Your D2C brand is struggling to stand out. You launch innovative products, but competitors copy them in months. The real, lasting advantage is hiding in plain sight: your product's physical form.

True D2C innovation comes from "hard tech1"—advancements in manufacturing, material science, and engineering. This creates a defensible "moat" that software can't match, securing your market position and delivering a superior user experience that earns 5-star reviews.

You've seen it happen a dozen times. A new D2C brand launches with a "smart" product and a slick app. A year later, ten clones are on the market, and the original brand is fighting a price war. It feels like a race to the bottom. I've worked with many clients who have faced this exact problem. They build a beautiful brand, only to see their core idea become a commodity.

But what if your product's core innovation was physically impossible to copy overnight? What if the very materials and manufacturing processes2 you used were your greatest defense? This is not just a theory; it's the new reality for winning brands. Let's explore how "hard tech" is changing the game and how you can use it to build an unshakeable brand.

The global wellness market is projected to reach nearly $7.0 trillion by 2025.Wahr

According to the Global Wellness Institute, the wellness economy was valued at $4.4 trillion in 2020 and is forecast to grow significantly, indicating a massive market opportunity for innovative products.

All D2C brands that add an app to their product see a 50% increase in sales.Falsch

There is no data to support this claim. While apps can enhance user experience, their impact on sales varies wildly and is not a guaranteed success metric. Many 'smart' features are seen as gimmicks by consumers.

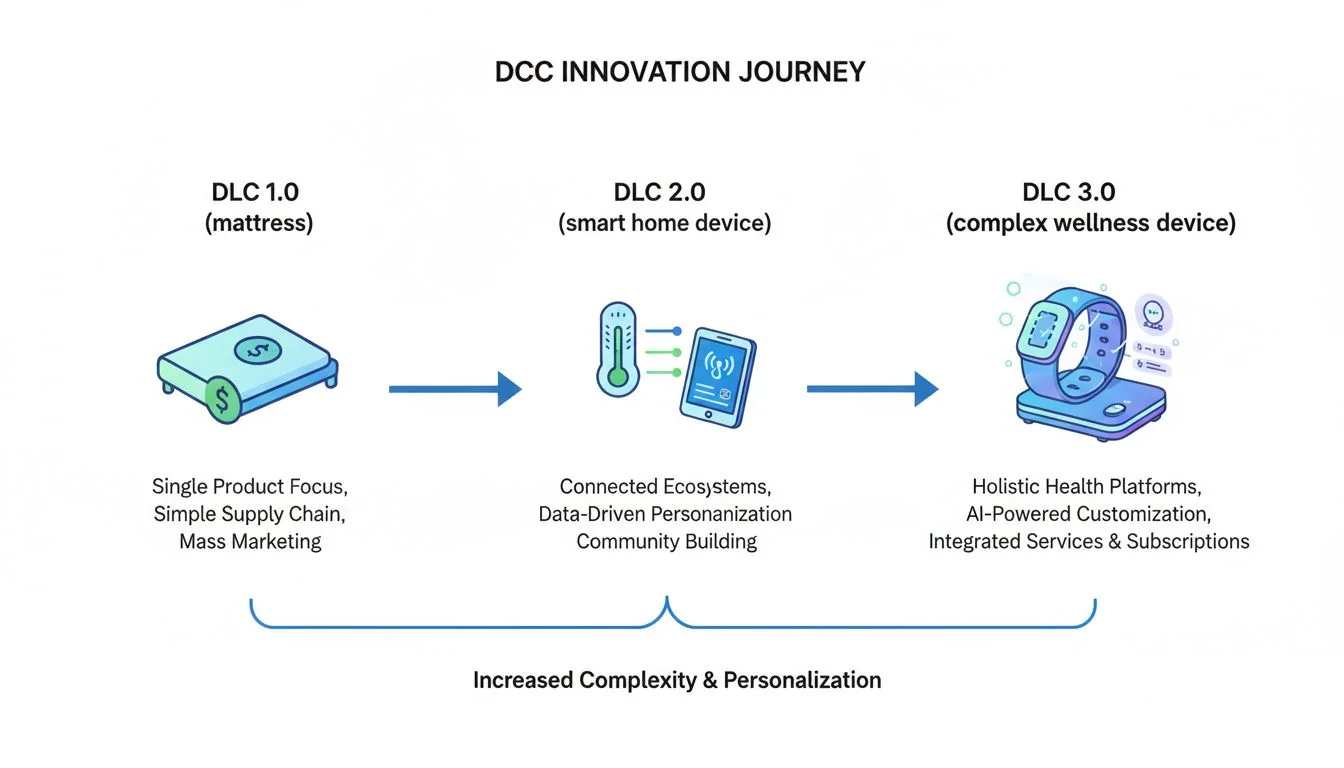

The "D2C 3.0" Shift: From Mattresses to Health?

