You want a unique device for your wellness brand, but the path is full of risk. The nightmare of a two-year, $200,000 project ending in a moldy product is real.

Brands can partner with "Platform-Based OEM1" manufacturers. This involves using a pre-engineered, pre-certified core (like a hygienic stainless steel base) and customizing the external design. This strategy dramatically cuts development time, cost, and the risk of product failure, especially concerning hygiene.

In my years in the mold and manufacturing business, I've seen many brands chase the dream of a completely custom product. They think "Original Equipment Manufacturer" (OEM) means starting with a blank sheet of paper. It sounds great in a boardroom, but the reality on the factory floor is often a long, expensive lesson in what can go wrong. I've seen promising projects get buried in unexpected costs and delays.

But what if there's a better way? A way to get a unique, signature product without the massive risk? There is, and it involves rethinking what an OEM partnership2 should look like. Let's break down the old way and explore a smarter, faster path to launching a device that truly represents your brand.

Developing a new consumer electronics product from scratch typically costs between $100,000 and $1,000,000.Правда

This range accounts for design, engineering, prototyping, tooling, and initial production runs. Complex devices with custom electronics and software are at the higher end.

Any OEM factory can easily handle the design and production of a hygienic, medical-grade wellness device.Ложь

Designing for hygiene, especially in water-based appliances, is a specialized skill. It requires expertise in material science, fluid dynamics, and microbiology that most general assembly factories do not possess.

Why Are "Signature Devices" a Wellness Brand's Greatest Asset?

Your brand has a powerful message, but you're selling a generic device anyone can buy on Alibaba. It's a race to the bottom on price, and your unique value gets lost.

A signature device3 is your greatest asset because it physically embodies your brand's promise, creating a unique market position and justifying a premium price. It turns you from a reseller into an innovator, building deep customer loyalty that competitors can't touch.

When you sell a generic product, you are just another option on a crowded shelf. A signature device changes that conversation entirely. It's more than just putting your logo on something. It's about creating a product that is an extension of your brand's core values. For a wellness brand, this is critical. If your brand promises health and purity, you can't sell a plastic humidifier that could grow mold. Your product is your promise. I've worked with clients who finally understood this, and it transformed their business. They stopped competing on price and started building a real, defensible brand.

The Power of a Unique Product

A signature device allows you to control the entire customer experience, from the unboxing to the daily use. This is how you build a loyal following.

| Характеристика | Generic "White-Label" Product | True "Signature" Device |

|---|---|---|

| Brand Identity | Weak, easily substituted | Strong, inseparable from the product |

| customer loyalty4 | Low, price-driven | High, built on unique experience |

| Pricing Power | Commodity-based, low margins | Value-based, premium margins |

| market position5 | Crowded, competitive | Differentiated, defensible |

Brands with high customer loyalty grow revenues approximately 2.5 times faster than their industry peers.Правда

According to a report by the Harvard Business Review, loyal customers buy more, more often, and refer others, creating a powerful engine for growth.

A signature device is only about unique aesthetics and visual design.Ложь

A true signature device also includes unique functional benefits, superior materials, and an improved user experience that solves a core problem better than generic alternatives.

