Your design is brilliant, but finding a factory to make it is a headache. Juggling separate design and manufacturing teams creates delays, miscommunication, and rising costs. You need a simpler way.

Manufacturers that offer both design and manufacturing are often called full-service or "design-to-manufacture" partners. They operate under models like OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer), handling your project from the initial concept sketch all the way through to mass production.

I've been in the mold industry for a long time, first on the factory floor and later running my own company. I've seen countless projects get stuck between the design studio and the production line. A designer like you, Jacky, knows the frustration of creating a perfect digital model only to be told it can't be made efficiently. This gap is where projects fail. But there is a better way. Finding a single partner who understands both worlds is the key to turning your ideas into real, successful products. Let's explore how to find them and what makes them so valuable.

Over 50% of product launch delays are caused by issues between the design and manufacturing phases.Vero

Studies and industry reports frequently cite manufacturability issues, communication gaps, and late-stage design changes as primary drivers of delays, all stemming from a disconnect between design and production teams.

All factories with CNC machines have in-house product design teams.Falso

Many factories are purely contract manufacturers. They have the machinery to produce parts based on provided designs but lack the R&D or design staff to develop a product from scratch.

What is the "Design vs. Factory" Disconnect?

Your design looks perfect on screen, but the factory says it's impossible to make. Now you're stuck in the middle, wasting time and money trying to fix it.

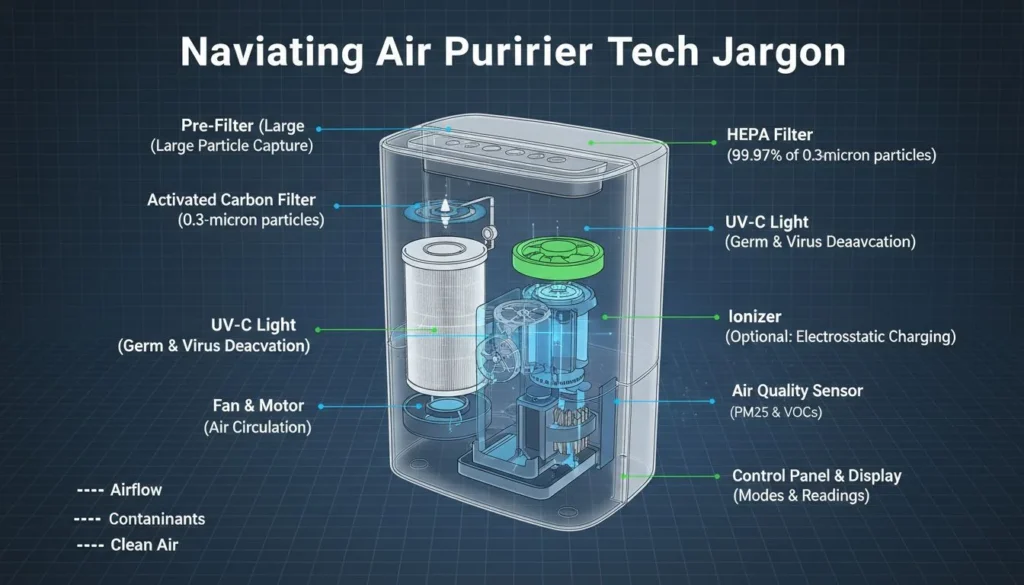

The "Design vs. Factory" disconnect happens when a design firm creates a product without considering the real-world limitations of manufacturing. This leads to endless revisions, increased costs, and significant delays because the design isn't optimized for production, a concept known as Design for Manufacturability (DFM).

I once had a client come to me with a beautiful design for a consumer electronics casing. It was sleek and futuristic. The problem was, the design firm they hired had no manufacturing experience. They designed it like a "concept car"—it looked amazing but was a nightmare to produce. The walls were too thin, the draft angles were wrong, and the material they chose was not suitable for the complex geometry. We had to spend weeks re-engineering it. This is a classic example of the disconnect. It creates two major problems.

The "Concept Car" Problem

Designers are trained to focus on aesthetics and user experience. Manufacturers focus on efficiency, cost, and reliability at scale. When these two worlds don't communicate from the start, you get a design that can't be built. It's like designing a car with no engine bay. This is why DFM (Design for Manufacturability) is so critical. It's not about compromising the design; it's about designing smartly so the product can actually be made.

