In an increasingly health-conscious world, the quality of the air we breathe indoors has moved from a niche concern to a global priority. Regulatory bodies are tightening standards, consumers are more aware than ever of airborne pathogens and pollutants, and businesses are seeking robust solutions to ensure the well-being of their occupants. For brands looking to enter or expand within the air purification market, simply offering a product is no longer enough. Success hinges on partnering with a manufacturer that not only possesses cutting-edge technology but also provides unparalleled customer support.

This blog post will delve into six technology-driven reasons why an advanced Original Equipment Manufacturer (OEM) or Original Design Manufacturer (ODM) is crucial for your brand's success in the air purification space. Beyond the hardware, we'll also explore the often-overlooked aspect of world-class customer support – a critical differentiator that transforms good products into lasting market advantages and secures your brand's reputation.

Rising Compliance Barriers

The landscape of air purification is increasingly shaped by stringent regulatory frameworks designed to protect public health. Navigating this complex web of standards, which varies significantly across regions, can be a daunting task for any brand. Key compliance barriers include:

- Zero-Ozone (UL 2998): This standard, particularly critical in North America, addresses concerns about ozone emissions from air purifiers, which can be harmful to respiratory health. Manufacturers must ensure their products do not produce ozone above a certain threshold.

- ISO 16890 Particulate Classes: This international standard classifies air filters based on their efficiency in capturing different sizes of particulate matter (PM). Understanding and meeting these classifications (e.g., ePM1, ePM2.5, ePM10) is vital for effective filtration and market acceptance, especially in commercial and industrial applications.

- Regional VOC Limits: Volatile Organic Compounds (VOCs) are a broad class of chemicals that can be emitted from various sources indoors and contribute to poor indoor air quality. Different regions have specific limits on VOC emissions from products, requiring careful material selection and manufacturing processes.

An R&D-driven manufacturer with deep expertise in advanced air purification technologies can de-risk multi-region certification in one shot. They possess the in-house testing capabilities, knowledge of global regulatory requirements, and the agility to design products that meet or exceed these standards from the outset. This proactive approach saves significant time and resources, preventing costly redesigns and delays in market entry.