The first D2C wave was about cutting out middlemen for simple products. The second was about subscriptions. Are you wondering what's next? Your brand is stuck, but customers want more.

"D2C 3.03" is the evolution from disrupting distribution and business models to disrupting the product itself. This means focusing on core engineering and materials, especially in the booming wellness market where physical product quality is paramount.

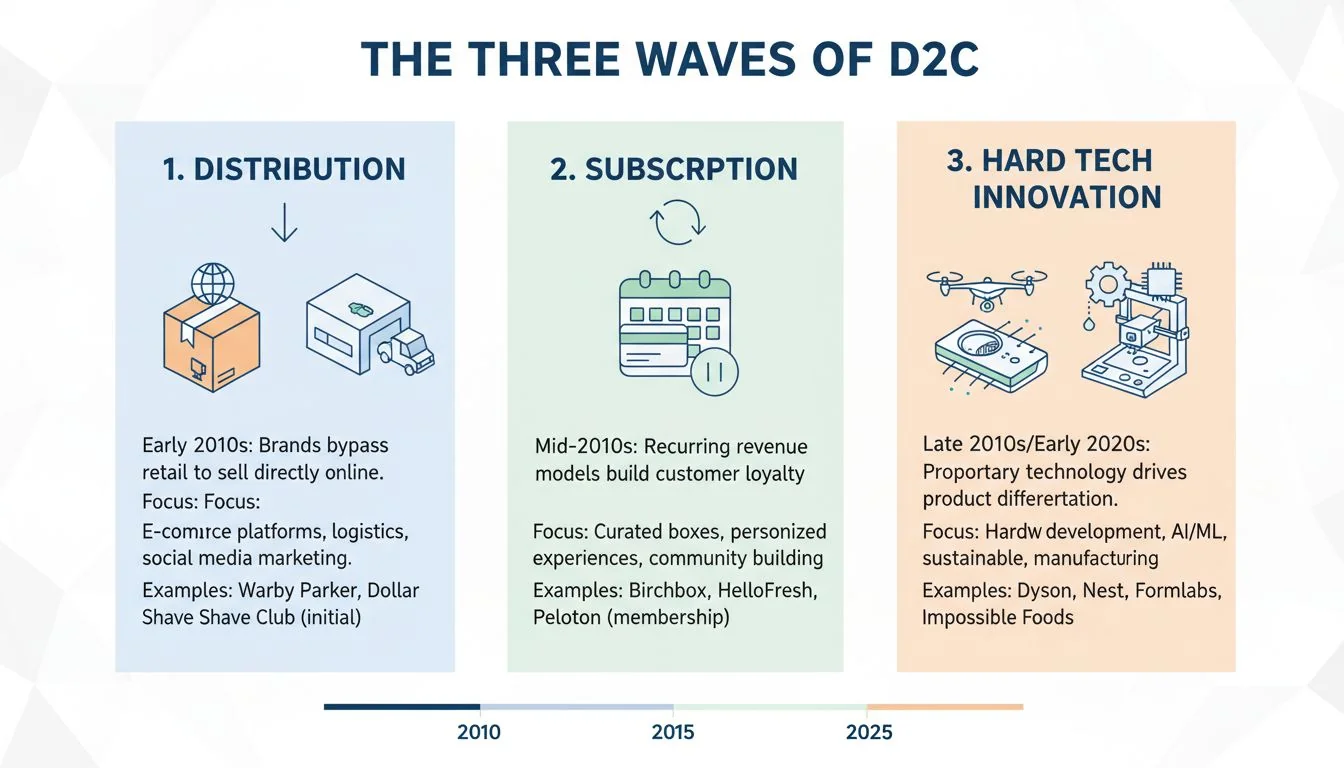

The Evolution of Direct-to-Consumer

I've watched the D2C space evolve for years. It's a story in three parts. Understanding this helps you see where the next opportunity is.