The Blame Game

When a problem arises, the factory blames the designer, and the designer blames the factory. You, the client, are caught in the middle, paying for the delays and redesigns. A single, integrated partner eliminates this completely. There is only one team and one point of accountability.

| Approach | Siloed (Separate Designer & Factory) | Integrated (Single Partner) |

|---|---|---|

| Comunicazione | Slow, indirect, prone to errors | Fast, direct, and clear |

| Accountability | Divided, leads to blame games | Singular and absolute |

| DFM | Applied late, causing rework | Integrated from the very beginning |

| Result | Delays, budget overruns, frustration | Speed, cost-efficiency, success |

Design for Manufacturability (DFM) can reduce a product's time-to-market by up to 50%.Vero

By addressing potential manufacturing issues during the design phase, DFM eliminates costly and time-consuming redesigns, tooling changes, and production line problems, significantly accelerating the overall product development cycle.

The most creative designs are always the easiest to manufacture.Falso

Often, the most innovative and aesthetically pleasing designs push the boundaries of materials and processes, making them inherently more complex and challenging to manufacture at scale without careful DFM consideration.

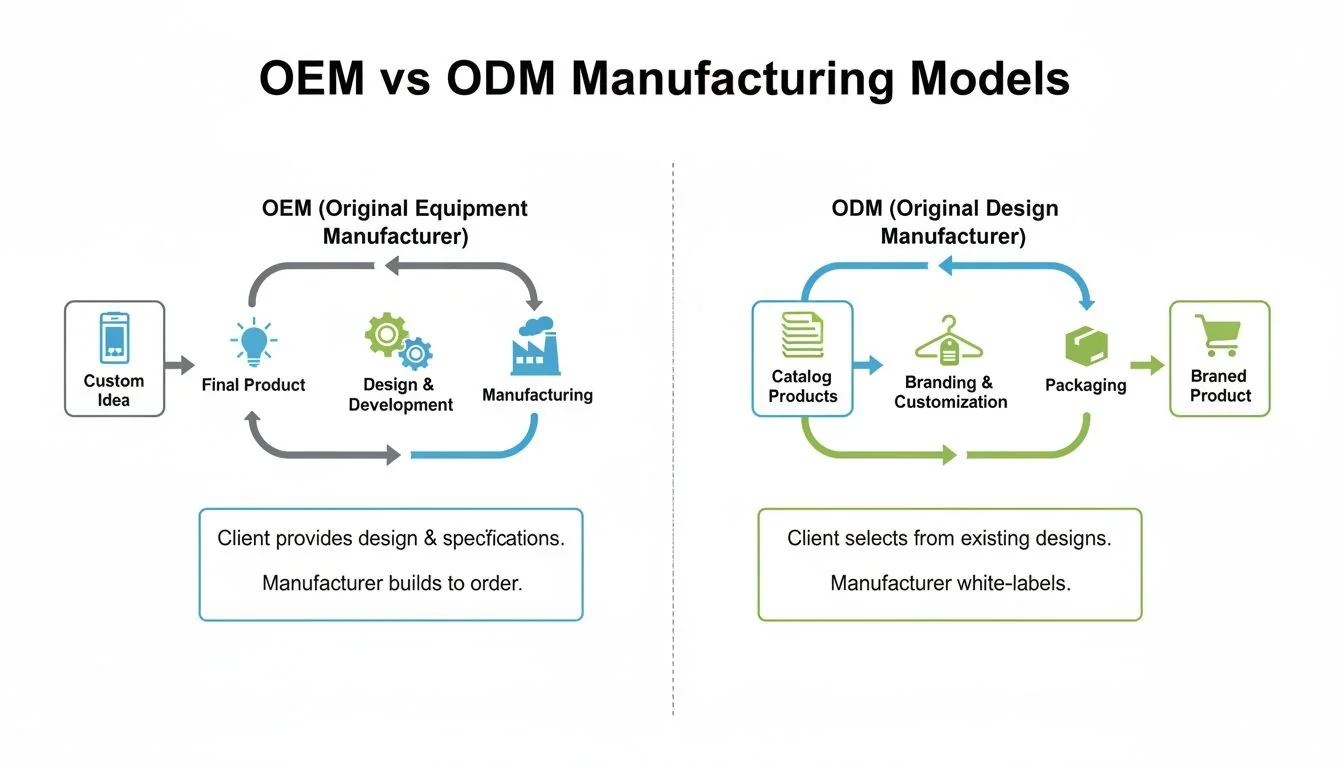

What's the difference between an OEM and ODM partner?

