Your client wants a premium product, but the plastic housing feels cheap. You're stuck between design intent and material limits. The market is shifting, and your designs need to adapt.

This shift is because stainless steel1 offers superior purity, durability, and a premium aesthetic that plastic cannot match. For wellness brands, the material itself becomes a marketing tool, reinforcing their message of health, sustainability, and long-term value, justifying a higher price point for consumers.

I've spent my life in the mold and manufacturing industry. I’ve seen trends come and go. But the move towards premium materials in everyday products isn't just a trend; it's a fundamental change in consumer values. A designer like you, Jacky, needs to understand not just dass it's happening, but why it's happening and what it means for your work. It's about more than just the final product; it's about the design choices2, the tooling, and the manufacturing processes that get you there. This shift from plastic to steel in categories like water purifiers is a perfect case study. Let's break down what this means for you on the factory floor and in your CAD software.

BPA-free plastics do not leach any chemicals into water.Falsch

Studies have shown that even BPA-free plastics can release other synthetic compounds, especially when exposed to heat or UV light. Stainless steel is widely considered more inert.

304 stainless steel is a common food-grade material used in kitchen appliances.Wahr

Also known as 18/8 stainless steel, its composition of chromium and nickel makes it highly resistant to rust and corrosion, making it ideal for contact with food and water.

1. Beyond the Filter: Is the Health & Purity Case for Stainless Steel That Strong?

Your client's brand promises purity, but the product is housed in plastic. This creates a disconnect. Consumers are learning that the container is as important as the contents inside.

Yes, the case is very strong. Stainless steel is non-porous and inert, meaning it doesn't leach chemicals or harbor bacteria in micro-scratches like plastics can. This makes it the superior material choice for any brand whose core message is built on health, purity, and non-toxicity.

When I work with designers on new products, the first conversation is always about materials. For a product designer like you, Jacky, this choice has huge implications. The wellness market's focus on "purity" goes beyond the filter's specs; it extends to the very housing of the purifier. I remember a project where we prototyped a water container in polycarbonate. It looked great, but the client's wellness consultant rejected it. They pointed out that even BPA-free plastics can develop micro-scratches from cleaning, which can become breeding grounds for bacteria. We had to pivot to 304 stainless steel. This changed everything, from the draft angles to the tooling. It was a lesson in how consumer perception directly impacts engineering decisions.

Material Properties for Purity

| Merkmal | Injection-Molded Plastic (e.g., SAN, ABS) | Formed Stainless Steel (e.g., 304) | Design Implication |

|---|---|---|---|

| Porosity | Microporous surface | Non-porous | Steel is easier to clean and sterilize, preventing biofilm buildup. |

| Leaching | Potential to leach chemicals (even if BPA-free) | Inert, no chemical leaching | For a "pure" brand, steel is the only choice that guarantees no material interaction. |

| durability3 | Prone to scratches, staining, and cracking | Highly resistant to scratches, dents, and corrosion | The product's "clean" look lasts longer, reinforcing the purity message over time. |

This isn't just a marketing point; it's a design constraint that you must address from the start.

All stainless steel is magnetic.Falsch

It depends on the type. Austenitic stainless steels, like the common 304 and 316 grades, are non-magnetic. Ferritic and martensitic steels are magnetic.

Stainless steel surfaces can inhibit bacterial growth.Wahr

The non-porous and smooth surface of stainless steel makes it difficult for bacteria to adhere and form biofilms, which is why it's the standard in commercial kitchens and medical facilities.

2. The "Aesthetic of Wellness": Can Durability and Design Coexist?

A clunky, plastic appliance cheapens a carefully designed kitchen. Your client wants a product that looks as good as it performs, something that feels like a permanent fixture, not a disposable gadget.

Absolutely. The "aesthetic of wellness" demands products that are both beautiful and built to last. Stainless steel's sleek finish and structural integrity allow for minimalist designs that plastic can't replicate. It becomes a piece of functional art that signals a commitment to quality.