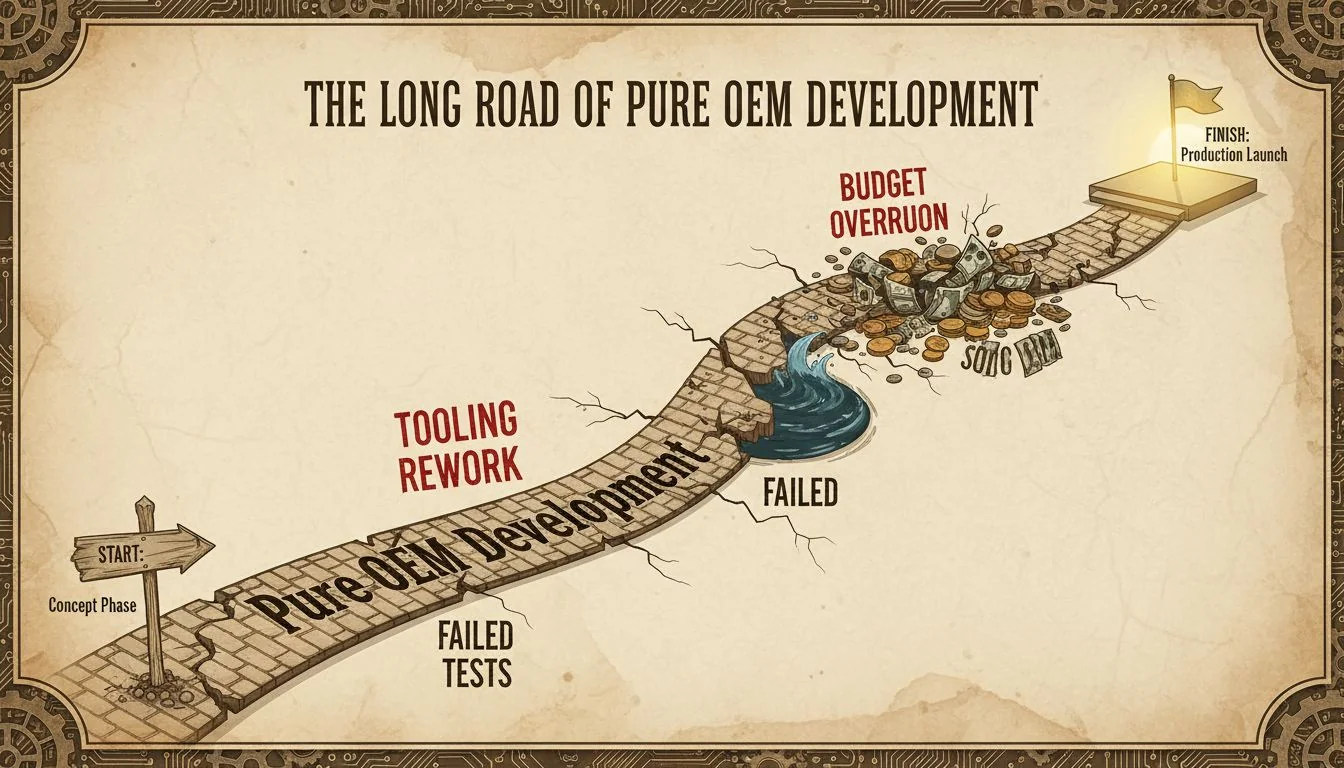

What Is the "Pure OEM" Dream and Why Does It Become a 24-Month Reality?

You have a brilliant idea for a custom device. You think, "I'll just find a factory to build it from scratch." It seems so simple. But then the timeline doubles, and costs explode.

The "Pure OEM" dream is creating a 100% unique product6 from a blank slate. The reality is often a 24-month (or longer) marathon of R&D, prototyping, tooling, and compliance testing. Each stage is a hidden trap of time and money, turning the dream into a costly ordeal.

I've guided many clients through this process. The initial excitement of a "from scratch" project is powerful. But the reality is a brutal series of hurdles. You aren't just paying for a mold; you're paying for the entire learning curve of the factory. Every engineering change, every failed test, every mold adjustment adds months and thousands of dollars to the project. I remember a client who wanted a unique vaporizer. They budgeted for one year. Three years and nearly half a million dollars later, they were still stuck trying to pass EPA certification. This is the hidden reality of "Pure OEM."

The Hidden Timeline of "From Scratch" Development

Here is a more realistic breakdown of the process:

| Сцена | Estimated Time | Potential Hidden Costs & Delays |

|---|---|---|

| Design & Engineering | 9-15 months | Multiple prototype revisions, engineering change orders (ECOs). |

| Tooling & Setup | 6-8 months | Mold adjustments, material testing failures, surface finish issues. |

| Compliance & Certification | 9-12 months | Failed safety/emissions tests, re-engineering, re-submission fees. |

| Total | ~24-35 months | $150,000 - $300,000+ |

The average time-to-market for a new hardware product developed from scratch is 18-36 months.Правда

This is a widely accepted industry average that accounts for the full cycle of ideation, design, engineering, prototyping, tooling, certification, and mass production setup.

The initial quote from an OEM factory covers all potential costs for the project.Ложь

Initial quotes rarely account for unforeseen complexities. Rework, failed tests, and design changes are almost always billed as additional costs, leading to significant budget overruns.

For a Wellness Brand, What Is the Real Risk of OEM?

You've budgeted for the time and money of a Pure OEM project. You think you've covered your bases. But what if, after all that, your new humidifier grows mold?

The real risk of OEM for a wellness brand isn't the money you lose on the project; it's the catastrophic damage to your brand's reputation. A product that fails on its core promise of "wellness" by being unhygienic can destroy customer trust forever.

This is the risk that keeps brand managers up at night. I've seen it happen. A brand spends two years and a fortune developing a beautiful plastic device. It launches, and the reviews are great... for the first month. Then, the emails start coming in. Pictures of pink slime and black mold in hard-to-clean corners. The brand is forced into a massive recall. The trust they spent years building is gone in an instant. This isn't a simple product failure7; it's a brand identity crisis.

The Hygiene Problem is an Engineering Problem

Solving for hygiene is not simple. It's a specialized discipline.

- The Plastic Problem: Most plastics are porous on a microscopic level. They have tiny crevices where bacteria can hide and form biofilm. Complex shapes with internal corners are almost impossible to clean perfectly.

- The Brand Promise: If you sell "wellness," "purity," or "health," your product must be flawless. A hygienic8 device is not a feature; it's the entire foundation of your promise.

- The Cost of Failure: A recall can cost millions, but the loss of brand equity is immeasurable. You become the brand known for the "moldy humidifier."

Biofilms, which are communities of bacteria, can form on many common plastic surfaces within 24-48 hours in a moist environment.Правда

This is a well-documented microbiological phenomenon. The porous nature and surface energy of many plastics make them susceptible to biofilm adhesion.

