You admire the flawless quality of Japanese products, but replicating it feels impossible. It’s a frustrating gap between your brand’s ambition and its reality. The secret is closer than you think.

Japanese brands achieve this by creating a perfect manufacturing process based on "Kaizen1" and "Monozukuri" principles. They then partner with dedicated OEM factories whose sole job is to execute this process flawlessly, ensuring every single product meets their incredibly high standards.

For years, I’ve worked with brands trying to capture that "Japanese Quality." I've seen them focus on copying the look, but they miss the system behind it. It's a system I deeply respect, one I've studied and implemented for my clients. But I've also seen its one major blind spot, a blind spot that creates a huge opportunity for modern D2C brands like yours.

In this post, I'll break down the exact system Japanese brands use. More importantly, I'll show you the pivot—the one shift in thinking that lets you not just match their quality, but evolve beyond it. This is about moving from legacy precision to what I call "Modern Precision2."

Japan is home to over 5,500 companies that are more than 100 years old.Wahr

This longevity is often attributed to a cultural focus on long-term quality and craftsmanship (Monozukuri) over short-term profits.

Japanese manufacturing is a myth and their quality has declined.Falsch

While some high-profile recalls have occurred, the underlying principles of Kaizen and Monozukuri remain central to Japan's industrial identity and are still considered a global benchmark for quality control.

The "Kaizen" & "Monozukuri" System: What is "Japanese Precision" Really Based On?

"Japanese Precision" sounds like a marketing term, not an engineering spec. This makes it hard to apply. But it's built on two powerful, actionable ideas: Kaizen and Monozukuri3.

Japanese precision is a direct result of two cultural philosophies. "Kaizen" is the drive for continuous, incremental Process improvement4. "Monozukuri" is the spirit of craftsmanship and the art of making things. Together, they create a system obsessed with perfecting the manufacturing process itself.

When I first started in a mold factory, I thought quality was about the final inspection. If the part passed, we did a good job. But my first visit to a factory that supplied a major Japanese electronics brand changed my entire perspective. Their focus wasn't on the end of the line; it was on every single step that came before it. They were living and breathing Kaizen and Monozukuri. It’s a mindset that turns manufacturing from a job into a craft.

The Two Pillars of Process Perfection

To understand their system, you have to understand these two ideas. They are not just buzzwords; they are the operational code for every worker on the factory floor.

-

Kaizen (改善): The Science of Small Steps

Kaizen means "change for the better." In manufacturing, it's about continuous improvement. It’s not about one big, revolutionary idea. It's about thousands of small improvements made over time. A worker might suggest moving a bin two inches to the left to save 0.5 seconds. That change is tested, and if it works, it becomes the new standard. Multiplied across thousands of workers and millions of units, these tiny changes create a nearly perfect, waste-free process. -

Monozukuri (ものづくり): The Spirit of Making Things

Monozukuri is harder to translate. It means "making of things," but it implies a deep pride and expertise in your craft. It’s the difference between assembling a product and building it. It’s an engineer who understands the material so well they can predict its behavior. It’s a factory manager who sees the entire production line as a single, interconnected organism. It’s the soul of the machine.

| Philosophy | Core Principle | Practical Application |

|---|---|---|

| Kaizen | Continuous Improvement | Small, incremental changes to the process. |

| Monozukuri | Pride in Craftsmanship | Deep knowledge of materials and techniques. |

This dual focus on process and pride is what creates the foundation for legendary Japanese quality.

The Toyota Production System (TPS) is a famous implementation of Kaizen.Wahr

TPS is studied globally as a benchmark for efficiency and quality, focusing on eliminating waste ('muda') through continuous improvement.

Monozukuri only applies to traditional crafts like sword making.Falsch

The term is actively used by modern, high-tech Japanese companies like Toyota and Panasonic to describe their manufacturing philosophy and commitment to quality.