You hear terms like OEM and ODM, but you are not sure which is right for you. Choosing the wrong model can waste your budget and time, so let's clarify them.

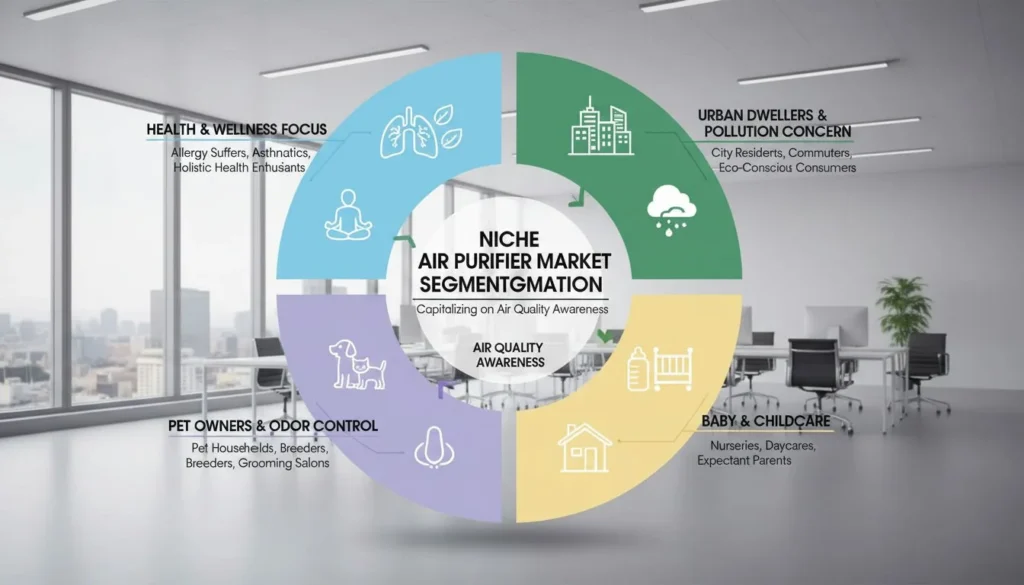

OEM (Original Equipment Manufacturer) is when a factory builds your 100% custom design. ODM (Original Design Manufacturer) is when you choose a pre-existing, factory-proven design and brand it as your own. A good partner offers both, giving you flexibility for any project or budget.

Understanding these two paths is crucial for any product developer. Your choice depends on your goals, budget, and timeline. I've worked with clients on both sides. Startups with a revolutionary idea need an OEM partner. Established brands wanting to quickly expand a product line often choose ODM. The best manufacturers have mastered both, and that's a huge sign of their competence.

OEM: Your Unique Vision

OEM is for your big idea. It's a 100% custom project where the factory acts as your production partner, bringing your unique design to life. This path offers complete creative control and ensures your intellectual property (IP) is yours alone. However, it requires more time and a larger upfront investment in R&D and tooling. This is where having an IP-secure partner is non-negotiable. You need to trust that your idea is safe.

ODM: Speed and Reliability

ODM is the fastest way to get a product to market. The manufacturer has already done the R&D, designed the product, and created the molds. You simply select a product from their catalog, add your branding, and start selling. It's a lower-risk, lower-cost option. I always tell clients to look at a potential partner's ODM catalog. If their ODM products are well-designed and high-quality, it proves their R&D team1 is skilled. It builds trust for a future, more complex OEM project.

| Caratteristica | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Concept | Your unique, custom design | Manufacturer's existing design |

| IP Ownership | You own the design IP | Manufacturer owns the design IP |

| Time to Market | Longer (6-18+ months) | Shorter (1-4 months) |

| Upfront Cost | High (R&D, custom tooling) | Low (minimal or no tooling costs) |

| Best For | Unique, innovative products | Fast market entry, product line extension |

ODM products allow a brand to launch a new product in as little as 30 days.Vero

Since the design, engineering, and tooling are already complete, the ODM process can be as fast as finalizing branding, packaging, and placing a production order, making extremely short timelines possible.