Designing a mold-resistant humidifier is as simple as choosing an 'anti-bacterial' plastic.Ложь

While some plastics have antimicrobial additives, true hygiene comes from design (no sharp corners, easy disassembly) and material choice (non-porous surfaces like stainless steel). It's a complex engineering challenge, not a simple material swap.

What Is "Platform-Based OEM" and Why Is It a Smarter Strategy?

The "Pure OEM" path is too slow and risky. But a generic product won't build your brand. Are you stuck? No. There's a third way.

Platform-Based OEM is a hybrid model where you start with a pre-engineered, pre-certified "core platform" that has already solved the hardest 80% of the problem (like hygiene and compliance). You then focus your resources on customizing the "signature" 20%—the look and feel.

Think of it like building a custom car. You don't design a new engine, transmission, and safety system from scratch. You start with a proven, world-class chassis and engine from a company like Porsche or Mercedes. Then, you hire a master coachbuilder to design a unique, beautiful body. You get a one-of-a-kind car, but it's built on a foundation of proven, reliable, high-performance engineering. Platform-Based OEM applies this same smart logic to product development. You leverage a partner's investment in core technology so you can focus on what you do best: building a brand.

The 80/20 Rule of Product Development

This model lets you de-risk the hardest parts and focus on what makes your brand unique.

| Характеристика | Pure OEM (From Scratch) | Platform-Based OEM |

|---|---|---|

| Core Engineering | Your risk & cost | Solved by partner |

| Hygiene & Safety | Your risk & cost | Solved by partner |

| Сертификаты | Start from zero (12+ mo) | Pre-certified (0-3 mo) |

| Time-to-Market | 24+ months | 6-9 месяцев |

| Upfront Investment | High ($150k+) | Moderate ($30k+) |

| Настройка | 100% (High Risk) | ~20-40% (Low Risk) |

Using a pre-certified module or platform can reduce a product's certification time by over 75%.Правда

If the core components affecting safety, emissions (like FCC/CE), and materials are already certified, the new product may only need partial or 'delta' testing for the new enclosure, which is much faster and cheaper.

Platform-Based OEM results in a product that looks the same as everyone else's.Ложь

The 'platform' is the internal core technology. The external housing, color, material, finish (CMF), and user interface are all fully customizable, allowing for significant brand differentiation.

How Does a "Hygienic Signature" Humidifier Come to Life?

This all sounds good in theory, but what does it look like in practice? How do you get a unique product from a platform?

Let's walk through it. A wellness brand partners with an innovator like Hisoair. They start with the certified, stainless steel water tank and core engine. The brand's designers then create a unique outer shell, select custom finishes, and launch in months, not years.

This is where the partnership becomes real. You're not just sending a purchase order to an assembler. You're collaborating with an engineering partner.

Step 1: Start with the "Certified Hero Platform"

You begin with a core unit that is already a masterpiece of engineering. Imagine a humidifier base and water tank made from a single piece of medical-grade stainless steel. It's designed to be boiled or put in a dishwasher. There are no hidden corners for mold to grow. Crucially, this platform has already passed the big, expensive tests: ETL for safety, CARB for emissions, and EPA for compliance. The 12-month, $50,000+ certification headache is gone.

Step 2: Design Your Signature Housing

Now, your team does what it does best. You design the "dress" for this core platform. You are not reinventing the engine; you are designing the beautiful car around it. You choose the shape, the materials for the outer shell, the color palette, the button layout, and the user interface. You create the signature experience that is unique to your brand.

Step 3: Fast-Track to Market

Because the core is pre-certified, the path to launch is incredibly fast. You finalize your design, create the new molds for the outer shell (a much simpler and cheaper tool), and move to production. You can go from concept to market in as little as 6-9 months.

Stainless steel is non-porous, corrosion-resistant, and can be sanitized at high temperatures, making it a superior material for hygienic applications compared to most plastics.Правда

This is a fundamental property of the material, which is why it is the standard for medical instruments, food processing equipment, and high-end kitchenware.

Any cosmetic change to a pre-certified device requires a full, year-long re-certification process.Ложь

If the core electrical, heating, and water-contact components remain unchanged, modifications to the external, non-functional housing typically require only minimal 'delta' testing, if any.

Заключение

To launch a signature wellness device, skip the slow, expensive risks of "Pure OEM." Find a true partner who offers an innovative, pre-certified platform, and build your unique brand on a foundation of proven excellence.

References

-

Explore how Platform-Based OEM can streamline your product development process and reduce risks. ↩

-

Understand the advantages of partnering with OEM manufacturers for product development. ↩

-

Learn how a signature device can enhance your brand identity and customer loyalty. ↩

-

Find out how building customer loyalty can significantly boost your brand's revenue. ↩

-

Discover strategies for establishing a strong market position in a competitive landscape. ↩

-

Explore the elements that contribute to a product's uniqueness and market differentiation. ↩

-

Investigate the risks of product failure and how to mitigate them in your projects. ↩

-

Discover the importance of hygiene in wellness products and how it affects customer trust. ↩