Designing water appliances is a balancing act. You worry about safety, cost, and durability1. The material you choose defines your product's success or failure in the market.

This article compares Polypropylene (PP), Tritan, and 304 Stainless Steel2 based on heat resistance, chemical stability, and consumer perception. While PP serves budget needs and Tritan offers a premium plastic alternative, Stainless Steel provides the highest hygiene standard and durability for wellness-focused brands.

Many designers stop at the cost per part. They look at the spreadsheet and pick the cheapest option. However, in the wellness industry, the material is the marketing. Let's look at the science behind these three choices.

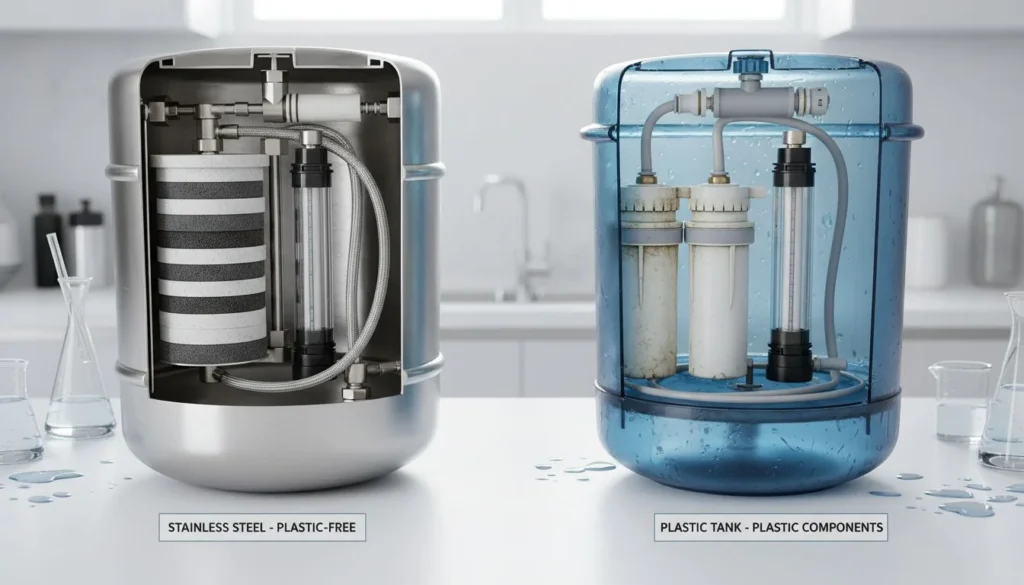

Stainless steel is the only material among the three that is 100% free from microplastic risks.صحيح

Metals do not degrade into microplastics, whereas all polymers, including Tritan and PP, have the potential to release micro-particles over time due to wear and heat.

Tritan plastic contains BPA and BPS.خطأ

Tritan is specifically engineered to be free of bisphenol A (BPA) and bisphenol S (BPS), making it a safer plastic alternative.

Is the "Material" Your Brand's Most Important Message?

Your design specs are just numbers on a page. The material you choose tells the customer exactly who you are. It is the first thing they touch.

Material selection dictates market positioning. PP signals economy, Tritan3 signals durability, and Stainless Steel signals medical-grade wellness. Choosing the right material forces a brand to decide if they want to be a commodity or a premium solution.

I have seen many projects fail because of a mismatch between the brand promise and the material reality. As a designer, you know that a mold for a high-gloss plastic part requires different polishing than a textured surface. But we need to look beyond the mold cavity. We need to look at the hierarchy of value.

Think of it as a ladder. At the bottom, you have the "Commodity." This is where you compete on price. If you use basic plastics, you are telling the customer that this product is temporary. In the middle, you have "Premium Plastic." This is where Tritan lives. It is better, clearer, and stronger. It says, "I am a good product."

But at the top, you have "Medical-Grade/Ultimate Wellness." This is Stainless Steel. When you specify steel in your CAD drawings, you are not just increasing the BOM (Bill of Materials) cost. You are moving the product into a different category. You are moving from a "kitchen gadget" to a "countertop appliance." This visual cue justifies a 2x or 3x higher price point for your clients. It is not just about engineering; it is about perceived value.

Consumers perceive weight as a sign of quality in home appliances.صحيح

Psychological studies in product design show that heavier items are often perceived as more durable and valuable compared to lightweight plastic alternatives.

Material choice has no impact on the mold design process.خطأ

Material choice dictates shrinkage rates, cooling lines, gate locations, and steel types for the mold base.

The "Commodity" Material: Is PP (Polypropylene) Enough?

You use PP every day. It is cheap, easy to mold, and chemically resistant. But is it good enough for premium water products in 2025?

PP is cost-effective and chemically resistant but lacks heat stability and aesthetic appeal. It is best for budget-friendly, disposable, or hidden components, but it fails to convey a sense of premium quality or long-term hygiene.

I started my career in a mold factory, and we ran PP day and night. It is a forgiving material. The shrinkage is predictable (usually around 1.5-2.0%), and it flows well. For internal components like pump housings or brackets, PP is fantastic. It resists fatigue, which is why we use it for living hinges.

