You design a beautiful product, but the core technology feels outdated. Customers today want more than just dust removal; they want total protection from invisible threats in their homes.

Next-generation filtration1 moves beyond passive trapping to active sterilization. Technologies like UV-C, Plasma, and PCO destroy pathogens and VOCs rather than just holding them, offering a "Bio-Secure" solution that outperforms traditional HEPA standards.

I used to believe that a thick, folded HEPA filter was the end of the story for air purification. But after years in the manufacturing industry, I have seen the limitations firsthand. We need to look at the engineering shifts happening right now.

HEPA filters can trap particles as small as 0.3 microns.True

High Efficiency Particulate Air (HEPA) filters are certified to capture 99.97% of particles that are 0.3 microns in diameter.

HEPA filters actively kill bacteria and viruses upon contact.False

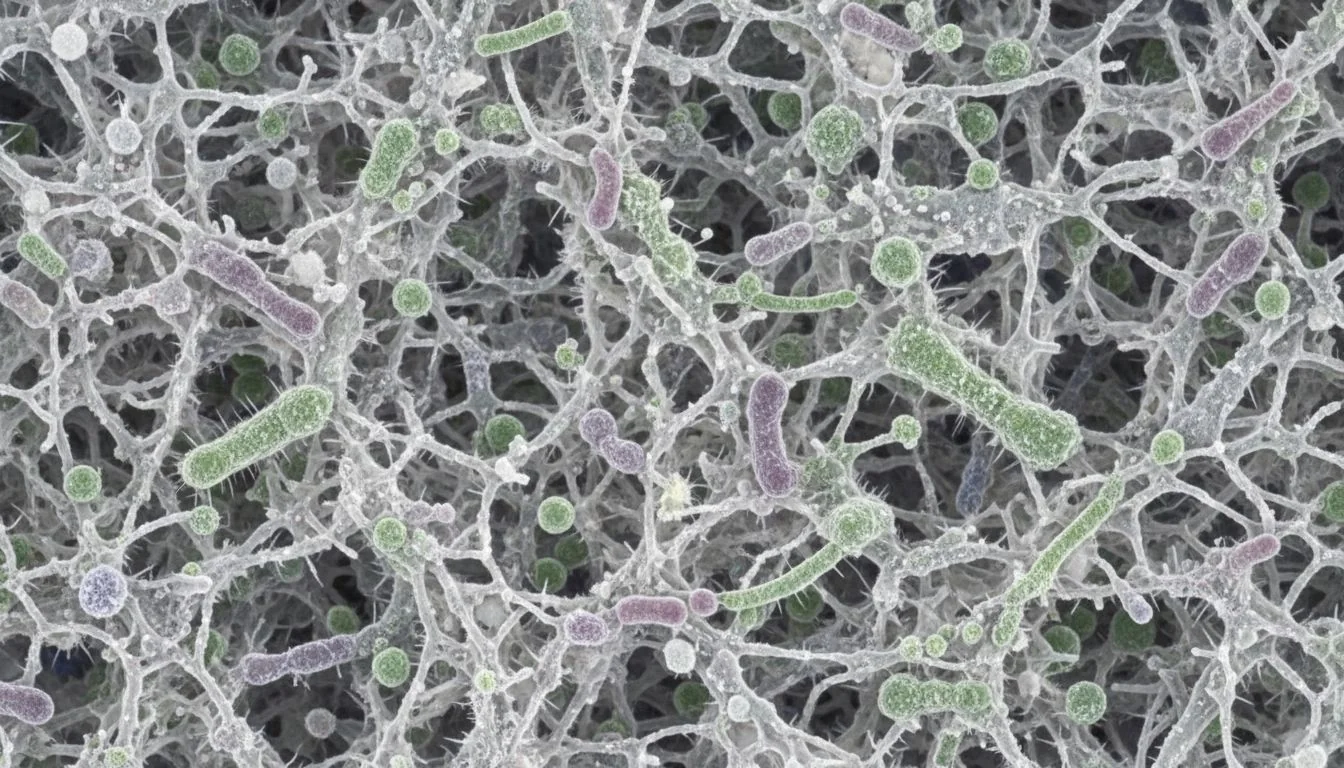

HEPA filters only trap contaminants; they do not kill them. Bacteria can remain alive on the filter surface.

