Launching a unique wellness product feels impossible. You're stuck between generic items and slow, costly custom design. This choice can kill your brand before it even starts.

For emerging wellness brands, co-development1 is the superior path. It merges the speed of a proven private label platform with the unique branding of custom design, helping you avoid the commodity trap while getting to market quickly.

I've seen so many great ideas fail because of this exact problem. A client comes to me with a vision for a new wellness device, but they're paralyzed by the manufacturing choice. They think it's either "pick a product from a catalog" or "spend two years and a million dollars building from scratch." But that's a false choice. The real secret to launching a successful, premium brand lies in a third option that most factories don't talk about. Let's break down why this "smart hybrid" approach is the game-changer you've been looking for.

Over 60% of new consumer products fail within the first year.Wahr

Market research firms like Nielsen have reported similar failure rates for new CPG products, often due to a lack of differentiation or market fit.

Pure OEM development always takes more than two years.Falsch

While complex OEM projects can take years, simpler products can be developed much faster. However, for a complex device like a humidifier, 18-24 months is a realistic timeline for a new brand starting from zero.

1. Introduction: The "Uniqueness vs. Speed" Dilemma?

You have a brilliant idea for a wellness product but face a tough choice. Go fast with a generic product or go slow and build something truly unique?

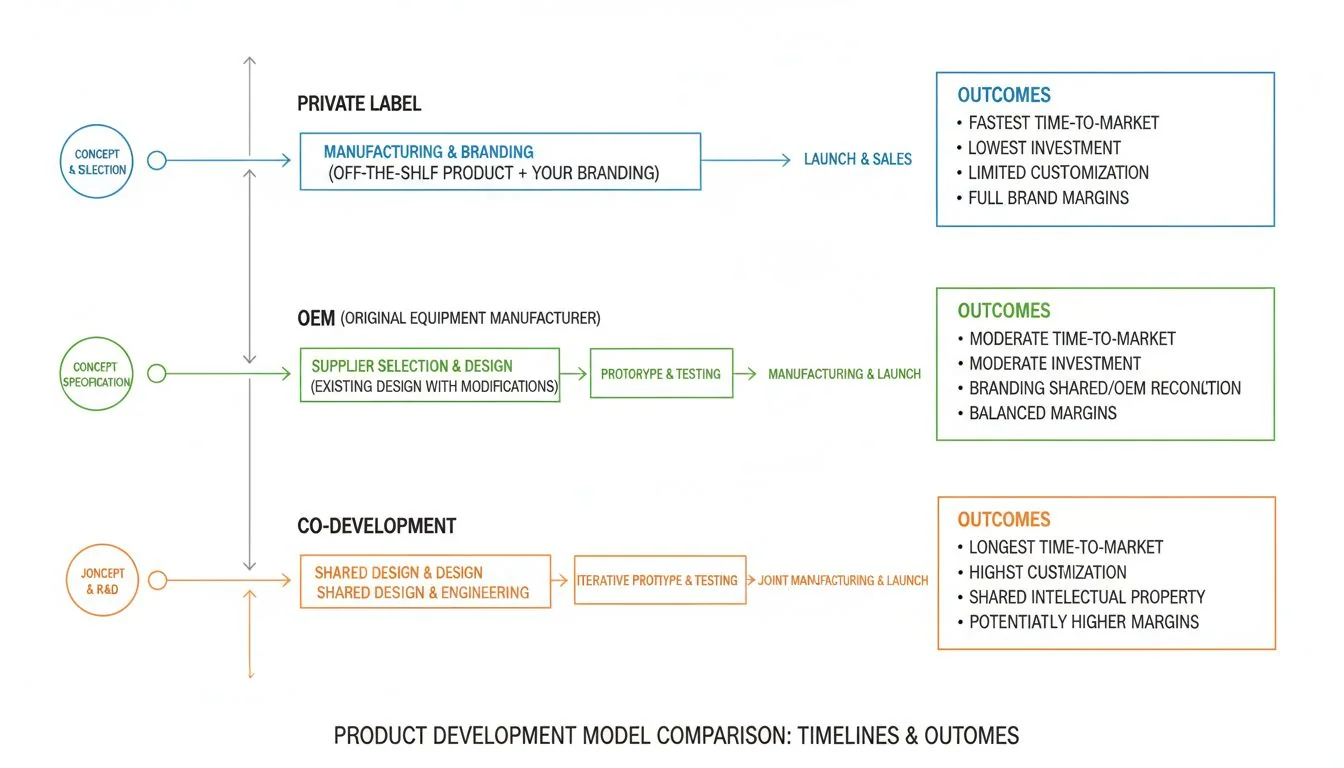

This dilemma forces brands to choose between speed-to-market and brand differentiation. private label2 offers speed but no uniqueness. Full custom offers uniqueness but is slow and risky. The challenge is finding a balance.