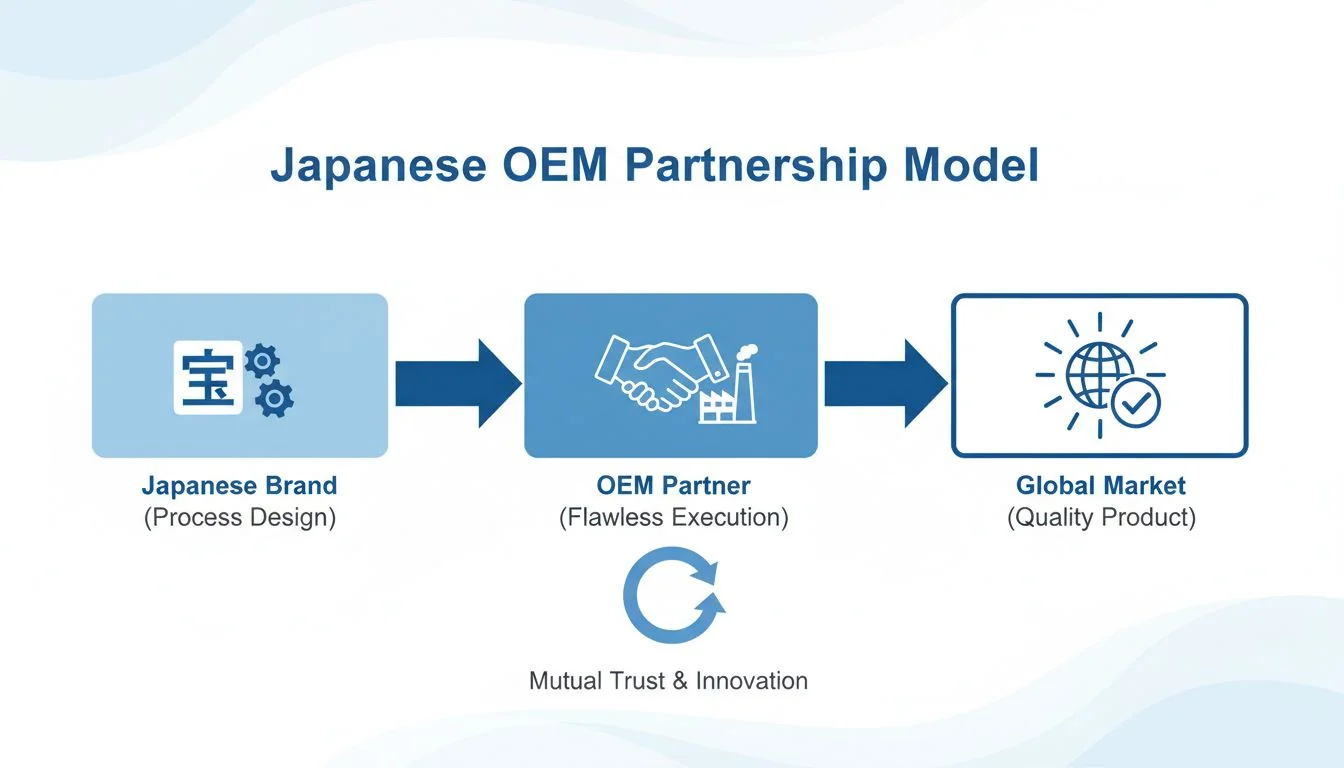

The OEM Partner's Role: How Do They Guarantee "Flawless Execution"?

You have a perfect process on paper, but you can't build a million units yourself. You need a partner. But the wrong partner can destroy even the best-laid plans.

Japanese brands select OEM partners not for their creativity, but for their discipline. The OEM's role is to be a perfect executor of the brand's process. They are trained and audited relentlessly to ensure they can replicate the process without any deviation, guaranteeing quality at scale.

I’ve helped D2C brands set up their manufacturing in Asia, and I’ve seen the difference. Many brands just send a CAD file and a purchase order. The factory is left to figure out the "how." This is a recipe for disaster. A Japanese brand, however, provides a book—a bible—detailing every single step, every temperature, every torque setting. The OEM's job is not to think, but to do. They are an extension of the brand's will.

The Brand-OEM Contract

This relationship is built on a clear division of labor. It's a partnership where one side is the brain and the other is the hands. Misunderstanding this is a critical mistake many companies make when they try to copy this model.

-

The Japanese Brand's Responsibility: The "Perfect Process"

The brand invests years of R&D into designing the product und the process to build it. They define every variable. They create the Qualitätskontrolle5 checkpoints. They are the architects of the entire system. Their intellectual property isn't just the product design; it's the manufacturing method itself. -

The OEM Partner's Responsibility: "Flawless Execution"

The OEM is chosen for its ability to follow instructions. They must have the equipment, the clean facilities, and most importantly, a culture of discipline. They are audited constantly, not just on the final product, but on their adherence to the process. A deviation from the process is a failure, even if the final product looks okay.

| Rolle | Responsibilities | Key Metric |

|---|---|---|

| Japanese Brand | Process Design, R&D, Quality Standards | Process Robustness |

| OEM Partner | Process Execution, Scaling, Labor | Process Adherence |

This strict separation is how they maintain control and ensure that the millionth unit is identical to the first.