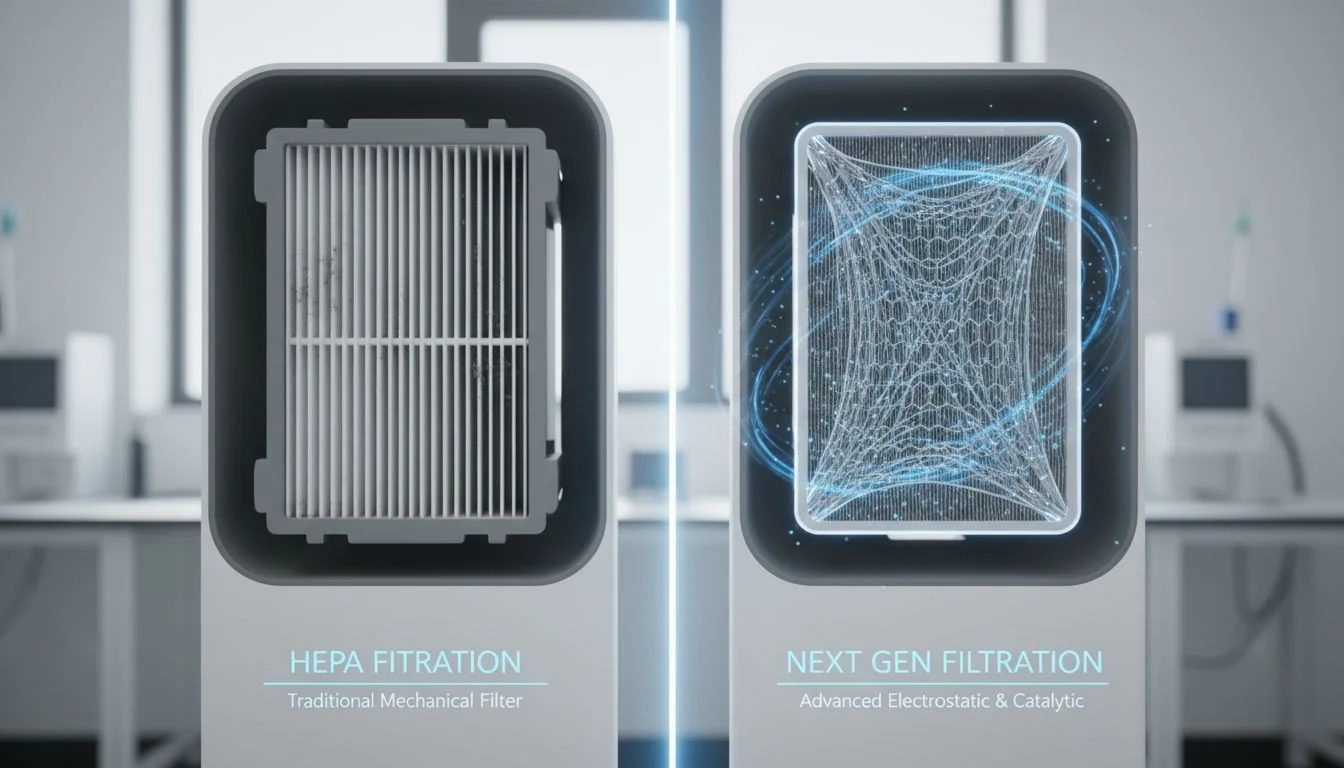

Why Is HEPA No Longer Enough for Modern Needs?

We have relied on HEPA filters for decades, but they have a major flaw. They act like a jail cell, trapping bad things but keeping them alive inside the unit.

HEPA filters function as passive traps, capturing particulates but failing to neutralize biological threats or gases. In a health-conscious market, the value proposition has shifted from "trapping" dirt to "killing" pathogens, requiring a move toward bio-secure designs.

When we look at the "Trap vs. Kill" concept, the difference becomes clear. A HEPA filter is like a prison. It holds dust, pollen, and bacteria. However, if the environment is humid, that filter can actually become a breeding ground for mold and bacteria. As a mold designer, I see the irony here. We try to prevent mold in our plastic injection processes, yet we design machines that might grow it on the filter.