I remember a client, a sharp product designer just like you. Let's call him Jacky. He wanted to launch a premium air purifier. He found a factory that offered a "private label" model. It was fast and cheap. But the product looked exactly like ten others on Amazon. He knew he couldn't build a premium brand on a commodity product. Then he explored full custom development (OEM). The factory quoted him 18 months and a six-figure tooling fee just to get a working prototype. His investors balked. This is the classic trap.

The Speed Trap

You use a generic, off-the-shelf product. You get to market in 3-6 months. But you have no unique features, no IP, and you compete only on price. Your brand is just a logo on a box.

The Uniqueness Trap

You design everything from scratch. You get a truly unique product. But it takes 18-24 months, costs a fortune in R&D and tooling, and you bear all the risk of compliance and engineering failures. For an emerging brand, neither of these is a winning strategy.

Private label products allow a brand to launch in under 3 months.Falsch

While faster than OEM, even private label requires time for branding, packaging, quality control, and shipping, typically taking 4-6 months.

The average cost for new plastic injection molds for a consumer product is over $50,000.Wahr

According to industry reports and my own experience, complex molds for consumer electronics can easily range from $10,000 to over $100,000, depending on size, complexity, and cavitation.

2. What is "Private Label" (ODM)? The "Commodity Trap"?

You need a product to sell, fast. A factory catalog full of ready-made options seems like the perfect solution. But soon you realize your "unique" product is sold by dozens of competitors.

Private label, or ODM, is when you put your brand on a pre-existing product. While it offers speed, it traps you in a commodity market where you can only compete on price, killing your brand's premium potential.

Let's be clear about what ODM (Original Design Manufacturing) is. A factory invests its own R&D to create a finished product. They own the design, the engineering, and the tooling. They offer it to anyone who will meet their minimum order quantity (MOQ). You get to change the color, print your logo on it, and design the packaging. That's about it. I've seen this play out countless times. A brand invests heavily in marketing, creating a beautiful story. But customers are savvy. A quick search on Alibaba or Amazon reveals the truth: the product is a generic shell. This model is fine if you want to be a reseller. But if you're trying to build a brand, especially a premium wellness brand, ODM is a dead end.

The Pros and Cons of ODM

| Merkmal | Pro (The Lure) | Con (The Trap) |

|---|---|---|

| Speed | Very fast to market (4-6 months) | Everyone else is just as fast. |

| Kosten | Low upfront investment (no R&D/tooling) | Margins are thin due to price competition. |

| Risk | Low technical risk; the product works. | High market risk; no differentiation. |

| Uniqueness | None. You are just another label. | Your brand value is tied to a generic item. |

With ODM, you own the intellectual property of the product design.Falsch

In a standard ODM agreement, the factory retains ownership of the design, engineering, and tooling. The brand only owns its logo and packaging design.

ODM products often have lower per-unit costs than custom-developed ones.Wahr

Because the factory amortizes the R&D and tooling costs over many clients, the per-unit price for an ODM product is typically lower than for a bespoke OEM product.

3. What is "Co-Development" (The Smart Hybrid)?

You want a unique product without the crippling costs and delays of starting from scratch. It feels like an impossible ask. But a new model, co-development, offers the perfect blend.

Co-development is a hybrid model where a brand uses a manufacturer's pre-developed "platform" (the core tech) and collaborates to build a unique housing, UI, and feature set on top. It's the smart way to get uniqueness and speed.

Imagine a car company. They don't design a new engine and chassis for every single model. They develop a core "platform" and then build different cars on top of it. This is co-development. In our world, a forward-thinking manufacturer might develop a "hero platform." For example, a stainless steel, easy-to-clean, fully certified humidifier base. This is the hard 80% of the work. It's the part that has to be perfect for hygiene and safety. They bring this platform to you, the brand. You then work with their R&D team to design the "signature 20%."

Your Customization Zone

- Industrial Design: A unique external housing that reflects your brand's aesthetic.

- User Experience (UX): Custom buttons, displays, or even a companion app.

- Special Features: Adding things like an essential oil diffuser, a specific type of night light, or unique materials.

You're not just slapping a label on something. You're co-creating a new product on a proven, reliable foundation. You get a unique product without having to reinvent the wheel.

