ) for custom plastic parts2 typically starts between 1,000 to 5,000 units but can go much higher. This number is not fixed; it depends heavily on your part's complexity, the raw material you choose, and your manufacturing partner's operational costs.

That high number on a quote sheet can be intimidating. I've seen it discourage many aspiring product creators. But I'm here to tell you that the MOQ is not a final verdict. It's the start of a conversation. When I first started my own company, I had to learn how to navigate these discussions. It’s a skill, and like any skill, you can learn it. Understanding what actually goes into that number is the first step to taking control of your production costs and turning your design into a reality. Let's break it down together.

Every injection molding factory has a standard MOQ of 5,000 units.Falso

There is no industry-wide standard MOQ. It varies greatly depending on the factory's size, machinery, and the specifics of the project.

The cost of the injection mold itself is separate from the MOQ part price.Verdadeiro

The MOQ quote covers the cost of producing the parts. The mold (tooling) is a significant, one-time capital expense that you pay for upfront.

Your Product Dream & The MOQ Hurdle?

You’ve spent months perfecting your design in CAD. But when the quotes come back, the huge minimum order feels like a wall. It can seem like your project is over before it even begins.

The MOQ exists because manufacturing has significant setup costs. It represents the smallest batch a factory can produce to cover the expense of machine setup, labor, and material handling while still making a profit. It’s a number that makes the production run viable for them.

Let's dive deeper into why this number is so important to the manufacturer. Think about what it takes to start a production run. First, a technician has to retrieve your heavy steel mold from storage and carefully install it into an injection molding machine. This can take hours. Then, they have to heat the machine to the correct temperature for your specific plastic, which uses a lot of energy. They purge any old material from the barrel and load your new resin. Only after all this setup, which costs them time and labor where no parts are being made, can they start your run. If they only make 100 parts, the cost of that setup time spread across those few parts would be enormous. The MOQ ensures the run is long enough to make this entire process efficient and financially sensible for the factory.

Setup for an injection molding run takes only a few minutes.Falso

A proper mold setup, including installation, heating, and material purging, can take several hours, representing a significant labor and machine-time cost.

A manufacturer loses money during machine setup time.Verdadeiro

During setup, the machine is not producing parts, so the factory is incurring labor and energy costs without generating revenue, making short runs inefficient.

What Key Factors Influence Your MOQ?

Are you confused why one manufacturer quotes 2,000 units while another demands 10,000 for the same part? The factors driving your MOQ are often hidden in the details of your design and material choices.

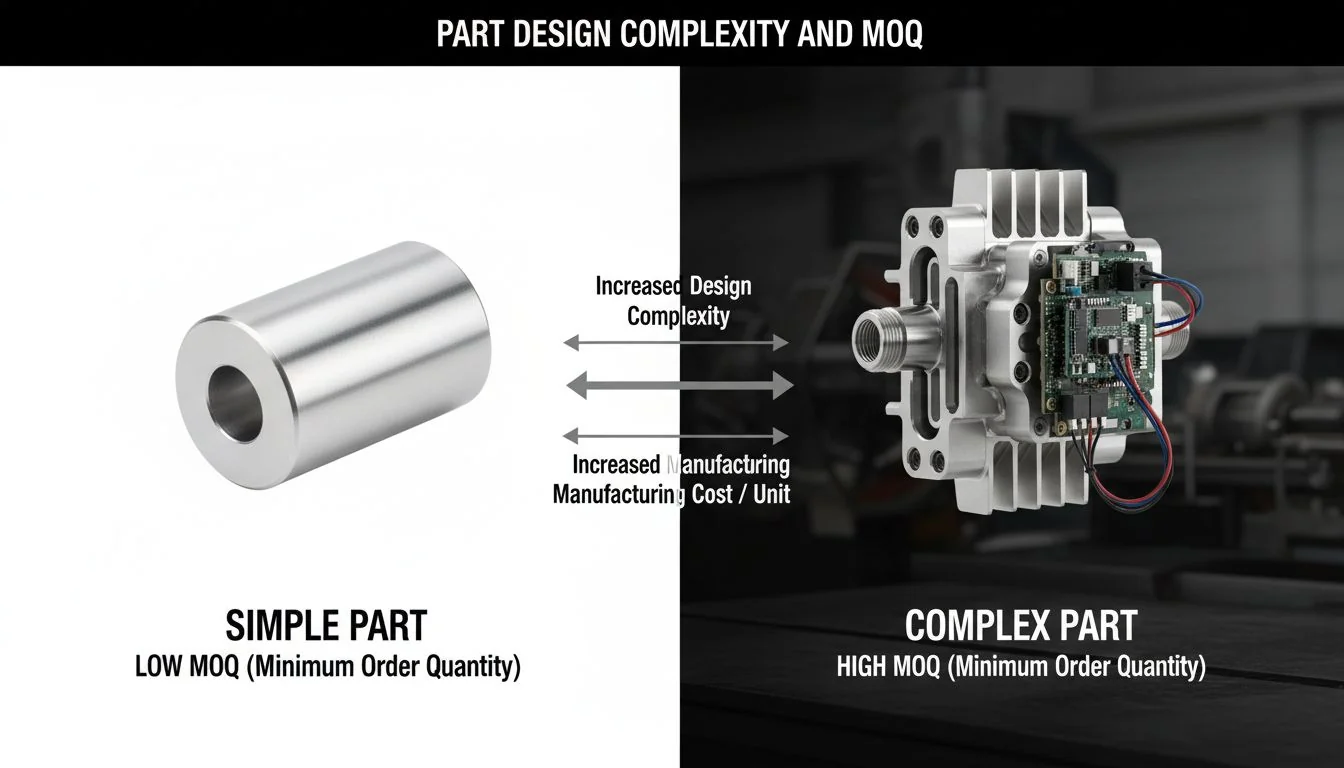

The most significant factors that dictate your MOQ are your choice of raw material3, the complexity of your part's design, and any required secondary operations like printing or assembly. Choosing a standard, widely available material for a simple part will always give you the lowest possible MOQ.