The market is demanding a "Bio-Secure" device. This is where the "Kill" mechanism comes in. We need to think of the air purifier not as a net, but as an executioner. This shift changes how we design the internal chassis. We are not just managing airflow anymore; we are managing sterilization chambers. For a designer like Jacky, this means considering how to integrate these kill-steps without restricting the Clean Air Delivery Rate (CADR). We have to move past the idea that a dense physical barrier is the only solution. The future is about neutralizing the threat completely, ensuring that when a customer changes a filter, they are not touching a colony of live viruses.

HEPA filters are effective against Volatile Organic Compounds (VOCs).False

HEPA filters are designed for particulates. They cannot capture gases or chemical vapors like VOCs.

Bio-secure devices aim to neutralize pathogens rather than just contain them.True

Newer technologies focus on destroying the DNA or protein structure of pathogens to prevent replication.

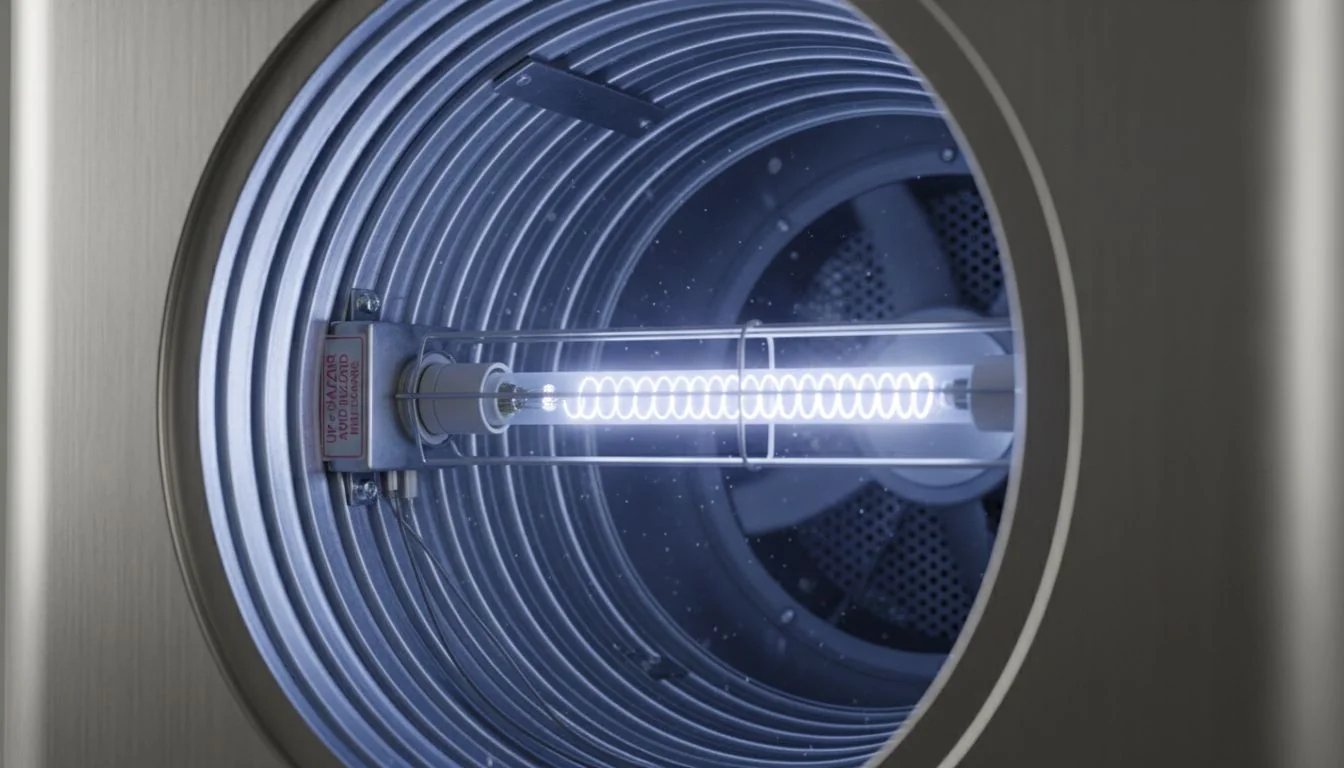

How Does UV-C Light Function as the "Silent Sterilizer"?

UV-C light adds a layer of biological safety that physical filters cannot match. It works silently inside the machine to disrupt the DNA of viruses and bacteria.

UV-C technology2 integrates into air ducts to irradiate pathogens as they pass through, acting as a sterilizer. This requires precise internal geometry in the mold design to maximize exposure time without allowing harmful light leakage.

