Choosing a material for a water appliance feels overwhelming. Make the wrong call, and you risk health concerns or brand damage. Let's break it down into a clear "Good, Better, Best" framework.

For water appliances, food-grade stainless steel1 is the optimal choice for health and longevity. Its inert nature prevents chemical leaching and microplastic shedding. Tritan is a premium plastic alternative, while PP serves as a baseline, food-safe standard with more significant long-term drawbacks.

I've spent my life in the mold and manufacturing industry. I've seen trends come and go. One thing that never changes is the need for safe, reliable materials, especially for products that touch our food and water. The term "food-safe" gets thrown around a lot, but it's really just the minimum requirement. It means a material meets government regulations. But for designers like you, Jacky, who are creating premium products, the minimum isn't good enough. Your customers are smart. They worry about the "hidden" risks—things like microplastics2 and bacterial growth that aren't always covered by basic safety standards.

That's why we need to look beyond "safe" and start talking about which material is truly "inert." An inert material doesn't react with its contents. Period. This is the new gold standard for health-conscious design3, and understanding the difference is key to creating products that build trust and last a lifetime. Let's dive into the three most common materials you'll encounter for water appliances.

All plastics used in food-contact applications are completely inert and do not interact with food or water.Falsch

While regulated to be 'food-safe,' no plastic is completely inert. Factors like heat, age, and scratches can cause them to leach chemicals or shed microplastics.

Stainless steel is considered an inert material, meaning it is highly resistant to leaching and reacting with food or beverages.Wahr

Food-grade stainless steel is a stable alloy that is non-reactive, non-porous, and does not break down into microparticles, making it an ideal material for health and hygiene.

Level 1: Is PP (Polypropylene) Good Enough for Your Baseline Standard?

You need a cost-effective, proven material for your project. But you worry its limitations could compromise the product's hygiene and lifespan, reflecting poorly on the design. Let's define PP's role as the baseline.

PP is a widely used, food-safe plastic that is very cost-effective. However, it is the most prone to scratches, which can harbor bacteria, and it degrades over time. This makes it a "good" but not the "best" choice for health-focused, long-lasting water appliances.

In my early days at the mold factory, we churned out millions of parts made from Polypropylene. It's the workhorse of the plastics world. It's cheap, easy to mold, and has good chemical resistance. You see it everywhere, from yogurt cups to car parts. For many applications, it's a perfectly fine choice. It meets all the "food-safe" regulations, and for single-use or low-cost items, it gets the job done.

But when we're talking about a reusable water appliance—something a person will use every day for years—the conversation changes. PP's biggest weakness is its softness. It scratches easily. I'm not just talking about cosmetic damage. Every tiny scratch on the inside of a water tank or pitcher becomes a hiding place for bacteria, creating something called a biofilm that is very difficult to clean. Over time, exposure to heat and cleaning detergents also causes PP to degrade, becoming brittle and potentially shedding microplastics into the water. It's the "good" option, the baseline, but it's far from optimal.

The Pros and Cons of Polypropylene

| Merkmal | Vorteil | Disadvantage |

|---|---|---|

| Kosten | Very low material and processing cost. | Can make a product feel "cheap." |

| durability4 | Flexible and resistant to breaking from impact. | Scratches and stains easily. |

| Hygiene | Meets "food-safe" standards when new. | Porous surface and scratches can harbor bacteria. |

| Langlebigkeit | Good for short-term or disposable items. | Degrades with heat, UV light, and age. |

Polypropylene is completely resistant to staining from all food and drink products.Falsch

PP is a porous plastic and is known to stain, especially from strongly colored substances like tomato sauce or certain teas.

PP is one of the most widely produced and recycled commodity plastics in the world.Wahr

Due to its versatility and low cost, PP is used extensively in packaging, textiles, and automotive parts, and it is designated with the recycling code 5.

You want the premium, glass-like look for your appliance without the risk of shattering. But is this "premium" plastic truly better for long-term health and hygiene? Let's look past the marketing claims.

Tritan5 offers glass-like clarity and better durability than other plastics, and it is BPA-free. While a "better" option than PP, it is still a petroleum-based product. Its long-term non-leaching properties are less proven than stainless steel's, and it can still scratch.