Co-development is just a fancy name for private label with more color options.Falsch

Co-development involves collaboration on significant aspects like industrial design, user interface, and features, built upon a core platform. It's fundamentally different from the cosmetic changes of private label.

Using a pre-certified platform in co-development can save 6-12 months in project timelines.Wahr

Certifications like ETL, FCC, and EPA can take many months and significant cost. Leveraging a pre-certified core platform eliminates this entire phase, dramatically accelerating speed-to-market.

4. Why Co-Development is the Accelerator for Emerging Brands?

As an emerging brand, your two most precious resources are time and money. A wrong move in manufacturing can burn through both, leaving you with nothing to show for it.

Co-development accelerates emerging brands by drastically reducing time-to-market and financial risk. By using a pre-certified core platform, you bypass months of R&D and compliance testing, focusing capital on brand-building instead.

For a new wellness brand, the biggest hurdles aren't just designing a pretty shell. They are the invisible, expensive, and time-consuming ones. I'm talking about compliance. For a humidifier sold in the US, you need Zertifizierungen3: ETL for electrical safety, CARB for air quality, and EPA for antimicrobial claims. Each can take months and cost tens of thousands of dollars. If you fail a test, you go back to the drawing board. This is where co-development becomes your secret weapon. A partner with a certified platform sells you "Speed-to-Market" and "Risk Removal." They've already done the hard part.

The "Compliance-as-an-Accelerator" Advantage

| Traditional OEM Path | Co-Development Path |

|---|---|

| 1. Design from scratch | 1. Select certified platform |

| 2. Build prototype | 2. Co-develop unique housing/features |

| 3. Test and debug | 3. Tooling for custom parts |

| 4. Submit for ETL, CARB, EPA (6-9 months) | 4. Leverage existing certifications |

| 5. Redesign if failed | 5. Production |

| 6. Tooling & Production | 6. Launch (9-12 months) |

| 7. Launch (18-24 months) |

Product safety certifications like ETL are optional for selling in the US market.Falsch

While not always federally mandated, major retailers like Amazon, Target, and Walmart require ETL or UL certification for electrical products to ensure safety and limit liability.

Co-development can cut upfront R&D and certification costs by over 50% compared to pure OEM.Wahr

By eliminating the need to develop and certify the core electronic and mechanical systems from scratch, brands can save significantly on engineering time and expensive third-party lab testing fees.

5. How to Find a "Co-Development" Partner (Not a "Commodity" Factory)?

You're sold on co-development, but how do you find the right partner? Most factories just want to sell you what's in their catalog. You need to look for specific signs.

To find a co-development partner, look for a manufacturer with a dedicated in-house R&D team, a portfolio of their own patents, and a certified "platform." Ask about their collaborative process, not just their product catalog.

When I vet factories for my clients, I don't start by looking at their products. I start by looking at their people and their process. A commodity factory has a big sales team. A co-development partner has a big R&D team. This is the most important difference. You are not buying a product; you are buying access to their engineering expertise. During your first conversation, don't ask "What products do you have?" Instead, ask these questions.

The Partner-Vetting Checklist

- "Can you walk me through your R&D team's structure?"

- Red Flag: "Our engineers are very busy."

- Green Flag: "We have 15 engineers: 5 in mechanical, 5 in electronics, and 5 in software. Let me introduce you to the team lead."

- "What core technologies or platforms have you developed internally?"

- Red Flag: "We can make anything you want."

- Green Flag: "Our core IP is our hygienic stainless steel water tank and ultrasonic module. It's already ETL and CARB certified. We can build your design around it."

- "Can you show me examples of co-development projects you've completed?"

- Red Flag: They show you a catalog of ODM products.

- Green Flag: They show you case studies of how they helped Brand X create a unique product based on their platform.

All factories listed on Alibaba are capable of co-development.Falsch

The vast majority of factories on platforms like Alibaba are focused on high-volume ODM or basic OEM. True co-development partners with strong R&D are a small, specialized subset.

A manufacturer with patents demonstrates a commitment to innovation and protecting intellectual property.Wahr

Patents are a clear, legal indicator that a company invests in R&D and creates novel technology, making them a more capable and reliable partner for co-development.

Schlussfolgerung

Stop "Labeling." Start "Partnering." Find a true co-development partner to build something unique on a proven, certified foundation. This is how you build a lasting wellness brand.

References

-

Co-development merges speed and uniqueness, making it a game-changer for emerging brands. ↩

-

Understanding private label can help brands avoid the commodity trap and enhance their market strategy. ↩

-

Understanding necessary certifications can help brands navigate compliance and market entry effectively. ↩