-

D2C 1.0: The Distribution Play. This was the beginning. Brands like Casper (mattresses) and Warby Parker (glasses) realized they could sell directly to customers online. They cut out the retail middleman. Their innovation wasn't the product itself, but the business model. It was brilliant, but simple to copy.

-

D2C 2.0: The Community Play. Then came brands like Dollar Shave Club and Glossier. They built on the 1.0 model by adding subscriptions and building powerful brand communities. The focus shifted to customer loyalty and recurring revenue. Again, the product was often standard, but the marketing was new.

-

D2C 3.0: The Product Play. This is where we are now. The market is crowded. A new business model isn't enough. The next frontier is tangible innovation in the product itself. This is especially true in the wellness space. Customers care deeply about the materials, hygiene, and durability of products they use for their health. This is a shift from marketing innovation to engineering innovation.

| D2C Wave | Primary Innovation | Key Focus | Beispiel |

|---|---|---|---|

| 1.0 | Distribution | Cutting out the retailer | Casper |

| 2.0 | Business Model | Subscription & Community | Dollar Shave Club |

| 3.0 | product engineering4 | "Hard Tech" & Materials | Hygienic Humidifiers |

The average consumer is willing to pay more for products they perceive as healthier or more hygienic.Wahr

Multiple market studies, including reports from Nielsen and McKinsey, show a clear trend of consumers prioritizing health, wellness, and hygiene, and they are often willing to pay a premium for products that meet these criteria.

D2C 1.0 brands never focused on product quality.Falsch

This is an oversimplification. While their primary innovation was distribution, brands like Warby Parker and Casper still had to deliver a quality product to succeed. However, the core product itself was not a radical departure from existing market offerings.

The "Wellness Tech" Trap: Why Is "Soft Tech" (Software) Not Enough?

You think adding an app makes your product "innovative." But your app is easily copied by competitors in months. Your "tech" advantage disappears, and you're in a software arms race.

"Soft Tech," like apps and software, is not enough because it has low barriers to entry and is easily copied. It's a commodity. True, defensible innovation—your brand's "moat"—is built with "Hard Tech," rooted in physical manufacturing and material science5.

The Difference Between "Soft" and "Hard" Tech

As someone who lives and breathes manufacturing, I see brands fall into the "soft tech" trap all the time. They spend a fortune on app development, thinking it makes them a tech company. But it's a fragile advantage. Let's define these terms clearly.

-

"Soft Tech" is software. It's the app that connects to your device, the data it tracks, and the firmware that runs it. It's code. And code can be copied. A competitor can hire a few developers and replicate your app's core functionality in a matter of months. It becomes a feature-matching game that you can't win on a budget.

-

"Hard Tech" is the physical thing. It's the material science, the manufacturing process, and the mechanical engineering. It's the choice to use stainless steel6 instead of plastic. It's the custom tooling that costs $200,000 to create. It's the patented mechanical design that makes a product easier to clean. This is not easy to copy. It requires deep expertise and serious capital investment.

Think of it this way: "Soft Tech" is the paint job on a car. "Hard Tech" is the engine. Which one provides the real, lasting value and performance?

| Merkmal | "Soft Tech" (App) | "Hard Tech" (Manufacturing) |

|---|---|---|

| Barrier to Entry | Niedrig | Hoch |

| Cost to Copy | Low (developer time) | High (tooling, R&D) |

| Defensibility | Weak | Strong (a "moat") |

| User Impact | Can be useful, often a gimmick | Fundamental to performance & UX |

Developing a simple mobile app costs over $500,000.Falsch

While complex apps can cost this much or more, a simple app with basic functionality can be developed for much less, often in the $25,000-$75,000 range. The low cost of entry is precisely why it's not a strong competitive moat.

Competitors can often reverse-engineer and replicate software features faster than hardware features.Wahr

Software development cycles are inherently faster than hardware development cycles, which involve physical prototyping, tooling, and supply chain setup. A software feature can be coded in weeks, while new manufacturing tooling can take many months or years to develop.

What Is the Real Innovation in "Hard Tech" (Manufacturing & Material Science)?

As a product designer, you focus on aesthetics and function. You might leave material choices to the factory. This is where you lose your edge. Standard processes lead to standard, vulnerable products.