“Combo” Filtration Is the New Normal

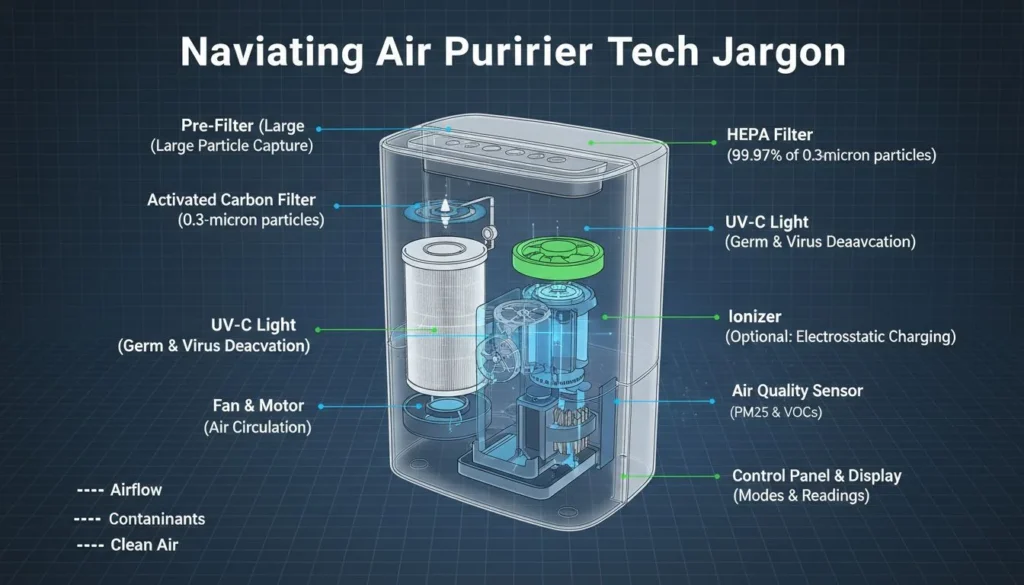

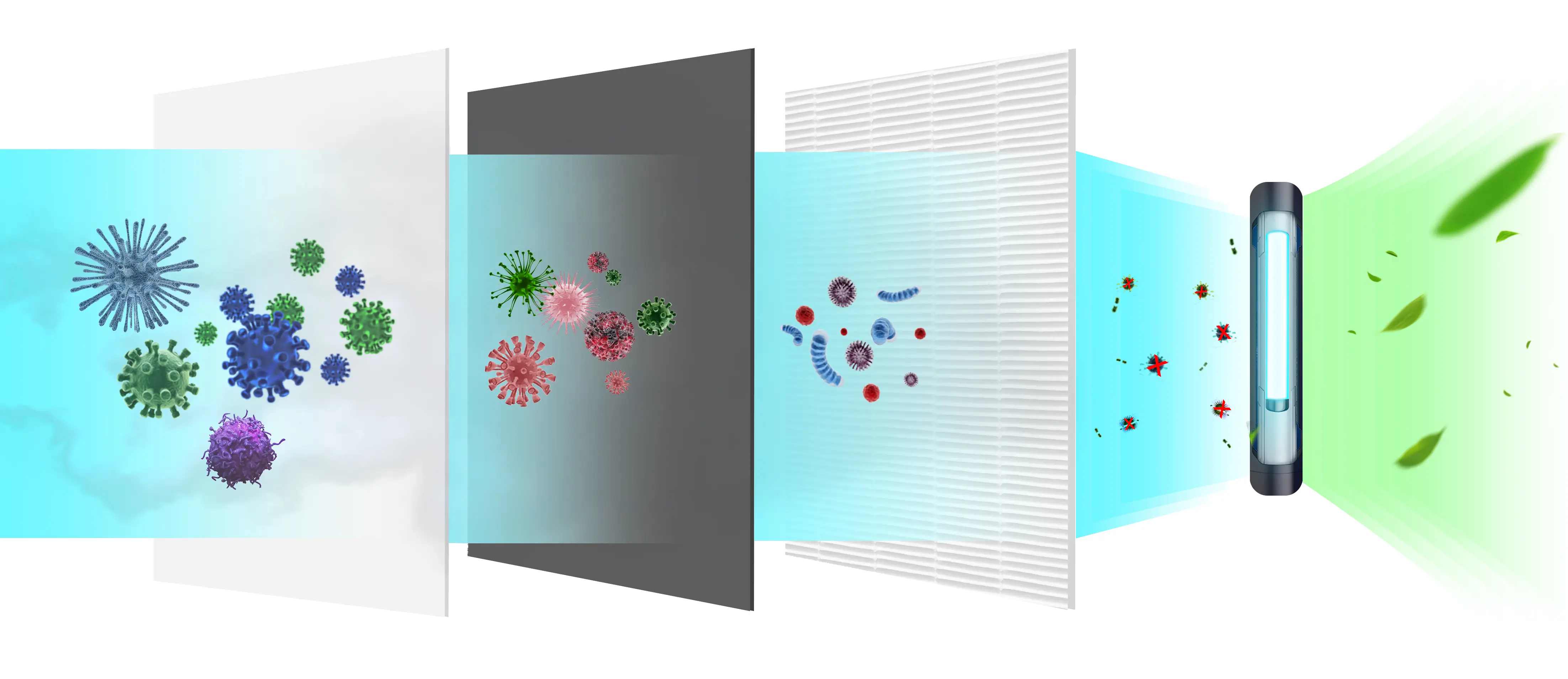

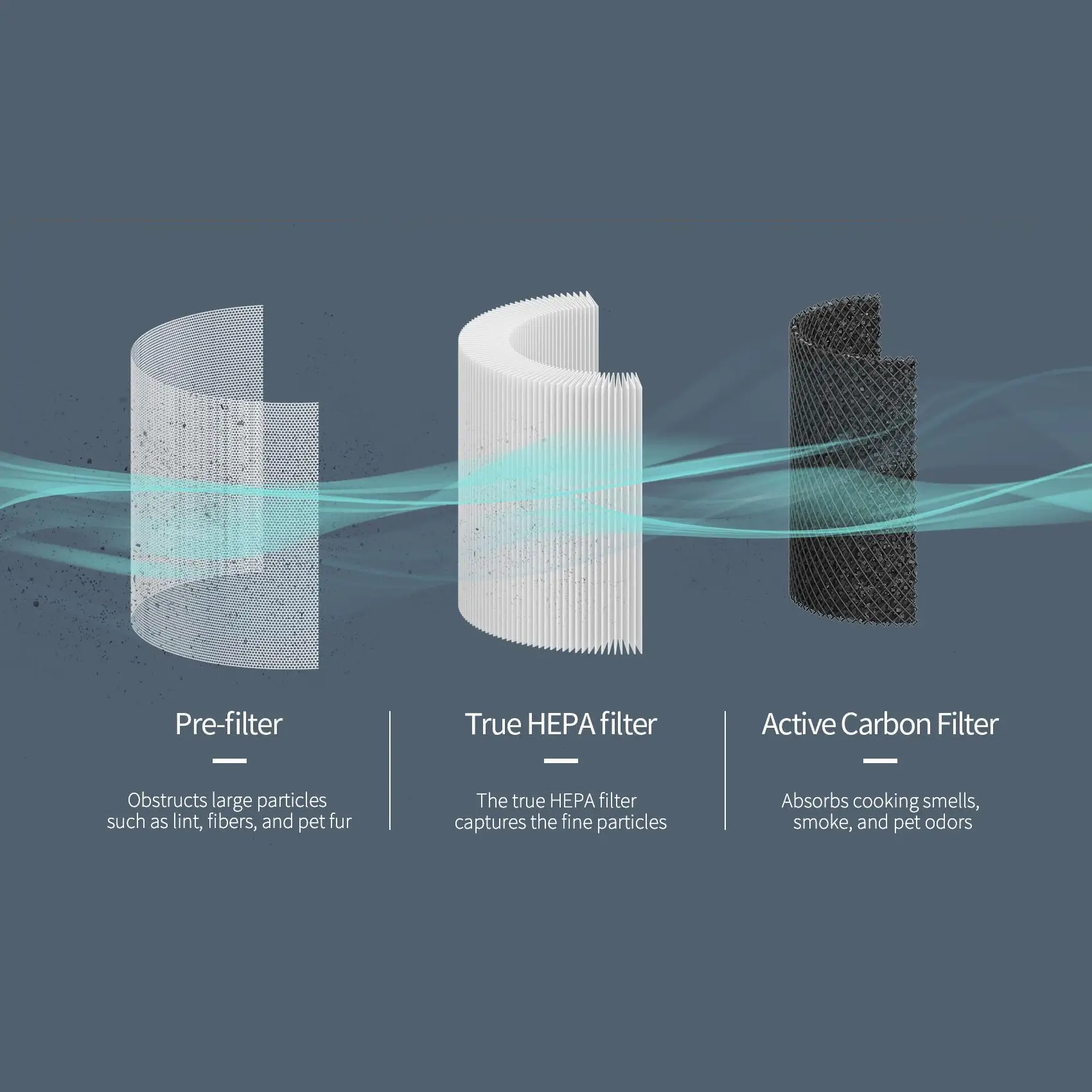

The days of single-mechanism air purification are largely behind us. Modern air quality challenges demand a multi-pronged approach, leading to the dominance of “combo” filtration systems in commercial and high-performance residential applications. These systems often integrate several technologies to address a wider spectrum of pollutants:

- HEPA (High-Efficiency Particulate Air) Filters: The cornerstone of particulate removal, HEPA filters are highly effective at capturing microscopic particles, including dust, pollen, pet dander, and mold spores.

- UV-C (Ultraviolet-C) Light: UV-C technology is employed for its germicidal properties, effectively neutralizing bacteria, viruses, and other microorganisms by disrupting their DNA or RNA.

- Activated Carbon Filters: These filters are crucial for adsorbing gases, odors, and Volatile Organic Compounds (VOCs) that HEPA filters cannot capture.

- Photocatalysis: This advanced oxidation process uses a photocatalyst (often titanium dioxide) and UV light to break down harmful organic compounds into harmless substances like water and carbon dioxide.

While the integration of these technologies offers superior air purification, it also presents significant engineering challenges. A critical distinction lies between a “parts-stacker” and an integrative engineering team. A “parts-stacker” simply combines off-the-shelf components without a holistic design approach, often leading to inefficiencies, suboptimal performance, and potential safety issues. In contrast, an integrative engineering team meticulously designs each component to work synergistically, optimizing airflow, maximizing purification efficiency, and ensuring the longevity and safety of the system. This involves complex considerations such as fan dynamics, material compatibility, and the precise placement of each purification stage to achieve the best possible results.