Foxconn, a major OEM for Apple, employs over one million people in China.Wahr

This demonstrates the massive scale at which OEM partners operate to execute the designs and processes of major global brands.

OEMs are just cheap labor.Falsch

High-end OEMs are sophisticated manufacturing partners with advanced robotics, clean rooms, and highly trained staff, chosen for their execution capabilities, not just low cost.

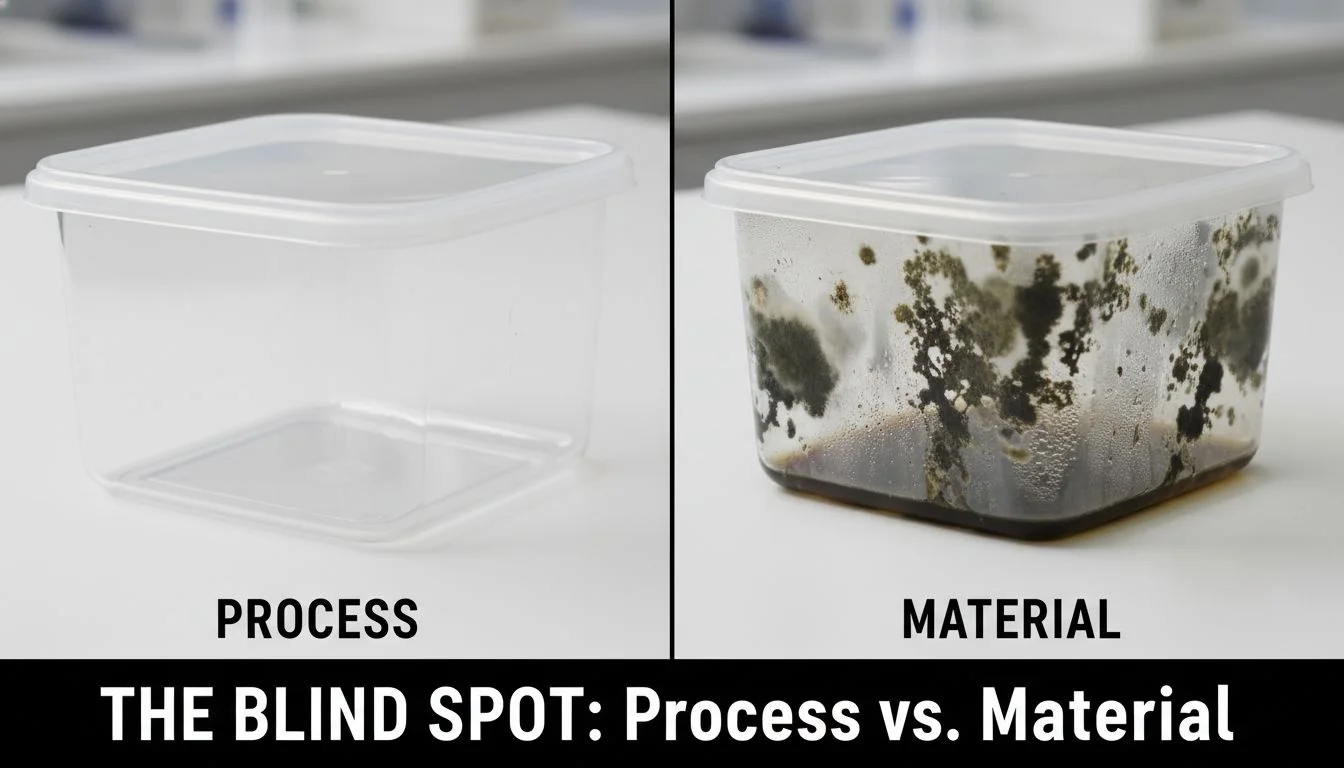

The "Process Blind Spot": Is a Perfect Process on a Flawed Material Still Perfect?

You've done it. You have a perfect process and a disciplined OEM. The products roll off the line looking flawless. But then the 1-star reviews appear: "It got moldy," "It's impossible to clean."

No. A perfect process cannot save a flawed material. The traditional model's blind spot is its intense focus on assembly. It can create a perfectly molded plastic box, but it can't stop that box from being a breeding ground for mold and bacteria. The process is perfect, but the material is flawed.

