You have a brilliant hardware idea. But the thought of building a factory, with its massive costs and risks, is a total nightmare. What if there's another way?

You can launch a hardware product without a factory by partnering with the right manufacturer. Instead of building from scratch, you leverage their existing infrastructure, expertise, and even their pre-certified technology platforms to bring your unique vision to life faster and with less risk.

I've spent my life in the world of molds and manufacturing. I started on the factory floor and eventually built my own trading company. I’ve seen countless founders with incredible vision. They have a dream for a product that will change the world. But then they hit a wall. It’s the wall of manufacturing. The reality of building a physical product is often a nightmare of engineering, compliance, and cash. This article is for those founders. I want to show you that you don't need to build a factory. You just need to find the right kind of partner. Let's explore the paths you can take.

Over 90% of hardware startups ultimately fail.Wahr

According to a report by CB Insights, hardware startups face unique challenges including high upfront costs, manufacturing complexities, and supply chain management, leading to a high failure rate.

Building a small factory costs less than $100,000.Falsch

Even a small-scale manufacturing facility requires millions of dollars in investment for real estate, machinery, regulatory compliance, and skilled labor, making it prohibitive for most startups.

1. The "Hardware Dream" vs. the "Factory Nightmare"?

You have a game-changing idea for a new device. But the dream quickly fades when you imagine the reality: finding land, building a factory, and buying million-dollar machines.

The "Factory Nightmare" is the massive upfront cost, complex logistics, and endless regulations of owning your own production. It stops most hardware dreams before they even start. The good news is, you can completely sidestep this nightmare by choosing the right Manufacturing Strategy1 from the beginning.

The Founder's Dilemma

As a founder, you are "vision-rich." You know the customer, the problem, and the unique experience you want to create. The problem is that you are often "engineering-poor." You don't have a team of 50 engineers or a multi-million dollar R&D budget. This is the core dilemma. Your great idea is separated from the market by a huge wall of technical execution.

In my years of helping clients with molds, I've seen this story play out again and again. A brilliant product concept dies because the founder couldn't navigate the complexities of turning a 3D model into a reliable, mass-produced product. They get bogged down in tooling details, material science, and international certifications. Their vision gets lost in the weeds of execution. The dream of a beautiful product is crushed by the nightmare of making it.

Most hardware founders have deep engineering backgrounds.Falsch

Many successful hardware founders are designers, marketers, or business strategists who have a strong product vision but rely on partners for technical execution.

The cost of product certification (like UL or CE) can exceed $50,000 per product.Wahr

Depending on the product's complexity, testing and certification by bodies like Underwriters Laboratories (UL) or for Conformité Européenne (CE) marking is a costly and time-consuming process that is mandatory for market access.