In my experience, the look and feel of a product are non-negotiable for premium brands. They need that "Instagrammable" quality. As a designer, you know how hard it is to make plastic feel truly premium. You can specify high-gloss finishes, but that requires expensive mold polishing and makes parting lines and sink marks more obvious. Steel is different. Its inherent value and finish options, like brushed or matte, communicate quality instantly. For you, Jacky, this means thinking about different manufacturing processes4. Instead of injection molding, you're looking at deep drawing, stamping, and hydroforming. These methods create seamless forms that are impossible with plastic molding, hiding joints and creating a monolithic, high-end look.

Design & Manufacturing Considerations

| Aspekt | Plastic Injection Molding | Stainless Steel Forming | Impact on Your Design Process |

|---|---|---|---|

| Wall Thickness | Requires uniform wall thickness to avoid defects. | Can have more variation, but deep drawing has limits. | You have different geometric freedoms and constraints. |

| Finish | Finish depends on mold surface (SPI standards). | Finish is a secondary process (brushing, polishing). | More control over the final texture, independent of the forming tool. |

| Parting Lines | Inevitable and must be strategically hidden. | Can be designed with seamless bodies or hidden welds. | Allows for cleaner, more minimalist final forms. |

| Werkzeugbau | Complex injection molds. | Stamping dies, drawing dies, welding fixtures. | Requires a different kind of DFM (Design for Manufacturing) analysis. |

The shift to steel forces you to become a more versatile designer, fluent in the language of both plastics and metals.

Stainless steel is a single material.Falsch

Stainless steel is an alloy of iron, chromium, and in many cases, nickel and other metals. There are over 150 different grades.

Brushed finishes on stainless steel can help hide fingerprints and minor scratches.Wahr

The fine, parallel lines of a brushed finish diffuse light and make small imperfections less noticeable than on a mirror-polished surface, making it a practical choice for high-touch appliances.

3. Sustainability as a Core Wellness Value: Is Steel Really Greener?

The modern premium customer cares about the planet. They see a plastic purifier as future landfill waste. A brand promoting personal wellness can't ignore planetary wellness. This is a major conflict.