This is the pivot. This is the point where I have the most important conversations with my clients. For decades, the Japanese model was untouchable because the process was so good. But consumer expectations have changed. A product that looks good is not enough. Today, it also has to be hygienic, durable, and safe. A perfectly assembled plastic baby bottle that grows mold is a failure. The customer doesn't care how well it was molded; they care that it's unhygienic.

The Material is the New Bottleneck

The old system assumed the material was a given. The challenge was how to shape and assemble it perfectly. But what if the material itself is the problem?

-

The Problem with Plastic

Plastic is cheap, versatile, and easy to mold. It was the perfect material for the mass-manufacturing era. But it has inherent flaws. It's porous on a microscopic level. It scratches easily. These tiny scratches and pores become breeding grounds for bacteria and mold. No amount of process perfection can change the fundamental nature of the material. -

The Customer's Reality

As a product designer like Jacky, you design for function and aesthetics. But the customer lives with the product. They experience the frustration of trying to clean a complex plastic part. They see the black spots of mold that won't wash away. Their user experience is defined by the material's weakness, not the process's strength.

| Focus Area | Legacy Precision (The Past) | Modern Demands (The Present) |

|---|---|---|

| Primary Goal | Flawless Assembly & Fit | Hygiene, Durability, & Safety |

| Key Material | Kunststoff | Advanced, Non-Porous Materials |

| Source of Failure | Process Error (e.g., bad seam) | Material Failure (e.g., mold) |

This blind spot doesn't mean the Japanese system is wrong. It means it's incomplete for the modern world.

Microplastics can be found in 90% of table salt brands.Wahr

This highlights the pervasive issue of plastic degradation and its entry into the food chain, a long-term consequence of the material's nature.

All plastics are unhygienic.Falsch

While many common plastics are porous and can harbor bacteria, specialized medical-grade polymers are designed for hygienic applications. However, these are often not used in consumer goods due to cost.