When my trading company was active, we saw a huge surge in demand for Tritan. It was a game-changer for designers. Finally, a plastic that looked like glass but wouldn't shatter into a million pieces if you dropped it. It's tough, it's beautiful, and the "BPA-Free" label made it an easy sell to health-conscious consumers. It quickly became the go-to material for high-end blenders, water bottles, and pitchers. It is, without a doubt, a "better" choice than PP.

However, we must be critical. Tritan is still a plastic. It's a petroleum product. While it's free of BPA, questions remain about the long-term effects of other compounds used in its manufacturing. More importantly, while it's much more scratch-resistant than PP, it can still scratch. And just like with PP, those scratches can become breeding grounds for biofilm. Another "feature"—its clarity—is actually a disadvantage for stored water. Light penetration can encourage algae or bacterial growth6. Tritan is a fantastic piece of material engineering, but it's a bridge, not the final destination for ultimate health and safety.

Clarity vs. Purity: The Tritan Trade-off

| Merkmal | Vorteil | Disadvantage |

|---|---|---|

| Ästhetik | Glass-like clarity and gloss. | Light penetration can promote bacterial growth. |

| Dauerhaftigkeit | Highly shatter-resistant and durable. | Can still be scratched, creating havens for bacteria. |

| Sicherheit | BPA-Free. | Still a plastic with less long-term safety data than steel. |

| Perception | Marketed as a "premium" and "safe" material. | Potential for microplastic shedding as it ages or gets scratched. |

Tritan plastic is completely scratch-proof under all conditions.Falsch

While highly scratch-resistant compared to other plastics like polycarbonate or PP, Tritan can still be scratched by abrasive materials or sharp objects.

Tritan is a copolyester that is free of BPA, BPS, and other bisphenols.Wahr

Tritan, developed by Eastman Chemical Company, was specifically designed as a replacement for polycarbonate, offering similar clarity and toughness without the use of bisphenol-A (BPA) or other bisphenol compounds.

Level 3: Why is Food-Grade Stainless Steel the Optimal Choice?

You want to design a product with the absolute best material for health and durability. The higher initial cost might seem like a barrier. Let's explore why steel's benefits make it the ultimate long-term investment.

Food-grade stainless steel is the optimal choice because it is inert, meaning it does not leach chemicals or shed microplastics. Its non-porous surface resists bacteria and biofilm, and it blocks all light, ensuring maximum hygiene and water stability for long-term health.

This is where we separate the good from the best. I remember working with a client who was developing a high-end water filtration system. We debated materials for weeks. They were tempted by Tritan's look, but I pushed hard for 304 food-grade stainless steel. The initial tooling and material costs were higher, but I urged them to think about the brand message. Choosing steel says, "We prioritize your health above all else." They took the advice, and their product became a benchmark for safety and quality.

This is because stainless steel is inert. It doesn't play games. It doesn't react with the water, it doesn't leach unknown compounds, and it doesn't shed microplastics, no matter how old it gets. Its surface is non-porous, meaning there are no microscopic holes for bacteria to hide in. It's incredibly durable and will last a lifetime. And its opacity, which some might see as a downside, is a huge benefit for water storage—it blocks 100% of light, preventing anything from growing. It's not just "food-safe"; it's the closest thing to a perfectly non-interactive material you can get. It is the "best" choice.

The Power of an Inert Material

| Merkmal | Vorteil | Disadvantage |

|---|---|---|

| Health | Inert, non-leaching, no microplastics. | Higher initial material cost. |

| Hygiene | Non-porous surface resists bacteria/biofilm. | Opaque, so you can't see the water level. |

| Dauerhaftigkeit | Extremely durable, corrosion-resistant, lasts a lifetime. | Can be dented with extreme force. |

| Stability | Blocks 100% of light, keeping water pure. | Can be heavier than plastic alternatives. |

Stainless steel adds a metallic taste to water stored in it for long periods.Falsch

High-quality, food-grade stainless steel (like 304 or 316) is non-reactive and does not impart any taste or odor to its contents. A metallic taste usually indicates low-quality steel or improper finishing.