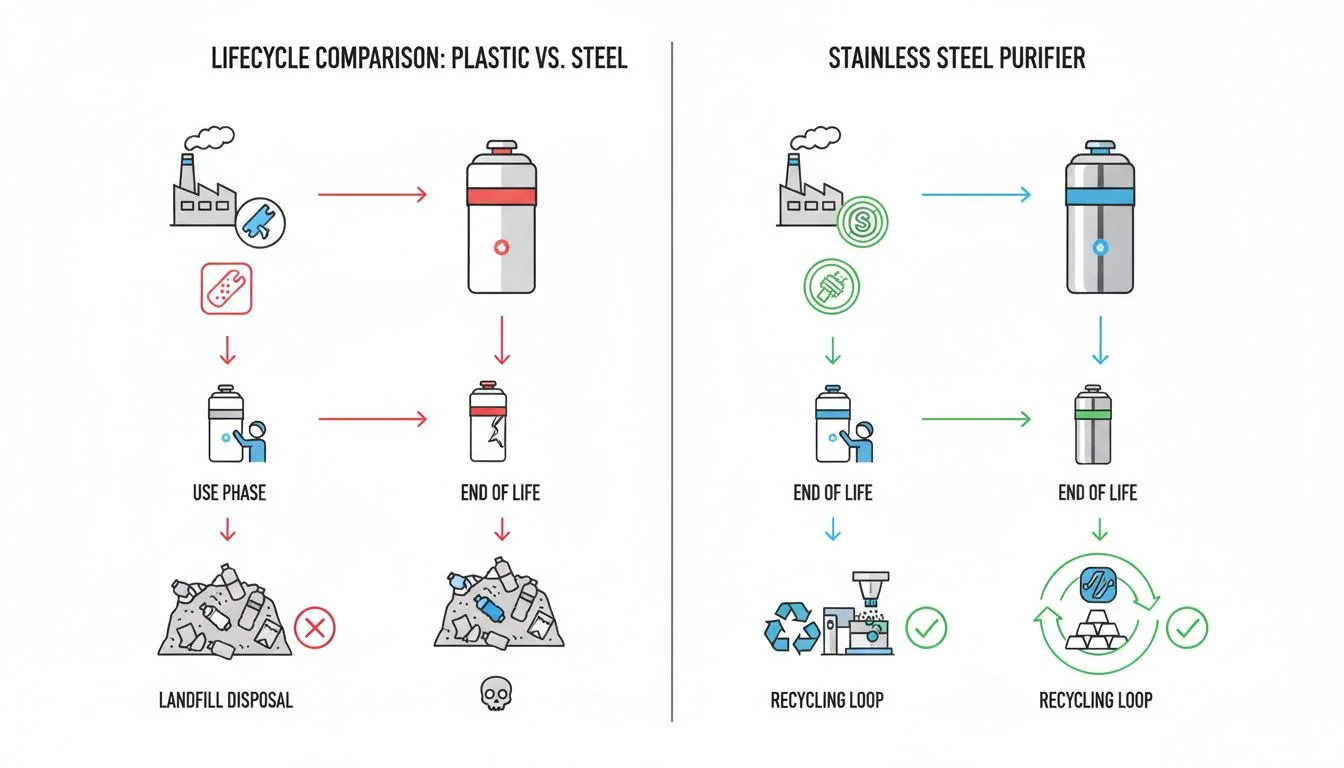

Yes, from a longevity and recyclability5 standpoint, steel is a far more sustainable choice. While its initial production is energy-intensive, its durability means a "buy it for life" product. Unlike plastic, steel is 100% and infinitely recyclable without loss of quality.

I've seen clients struggle with this. They want the low per-unit cost of plastic, but their marketing department knows the sustainability story is a huge selling point. As a designer, you are at the center of this decision. Choosing steel over plastic is a strategic move that aligns the physical product with the brand's values. It tells the customer, "We invested in a material that will last, so you don't have to replace it every few years." This changes the product from a consumable to a permanent fixture. For your design process, this means focusing on timelessness. You're not designing for a 3-year trend; you're designing a product that should still look good and function perfectly in 15 years.

Sustainability Trade-offs for Designers

| Faktor | Kunststoff | Stainless Steel | Your Consideration |

|---|---|---|---|

| Production Energy | Lower energy for molding. | Higher initial energy for production. | The total lifecycle energy may be lower for steel due to its long life. |

| Product Lifespan | Shorter. Prone to cracking, staining. | Very long. Highly durable. | Design for longevity: use standard fasteners, make parts serviceable. |

| End-of-Life | Often downcycled or sent to landfill. | Highly and easily recycled back into high-quality steel. | Designing for disassembly can make steel recycling even more efficient. |

Your role expands from just designing a product to designing its entire lifecycle. That's a powerful position to be in.

Recycling plastic restores it to its original quality.Falsch

Most plastics are downcycled, meaning they are turned into lower-quality products. They cannot be infinitely recycled like metals such as aluminum or steel.

The recycling rate for stainless steel is very high, over 85% in some sectors.Wahr

Steel is one of the most recycled materials on earth. Its magnetic properties (in some grades) make it easy to separate, and its value provides a strong economic incentive for recycling.

