На современном конкурентном рынке воздухоочистителей заказной воздухоочиститель позволяет брендам выделиться благодаря уникальным характеристикам, индивидуальному дизайну и специфическим функциям, которые ориентированы непосредственно на их целевых покупателей. Если вы стремитесь занять премиальный сегмент или удовлетворить потребности нишевой аудитории, заказной воздухоочиститель может обеспечить уникальное преимущество, необходимое вашему бренду.

Но создание индивидуального воздухоочистителя от концепции до выхода на рынок требует опыта, ресурсов и надежного OEM/ODM-партнера. Это руководство поможет вам пройти пошаговый процесс создания индивидуального очистителя воздуха с помощью HisoAir, обращая особое внимание на такие ключевые моменты, как эффективная коммуникация, бюджетирование и выбор технологий, которые ведут к успешному запуску продукта.

Раздел 1: Зачем строить индивидуальный воздухоочиститель?

Индивидуальные воздухоочистители позволяют брендам создавать уникальные ценностные предложения, подстраивая характеристики, дизайн и функциональность продукта под конкретные рынки и предпочтения покупателей. На рынке, где дифференциация продукции является ключевым фактором, уникальная модель воздухоочистителя может выделить ваш бренд и повысить лояльность клиентов.

1.1 Преимущества индивидуальных воздухоочистителей

При изготовлении воздухоочистителя на заказ у брендов появляется свобода выбора дизайна и интеграции функций, которые наиболее важны для их клиентов. Будь то усовершенствованная фильтрация для потребителей, заботящихся о своем здоровье, интеллектуальные функции IoT для технически подкованных пользователей или элегантный дизайн, соответствующий современному интерьеру, - заказная модель может привлечь и удержать клиентов, которые ищут что-то сверх стандартных предложений.

1.2 Преимущество работы с опытным OEM/ODM-партнером

Выбор такого опытного партнера, как HisoAir, гарантирует гладкий и эффективный процесс от начала и до конца. Имея более 20 лет опыта производства воздухоочистителей, HisoAir обладает техническим опытом, мощными производственными мощностями и послужным списком высококачественных воздухоочистителей, изготовленных по индивидуальным заказам для ведущих мировых брендов.

Раздел 2: Основные проблемы при разработке индивидуального проекта воздухоочистителя

Создание индивидуального воздухоочистителя - это полезный, но сложный процесс, сопряженный с рядом потенциальных проблем. Главной из них является коммуникация, которая может сделать или разрушить проект.

2.1 Важность четкой коммуникации

Общение - основа успешного партнерства OEM/ODM. Четкая коммуникация на каждом этапе очень важна, чтобы избежать недопонимания и дорогостоящих ошибок. Опытные менеджеры проекта HisoAir обеспечивают соответствие каждой детали ожиданиям вашего бренда - от первоначальных требований к продукту до окончательной корректировки производства.

2.2 Управление культурными и языковыми различиями при трансграничном сотрудничестве

Работа с международным партнером-производителем может быть сопряжена с культурными и языковыми проблемами. В компании [HisoAir] (http://hisoair.com "HisoAir") мы уделяем первостепенное внимание бесперебойному общению посредством плановых обновлений, подробной документации и использования инструментов управления проектами, которые позволяют обеим сторонам согласовывать сроки, требования к конструкции и основные этапы.

Раздел 3: Пошаговое руководство по процессу создания индивидуального воздухоочистителя

3.1 Исследование рынка и разработка концепции продукта

Первый шаг к созданию индивидуального воздухоочистителя - это понимание рынка. С HisoAir вы получите доступ к информации о предпочтениях потребителей и анализу конкурентов, что поможет вам определить характеристики продукта, которые будут соответствовать требованиям рынка и выделяться на фоне конкурентов.

3.2 Совместное проектирование и создание прототипов продуктов

Команда дизайнеров HisoAir тесно сотрудничает с клиентами, чтобы создать дизайн продукта, отражающий видение бренда. С помощью 3D-моделирования, промышленного дизайна и создания прототипов мы воплощаем в жизнь первоначальную концепцию. Во время создания прототипа у клиентов есть возможность протестировать и доработать функции, характеристики и элементы дизайна продукта, чтобы убедиться, что он соответствует как функциональным, так и эстетическим стандартам.