Real innovation lies in "Hard Tech"—the deliberate choice of advanced materials and manufacturing processes. This isn't just about how a product looks, but what it's made of and how it's made. This is the foundation for superior performance and durability.

How Manufacturing Choices Define Your Product

This is my world. For over 20 years, I've been obsessed with how things are made. A product designer like you, Jacky, designs the "what." My job is to perfect the "how." And the "how" changes everything.

Let's take a common process: plastic injection molding. It's cheap and fast for high volumes. But it has rules. You need draft angles so the part can be ejected from the mold. You have to worry about sink marks. The process itself creates complex shapes with ribs and tight corners that are necessary for structural integrity. These features, born from the manufacturing process, can become dirt traps that are impossible for the user to clean. The choice of a standard process leads directly to a poor user experience7.

Now, let's contrast that with a "Hard Tech" approach. Imagine using stainless steel deep-drawing. This process pulls a sheet of metal into a seamless shape, like a kitchen sink. Suddenly, you have no internal corners, no ribs, no hidden areas. You have a simple, smooth basin. The material itself, 304 stainless steel, is non-porous. It doesn't harbor bacteria the way plastic does. The innovation isn't an app; it's the decision to use a superior material and process that solves the user's biggest problem: hygiene.

Deep-drawing is a cheaper manufacturing process than plastic injection molding.Falsch

This is generally false. While costs vary by complexity and volume, the tooling for deep-drawing metal is often significantly more expensive than for injection molding, and material costs for stainless steel are higher than for common plastics like ABS or PP.

The choice of manufacturing process directly impacts a product's final geometry and features.Wahr

This is a fundamental principle of 'Design for Manufacturing' (DFM). A part designed for injection molding will look very different from one designed for sheet metal stamping or CNC machining, as each process has unique capabilities and constraints.