You always own the intellectual property for an ODM product you sell.Falso

In an ODM arrangement, the manufacturer owns the original design and tooling. You are essentially licensing the product to sell under your brand. The IP for the design itself remains with the factory.

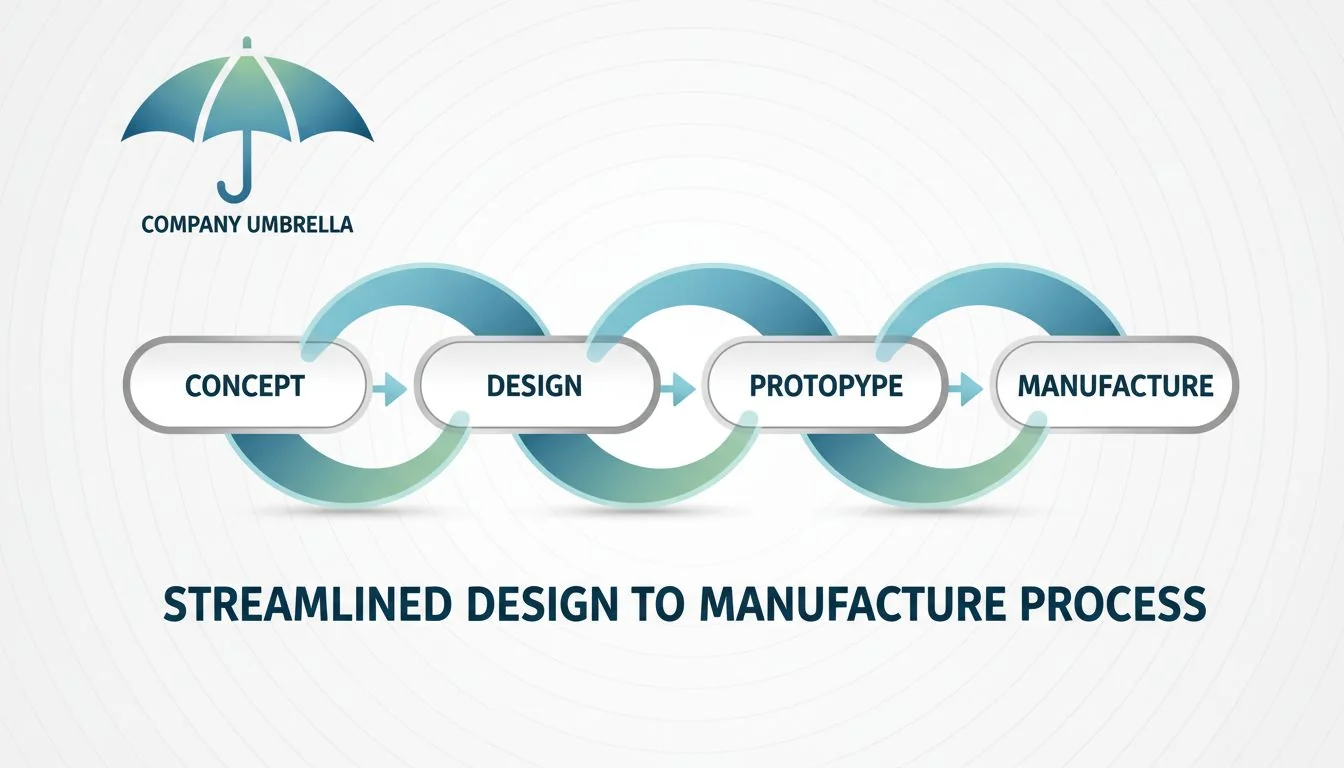

Why should you choose a single "Design-to-Manufacture" partner?

Managing multiple vendors for a single project is complex and inefficient. Communication breaks down, details get lost, and accountability disappears. A single partner simplifies everything and delivers better results.

A single "design-to-manufacture" partner streamlines communication, ensures accountability, and accelerates your timeline. They apply Design for Manufacturability (DFM) from day one, reducing costs and preventing production issues. This integrated approach is simply faster, cheaper, and less risky than juggling separate firms.