I call UV-C the "Silent Sterilizer." It is a powerful tool, but it brings specific challenges to mold design. You cannot just stick a light bulb inside a plastic box. UV-C light degrades many standard plastics over time. If you use the wrong polymer for the internal housing, the machine will become brittle and crack after a year or two. We need to select UV-stabilized materials or use metal shielding.

Furthermore, the geometry matters. The air needs to flow past the light slowly enough to get a lethal dose of radiation, but fast enough to keep the CADR high. This is a classic engineering trade-off. We also have to ensure zero light leakage. UV-C is harmful to human eyes and skin. This means the mold design must have complex baffles or light traps at the intake and exhaust vents. It is a "Trap vs. Kill" scenario again. The HEPA traps the dust, and the UV-C kills the biologicals caught in the airflow. For a designer, this adds complexity to the tooling, but it creates a much higher-value product. It turns a simple fan into a medical-grade device.

UV-C light at 254nm is effective at germicidal irradiation.True

This specific wavelength disrupts the DNA/RNA of microorganisms, preventing them from reproducing.

Standard ABS plastic is immune to UV-C degradation.False

Standard ABS can yellow and become brittle under prolonged UV-C exposure; UV-stabilized additives or different materials are required.

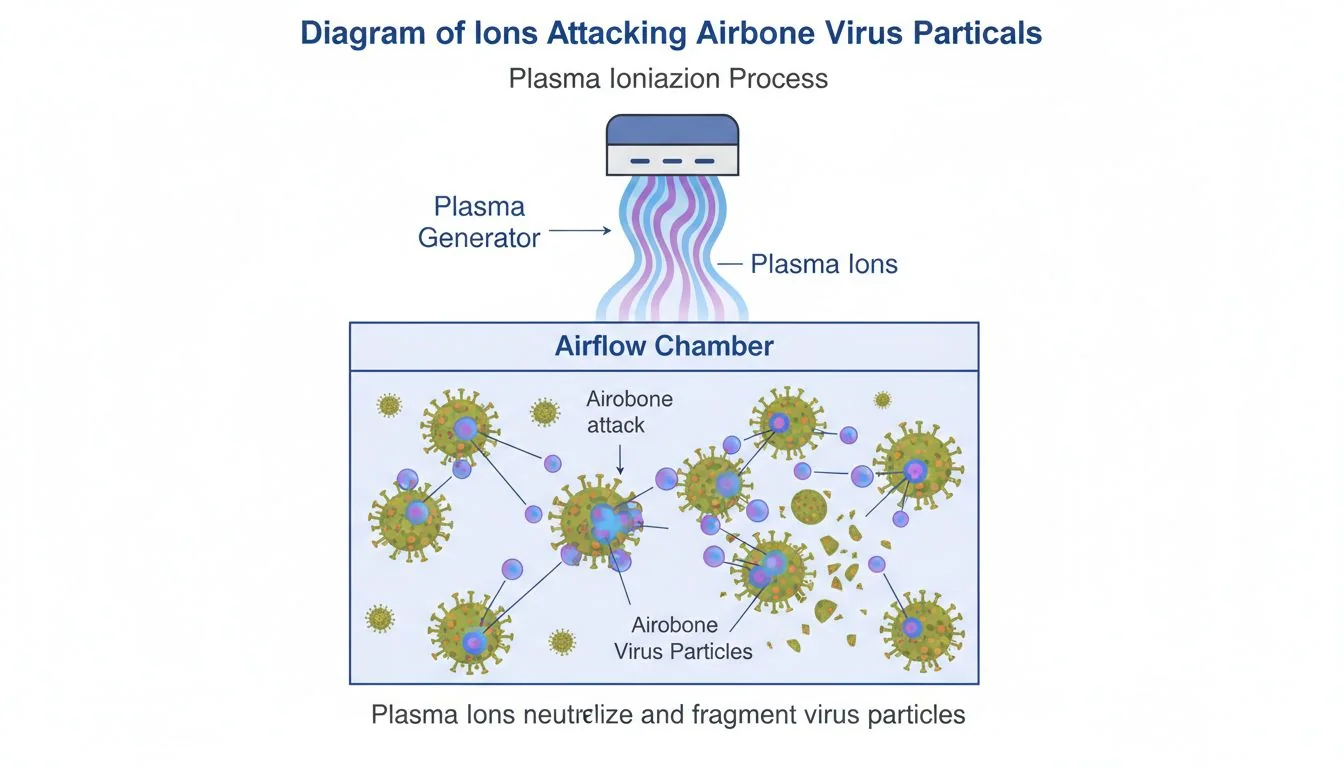

Is Plasma and Ionization the Best Active Air Defense?