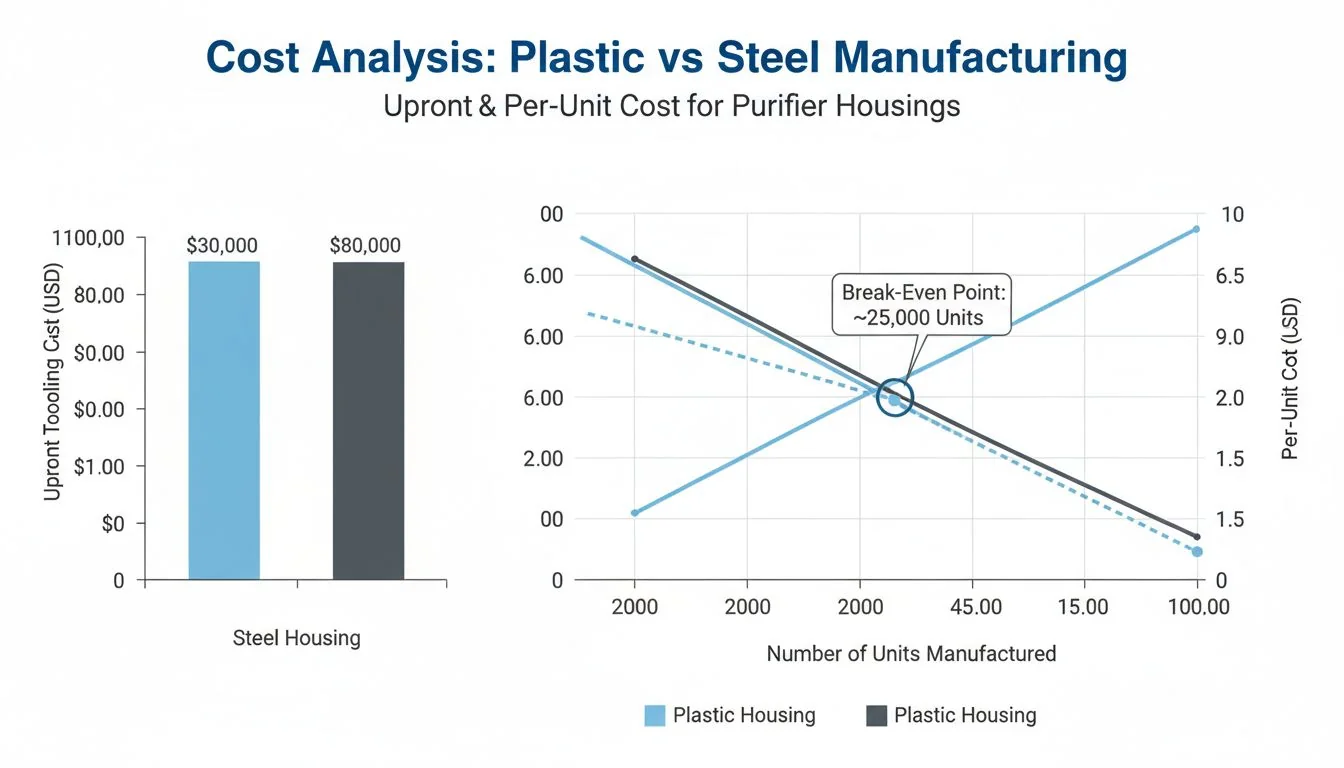

Your purchasing department sees the raw material cost of steel and balks. They see a plastic part that costs a dollar and a steel part that costs five. How do you justify the switch?

Yes, because the value is calculated over the product's lifetime. The higher upfront cost for steel tooling and material is offset by the premium price the product commands and the brand loyalty it builds. It's an investment in brand equity6, not just a manufacturing cost.

This is a conversation I have all the time. It's the classic battle between cost and value. As a mold designer, you understand tooling investment better than anyone. An injection mold for a complex purifier housing can cost tens of thousands of dollars. The tooling for deep-drawing steel is also significant. The key is to frame the discussion around total cost of ownership7 and Brand Value. The steel product isn't competing with the plastic one on price; it's competing in a different market segment. I once worked on a project where we ran the numbers.

