You have a great product idea, but the path to a finished product seems complex. Choosing the wrong manufacturing partner can derail your vision. I'm here to clarify it.

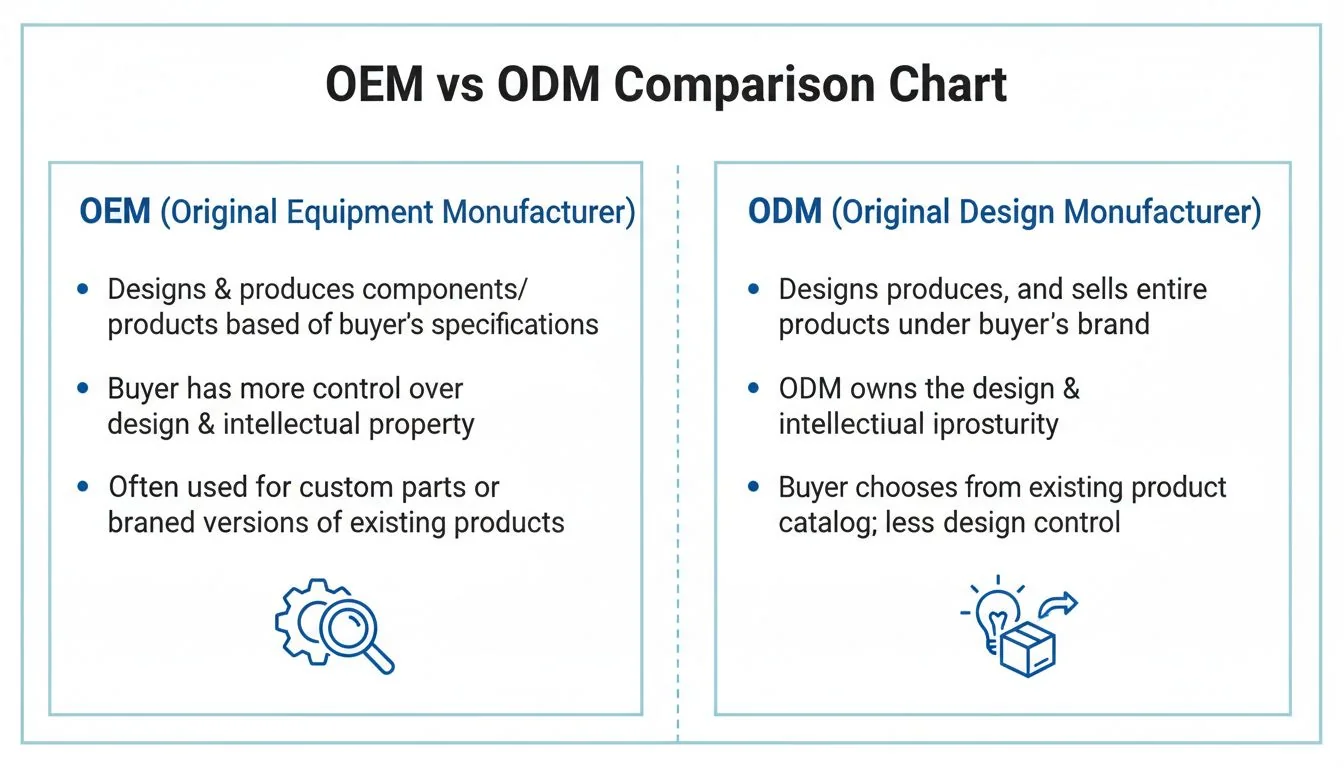

The core difference is who owns the design. With Original Design Manufacturing (ODM), you choose a factory's existing product design. With Original Equipment Manufacturing (OEM), you provide your own unique design for the factory to produce exclusively for you. This choice impacts cost, speed, and geistiges Eigentum1.

Choosing your manufacturing path is one of the most important decisions you'll make. It affects your budget, your timeline, and the very identity of your brand. I've seen many entrepreneurs get stuck here, unsure of the terms and what they really mean for their business. It's not just about finding a factory; it's about finding the right type of partnership. Let's break down these two fundamental models so you can move forward with confidence and turn your idea into a reality.

OEM always results in a higher quality product than ODM.Falsch

Quality is determined by the factory's standards, materials, and quality control processes, not the manufacturing model itself. A high-end ODM product can be better than a poorly executed OEM product.

