Ever wondered where your ZeroWater pitcher and filters come from? You might think the answer is simple, but the story behind the "Made In" label is a fascinating journey into global manufacturing, corporate strategy, and the quest for pure water. The short answer? Your ZeroWater filter is most likely made in Mexico. But the real story is far more interesting.

It’s a tale of a small, innovative company that got acquired by a global giant, and how that changed everything. It’s a perfect example of how modern products are made, with components and expertise sourced from around the world. Let's dive into the details and uncover the truth behind your ZeroWater purifier.

From a Niche Innovator to a Global Brand: The ZeroWater Story

To understand where ZeroWater products are made today, we first need to look at the company's history. ZeroWater wasn't always the well-known brand it is today. It started in 2002 as Zero Technologies, LLC, a small company with a big mission: to challenge the giants of the water filtration market like Brita and PUR.

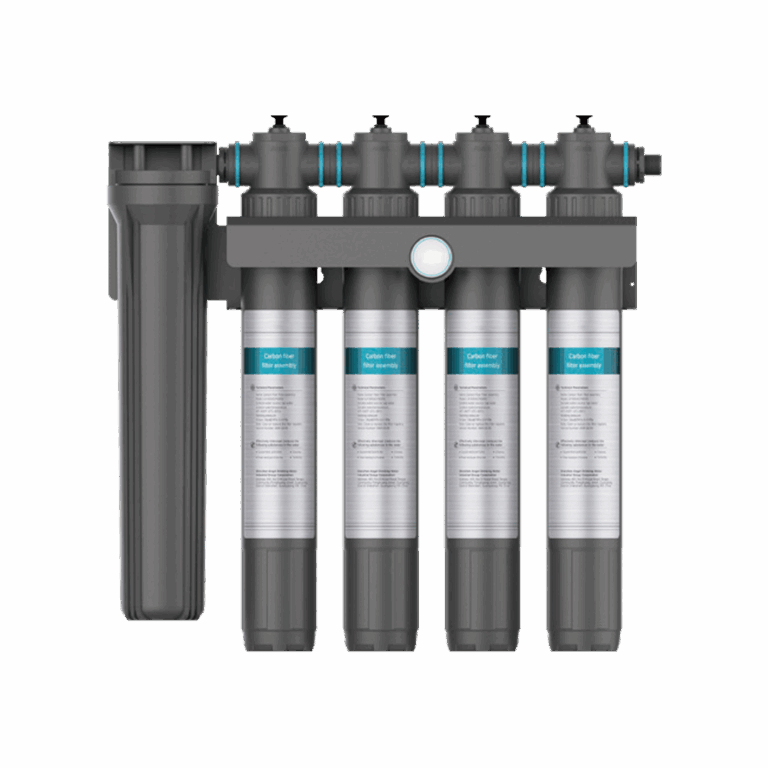

Their secret weapon? A revolutionary 5-stage ion-exchange filtration system. This was a major leap forward from the 2-stage carbon filters that were common at the time. ZeroWater's technology was so effective that it could remove virtually all total dissolved solids (TDS) from tap water. To prove it, they included a digital TDS meter with every pitcher. This clever marketing strategy empowered consumers and helped ZeroWater build a loyal following.

For years, the company operated from its headquarters in Trevose, Pennsylvania. But like many modern brands, they didn't own the factories that made their products. Instead, they relied on a network of contractors and suppliers. This all changed in 2020.

The Culligan Acquisition: A Game-Changing Move

On March 26, 2020, everything changed for ZeroWater. The company was acquired by Culligan International, a global leader in water treatment with a history stretching back to 1936. This wasn't just a simple purchase; it was a strategic merger that would reshape ZeroWater's future.

Culligan saw the potential in ZeroWater's advanced filtration technology. They wanted to combine it with their own expertise and global reach. The result? The brand was renamed "Culligan ZeroWater," a clear signal that this was a new era. The message was simple: the ZeroWater technology you love, now backed by the power of a global leader.

This acquisition had a profound impact on how ZeroWater products were made. Culligan began to integrate ZeroWater into its massive global operations. The company assured customers that the core 5-stage filter technology would remain the same, but behind the scenes, a major shift was underway. Culligan's goal was to optimize operations, and that meant leveraging its own manufacturing facilities to produce ZeroWater products more efficiently.

Pinpointing the Production: Where the Magic Happens

So, where are ZeroWater products actually made now? The answer lies in Culligan's global manufacturing network. By examining product data and import records, we can piece together the puzzle.

The Heart of the System: The 5-Stage Filter

The most important part of the ZeroWater system is the 5-stage filter. This is where the magic happens, where the impurities are removed from your water. And the evidence is clear: the filters are made in Mexico.

This is a crucial piece of information. The filter is a complex and technologically advanced component. The fact that it's manufactured in Mexico tells us a lot about Culligan's strategy. They are leveraging their new, state-of-the-art facility in Monterrey, Mexico, to produce the core component of the ZeroWater system for the North American market.

The Pitchers and Dispensers: An

Intriguing "Imported" Label

What about the pitchers and dispensers? Here, the label is a bit more mysterious. Retailers like Target list the origin as simply "Imported." This is a generic label that could mean anywhere outside the United States.

However, when you think about it from a logistics perspective, it makes perfect sense that the pitchers and dispensers are also made in Mexico. Why would Culligan ship empty plastic containers across the ocean to be packaged with filters made in Mexico? It would be a logistical nightmare. The most efficient solution is to make everything in the same place. So, while the label is vague, the evidence strongly suggests that the entire ZeroWater system, for the North American market, is assembled in Mexico.

The TDS Meter: A Globally Sourced Component

Every ZeroWater pitcher comes with a TDS meter, a handy tool that lets you see the filter in action. This small electronic device is a perfect example of global sourcing. It's likely made by a specialized manufacturer in Asia, probably in China or Taiwan, and then shipped to Mexico to be packaged with the final product. This is a common practice in modern manufacturing, where companies source components from all over the world to get the best quality and price.

Culligan's Global Manufacturing Powerhouse

The decision to make ZeroWater products in Mexico is part of a larger strategy. Culligan has a massive global manufacturing network, and they are constantly looking for ways to make their operations more efficient. The company operates on a "global by design, local by necessity" model. This means they source components globally but have regional hubs to serve specific markets.

Their new plant in Monterrey, Mexico, opened in 2023, is a key part of this strategy. It's a state-of-the-art facility designed to produce high-volume residential products for the North and South American markets. By moving production closer to its customers, Culligan can deliver products faster, reduce costs, and be more resilient to supply chain disruptions.

Schlussfolgerung

So, what does this all mean for you, the consumer? It means that your ZeroWater pitcher is a truly global product. It's the result of a small company's innovation, a global giant's manufacturing power, and a complex web of international supply chains. The fact that it's made in Mexico is a sign of the times, a strategic move to bring manufacturing closer to home and create a more efficient and resilient supply chain.

Next time you fill up your ZeroWater pitcher, take a moment to appreciate the incredible journey it has taken to get to your kitchen. It's a story of innovation, strategy, and the relentless pursuit of pure, clean water. And now, you know the rest of the story.