Simplified Cost-Value Analysis

| Metric | Plastic Purifier | Stainless Steel Purifier | The Takeaway for a Designer |

|---|---|---|---|

| Tooling Cost | High (e.g., $80,000) | High (e.g., $70,000) | Tooling is a major investment for both, but in a similar ballpark. |

| Per-Unit Cost | Low (e.g., $5) | Higher (e.g., $20) | The material and process drive up the unit cost significantly. |

| Retail Price | Low (e.g., $50) | Premium (e.g., $250) | The higher retail price more than covers the increased unit cost. |

| Brand Value | "Affordable," "Disposable" | "Premium," "Permanent," "Pure" | The material choice directly enables the premium branding and pricing strategy. |

Your job is to show how the design and material choice enable the business strategy. The "premium" cost is what allows the product to be a "premium" brand.

Hydroforming allows for the creation of complex metal shapes with uniform thickness.Wahr

This process uses high-pressure fluid to press sheet metal into a die. It's excellent for creating complex, strong, and lightweight structural parts that would be difficult or impossible with standard stamping.

Tooling for deep drawing steel is always cheaper than for injection molding.Falsch

It's highly dependent on the complexity of the part. A simple drawn can may have cheaper tooling, but a multi-stage deep-draw tool for a complex housing can be just as expensive as an injection mold.

5. How Do You Design a Purifier That Aligns With Brand Values?

The marketing team wants "purity and sustainability," but the engineering team needs a product that can be manufactured efficiently. You are the bridge between these two worlds. How do you make the right choices?

You start with the brand's core value proposition. This dictates your material choice, which in turn dictates your design and manufacturing process. Your role is to translate the abstract value—like "purity"—into concrete engineering specifications.

This is where a designer like you, Jacky, truly shows their value. You're not just a CAD operator; you're a technical translator. If a brand's primary value is "accessibility for all," then designing for low-cost injection-molded plastic is the right call. But if the value is "uncompromising wellness," you have to advocate for the material that best represents that. I've found that using a simple decision matrix helps get everyone on the same page. It forces the team to prioritize what matters most and makes the material choice logical and defensible, not just a matter of opinion. It's your job to present these trade-offs clearly.

Value-Based Design Matrix

| Brand Value Priority | Best Material Choice | Key Design Focus | Manufacturing Process |

|---|---|---|---|

| 1. Purity & Health | Stainless Steel | Seamless interior, ease of cleaning, non-porous surfaces. | Deep Drawing, Welding |

| 2. Aesthetics & Durability | Stainless Steel | Minimalist form, high-quality finish, timeless design. | Stamping, Hydroforming |

| 3. Sustainability | Stainless Steel | Design for disassembly, use of recycled steel content. | Standardized fasteners |

| 4. Affordability | Plastic (PP, SAN) | Design for manufacturability, minimize cycle time. | Spritzgießen |

By leading this conversation, you move from being a service provider to a strategic partner in the product's success.

Design for Manufacturing (DFM) only applies to plastic injection molding.Falsch

DFM is a crucial practice for all manufacturing processes, including sheet metal forming, casting, and machining. The principles change, but the goal of optimizing a design for efficient production remains the same.

A 'Purity Halo Effect' means consumers associate the qualities of a product's material with the product itself.Wahr

This is a marketing concept where a positive trait (like the clean, durable nature of steel) creates a 'halo' that makes consumers perceive the product's core function (like the water it purifies) as being of higher quality.

Plastic has dominated consumer goods for decades due to its low cost and versatility. Is this shift to steel a niche trend, or is it a sign of a bigger change for designers?

It signals a major change. While plastic will always have its place, steel is becoming the new default for any product positioned as premium, durable, or wellness-oriented. For designers, this means versatility and a deep knowledge of metal forming will become essential skills.

Looking ahead, I don't see this as a battle where steel "wins" and plastic "loses." I see a future of smarter material choices. As a top-tier designer, your value will come from knowing when to use which material. You might design a purifier with a main body of deep-drawn stainless steel for purity and durability, but use precision-molded plastic for the internal filter housing where complex geometry is critical and cost is a factor. The future is about hybrid designs. The most successful designers will be the ones who are fluent in both worlds. They will understand the tooling, the DFM principles, and the finishing techniques for both plastics and metals. This trend is a call to expand your expertise. Don't just be a plastic mold expert; become a master of creating premium products, whatever the material.