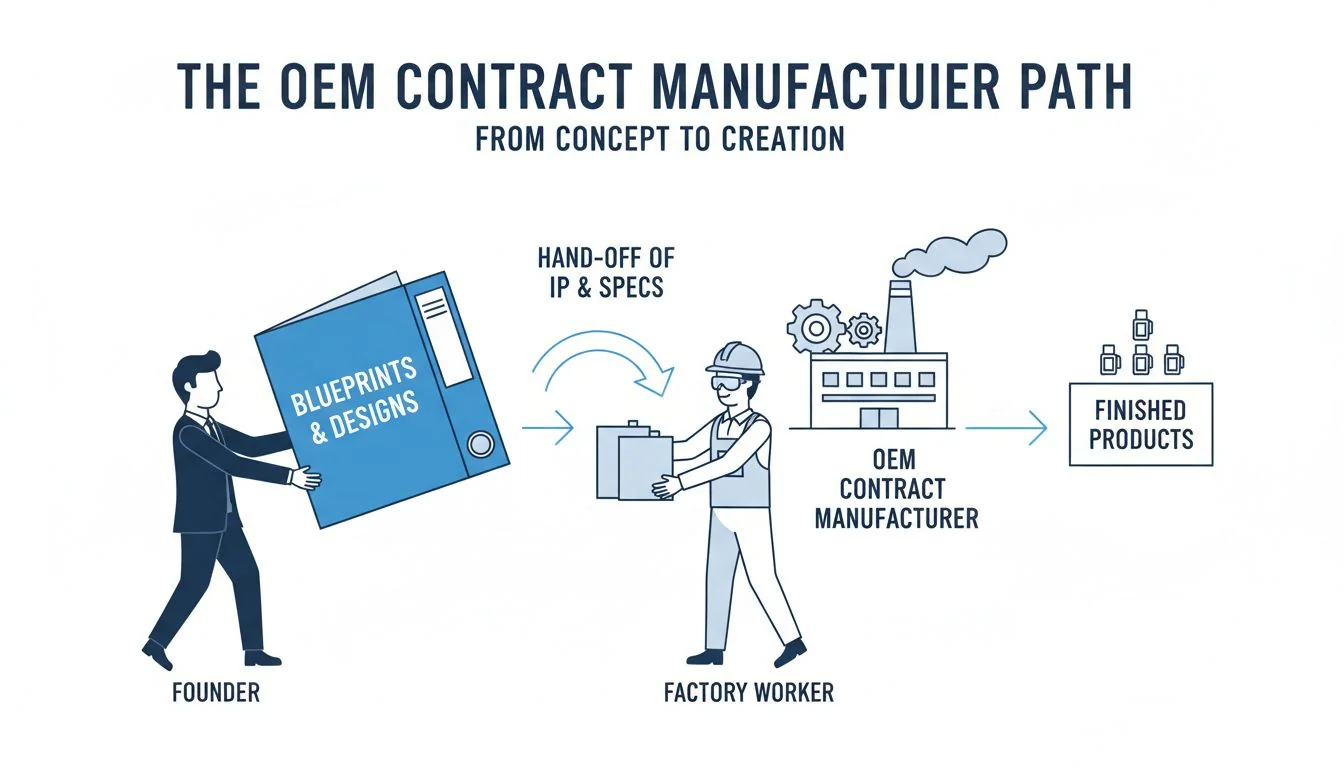

2. The "Contract Manufacturer" (Pure OEM) Trap?

You have a complete design and just need someone to build it. A Contract Manufacturer seems perfect. But are you prepared for the endless engineering loops and unexpected costs?

A Contract Manufacturer (OEM) builds your product based on your exact specifications. This path gives you full control but requires you to be "engineering-rich." You are responsible for all R&D, design, testing, and compliance, which can be slow, expensive, and full of hidden pitfalls.

Are You an Engineering Powerhouse?

The OEM, or Original Equipment Manufacturer, path is simple on the surface. You give them the blueprints, and they make the product. This is the model companies like Apple use. They have thousands of engineers who design every single component and process. They hand over a perfect plan to their manufacturing partner.

But you are not Apple. If you are a startup founder, providing a "perfect plan" is nearly impossible. Your design might have flaws that only appear during tooling. The material you chose might not pass safety tests. Each of these problems sends you back to the drawing board, costing you time and money. You are paying the OEM to wait while you fix the problems you are responsible for. I call this the "OEM Trap2" because it promises control but delivers delays and costs for anyone who isn't already an engineering giant.

| OEM (Contract Manufacturer) | Pros & Cons |

|---|---|

| Profis | ✅ Full control over IP and design. ✅ Potentially lower per-unit cost at massive scale. |

| Nachteile | ❌ You bear 100% of R&D cost and risk. ❌ Requires a large, experienced engineering team. ❌ Slow time-to-market due to design-test-fix loops. ❌ You are responsible for all compliance and certification. |

OEM manufacturing is the fastest way to launch a new hardware product.Falsch

The OEM path is often the slowest for startups because it requires the founder to complete all R&D, design for manufacturing (DFM), and prototyping before production can even begin.

With an OEM, the founder is solely responsible for product liability and safety compliance.Wahr

In a pure OEM relationship, the manufacturer is only responsible for building to the provided specifications. The brand owner (the founder) is legally responsible for the product's design, safety, and adherence to all market regulations.