The '304' in 304 stainless steel refers to its composition, which typically includes 18% chromium and 8% nickel.Wahr

This composition, often called 18/8 stainless steel, gives it excellent corrosion resistance and makes it the most common food-grade stainless steel used for kitchen equipment and water appliances.

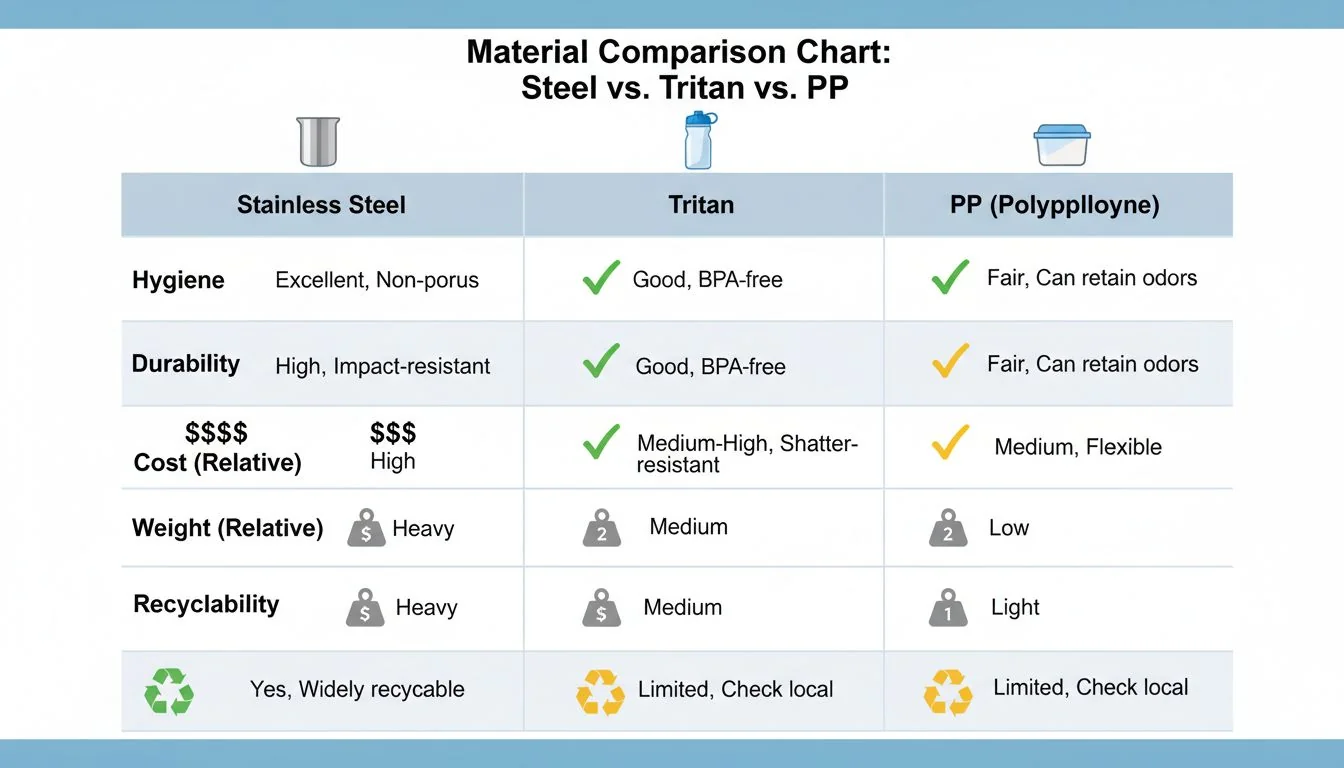

Head-to-Head: How Do Steel, Tritan, and PP Really Compare?

You have the individual details, but you need a clear, side-by-side view to make a final decision. A flawed comparison could lead to a flawed design. Let's put them all in one simple table.

In a direct comparison, stainless steel excels in every health and hygiene category due to its inert, non-porous nature. Tritan offers better aesthetics and durability than PP, but as plastics, both carry risks of microplastic shedding and biofilm formation that steel completely avoids.

As a designer, your job is to balance function, aesthetics, cost, and safety. Sometimes, compromises are necessary. But when it comes to a product that delivers drinking water, the weighting of those factors changes. For a designer like you, Jacky, this table isn't just data; it's a decision-making matrix that directly impacts the end-user's well-being and their trust in your product. I've always believed in choosing the right material for the job, and when the job is long-term health, the choice becomes very clear.