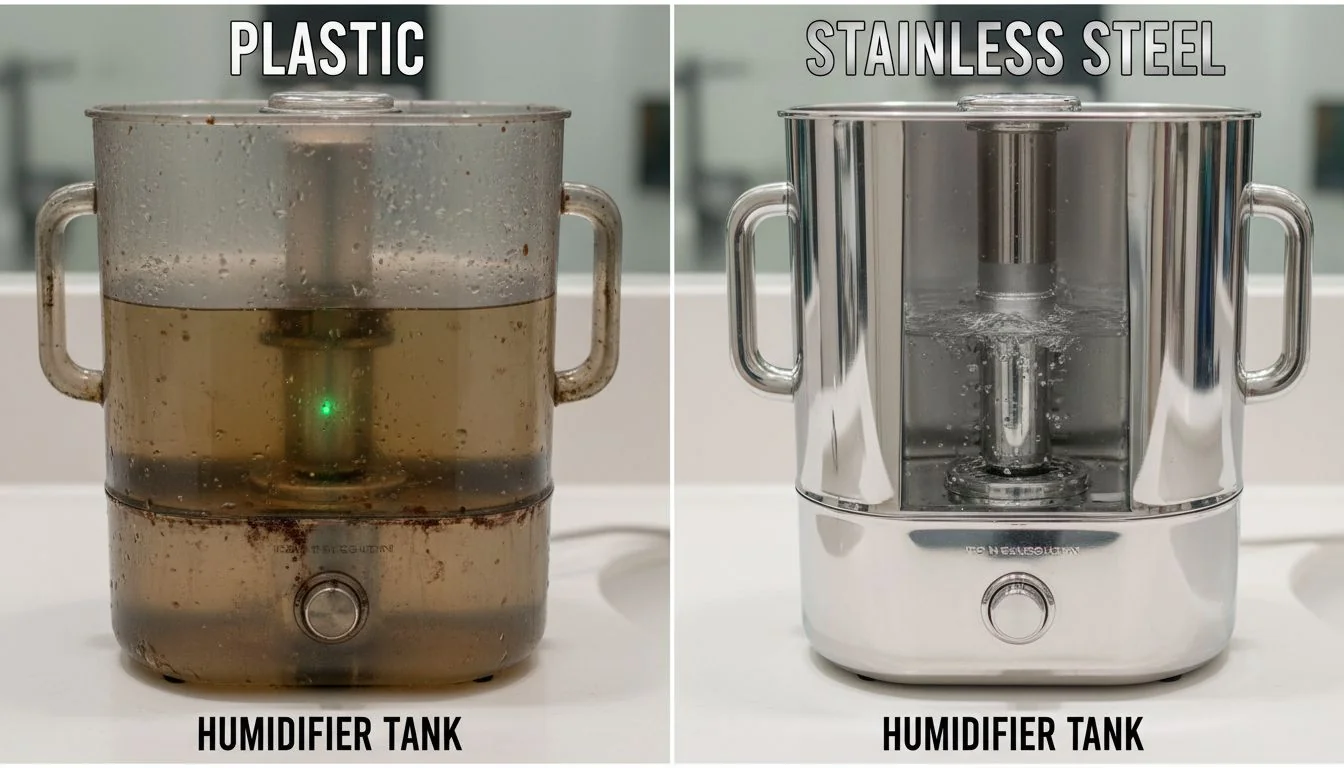

Case Study: The "Hygienic Hero Product" (Stainless Steel Humidifier)?

Your plastic humidifier looks great, but customers complain it's slimy and grows mold. Those 1-star reviews are killing your brand. "Impossible to clean," they say. Your reputation is tanking.

A stainless steel humidifier is a perfect case study. Unlike plastic, which is porous and prone to mold, stainless steel is non-porous and easy to sterilize. This manufacturing choice directly solves the biggest user pain point, turning 1-star reviews into 5-star raves.

From 1-Star Problem to 5-Star Solution

Let's get specific. I worked with a client who was developing a new wellness product, and we analyzed the humidifier market. It was a sea of 1-star reviews, all saying the same thing: "It grows black mold."

-

The Plastic Problem: We bought the top-selling plastic humidifiers and took them apart. They were all made with injection-molded plastic. The water tanks were full of tight corners and internal ribs—a direct result of the manufacturing process. These areas are impossible to reach and clean. The plastic itself, being a porous material, was a perfect surface for biofilm and mold to grow. The 1-star review wasn't the user's fault; it was a flaw designed and manufactured into the product.

-

The "Hard Tech" Hero: We decided to solve this problem at the source. Instead of plastic, we chose 304 stainless steel. Instead of injection molding, we used deep-drawing to create a simple, seamless water basin. There were no corners for mold to hide in. The material is non-porous and can be put in a dishwasher. We solved the single biggest user complaint not with an app, but with material science and manufacturing. This is how you earn a 5-star review that says, "Finally, a humidifier that's actually easy to clean!"

| Merkmal | Standard Plastic Humidifier | "Hard Tech" Steel Humidifier |

|---|---|---|

| Material | ABS/PP Plastic (Porous) | 304 Stainless Steel (Non-porous) |

| Herstellung | Spritzgießen | Deep-Drawing / Stamping |

| Cleanability | Poor (many corners, ribs) | Excellent (seamless, dishwasher-safe) |

| Dauerhaftigkeit | Low (can crack, degrade) | High (resists corrosion, durable) |

| Typical Review | "Grows mold, hard to clean." (1-Star) | "Hygienic, easy to clean." (5-Star) |

ABS plastic is a non-porous material.Falsch

While appearing smooth, most plastics, including Acrylonitrile Butadiene Styrene (ABS), are microscopically porous. This can allow moisture and bacteria to settle into the surface, making them harder to sterilize completely compared to non-porous materials like glass or stainless steel.

304 stainless steel is widely used in medical and food-grade applications due to its hygienic properties.Wahr

304 stainless steel is an industry standard for hygienic applications because it is non-porous, corrosion-resistant, durable, and easy to clean and sterilize, preventing the buildup of bacteria.

Why Is "Hard Tech" the D2C Brand's Greatest "Moat"?

You've built a great brand, but copycats are selling cheaper versions of your product. Your market share is shrinking, and you're in a price war. Your brand's uniqueness is gone.

"Hard Tech" is a D2C brand's greatest moat because it creates high barriers to entry. The investment in custom tooling, specialized engineering, and advanced materials is significant. A competitor can't simply copy your product in a few months; they'd need to replicate your entire manufacturing infrastructure.

Building Your Defensible Brand

In business, a "moat" is your competitive advantage. It's what protects you from competitors. For years, D2C brands thought their moat was their brand story or their customer data. Those are important, but they are not enough anymore. A true, deep moat is built into the physical product.