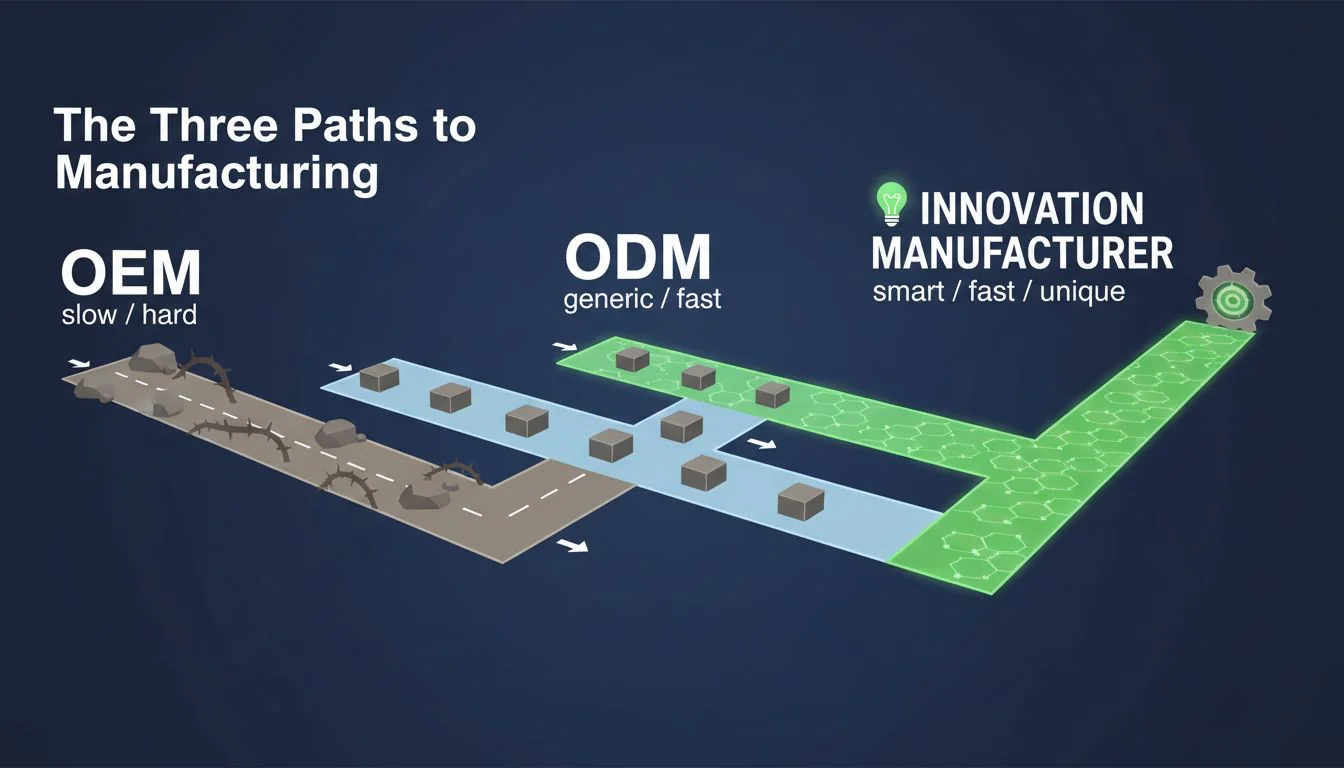

3. The "Private Label" (ODM) Commodity Trap?

You want to get to market fast. An ODM offers a ready-made product you can brand. But how will you stand out when competitors sell the exact same thing?

An Original Design Manufacturer (ODM) offers a pre-designed product that you can put your logo on. This is the fastest path to market, but it results in a "commodity" product with no unique features or intellectual property. You're just another brand selling the same thing.

The Race to the Bottom

The ODM, or Original Design Manufacturer, path is very tempting. You browse a catalog, pick a product, and the factory puts your logo on it. You can have a product on Amazon in a few months. I've seen many people take this path. It offers incredible "speed-to-market."

The problem is, it's not "Speed-to-Brand3." You don't own the design. You have no unique features. Your competitors can buy the exact same product from the same factory. What happens next? A price war. Your business becomes a race to the bottom, competing only on price and marketing spend. You haven't built a defensible business or a memorable brand. You've just become a reseller of a generic commodity. This path is a short-term solution that often leads to a long-term dead end.

| ODM (Private Label) | Pros & Cons |

|---|---|

| Profis | ✅ Extremely fast time-to-market. ✅ No R&D costs. ✅ Low barrier to entry. |

| Nachteile | ❌ No unique IP or product differentiation. ❌ You are competing with others selling the same product. ❌ Little to no control over quality or features. ❌ Creates a commodity, not a brand. |

ODM products allow for deep customization and unique features.Falsch

ODM products typically only allow for superficial changes like color, branding (logo), and packaging. The core design, technology, and features are fixed and owned by the manufacturer.

Using an ODM is a common strategy for building a long-term, defensible brand.Wahr

Many large brands start by using ODMs to test a market quickly before investing in their own unique designs. It's a valid market entry strategy, though it may not be a long-term solution for differentiation.

4. The "Smart" Path: Partner with an "Innovation Manufacturer"?

You want a unique product without the full R&D burden. The OEM and ODM paths feel wrong. Is there a hybrid approach that offers the best of both worlds?

The smart path is to partner with an "Innovation Manufacturer4." This partner brings their own core technology and IP to the table. You then co-develop a unique product around their proven platform, creating a defensible brand without starting from zero. It's a true partnership.

Co-Development is the Key

I believe we need a new term for this new way of working: the Innovation Manufacturer. This is not just a factory-for-hire. This is a partner that acts as your outsourced R&D department.

Here’s how it works. An Innovation Manufacturer has already invested years and millions of dollars developing a core "platform." This could be a unique motor, a special sensor, or a new material technology. It's their proven, patented IP. You, the founder, bring your market insight and brand vision. You work mit them to build your unique product on top of their platform. You design a unique housing, create a custom user interface, and build a brand story. The result is a product that is truly yours, but it's built on a foundation of proven, reliable technology. This is the best of both worlds: you get the speed and de-risking of an ODM, with the brand differentiation of an OEM.