This "Good, Better, Best" framework helps simplify the decision. PP is good for low-cost, disposable applications. Tritan is better for when aesthetics and shatter resistance are key, but it's still a compromise. Stainless steel is the best for when health, hygiene, and longevity are non-negotiable.

The Ultimate Material Showdown

| Criterion | PP (Good) | Tritan (Better) | Stainless Steel (Best) |

|---|---|---|---|

| Material Type | Standard Plastic | Premium Plastic | Inert Metal |

| Microplastic Risk | Yes, with age/scratches | Yes, with scratches | Keine |

| Biofilm Risk | High (scratches easily) | Moderate (can scratch) | Very Low (non-porous) |

| chemical leaching7 | Low (regulated) | Very Low (BPA-Free) | None (Inert) |

| Light Penetration | Opaque (Good) | High (Bad for storage) | None (Best) |

| Dauerhaftigkeit | Mäßig | Hoch | Lifetime |

| Kosten | Niedrig | Mittel | Hoch |

Tritan and stainless steel have the same level of resistance to bacterial growth.Falsch

Stainless steel's non-porous surface is inherently more resistant to bacterial colonization and biofilm formation than any plastic, including Tritan, which can develop microscopic scratches that harbor bacteria.

The choice of material can significantly impact a product's perceived value and brand positioning.Wahr

Using premium materials like stainless steel can signal quality, durability, and a commitment to health, justifying a higher price point and building long-term brand trust.

Why is Your Appliance's Material a Health Decision, Not Just a Design Choice?

You might see material selection as just another technical spec on your CAD file. But this view overlooks the growing consumer demand for genuinely health-conscious products. Let's reframe this as a core brand decision.

The material you choose directly impacts consumer health through potential chemical leaching, microplastic ingestion, and bacterial exposure. Shifting your mindset from a "food-safe" minimum to an "inert" optimum meets the modern consumer's demand for wellness and positions your product as a trustworthy choice.

In all my years helping clients bring products to market, I've seen one trend grow stronger every year: people care more and more about what goes into their bodies. They read labels, research ingredients, and are deeply concerned about long-term health. They are aware of "hidden" risks like microplastics. This isn't a fad; it's a fundamental shift in consumer consciousness. As a designer, you are on the front lines of this shift.

Choosing stainless steel over plastic is not just a technical upgrade; it's a statement. It tells your customers that you've thought about their health beyond the government-mandated minimums. It shows that you've considered the entire lifespan of the product, from day one to year ten. While PP and Tritan are "food-safe," stainless steel is inert. That distinction is powerful. It's about future-proofing your design against stricter regulations and rising consumer expectations. The brands that I've seen build the most loyal followings are the ones that make choices that demonstrate they are on the customer's side.

Consumers are generally unaware of the differences between food-safe plastics and inert materials.Falsch

A growing segment of health-conscious consumers is becoming highly educated about material safety, actively seeking out products made from glass and stainless steel to avoid potential risks associated with plastics.

Microplastic shedding from plastic containers increases with repeated use, washing, and exposure to heat.Wahr

Studies have shown that mechanical stress (scratching, washing) and thermal stress (hot liquids, dishwashers) accelerate the degradation of plastic surfaces, leading to higher rates of microplastic release.

Schlussfolgerung

Choosing the right material is a health decision. For water appliances, stainless steel is the inert, optimal choice for safety, hygiene, and long-term durability, making it the best investment.

References

-

Explore the advantages of food-grade stainless steel, known for its inert properties and safety in food and water applications. ↩

-

Discover the health implications of microplastics and their relevance in the materials used for water storage. ↩

-

Investigate how material choices in product design reflect a commitment to consumer health and safety. ↩

-

Explore the durability of various materials used in water appliances and their long-term performance. ↩

-

Learn about Tritan's properties and whether it truly offers a safe alternative to traditional plastics. ↩

-

Find out which materials are best at inhibiting bacterial growth, ensuring safe drinking water. ↩

-

Learn about chemical leaching from materials and its potential risks in water appliances. ↩