The primary legal difference between OEM and ODM is the ownership of the intellectual property (IP).Wahr

In OEM, the client owns the design IP. In ODM, the manufacturing factory owns the IP of the base product design.

1. You Have a Product Idea. Now What?

Got a brilliant concept for an air purifier but feel lost in the manufacturing maze? This first step is critical. Making the wrong choice can cost you dearly in time and money.

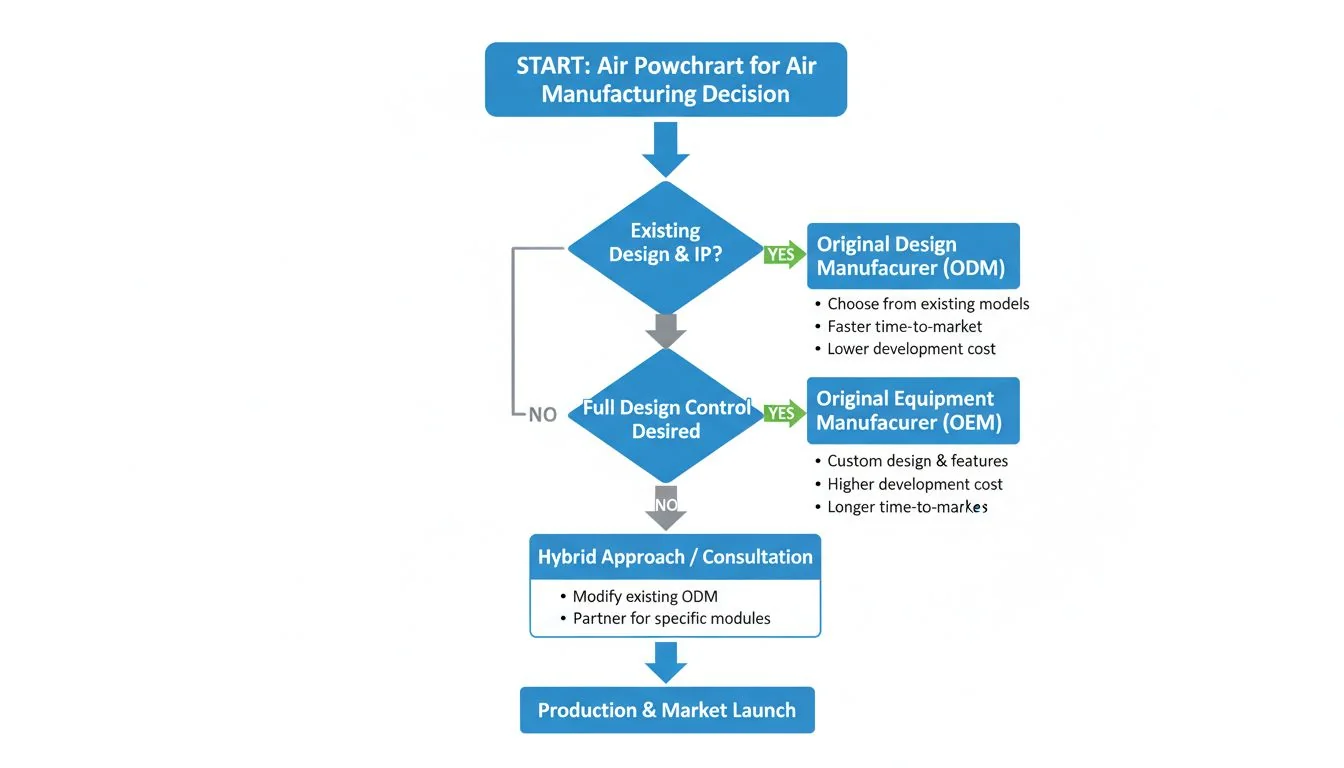

Your first major decision is choosing a manufacturing model2. This choice boils down to two main paths: ODM or OEM. Understanding the difference is the first step to finding a partner who can bring your specific vision for an air purifier to life effectively.

When I started my trading company, I saw this firsthand. Clients would come to me with fantastic ideas but no clear path forward. They were experts in their market but new to the world of production. The conversation always started with this fundamental question: are we creating something brand new, or are we adapting something that already exists? This is the heart of the OEM vs. ODM decision. It’s not just a technical detail; it’s the strategic foundation of your entire product launch3. Your answer will define your budget, your timeline, and how unique your product will be in the marketplace. It’s the difference between getting to market in three months or in two years. Let's make sure you choose the right path from the start.