3.3 Предпроизводственный инжиниринг и поиск материалов

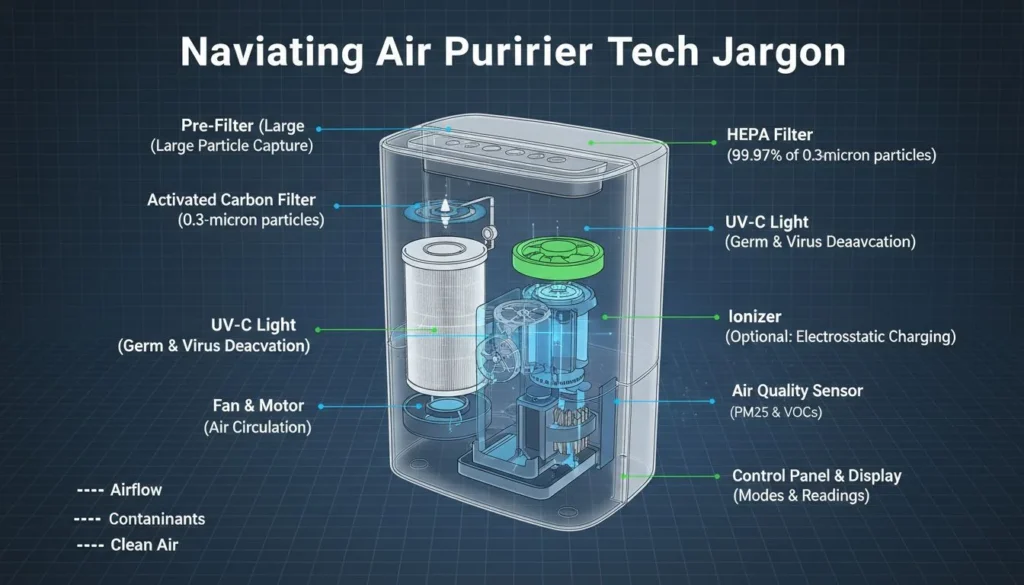

Чтобы убедиться, что конструкция готова к серийному производству, команда инженеров HisoAir оптимизирует каждый компонент для повышения эффективности производства. Приобретая высококачественные материалы и компоненты, такие как передовые фильтры HEPA, долговечные двигатели и шумоподавляющие элементы, HisoAir гарантирует, что продукт будет соответствовать стандартам долговечности, безопасности и производительности.

Раздел 4: Инвестиции и составление бюджета для проекта индивидуального очистителя воздуха

4.1 Факторы, которые необходимо учитывать при составлении бюджета

Стоимость проекта индивидуального воздухоочистителя зависит от множества факторов: качества материалов, технологических особенностей, требований сертификации и объема производства. HisoAir помогает клиентам понять каждый фактор стоимости и предлагает решения, позволяющие уложиться в бюджет без ущерба для качества.

4.2 Прозрачный процесс бюджетирования HisoAir

HisoAir делает упор на прозрачность, предоставляя четкую разбивку производственных затрат и стараясь избежать непредвиденных расходов. Каждая статья бюджета, начиная с проектирования и материалов и заканчивая производством и сертификацией, подробно описана, что позволяет клиентам точно планировать свои инвестиции.

4.3 Советы по максимизации окупаемости инвестиций с помощью персонализации

Инвестиции в функции, которые соответствуют потребностям клиентов и тенденциям рынка, могут максимизировать окупаемость инвестиций. Например, интеграция интеллектуальных IoT-возможностей привлечет клиентов, ориентированных на технологии, для которых приоритетом является возможность подключения, а антимикробные фильтры будут полезны для медицинских и образовательных учреждений, уделяющих особое внимание поддержанию стерильной среды. HisoAir направляет клиентов в выборе приоритетных функций, которые повышают привлекательность и долговечность на рынке, обеспечивая максимальную отдачу от инвестиций.

Раздел 5: Дифференцированные технологии - создание преимущества с помощью инноваций

Чтобы выделиться на конкурентном рынке воздухоочистителей, необходимы инновационные технологии. Команда разработчиков HisoAir помогает клиентам использовать передовые технологии для создания продуктов, обладающих явными преимуществами перед обычными воздухоочистителями.

5.1 Использование запатентованных технологий HisoAir

[запатентованные технологии HisoAir, такие как Decibel Cancellation™] (https://hisoair.com/decibel-cancellation-technology/ "запатентованные технологии HisoAir, такие как Decibel Cancellation™"), помогают брендам решить распространенные проблемы в области очистки воздуха. Технология шумоподавления снижает уровень шума при работе на 5-10 дБ, что делает ее идеальной для рабочих мест, школ и медицинских учреждений. Кроме того, уникальная конструкция воздуховодов HisoAir обеспечивает максимальную подачу чистого воздуха, сохраняя компактность и незаметность очистителя.