Co-development with a manufacturer means you give up ownership of your brand's IP.Falsch

In a good co-development partnership, the manufacturer retains IP for their core platform, while the founder retains IP for the unique design, user experience, and brand identity built on top of it. Contracts clearly define this separation.

The co-development model is a new concept from the last 5 years.Falsch

While the term 'Innovation Manufacturer' may be new, the concept of co-development has existed for decades, particularly in the automotive and aerospace industries, where suppliers and brands partner deeply on new technology.

5. How "Innovation Platforms" De-Risk Your Launch?

Product compliance and hygiene standards are terrifyingly complex and expensive. What if you could skip these multi-million dollar hurdles and get straight to building your brand?

An "Innovation Platform" is a pre-developed, pre-certified core technology. For example, Hisoair's stainless steel humidifier platform has already solved the huge challenges of hygiene and compliance. By building on this platform, you inherit its benefits, removing massive risk, cost, and time from your project.

Your Unfair Advantage

Let's use a real example. A company like Hisoair makes humidifiers. But they didn't just make a humidifier. They created an "Innovation Platform" based on hygienic, boil-clean, stainless steel technology. This is their core IP.

The Compliance Hurdle

Getting a new electronic product certified for sale in the US (UL, FCC) and Europe (CE) is a nightmare. It can take a year and cost tens of thousands of dollars. If you fail, you have to re-engineer and test again. Hisoair's core platform is already certified. By building on it, you skip 90% of this headache. This is a massive "risk removal" service.

The Hygiene Hurdle

For a humidifier, hygiene is a huge customer concern. Most plastic humidifiers get moldy and are hard to clean. Hisoair spent years and a fortune developing a stainless steel platform that can be boiled clean. For a startup, solving this problem from scratch is impossible. By partnering with them, you get to market with a product that has a huge, defensible advantage: it's the most hygienic. You didn't spend a dollar on that R&D, but you get all the brand benefits.

A product built on a pre-certified platform requires no additional testing.Falsch

While the core components may be certified, the final, assembled product with its unique housing and user-facing electronics will still require some level of final testing and certification, though the process is significantly faster and cheaper.

Stainless steel is inherently more hygienic than plastic for water-bearing products.Wahr

Stainless steel is non-porous, resisting bacterial growth. It can also be sanitized at high temperatures (like boiling), which is not possible with most plastics used in consumer humidifiers, making it a superior material for hygiene.

6. Conclusion: You Don't Need a Factory. You Need a Partner.

Building a hardware brand feels impossible alone. You're stuck between slow, expensive R&D and cheap, generic products. There has to be a better way to succeed.

Forget the factory. To build a successful hardware brand today, you need an "Innovation Manufacturer." This partner acts as your outsourced R&D department, providing a proven technology platform that accelerates your journey from a unique concept to a defensible brand in the market.

From Speed-to-Market to Speed-to-Brand

Let's review the paths. The OEM path is too slow and expensive for most founders. The ODM path is fast, but it's a commodity trap that doesn't build a real brand.

The smart path, partnering with an Innovation Manufacturer, offers "Speed-to-Brand." You can launch a unique, defensible product in 6-9 months because you are building on a proven foundation. You focus on what you do best: understanding the customer and building a brand they love. Your partner handles the deep engineering and compliance that would otherwise sink your dream. I've built my career on helping people make things. Trust me on this: the future of hardware isn't about owning the factory. It's about finding the right partner to bring your vision to life.

The 'Speed-to-Brand' timeline with an Innovation Manufacturer is typically 6-9 months.Wahr

This timeline is realistic because the core technology R&D is complete. The 6-9 months are spent on industrial design, tooling for the unique housing, UI/UX development, and final integration, which is much faster than a ground-up project.

All manufacturers now offer a co-development or 'Innovation Manufacturer' model.Falsch

This is still a relatively new and specialized approach. The vast majority of manufacturers in Asia operate on a traditional OEM or ODM model. Finding a true Innovation Manufacturer requires careful vetting and searching.

Schlussfolgerung

You don't need to own the machines. You need to own the vision and find the right partner to help you build it.

References

-

Explore various manufacturing strategies that can help startups succeed without owning a factory. ↩

-

Learn about the challenges and pitfalls of relying solely on OEMs for product manufacturing. ↩

-

Discover the concept of Speed-to-Brand and how it can benefit your hardware startup. ↩

-

Discover how partnering with an Innovation Manufacturer can accelerate your product development and reduce risks. ↩