Every new product requires creating custom molds from scratch.Falsch

ODM manufacturing utilizes existing molds and tooling owned by the factory, which is why it's faster and has a lower initial cost.

Choosing a manufacturing model is a strategic business decision, not just a production detail.Wahr

The choice between OEM and ODM directly impacts budget, time-to-market, brand differentiation, and long-term business strategy.

2. What is ODM? The "Ready-to-Brand" Approach?

Want to launch your product line quickly without massive upfront design costs? An existing factory design could be your ticket to market. But how do you make it feel like your own?

ODM, or Original Design Manufacturing, is where you select a pre-designed product from a factory's catalog and apply your own branding. This is the manufacturing process that powers the "private label4" business model, especially popular on platforms like Amazon.

I often tell my clients that ODM is the fastest way to get your foot in the door. Think of it as the engine of private labeling. When someone says they want to "private label" an air purifier, they are looking for an ODM partner. The factory has already done the heavy lifting: the design, the engineering, and the tooling. Your job is to choose a model you like and customize the finishing touches.

Key Aspects of ODM

- Speed: You can go from product selection to market in a matter of months, not years.

- Cost: You avoid the huge investment in research, development, and custom molds5.

- Simplicity: The process is straightforward, focusing on branding and packaging rather than complex engineering.

However, the main trade-off is uniqueness. Your competitors could potentially partner with the same factory and sell a very similar product under a different brand name. The core design and technology belong to the factory, not to you.

ODM products cannot be customized in any way.Falsch

While the core design is fixed, many ODM factories offer customization options for color, materials, branding (logo), packaging, and sometimes minor functional components.

ODM is a popular model for sellers on e-commerce platforms like Amazon.Wahr

The speed and low initial investment of ODM make it an ideal strategy for private label brands looking to quickly launch products and test market demand.

3. What is OEM? The "Your Design, Our Factory" Approach?

You've invested time and effort into a completely unique design. Now you need a factory to build it to your exact specifications. This path offers total control but requires a bigger commitment.

OEM, or Original Equipment Manufacturing, is the model where you, the client, provide the factory with a complete and original product design. The factory's role is to manufacture it exclusively for you. The most critical part is that you own the intellectual property (IP).

This is where my passion for mold making really comes into play. With OEM, we are creating something from nothing. The client brings the blueprint, and we build the custom molds and tooling that will bring it to life. This is the real dividing line between the two models: IP ownership. With an OEM project, the design is your asset. The molds we create for you belong to you. No one else can use them. This exclusivity is why brands are willing to invest significantly more time and money into the OEM process. They aren't just buying a product; they are building a unique, defensible part of their brand's identity. It's a long-term play for companies that want to stand out and lead the market with innovation.

With OEM, the factory can sell your product design to other brands.Falsch

In a proper OEM agreement, the client owns the intellectual property (IP) and the design is manufactured exclusively for them. The factory is contractually forbidden from selling the design to others.

OEM manufacturing typically involves higher Minimum Order Quantities (MOQs) than ODM.Wahr

Factories need to cover the high costs of setting up a new production line and creating custom tooling, so they require a larger initial order to make the project financially viable.

4. Key Differences at a Glance?

ODM and OEM might sound similar, but they represent two very different business strategies. Mistaking one for the other can lead to costly errors. Let's put them side-by-side for a clear comparison.

The biggest differences lie in who controls the design, who owns the IP, the initial cost and time, and the required order size. OEM is about creating a unique asset, while ODM is about leveraging an existing one for speed.

As someone who has managed countless mold design projects, the most tangible difference I see is the investment in tooling. For an ODM project, the factory has already absorbed the cost of the molds, which can be tens or even hundreds of thousands of dollars. For an OEM project, that cost falls on you, the client. This is often the single largest upfront expense. It's a major hurdle, but it's also what gives you ownership and control. Understanding this financial and strategic difference is crucial. Below is a table that breaks it down clearly.

| Merkmal | ODM (Original Design Manufacturing) | OEM (Original Equipment Manufacturing) |

|---|---|---|

| Design & IP | Factory owns the existing design and IP. | You provide and own the unique design and IP. |

| Anfängliche Kosten | Low (minimal R&D, no tooling costs). | High (significant R&D, custom mold & tooling costs). |

| Time-to-Market | Fast (weeks to a few months). | Slow (many months to over a year). |

| MOQ | Generally lower. | Generally much higher. |

| product uniqueness6 | Low; competitors can sell similar products. | High; your product is exclusive to your brand. |

| Kontrolle | Limited to branding, packaging, minor tweaks. | Full control over design, features, and quality. |

The MOQ for an OEM project is always 10,000 units.Falsch

MOQs are highly variable and depend on the product's complexity, the factory's policies, and material costs. It is negotiated on a per-project basis.