5.2 Интеграция IoT для интеллектуального управления и анализа данных

Для брендов, стремящихся завоевать рынок "умного дома" или технологически подкованных людей, интеграция IoT является ценным дополнением. Очистители воздуха [HisoAir's IoT-enabled air purifiers] (https://hisoair.com/air-purification-system/ "HisoAir's IoT-enabled air purifiers") позволяют осуществлять удаленный мониторинг, получать информацию о качестве воздуха в режиме реального времени и настраивать параметры, причем все это доступно через удобное приложение. Такая интеграция не только обеспечивает удобство, но и позволяет пользователям принимать решения о качестве воздуха в помещении на основе данных.

5.3 Как выбрать технологии, соответствующие целям бренда

Выбор правильной технологии зависит от позиционирования бренда и целевой демографической аудитории. Например, бренд, ориентированный на занятых профессионалов, может отдать предпочтение бесшумной работе и функциям дистанционного управления, в то время как бренд, ориентированный на здоровье семьи, может сделать акцент на улучшенной фильтрации HEPA и замках безопасности для детей. Команда HisoAir тесно сотрудничает с клиентами, чтобы убедиться, что каждая технологическая особенность соответствует их уникальному видению бренда.

Раздел 6: Проектирование и предпроизводственная подготовка

После завершения разработки дизайна и набора функций команда инженеров HisoAir готовит продукт к серийному производству, уделяя особое внимание эффективности, качеству и соответствию требованиям.

6.1 Проектирование для производства (DFM)

Проектирование для производства (DFM) - это важнейший этап, на котором инженерная команда HisoAir оптимизирует каждый компонент для обеспечения простоты производства и сокращения отходов. Оптимизируя проектирование для производства, HisoAir обеспечивает постоянный стандарт качества на всех крупных производственных партиях, сводя к минимуму риск дефектов и задержек.

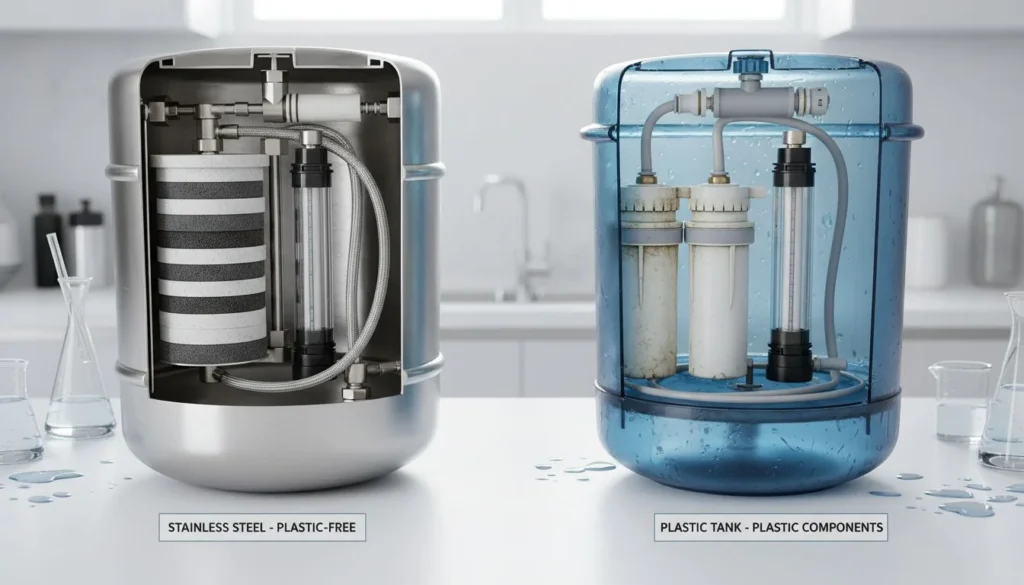

6.2 Поиск материалов и обеспечение качества

Выбор высококачественных материалов - это ключ к созданию долговечных и надежных воздухоочистителей. HisoAir закупает у надежных поставщиков такие высококачественные компоненты, как прочные материалы корпуса, прецизионные двигатели, высокоэффективные HEPA- и угольные фильтры. Каждый компонент проходит строгий контроль качества, гарантирующий, что конечный продукт соответствует высоким стандартам как HisoAir, так и клиента.