The biggest advantage of a single partner is their in-house R&D team. Many places call themselves "factories," but they are just assembly plants. They can put parts together, but they don't understand why a product works the way it does. A true partner has engineers and designers working alongside the production team. This is their biggest differentiator. They are not just a supplier; they are an extension of your team.

R&D is the Difference

When your manufacturing partner has a real R&D team, they can spot potential problems with your design and suggest improvements that will save you money and improve quality. They think like engineers, not just machine operators. I remember a project for a medical device where our integrated team suggested a small change to the plastic resin and a tiny tweak to a wall thickness. The change was almost invisible, but it cut the cycle time by 15% and improved the part's strength significantly. A simple assembly factory would never have found that.

The Benefits of Integration

| Benefici | Why It Matters |

|---|---|

| Streamlined Communication | One point of contact. No lost-in-translation errors between firms. |

| Total Accountability | The buck stops here. The partner is responsible for the final product, period. |

| Efficienza dei costi | DFM is applied early, preventing expensive redesigns and tooling changes. |

| Faster Time-to-Market | The entire process is seamless, with no hand-off delays between stages. |

Integrated product development teams can resolve manufacturing problems 60% faster than siloed teams.Vero

With designers, engineers, and manufacturing staff in constant communication, problems can be identified and solved in real-time collaborative sessions, rather than through slow, formal communication channels between separate companies.

Using a single partner for design and manufacturing is always more expensive.Falso

While the initial quote might seem higher than just a manufacturing quote, an integrated partner prevents costly redesigns, tooling errors, and delays, often resulting in a lower total project cost.

How can you find these full-service partners?

You know you need a full-service partner, but you are not sure where to look. A bad search can lead you to unqualified suppliers who claim to do it all but can't deliver.

Find full-service partners by searching on B2B platforms2 like Alibaba with specific keywords like "OEM plastic injection molding." Also, attend major industry trade shows, ask for referrals from your network, and look for manufacturers who prominently feature their in-house R&D and design capabilities on their websites.

Finding the right partner is like hiring a key employee. You need to be methodical. Don't just look for the lowest price. Look for evidence of expertise and a true partnership mentality. In my years of sourcing, I've found a few reliable methods that work time and time again. The key is to look for proof that they are more than just an assembly line.

Online B2B Platforms

Websites like Alibaba, Made-in-China, and Global Sources are powerful tools, but you have to use them correctly.

- Use specific keywords: Instead of "plastic factory," search for "custom OEM plastic enclosure design" or "ODM consumer electronics manufacturer."

- Look for "R&D": Check their company profile for a dedicated R&D department. Look at the number of R&D staff and engineers.

- Examine their products: Do they show both custom (OEM) projects and a catalog of their own (ODM) products? This is a great sign.

Industry Trade Shows

There is no substitute for meeting someone face-to-face. Trade shows3 like the K Show in Germany for plastics or CES for electronics are fantastic places to meet potential partners. You can see their product quality firsthand and speak directly with their engineers, not just salespeople.

Leveraging Your Network

Ask for recommendations. Talk to other designers, engineers, or business owners in your industry. A referral from a trusted contact is often the best lead you can get. I've found some of my best partners through simple conversations with people in my network.

Over 90% of B2B buyers use online searches during the purchasing process.Vero

According to Google and other market research firms, the vast majority of business buyers, including those sourcing manufacturing partners, start their journey with an online search to find and vet potential suppliers.

The best manufacturing partners do not have websites.Falso

In today's global market, a professional website that showcases capabilities, case studies, and R&D strength is a crucial tool for any credible, modern manufacturing partner looking to attract serious clients.

What key questions should you ask a potential partner?

You have found a potential partner, but you need to vet them properly. Asking the wrong questions will not reveal their true capabilities, and you might end up with the wrong fit.

Ask about their R&D team's size and experience. Request to see their ODM catalog to judge quality. Inquire about their DFM process and how they handle IP protection4. Also, ask for case studies of past OEM projects similar to yours to verify their expertise.

When I'm qualifying a new factory, I have a mental checklist of questions. This isn't just about getting information; it's about seeing how they think and how they respond. A good partner will welcome detailed questions and give you transparent answers. A weak supplier will be vague or defensive. Your goal is to confirm they are a true partner, not just a vendor.

Questions About R&D and Design

- Can you describe your R&D team? How many engineers and designers do you have?