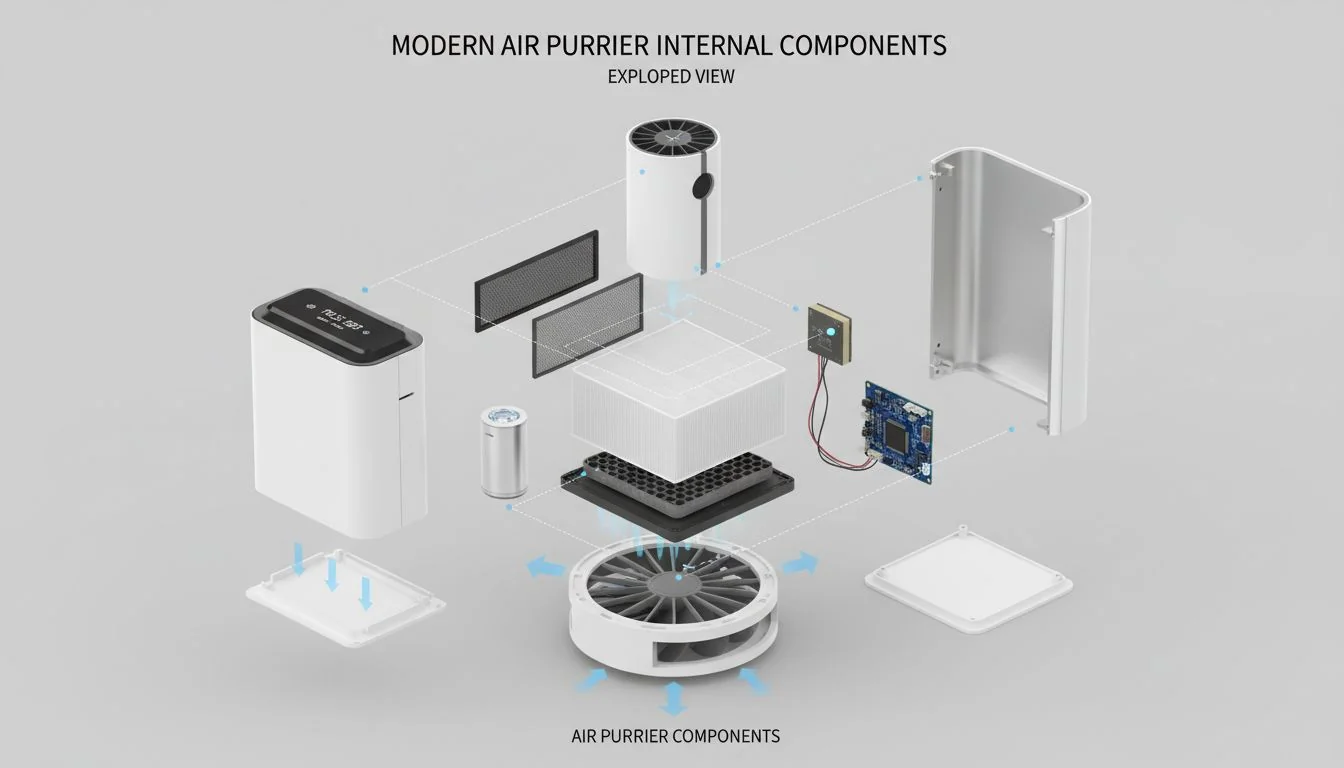

Passive filters wait for the air to come to them, but active technologies go out and hunt the pollution. Plasma and ionization3 push cleaning agents into the room itself.

Plasma and ionization technologies are "Active" solutions that disperse ions to neutralize contaminants in the air and on surfaces. This justifies different form factors, such as wall-mounted units, which disperse ions more effectively than floor units.

This is the "Active vs. Passive" debate. A HEPA filter is passive. It sits in the corner and waits. It can only clean the air that the fan manages to suck in. If you have a dead zone in the room, that air never gets cleaned. Plasma and ionization are different. They generate positive and negative ions that flood the room. These ions attach to dust, making it heavy so it falls, or they attack the surface of viruses.