Time-to-market is significantly faster with ODM than with OEM.Wahr

ODM skips the lengthy design, engineering, and tooling phases, allowing brands to launch products much more quickly.

5. Which Model is Right for Your Air Purifier Business?

Choosing between ODM and OEM for your air purifier isn't just a production detail; it's a core business strategy7. The right choice depends entirely on your goals, resources, and long-term vision.

For speed and low risk, choose ODM. It gets your brand into the market fast. For building a unique brand with a proprietary product, and if you have the capital, choose OEM.

In my experience, many of the most successful projects live in the gray area between these two models. A client might love an ODM air purifier's core performance but want a completely new control panel or to integrate a smart-home module. This is often called a "Hybrid" model or "ODM with customizations." It's a major value-add service we provide. This approach gives you more differentiation than standard ODM without the full timeline and cost of a ground-up OEM project. It's a fantastic balance.

Furthermore, I often advise new brands to think in phases. This is the "ODM as a Stepping Stone" strategy.

- Phase 1: Launch a customized ODM product to enter the market quickly, generate revenue, and gather customer feedback.

- Phase 2: Use the profits and market insights from your first product to fund the development of a unique, second-generation OEM product.

This approach minimizes your initial risk while allowing you to build toward a truly unique brand asset.

The 'Hybrid ODM' model offers a balance between the speed of ODM and the uniqueness of OEM.Wahr

This model involves taking a standard ODM product and making significant modifications, such as new electronics or custom components, to create a more differentiated product.

You must choose either pure ODM or pure OEM; there is no middle ground.Falsch

Many projects are a hybrid, where a client customizes an ODM product significantly, blurring the lines between the two models.

6. A Flexible Partner for Your Vision?

Your business will evolve, and your manufacturing needs will change. A straight line from idea to product is rare. You need a partner who can grow and adapt right alongside you.

The ideal manufacturing partner is not just a supplier; they are a flexible guide. They should be equipped to handle a simple ODM launch, a complex OEM build, and the customized hybrid models in between.

This is the philosophy I built my company on. We aim to be a long-term partner, not a one-time vendor. We understand the journey. We've helped startups get off the ground with a quick ODM product to test the waters. Then, when they're ready to make their mark with a truly innovative OEM design, our engineering and mold-making teams are ready to execute their vision. The goal is to build a lasting relationship. We celebrate when a client uses the success of their first ODM product to fund their dream OEM project with us. That's how I know we're doing our job right. True success in this industry is built on these long-term partnerships, helping clients navigate every stage of their growth.

A good manufacturing partner only needs to be good at one model, either OEM or ODM.Falsch

The best partners are flexible and have the expertise to support clients through different stages of growth, whether they need ODM, OEM, or a hybrid solution.

Using an ODM product as a 'stepping stone' to a future OEM product is a viable business strategy.Wahr

This phased approach allows a brand to enter the market with lower risk, generate revenue, and gather data to inform a more ambitious and unique OEM project later.

Schlussfolgerung

Choosing between OEM and ODM is a foundational strategic decision. Understand the key differences in cost, IP ownership, and speed to select the right path for your business's immediate and long-term success.

References

-

Understanding intellectual property is crucial for protecting your designs and innovations in manufacturing. ↩

-

Exploring various manufacturing models can help you choose the best strategy for your product development. ↩

-

Knowing the steps for a successful product launch can help you effectively bring your product to market. ↩

-

Private labeling can be a lucrative strategy for brands looking to enter the market quickly with existing products. ↩

-

Learning about custom molds is essential for understanding the costs and processes involved in OEM manufacturing. ↩

-

Product uniqueness can differentiate your brand in a competitive market, making it essential for long-term success. ↩

-

A solid business strategy guides your manufacturing decisions and helps align them with your overall goals. ↩