6.3 Подготовка к соответствию и сертификации

Чтобы помочь клиентам уверенно выйти на мировые рынки, HisoAir предоставляет рекомендации по получению необходимых сертификатов. Будь то сертификация CE, UL или AHAM, команда HisoAir оказывает помощь в обеспечении соответствия, гарантируя, что продукт соответствует нормативным стандартам. Такая подготовка гарантирует, что изготовленный на заказ воздухоочиститель будет готов к удовлетворению требований различных рынков.

Раздел 7: Производство и контроль качества

После завершения этапа проектирования и конструирования проект переходит к полномасштабному производству. Надежные процессы контроля качества HisoAir гарантируют постоянство и надежность каждого произведенного устройства.

7.1 Масштабирование от прототипа до массового производства

Производственные мощности HisoAir оборудованы для работы как с малыми, так и с большими объемами производства, с гибкими сроками для удовлетворения потребностей клиентов. Обеспечивая строгий контроль на этапе перехода от прототипа к серийному производству, HisoAir гарантирует, что каждое устройство будет соответствовать тем же стандартам качества, что и первоначальный прототип.

7.2 Контроль качества и протоколы испытаний

Контроль качества лежит в основе производственного процесса HisoAir. Каждый воздухоочиститель проходит множество проверок, от проверки CADR и тестирования уровня шума до оценки структурной целостности. Эти строгие протоколы контроля качества гарантируют, что продукт будет надежно работать в различных условиях и поддерживать ожидаемый стандарт эффективности очистки воздуха.

7.3 Упаковка и индивидуальный брендинг

Упаковка играет решающую роль в восприятии бренда. HisoAir предлагает индивидуальные варианты упаковки, чтобы улучшить впечатления от распаковки и усилить фирменный стиль с первого момента. От фирменных коробок до персонализированных инструкций - каждая деталь продумана до мелочей, чтобы создать незабываемое впечатление у покупателя, соответствующее вашему бренду.

Раздел 8: Стратегия запуска и поддержка после запуска

Успешный запуск продукта требует тщательной координации, и HisoAir предлагает поддержку, чтобы сделать его беспроблемным, от предпусковых до послепусковых услуг.

8.1 Координация успешного запуска продукта

HisoAir помогает клиентам подготовиться к успешному запуску, предоставляя высококачественные изображения продукта, технические характеристики и вспомогательные материалы, которые упрощают маркетинг. С помощью HisoAir бренды могут планировать эффективные запуски продуктов, которые привлекают внимание и способствуют росту продаж.

8.2 Услуги по поддержке после запуска

HisoAir заботится об успехе своих клиентов и после запуска, предлагая постоянную техническую поддержку, запасные части и помощь в устранении неполадок. Наша команда всегда готова решить любые проблемы, обеспечивая оптимальную работу вашего продукта для ваших клиентов.

8.3 Создание долгосрочного партнерства для будущих проектов

Партнерство не заканчивается с запуском продукта. HisoAir ценит долгосрочные отношения, и мы готовы помочь вам расширить линейку продукции или усовершенствовать существующие модели. Если вы хотите обновить функции или представить новый дизайн, наша команда готова поддержать ваши развивающиеся потребности.

Заключение

Создание индивидуального воздухоочистителя от концепции до выхода на рынок может быть сложным процессом, но с правильным OEM/ODM-партнером он превращается в упорядоченный и полезный процесс. HisoAir предлагает опыт, ресурсы и приверженность качеству, которые делают проекты по производству воздухоочистителей на заказ успешными - от первоначального проектирования до серийного производства и далее.

Благодаря нашим запатентованным технологиям, прозрачному бюджетированию и стремлению к удовлетворению потребностей клиентов HisoAir является идеальным партнером для компаний, желающих создать уникальный очиститель воздуха. Свяжитесь с нами сегодня, чтобы запланировать консультацию, и давайте начнем создавать высококачественный, индивидуальный воздухоочиститель, который отражает видение и ценности вашего бренда.

Призыв к действию (CTA): Готовы создать свой индивидуальный воздухоочиститель? Свяжитесь с экспертами HisoAir сегодня, чтобы начать свой путь от концепции к рынку с надежным OEM-партнером, который понимает ваше видение. Позвольте нам помочь вам создать продукт, который будет выделяться и удовлетворять потребности ваших клиентов.