Let's break down these key factors. I always tell my clients to think about these three areas before they even ask for a quote. It’s the best way to manage expectations and start the conversation on the right foot. A little planning here goes a long way in controlling your startup costs.

The Big Three MOQ Drivers

| Fator | Low MOQ Scenario | High MOQ Scenario |

|---|---|---|

| Raw Material | Using a standard "house" resin like natural PP or black ABS that the factory buys in bulk. | Requiring a custom Pantone-matched color, a special-grade polymer (e.g., medical-grade), or a resin with specific additives (e.g., glass-filled). The material supplier has their own MOQ. |

| part complexity4 | A simple, open-and-close mold design with no undercuts or complex features. | A complex part requiring side-actions, lifters, or unscrewing mechanisms in the mold. More complex tooling means longer, more costly setups. |

| Secondary Ops | The part comes out of the mold and is finished. No extra steps needed. | The part requires pad printing, ultrasonic welding, assembly with other components, or special custom packaging. Each additional step can have its own setup costs and MOQs. |

Using a custom color for your plastic part does not affect the MOQ.Falso

Custom color matching requires the factory to order a specific resin compound, which comes with its own MOQ from the material supplier. This cost is passed on to you.

A simple part design will generally have a lower MOQ than a complex one.Verdadeiro

Simple parts require simpler molds and faster setups, reducing the manufacturer's costs and allowing them to offer a lower minimum order quantity.

How Can You Launch Your Product with a Manageable MOQ?

Receiving a high MOQ quote can feel like a rejection, making it seem impossible to launch without huge funding. But there are smart strategies you can use to get your foot in the door.

To secure a manageable MOQ, start by simplifying your design and choosing a standard "house" resin from your manufacturer. More importantly, find a manufacturing partner5, not just a producer, who is open to negotiation and views your initial small order as the start of a long-term relationship.

I remember working with a startup that designed a clever new kitchen gadget. Their first quotes came back with 20,000-unit MOQs, which was impossible for them. I sat down with them and we made two changes. First, we switched their custom light-blue color to a standard white ABS the factory had in stock. Second, we found a partner factory that specialized in lower-volume runs. They agreed to a 2,000-unit run because we showed them a plan for a 10,000-unit order within six months if the launch was successful. Instead of just asking for a discount, we offered them future value. This is how you turn a negotiation into a partnership. You can do the same by asking, "Can we do a smaller 1,000-unit run if I pay a higher per-part price or a separate setup fee?" This shows you understand their business and respect their costs.

Manufacturers will never lower their quoted MOQ.Falso

Many manufacturers, especially those who value long-term relationships, are willing to negotiate the initial MOQ if you can offer value, such as committing to future orders or paying a higher per-unit price.

Choosing a manufacturer's standard material is a key strategy for a lower MOQ.Verdadeiro

Factories buy their standard 'house' resins in huge quantities at a lower cost, and they don't have to place a special order with a material supplier, eliminating a major cause of high MOQs.

Is the Quoted MOQ Your Total Launch Cost?

You've done it. You negotiated a great MOQ and a fair per-part price. But beware, hidden costs can quickly inflate your budget and jeopardize your project if you're not prepared for them.

No, the MOQ quote is almost never your total cost. It only covers the production of the parts. Your total investment must include the massive one-time mold tooling cost6, shipping, quality control, warehousing, and any secondary processing. Always create a complete budget.

This is the mistake I see most often. A new entrepreneur gets excited about a $1 per-part price for a 5,000-unit MOQ. They budget $5,000. They completely forget that the steel injection mold itself can cost anywhere from $5,000 to $50,000 or more. This is your single biggest upfront expense. On top of that, you have to ship the parts from the factory, which can be thousands of dollars. You should also budget for a third-party quality inspection before the goods are shipped. Don't let these "other" costs be a surprise. Plan for them from day one. A low MOQ is great, but it's only one piece of a much larger financial puzzle you need to solve to bring your product to market successfully.

The price per part is the only cost you need to budget for when manufacturing a product.Falso

The total cost includes the one-time mold tooling cost, part cost (MOQ x price), shipping, taxes, quality control, and warehousing, which can far exceed the cost of the parts alone.

Mold tooling is a one-time investment that you own.Verdadeiro

You pay for the creation of the injection mold. It is your asset, and the manufacturer uses it to produce your parts for every production run.

Conclusão

An MOQ isn't a wall; it's a number you can influence. By understanding the drivers—design, material, and partnership—you can turn the MOQ negotiation into a strategic first step toward a successful launch.

References

-

Understanding MOQ is crucial for managing production costs and planning your product launch. ↩

-

Explore resources on designing and producing custom plastic parts effectively. ↩

-

Learn about different raw materials and their impact on production and costs. ↩

-

Understanding complexity can help you design more cost-effective products. ↩

-

Finding the right partner can significantly impact your production success and costs. ↩

-

Mold tooling is a significant investment; understanding its costs is essential for budgeting. ↩