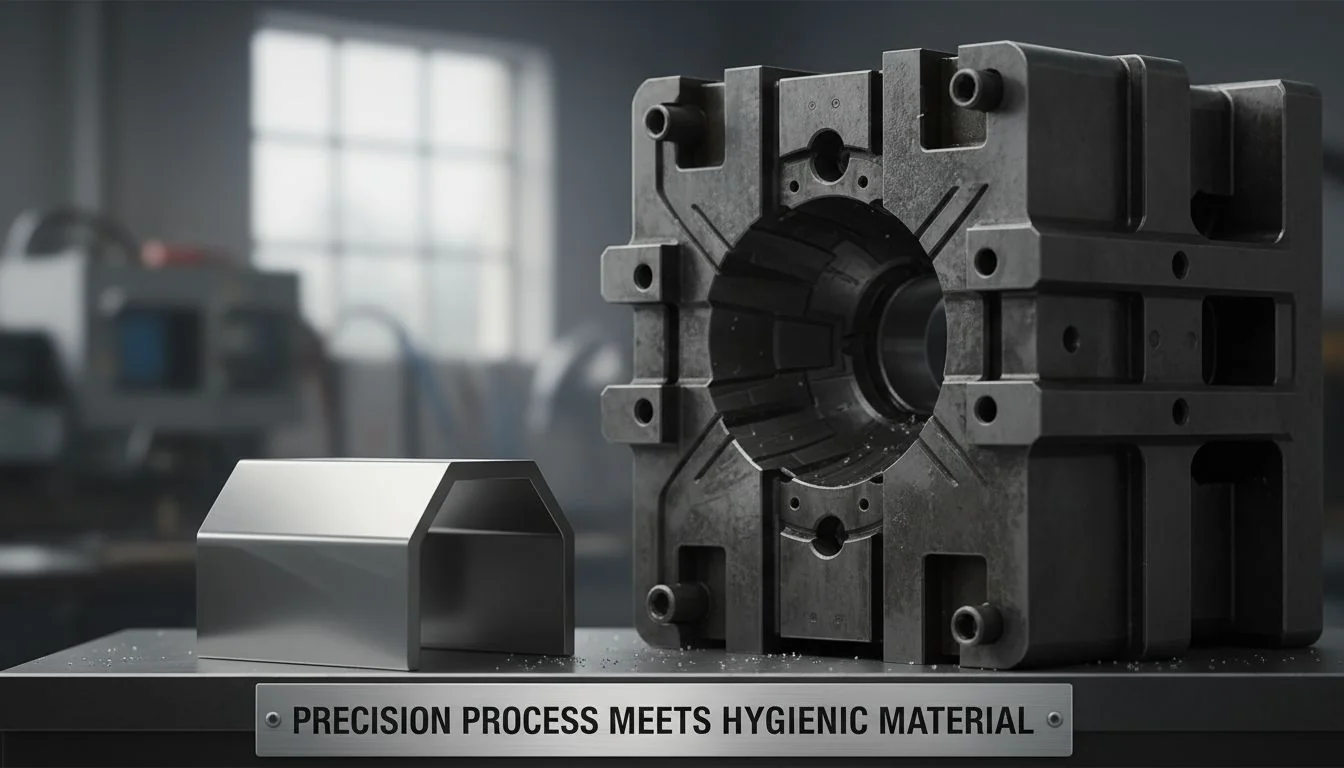

The 2025 Evolution: How Can "Precision Process" and "Hygienic Material" Create the Future of Quality?

You see the blind spot in the old model. You know material matters more than ever. So how do you build a better product? You don't replace the old system; you evolve it.

The future of quality, "Modern Precision," is the fusion of Japan's "Precision Process" with "Hygienic Material6 Innovation." It takes the best of the old world (process discipline) and combines it with the best of the new (advanced materials) to create a superior product.

This is where I get excited. This is the strategy I use to help my D2C clients leapfrog legacy giants. We don't try to beat the Japanese masters at their own game. We honor their game and add a new, winning dimension to it. The proof is in the products we help create. Think of a high-end D2C coffee grinder made from CNC-machined Stainless steel7. It requires incredible precision to assemble (the Japanese part), but its material solves the hygiene and durability problem of its plastic competitors (the evolution part).

Building a "Modern Precision" Product

This isn't just a theory. It's an engineering strategy. It's about making a conscious choice to prioritize material science at the beginning of your design process.

-

The "Hygienic Material": Stainless Steel

Stainless steel is non-porous. It doesn't scratch easily. It doesn't harbor bacteria. It can be cleaned perfectly. It solves the "moldy" 1-star review problem at the source. But it's also harder to work with. It requires precision engineering and advanced molding or CNC machining8 to get the same perfect fit and finish as plastic. -

The "Precision Process": Modern CNC & Molding

This is where you apply the Kaizen mindset. You need an OEM partner who has mastered stainless steel. You need a process that accounts for the material's unique properties. The goal is the same—flawless execution—but the techniques are more advanced. This is the tangible fusion: the discipline of the Japanese system applied to a superior, modern material.

| Aspekt | Legacy Precision | Modern Precision |

|---|---|---|

| Material | Kunststoff | Stainless Steel / Advanced Composites |

| Prozess | Spritzgießen | Precision CNC Machining, Metal Injection Molding |

| Key Benefit | Low Cost, Fast Production | Hygiene, Durability, Premium Feel |

| Result | A perfectly made plastic box | A perfectly made, hygienic steel box |

This is how you build a product that justifies a premium price and earns genuine customer loyalty.

Stainless steel is one of the most hygienic materials available because its surface is non-porous.Wahr

The lack of pores or cracks prevents bacteria, viruses, and mold from lodging and growing, which is why it is the standard in commercial kitchens and medical facilities.

Working with stainless steel is as easy as plastic.Falsch

Stainless steel is much harder and requires more powerful and precise machinery (like CNC mills) and more complex processes (like welding or metal injection molding) than standard plastic injection molding.

Conclusion: How Your D2C Brand Can Achieve "Modern Precision"

True quality today is not just about a perfect process. It's about applying that perfect process to a superior material. This is your path to creating a truly premium product.

References

-

Explore how Kaizen drives continuous improvement in manufacturing processes, enhancing quality and efficiency. ↩

-

Understand the concept of Modern Precision and how it combines traditional processes with advanced materials. ↩

-

Discover the spirit of craftsmanship behind Monozukuri and its impact on product quality and pride in manufacturing. ↩

-

Discover strategies for continuous process improvement that can enhance efficiency and product quality. ↩

-

Investigate the rigorous quality control measures that ensure consistency and excellence in production. ↩

-

Find out why hygienic materials are crucial for modern products and how they enhance user experience. ↩

-

Learn about the properties of stainless steel that make it ideal for hygienic applications in product design. ↩

-

Explore the benefits of CNC machining in achieving precision and quality in manufacturing. ↩