From a design perspective, this changes the ideal form factor. Floor units are great for heavy HEPA filters, but they are bad for ion distribution because furniture blocks the flow. Wall-mounted units are superior for active tech. They can shower the room with ions from above. This opens up new opportunities for us in mold design. We can design slimmer, lighter units that hang like pictures. We don't need massive motors to push air through thick paper. We just need to circulate the ions. However, we must be careful. Some early ionizers produced ozone, which is harmful. We need to design systems that are strictly controlled and safe.

Active air purification requires air to pass through a filter.False

Active technologies release ions or oxidizers into the room to clean air and surfaces remotely.

Wall-mounted units can distribute ions more evenly than floor units.True

Elevation allows ions to circulate with natural airflow patterns and avoid obstacles like furniture.

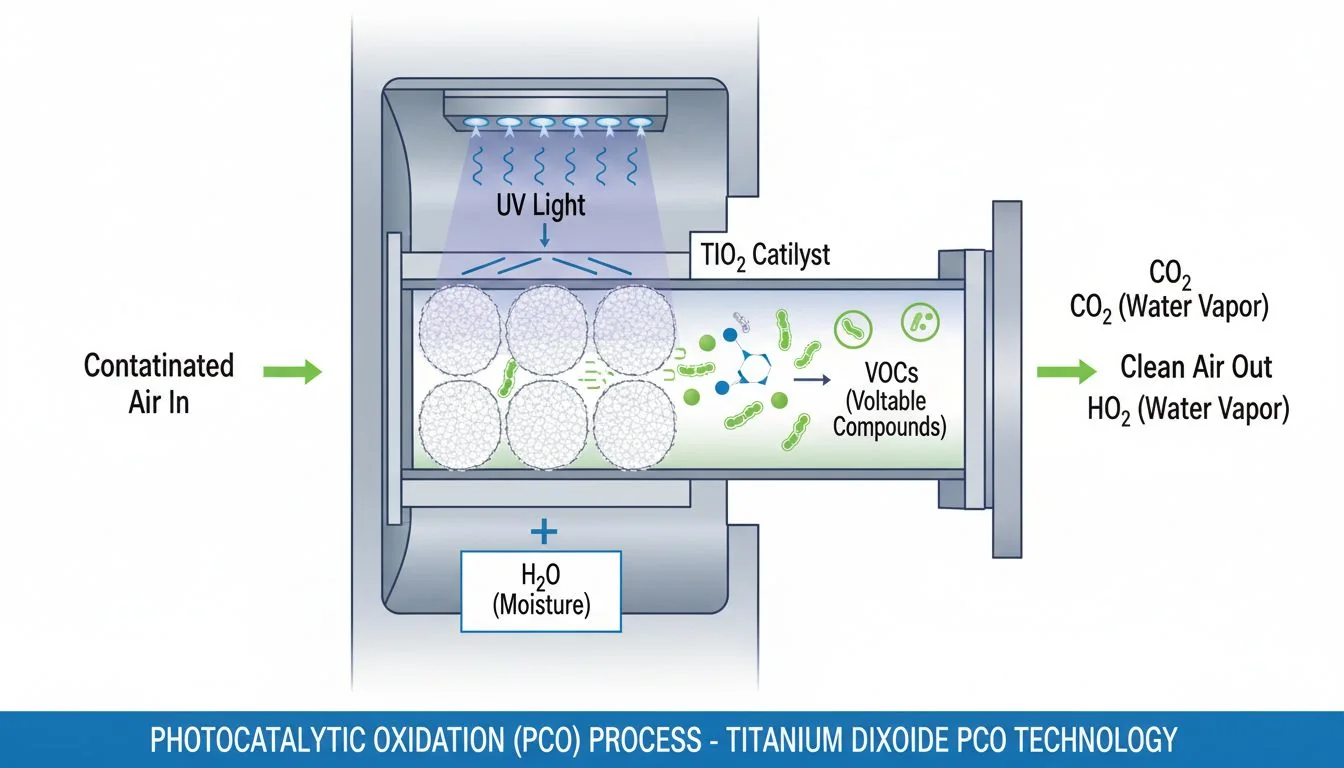

Can Photocatalytic Oxidation (PCO) Destroy Dangerous Gases?