However, for water-contact parts in a wellness product, PP has significant weaknesses. First, it looks cheap. Even with a high-polish mold finish, PP has a waxy feel. It scratches easily. Over time, those scratches become breeding grounds for bacteria.

Second, there is the heat issue. While PP has a high melting point, it softens at boiling temperatures. It does not hold its shape as rigidly as other materials under heat stress. In the eyes of the consumer, PP represents the "Commodity" tier. If your client wants to sell a $20 kettle, use PP. But if they want to sell a health product, PP sends the wrong message. It says "mass production," not "health protection."

PP is highly resistant to chemical solvents and acids.صحيح

Polypropylene has excellent chemical resistance, making it suitable for containers that hold cleaning agents or industrial fluids.

PP is the most transparent plastic available.خطأ

PP is naturally semi-crystalline and hazy. While it can be clarified, it never achieves the glass-like optical clarity of Tritan or Polycarbonate.

Clients love clear parts. You might suggest Polycarbonate (PC), but BPA is a dealbreaker. Tritan is the modern solution, but is it truly perfect?

Tritan is BPA-free, shatter-resistant, and clear like glass. It positions a product as "premium plastic" but still carries microplastic concerns under high heat. It is a strong middle-ground option but cannot match the sterilization4 capabilities of steel.

Tritan is an impressive material. From a molding perspective, it is more demanding than PP. You need to dry it thoroughly, and the processing window is tighter to avoid stress marks. But the result is beautiful. It looks like glass but does not break. This is why I call it the "Premium Plastic" challenger.

However, we must be honest about its limits. Don't attack Tritan unfairly; it is a good material. But it is still plastic. In the current market, the fear of microplastics5 is irrational but powerful. This is your ultimate weapon against all plastics.

Furthermore, consider sterilization. "Easy to clean" is subjective. "Boil-safe" is objective. Tritan has a high heat resistance6, but you cannot boil it repeatedly for years without some degradation or hydrolysis risk. It will eventually cloud or craze. If your client wants to claim their product is "hygienic," Tritan is good. But it is not the best. It forces the brand to choose: "Do I want to be better, or do I want to be the best?"

Tritan can withstand autoclave sterilization cycles indefinitely.خطأ

While Tritan handles heat well, repeated exposure to high-pressure steam and high temperatures (autoclaving) can cause hydrolysis and degradation over time.

Tritan is free of estrogenic and androgenic activity.صحيح

Third-party testing has confirmed that Tritan does not contain BPA, BPS, or other bisphenols that mimic hormonal activity.

The "Gold Standard" Material: Why Choose 304 Stainless Steel?

You want to eliminate all customer anxiety. You need a material that screams "clean." Steel is the only choice that offers total peace of mind.

304 Stainless Steel is the "Best" option, offering medical-grade hygiene, zero microplastics, and the ability to withstand repeated high-heat sterilization without degradation. It transforms a product from a gadget into a durable asset.

When I advise clients on high-end projects, I point them to 304 Stainless Steel. This is the "Gold Standard." Why? Because it is the only material that is 100% "plastic-free" and therefore "fear-free." You aren't just selling metal; you are selling freedom from anxiety.

Let's talk about the "Weaponization of Sterilization." Stainless steel can be boiled, steamed, and scrubbed. It does not absorb odors. It does not stain. It does not degrade. For a true "hygiene" product, this is a non-negotiable differentiator.

From a design standpoint, integrating steel requires more thought. You have to deal with overmolding or sealing gaskets. You have to consider thermal conductivity. But the payoff is massive. Steel looks like a medical instrument. It looks professional. When a customer sees a stainless steel tank, they trust the water inside it. This builds massive authority and trust for your brand. You choose steel because it is scientifically superior.

304 Stainless Steel is magnetic.خطأ

Austenitic stainless steels like 304 are generally non-magnetic due to their crystal structure, though cold working can induce slight magnetism.

Stainless steel creates a biofilm faster than plastic.خطأ

Stainless steel's non-porous surface is much more resistant to biofilm formation and easier to sanitize compared to the porous surface of plastics.