Smart & AI-Enabled Air Care

The evolution of air purification has moved beyond simple filtration to embrace the power of smart technology and Artificial Intelligence (AI). Modern air purifiers are no longer passive devices; they are intelligent systems capable of real-time monitoring, adaptive performance, and predictive maintenance. Key features that an advanced OEM must master include:

- Remote Dashboards: Allowing users and facility managers to monitor air quality data, control devices, and receive alerts from anywhere via a connected application. This provides unprecedented transparency and control over indoor environments.

- Pollutant-Adaptive Fan Curves: AI algorithms can analyze real-time air quality data from embedded sensors and automatically adjust fan speeds and purification modes to optimize performance based on the detected pollutant levels. This ensures efficient energy use and effective pollutant removal.

- Filter-Life Prediction: By tracking usage patterns, air quality data, and filter performance, smart systems can accurately predict when filters need replacement, notifying users in advance and ensuring continuous optimal performance. This enhances user convenience and prevents premature filter changes or delayed replacements.

- Embedded Sensing, Firmware, and Cloud Stacks: The backbone of smart air care lies in sophisticated embedded sensors that detect various pollutants (e.g., PM2.5, VOCs, CO2), robust firmware that manages device operations, and secure cloud infrastructure that enables data collection, analysis, and remote control. A manufacturer with expertise in these areas can deliver truly intelligent and connected air purification solutions, offering a significant competitive advantage in the market.

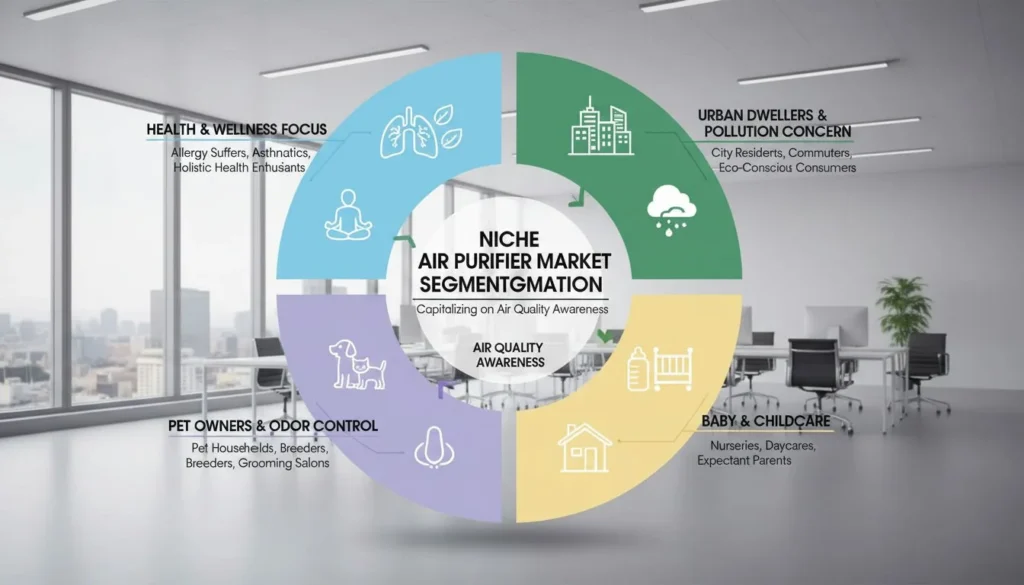

Follow the Margin: Growth in High-End Purification

The air purification market is not monolithic; while commodity purifiers address basic needs, significant growth and higher margins are increasingly found in the high-end and specialized segments. Brands looking for sustainable profitability should align their product roadmaps with these burgeoning niches. Data consistently shows robust Compound Annual Growth Rates (CAGR) in areas such as:

- UV-C Technology: Driven by heightened awareness of airborne pathogens, the demand for UV-C integrated air purification systems has surged, particularly in commercial, healthcare, and educational settings. These systems offer an additional layer of disinfection beyond particulate and gas filtration.