Modern homes are sealed tight, trapping chemicals from paint and furniture. HEPA cannot stop these gases, but PCO technology breaks them down at a molecular level.

PCO technology uses UV light and a catalyst to create hydroxyl radicals that decompose Volatile Organic Compounds (VOCs). This positions PCO units as the ideal solution for "New Homeowners" dealing with Sick Building Syndrome4.

Gas removal is the "Hidden" market in our industry. I have seen so many people buy expensive HEPA filters to get rid of the smell of new furniture or fresh paint. They are always disappointed. HEPA handles solids; it does nothing for gases. Carbon filters help, but they saturate quickly. PCO is the "Gas Destroyer."

It works by shining UV light onto a surface coated with Titanium Dioxide. This reaction creates hydroxyl radicals that tear apart VOC molecules. For new homeowners or renovation markets, this is a massive selling point. It cures "Sick Building Syndrome." For us as designers, the challenge is the catalyst surface area. We need to design internal structures, like honeycombs or meshes, that maximize the surface area coated with the catalyst without blocking airflow. It is a delicate balance. If we get it right, we offer a product that actually cleans the chemical environment, not just the dusty one. It is a huge upgrade for anyone living in a modern, airtight apartment.

PCO technology converts VOCs into harmless water and carbon dioxide.True

The chemical reaction breaks down complex organic molecules into simple, safe byproducts.

PCO is less effective than HEPA at removing dust.True

PCO targets gases and biologicals; it does not physically trap dust particles like a fibrous HEPA filter.

Is Electrostatic Precipitation (ESP) the Sustainable Option?

Recurring costs for filters are a major pain point for businesses. ESP technology offers a washable, permanent solution that eliminates waste and lowers long-term expenses.

ESP technology uses high-voltage plates to attract and trap particles, offering a washable, "Zero-Consumable Cost" solution. This sustainability angle is a powerful selling point for B2B buyers like schools and offices.

Sustainability is not just a buzzword; it is a budget line item. In the B2B world, facility managers hate buying replacement filters every three months. It is expensive and creates waste. ESP is the answer. It uses electrically charged plates to act like a magnet for dust. When it gets dirty, you pull it out, wash it in the sink, and put it back.

Positioning ESP as the "Zero-Consumable Cost" option is smart. But designing for it is hard. We are dealing with high voltage inside the unit. The tolerances in the mold design must be perfect. If the plates are too close, they arc and make a snapping noise. If they are too far, they don't catch dust. Also, safety is critical. We need interlock switches that cut the power the moment the access door is opened. As a mold enthusiast, I love the precision required here. It forces us to be better engineers. We are not just making a plastic box; we are making a precision instrument that saves money and the planet over time.

ESP filters require replacement every 6 months.False

ESP filters are washable and reusable, eliminating the need for frequent replacement.

ESP technology generates a static charge to trap particles.True

Particles are ionized and then attracted to oppositely charged collector plates.