Skills for the Future-Focused Designer

| Skill Area | Why It's Important |

|---|---|

| Metal Forming DFM | Understanding deep drawing, stamping, and hydroforming constraints. |

| Material Science | Knowing the properties of different steel grades (304 vs. 316) and high-end polymers. |

| Joining & Finishing | Expertise in welding, brazing, polishing, and coating for metals. |

| Lifecycle Design | Designing for durability, serviceability, and end-of-life recycling. |

The industry needs leaders who can navigate these complex material decisions. This is your opportunity to be one of them.

3D printing of metal parts is becoming a viable option for mass production.Falsch

While metal 3D printing (like DMLS and SLM) is revolutionary for prototyping and complex, low-volume parts, it is still far too slow and expensive for mass-producing consumer goods compared to traditional methods like stamping or casting.

The global stainless steel market is expected to continue growing.Wahr

Market forecasts project continued growth driven by demand in construction, automotive, and consumer goods, reflecting its ongoing importance as a key industrial and commercial material.

Schlussfolgerung

This shift to stainless steel is more than a trend; it's a lesson in value. It teaches us that the right material choice elevates a product, justifies a premium, and builds a brand.

References

-

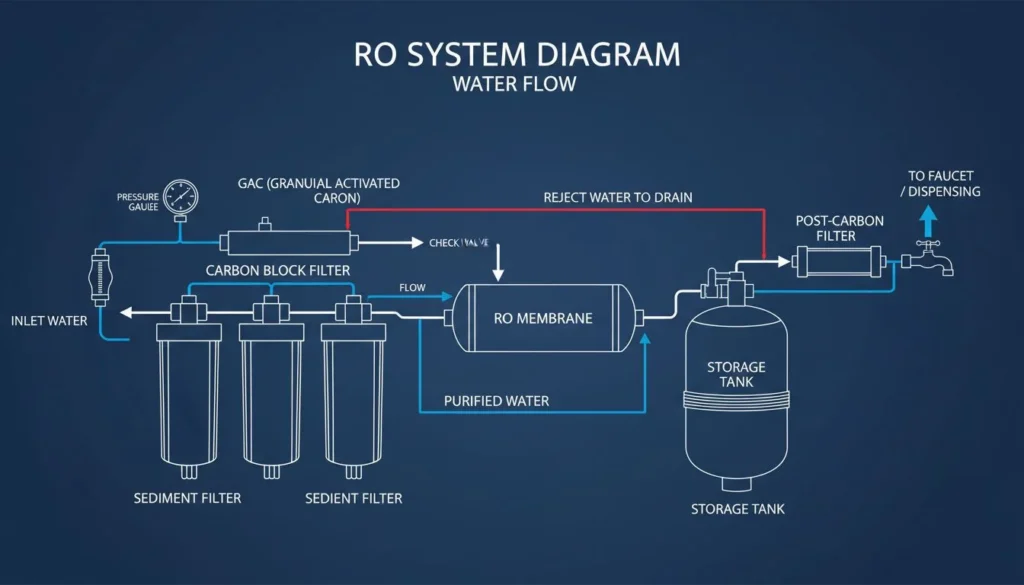

Explore how stainless steel enhances purity and durability in water purification. ↩

-

Investigate the relationship between design choices and their impact on product success. ↩

-

Understand the advantages of stainless steel's durability over plastic in long-term use. ↩

-

Learn about the manufacturing techniques that enhance the quality of stainless steel products. ↩

-

Find out why stainless steel is a more sustainable choice for the environment. ↩

-

Discover how the choice of materials can enhance a brand's market position. ↩

-

Understand the importance of considering long-term costs in material selection. ↩