Here’s why "Hard Tech" creates such a powerful moat:

-

High Capital Investment: The custom steel deep-drawing tools for that humidifier I mentioned? They can cost over $200,000. A cheap copycat competitor is not going to make that investment. They will stick to cheap, off-the-shelf plastic molds. The high cost of entry immediately filters out low-effort competition.

-

Specialized Expertise: You can't just email a factory and ask for a deep-drawn stainless steel part. It requires deep engineering knowledge of material properties, stress, and tolerances. Finding a partner with this expertise is difficult. This knowledge gap is a huge barrier.

-

Intellectual Property (IP): Unique mechanical designs and manufacturing processes can often be protected with design and utility patents. This gives you a legal right to stop copycats, a much stronger position than trying to protect the look and feel of an app.

A "soft tech" moat is a shallow ditch. A "hard tech" moat is a deep, wide channel that protects your castle.

The cost of a high-quality, multi-cavity injection mold for a complex part can exceed $100,000.Wahr

Tooling is a major capital expense in manufacturing. Depending on the part's complexity, size, material, and required production volume, the cost for industrial-grade steel molds can range from tens of thousands to hundreds of thousands of dollars.

Any factory in the world can produce any product if you send them the design files.Falsch

This is a dangerous misconception. Factories specialize in specific materials, processes, and quality levels. A factory that excels at plastic toys will not have the equipment or expertise to produce high-precision medical-grade steel components. Partner selection is critical.

How Can You Partner for the "Next Frontier"?

You're a D2C brand owner, not a manufacturing expert. The idea of investing $1M and two years in R&D is terrifying. So you stick with what's easy and miss out on real innovation.

To enter the "next frontier" without the massive upfront cost and risk, D2C brands should partner with a "Hard Tech Enabler." This is a manufacturing partner who has already invested in the R&D, tooling, and engineering for an innovative product platform.

The Smart Way to Innovate

You don't have to become a manufacturing expert overnight. You don't have to spend millions on tooling. The smartest D2C brands are not building this capability in-house. They are partnering.

This is where a new type of company comes in: the "Innovation Partner" oder "Hard Tech Enabler." I've built my career on being this kind of partner for my clients.

Here is what this partnership looks like:

-

Access to a Pre-Engineered Platform: The partner has already done the hard part. They've designed, engineered, and tooled a core product platform—like the stainless steel humidifier base. They own the expensive tools and have solved the complex engineering problems.

-

Drastically Reduced R&D: You get to bypass the 2-year, $1M+ R&D cycle. You can go from idea to market-ready, innovative product in a fraction of the time and cost.

-

Focus on Your Strengths: The partner handles the "Hard Tech." You handle what you do best: branding, marketing, customer experience, and the "Soft Tech" layer if you choose to add one. You can design a beautiful outer shell and a great user interface, all built on a foundation of defensible hard tech.

This is the future. It's a collaboration where D2C brands get an unfair advantage, and manufacturing partners get to see their innovation reach a global audience. It's how you launch a next-generation product without betting the entire company.

The average time to bring a new consumer electronics product from concept to market is 6-12 months.Falsch

While simple products can be fast, complex hardware involving custom engineering and tooling typically takes 18-24 months or longer. This includes phases for R&D, design, prototyping, tooling, testing, and compliance.

ODM (Original Design Manufacturer) partnerships allow brands to launch products with minimal R&D.Wahr

The model described is a form of advanced ODM or a Joint Development Manufacturing (JDM) partnership. Brands leverage the manufacturer's existing R&D and platforms to bring a customized product to market quickly, reducing their own R&D burden.

Schlussfolgerung

To win in D2C 3.0, stop competing on software. Build a moat with hard tech innovation through smart manufacturing partnerships. That is how you create a truly defensible brand.

References

-

Understanding hard tech is crucial for brands looking to innovate and create defensible products that stand out in a crowded market. ↩

-

Exploring new manufacturing processes can reveal innovative ways to enhance product quality and user experience. ↩

-

D2C 3.0 represents a shift towards product innovation, making it vital for brands to understand this evolution to stay competitive. ↩

-

Best practices in product engineering can help brands create innovative and effective wellness products that resonate with consumers. ↩

-

Material science is key to creating products that are not only functional but also durable and hygienic, which is essential in wellness technology. ↩

-

Stainless steel's properties make it ideal for hygienic applications, making it a key material for brands focused on health and wellness. ↩

-

User experience is critical for product success; exploring how manufacturing affects it can lead to better design choices. ↩