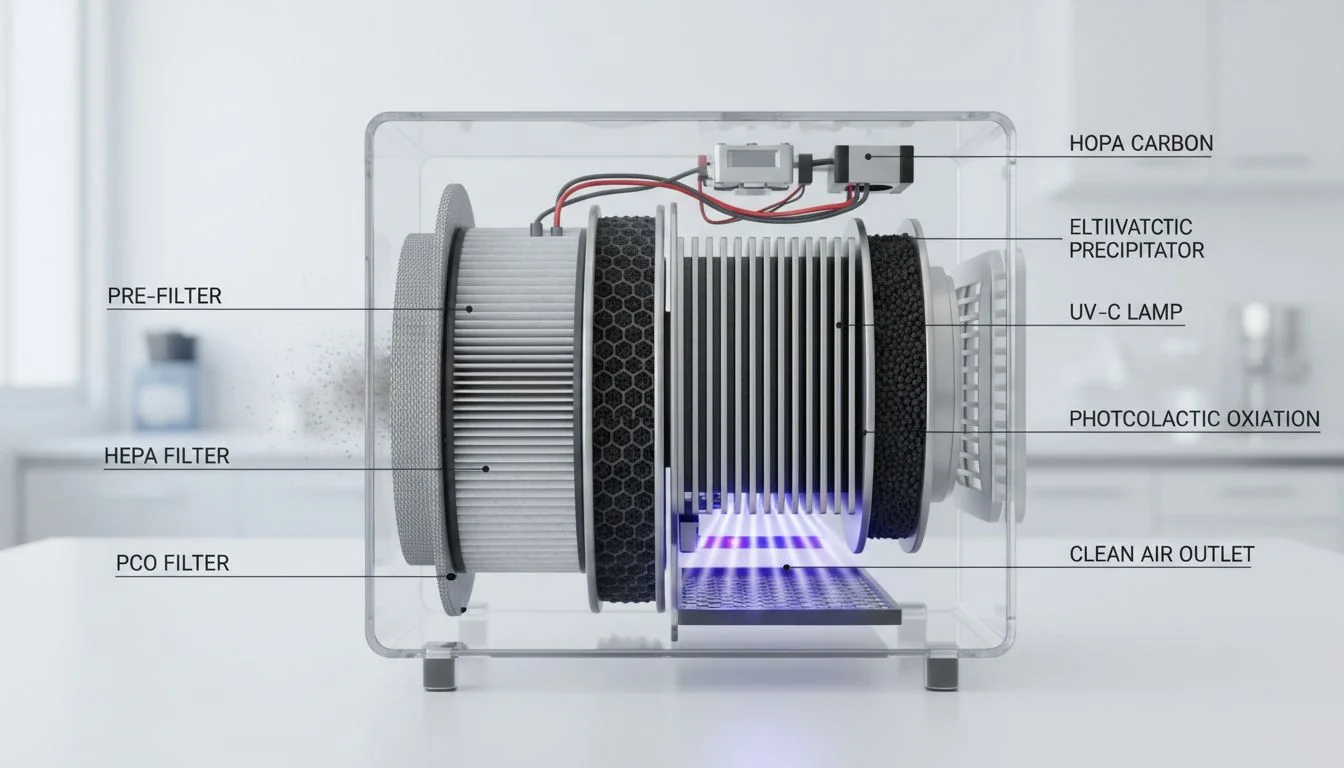

Is the Future of Filtration "Hybrid"?

No single technology solves every problem perfectly. The ultimate solution lies in combining these technologies into a safe, integrated system that traps, kills, and cleans.

The future belongs to "Hybrid Filtration5" that combines the strengths of HEPA, UV, and Plasma. However, integrating these requires a "Safe Engineering Partner" like Hisoair to manage risks like ozone and UV leakage, ensuring a certified, bio-secure product.

We have looked at the pieces, but the real magic happens when you put them together. A hybrid system uses HEPA to trap the dust, UV-C to kill the viruses on the filter, and Plasma to scrub the air in the room. This is the ultimate "Bio-Secure" device. But there is a danger here.

When you mix high voltage, UV light, and airflow, things can go wrong. You can accidentally generate ozone or leak harmful light. This is why the role of the "Integrator" is so important. You cannot just buy parts off the shelf and hope they work. You need a partner who understands the safety engineering. Companies like Hisoair position themselves exactly here. They act as the "Safe Engineering Partner." They ensure that the plasma is ozone-free (CARB-certified) and that the UV is shielded. For a designer like Jacky, working with a partner like Hisoair means you don't have to be a chemist or a physicist. You can focus on the product design, knowing that the core technology is safe and certified. The future is not just about having the best tech; it is about integrating it safely.

Hybrid systems can address particulates, biologicals, and gases simultaneously.True

By layering technologies, a single unit can cover the weaknesses of individual filtration methods.

All hybrid systems are automatically safe for home use.False

Poor integration can lead to ozone generation or UV leaks; certification and proper engineering are essential.

Conclusion

To wrap this up, the era of simple HEPA filters is ending. By embracing "Trap vs. Kill" and active cleaning, we can design superior products. Whether it is the sustainability of ESP or the gas-fighting power of PCO, the key is safe integration.

References

-

Explore how next-gen filtration technologies enhance air quality and safety beyond traditional methods. ↩

-

Discover the science behind UV-C technology and its effectiveness in sterilizing air and surfaces. ↩

-

Find out how Plasma and ionization technologies actively combat air pollution for cleaner spaces. ↩

-

Discover the causes of Sick Building Syndrome and how advanced filtration can help alleviate its effects. ↩

-

Learn about the advantages of Hybrid Filtration systems that combine multiple technologies for optimal performance. ↩