- Medical-Grade Segments: The need for ultra-clean air in hospitals, clinics, laboratories, and other sensitive environments has fueled the expansion of medical-grade air purifiers. These devices often feature advanced HEPA filtration (e.g., H13/H14), stringent air change rates, and robust construction to meet demanding healthcare standards.

Partnering with technology leaders in air purification allows your brand to tap into these fastest-growing niches. Such manufacturers are already investing heavily in the R&D, certifications, and manufacturing capabilities required for these advanced technologies. This strategic alliance enables your brand to introduce products with higher Average Selling Prices (ASPs) and better profit margins compared to competing in the saturated commodity market. By leveraging their expertise, you can accelerate your time to market with cutting-edge solutions that resonate with discerning customers and address critical air quality challenges.

Rapid Response to Emerging Threats

The world has become acutely aware of how quickly new airborne threats can emerge, from global pandemics like COVID-19 to localized issues such as formaldehyde spikes in new constructions or wildfire smoke. In such scenarios, the speed at which an air purification manufacturer can innovate and adapt its technology becomes paramount. This agility is a critical differentiator for brands seeking to provide timely and effective solutions.

An advanced manufacturer possesses the R&D infrastructure and flexible production capabilities to pivot quickly. This includes:

- Prototyping Speed: The ability to rapidly design, test, and iterate on new purification mechanisms or product modifications. For instance, a manufacturer might develop a UV-LED upgrade for existing platforms in a matter of weeks to address a new viral threat.

- Material Sourcing Agility: Access to a robust global supply chain that can quickly source new or alternative materials required for novel filtration or disinfection technologies.

- Regulatory Foresight: Staying ahead of emerging health guidelines and potential regulatory changes, allowing for proactive product development rather than reactive adjustments.

Consider the example of the COVID-19 pandemic. Manufacturers with advanced R&D capabilities were able to quickly develop and integrate enhanced filtration (e.g., higher-grade HEPA) and disinfection technologies (e.g., improved UV-C systems) into their air purifiers. This rapid response allowed their brand partners to meet urgent market demands and provide essential public health tools. Conversely, manufacturers lacking this agility were left behind, unable to capitalize on the critical need for advanced air purification solutions. Partnering with a manufacturer that can demonstrate a proven track record of rapid innovation in the face of emerging threats ensures your brand remains relevant and responsive in a dynamic air quality landscape.

Lifecycle Performance & User Retention

Beyond initial purchase, the long-term performance and user experience of an air purification system significantly impact customer satisfaction, brand loyalty, and ultimately, repeat purchases. A truly advanced manufacturer understands that designing for lifecycle performance is crucial for user retention. This involves focusing on factors that contribute to lower Total Cost of Ownership (TCO) and a superior user experience:

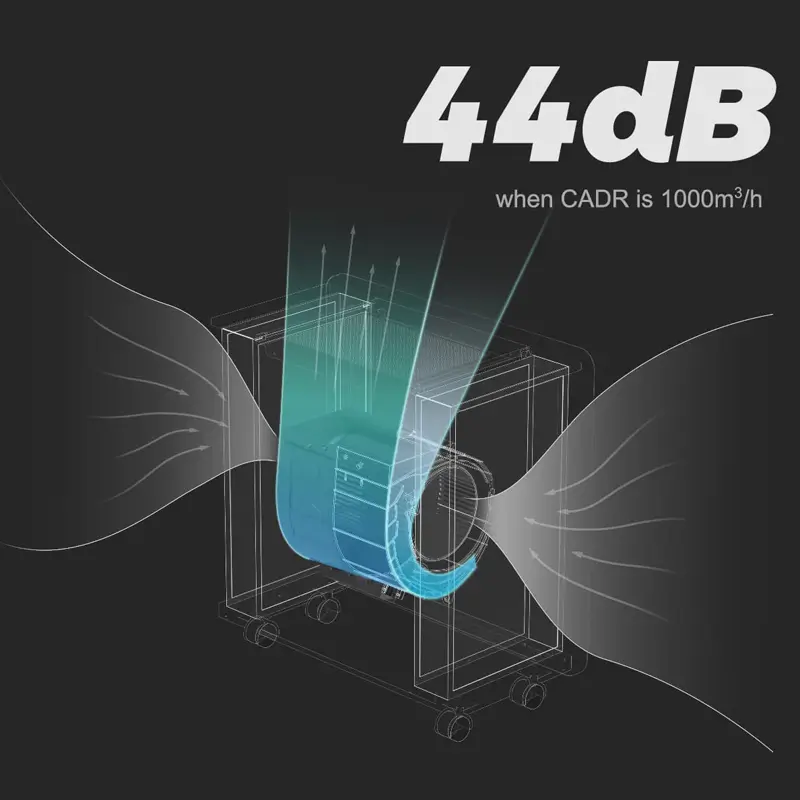

- Energy Savings: Energy-efficient designs, often achieved through optimized fan motors, intelligent controls, and low-pressure-drop filtration media, reduce operational costs for the end-user. This is a significant selling point, especially for commercial and industrial clients with large fleets of devices.

- Quiet Operation: Noise is a major concern for air purifiers, particularly in residential and office environments. Advanced manufacturers employ sophisticated acoustic engineering, including optimized fan blade designs, motor isolation, and sound-dampening materials, to achieve maximum purification with minimum noise. HisoAir's "Decibel Cancellation™ Technology" is a prime example of this commitment, ensuring their purifiers are ideal for noise-sensitive environments.

- Predictive Maintenance: As discussed in the 'Smart & AI-Enabled Air Care' section, the ability to predict filter life and other maintenance needs ensures continuous optimal performance and prevents unexpected downtime. This proactive approach enhances user convenience and reduces frustration.

The importance of designing for data feedback loops from day one cannot be overstated. By integrating sensors and connectivity, manufacturers can collect real-world performance data, allowing for continuous improvement of future product generations. This data can inform filter replacement schedules, identify common usage patterns, and even highlight areas for further energy optimization. When users experience reliable, quiet, and cost-effective operation, coupled with intelligent maintenance notifications, they are far more likely to remain loyal to your brand and recommend your products to others. This focus on lifecycle performance transforms a one-time sale into a long-term customer relationship.

While cutting-edge technology and superior product performance are undoubtedly critical for success in the air purification market, there’s a hidden multiplier that often determines long-term brand loyalty and market leadership: world-class customer support. For many businesses, the true value of a manufacturing partnership extends far beyond the hardware itself. It encompasses the comprehensive support infrastructure that ensures smooth operations, rapid problem resolution, and sustained market advantage. Here are key aspects of customer support that differentiate a truly valuable manufacturing partner:

- 24/7 Engineering Back-Up: In the fast-paced world of technology, issues can arise at any time. A manufacturer offering round-the-clock engineering support for live failure analysis and rapid firmware hot-fixes (e.g., within 48 hours) provides an invaluable safety net. This ensures minimal downtime for your products in the field, protecting your brand’s reputation and customer satisfaction.

- Global Spares & Service Hubs: The ability to quickly provide replacement parts and service in major markets is crucial for maintaining product uptime and customer trust. A manufacturer with strategically located global spares and service hubs can ensure replacement parts are shipped within 72 hours, significantly reducing service turnaround times.

- Contractual SLAs (Service Level Agreements): Beyond informal promises, a reliable manufacturer will offer contractual SLAs that include downtime penalties, End-of-Life (EOL) component guarantees, and proactive compliance updates. These agreements provide a clear framework for accountability and ensure your supply chain remains robust and compliant.

- Co-Marketing & Training: A true partner invests in your success. This includes providing comprehensive sales-team enablement, retailer education, and access to certification libraries. Co-marketing initiatives can amplify your brand’s message, while thorough training ensures your sales force and channel partners are well-equipped to articulate the value of your products.

Key Message: Advanced technology secures the sale, but responsiveness secures the brand reputation—and repeat orders.

In essence, while innovative air purification technology provides the initial appeal and performance, it is the unwavering commitment to customer support that builds lasting trust and ensures repeat business. A manufacturer that stands by its products with robust support mechanisms transforms potential challenges into opportunities for strengthening customer relationships and reinforcing your brand’s commitment to excellence.

Conclusion

In a world where clean air is non-negotiable, the brands that win aren’t just shipping filters—they’re shipping confidence. They are building trust through superior technology, unwavering reliability, and a partnership that extends far beyond the factory floor. By choosing a manufacturer with deep expertise in advanced air purification technologies and a steadfast commitment to world-class customer support, your brand can not only meet the growing demand for clean air solutions but also establish itself as a leader in this vital industry.