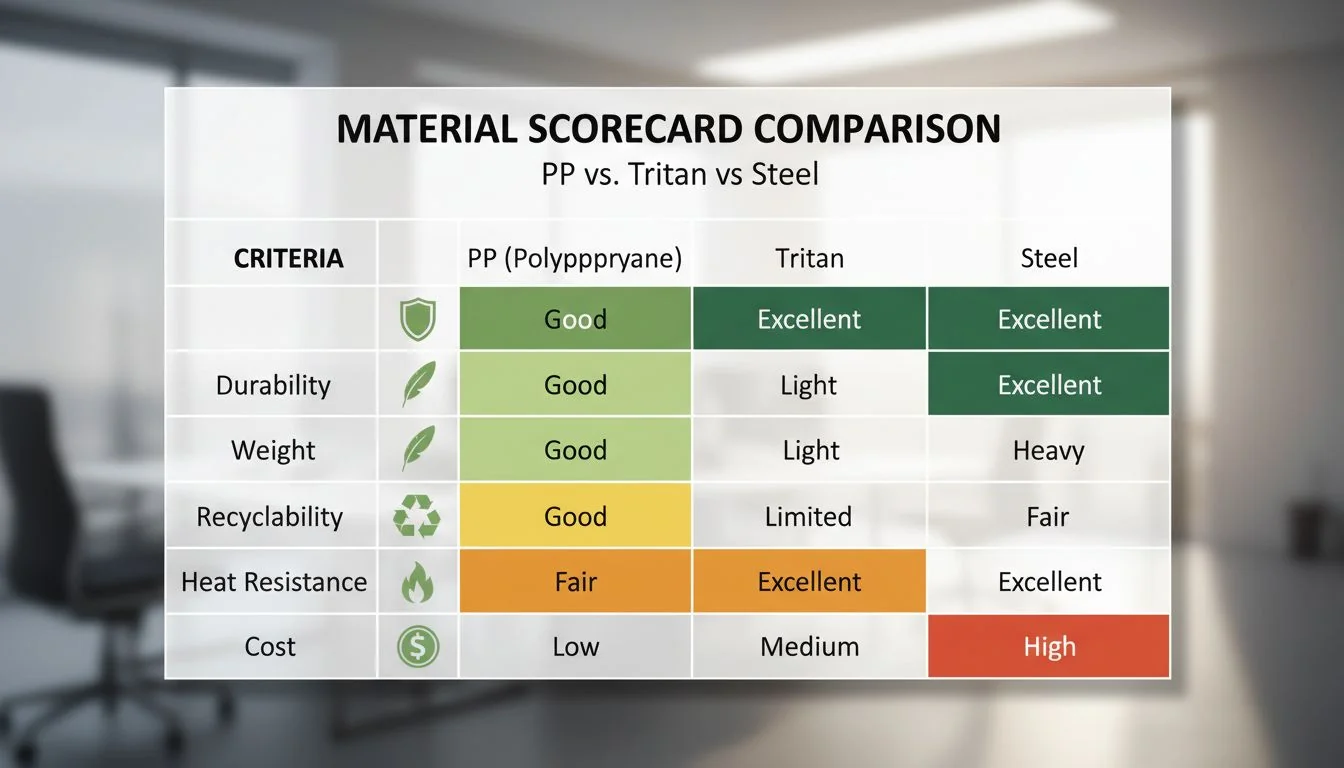

The 2025 Wellness Brand Scorecard: How Do They Compare Side-by-Side?

We have discussed the theory. Now let's look at the data. You need a quick reference for your next engineering meeting or client presentation.

This comparison evaluates PP, Tritan, and Steel across durability, heat resistance, cost, and consumer perception7 to help you make the right engineering choice. It highlights the trade-offs between cost and premium positioning.

To make the right decision, we need to see the trade-offs clearly. I have created this hierarchy based on the "Good, Better, Best" model.

| الميزة | PP (The Commodity) | Tritan (Premium Plastic) | 304 Steel (The Gold Standard) |

|---|---|---|---|

| التكلفة | منخفضة | متوسط | عالية |

| Visual Value | Low (Looks cheap) | High (Glass-like) | Premium (Appliance feel) |

| Microplastic Risk | High (Over time) | Low (But exists) | Zero |

| Sterilization | Low (Softens) | Medium (Heat resistant) | High (Boil-safe) |

| المتانة | Medium (Scratches) | High (Shatterproof) | Ultimate (Lifetime) |

| Consumer Fear | High (Leaching?) | Medium (Is it safe?) | None (Fear-free) |

As you can see, the jump from PP to Tritan is about aesthetics and durability. But the jump from Tritan to Steel is about wellness and trust. If your client wants to dominate the high-end market, the scorecard shows only one winner.

Stainless steel is more expensive to manufacture than plastic.صحيح

Steel requires stamping, welding, or deep drawing, which are generally more energy and labor-intensive processes than injection molding plastic.

Microplastics are a primary concern for modern wellness consumers.صحيح

Recent studies and media coverage have significantly increased consumer awareness and anxiety regarding microplastic ingestion from food and water containers.

الخاتمة

The choice depends on your target market. "Premium Plastic" is a great upgrade, but it is still plastic. For true wellness and anxiety-free hygiene, Stainless Steel is the only option.

References

-

Durability is a key factor in product longevity and customer satisfaction, making it essential to choose the right material. ↩

-

304 Stainless Steel is known for its durability and hygiene, making it a top choice for wellness-focused products. ↩

-

Tritan is a BPA-free alternative that offers clarity and strength, appealing to consumers seeking premium options. ↩

-

Understanding sterilization methods is crucial for maintaining product safety and hygiene over time. ↩

-

Microplastics pose significant health concerns, making it crucial to choose materials that minimize this risk. ↩

-

Heat resistance is vital for ensuring the longevity and safety of water appliances, especially under high temperatures. ↩

-

Material choice can significantly impact how consumers view the quality and value of a product. ↩