- What is your Design for Manufacturability (DFM) process? Can you give me an example of how you improved a client's design?

- Can I see your ODM catalog? (This is a quick way to judge their design and engineering quality.)

Questions About Manufacturing

- What are your core Manufacturing capabilities5 in-house? (e.g., injection molding, CNC, assembly)

- Can you share a case study of an OEM project similar to mine in complexity or industry?

- How do you handle quality control at each stage of production?

Questions About IP and Partnership

- How do you protect your clients' intellectual property (IP)? What specific documents or procedures do you use? (e.g., NDAs)

- Who would be my main point of contact? Will I be speaking directly with an engineer?

- What is your process for handling design changes or problems during production?

Asking about IP protection upfront is critical. It shows you are a serious client and forces them to be clear about their commitment to keeping your ideas safe.

Discussing IP protection early in the conversation is a key indicator of a serious and professional client.Vero

Experienced manufacturers recognize that clients with valuable IP are rightly concerned about its security. Proactively addressing IP demonstrates professionalism and builds a foundation of trust necessary for a high-stakes OEM partnership.

A Non-Disclosure Agreement (NDA) is the only thing needed to fully protect your IP overseas.Falso

While an NDA is a crucial first step, true IP protection involves a multi-layered strategy, including working with reputable partners, understanding local laws, and potentially registering patents or trademarks in the country of manufacture.

Why is Hisoair a great partner from concept to completion?

Finding a partner who truly excels at both custom OEM work and reliable ODM products is rare. You need a trusted expert who can support your project, no matter the path you choose.

Hisoair is a prime example of a full-service partner. They have a strong in-house R&D team, a polished ODM catalog that proves their skill, and a secure process for custom OEM projects. They are the "best of both worlds" partner I've been describing in this article.

Throughout my career, I've learned to spot the difference between a simple supplier and a true partner. A partner invests in their own capabilities, respects your vision, and has the technical depth to bring it to life. When I look at a company like Hisoair, they check all the boxes of what I would look for if I were launching a new product today. They embody the principles we've discussed.

The "Best of Both Worlds"

Hisoair is the perfect example of a company that can help you whether you have a 100% custom idea (OEM) or want to launch a proven design next month (ODM). This flexibility is invaluable. Their strong ODM catalog is a real-world portfolio that proves their R&D team is competent. It gives you the confidence to trust them with your most ambitious, custom OEM projects. They have a dedicated R&D team that understands why a product works, not just how to assemble it. They are experts in DFM, ensuring your product is designed for efficient, reliable mass production from day one. For OEM clients, they have clear, proactive processes to ensure your intellectual property is secure. They are the IP-secure partner you need for a high-value project.

| Hisoair's Integrated Model | Descrizione |

|---|---|

| OEM Services | Full support for custom projects, from concept, DFM, and prototyping to tooling and mass production. |

| ODM Services | A catalog of market-proven products ready for your branding, enabling rapid market entry. |

| Key Differentiator | A strong, in-house R&D team that bridges the gap between design and manufacturing. |

| IP Security | A core focus on protecting client IP with robust NDAs and secure project management. |

A manufacturer with a strong ODM catalog is more likely to succeed with a complex OEM project.Vero

A quality ODM catalog is direct evidence of a company's proven R&D, design, engineering, and manufacturing capabilities. It shows they can successfully manage a product's entire lifecycle, which de-risks a new OEM project.

Companies that offer both OEM and ODM services are typically startups.Falso

Developing both robust OEM capabilities and a successful ODM product line requires significant experience, capital, and a mature R&D department. This is typically a hallmark of an established and sophisticated manufacturer.

Conclusione

Choosing a single partner for design and manufacturing saves time, cuts costs, and ensures a better final product. It turns a supplier into a true, invested partner for your success.

References

-

A capable R&D team can identify design flaws early, saving time and costs in production. ↩

-

Utilizing the right B2B platforms can connect you with qualified manufacturers that meet your project needs. ↩

-

Trade shows provide direct access to manufacturers and insights into their capabilities and products. ↩

-

Understanding IP protection is crucial for safeguarding your innovations when working with manufacturers. ↩

-

Knowing essential manufacturing capabilities ensures you choose a partner that can meet your project requirements. ↩