Worried about having all your manufacturing in one place? The "China+1" strategy seems like the perfect answer. But moving production is more complex than just changing an address.

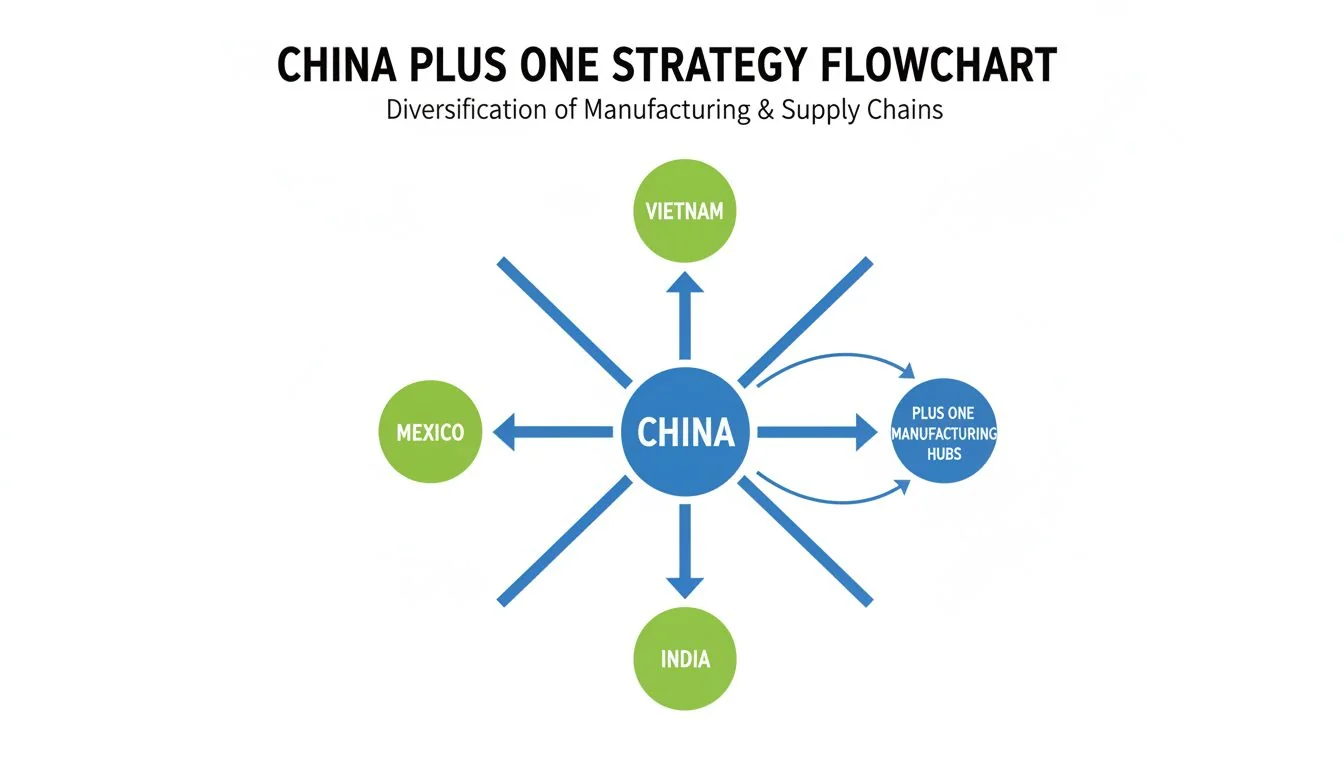

The "China+1" strategy is a business plan to diversify manufacturing away from relying only on China. Companies keep a base in China but also open a second factory in another country, like Vietnam, Mexico, or India. This helps reduce risks from tariffs and supply chain disruptions1.

I talk to product designers like you every day. Many are being asked by their bosses to explore manufacturing in new countries. It's a smart conversation to have. Diversifying your supply chain is a sound business principle, and I've helped many clients navigate this exact path. But there's a conversation that often gets missed in the rush to find a new factory. It's a detail that can mean the difference between a successful product launch and a warehouse full of 1-star inventory. Let's talk about what "China+1" really means for innovative products, especially in a competitive space like wellness hardware.

The China+1 strategy guarantees lower overall production costs.Falso

While labor might be cheaper in a '+1' country, costs for logistics, training, and fixing quality issues can often negate these savings, especially in the initial phases.

Vietnam, India, and Mexico are the most common '+1' countries for manufacturing diversification.Vero

These countries are popular choices due to their geographic locations, labor costs, and growing manufacturing infrastructure, each serving different regional markets.

1. What is the "China+1" Strategy and Why Is Everyone Talking About It?

You see headlines about tariffs and supply chain risks. Your boss is getting nervous. The pressure is on to find alternatives and secure your production. It feels urgent.

The "China+1" strategy is a risk management approach where companies add a manufacturing location in another country while keeping some operations in China. It’s a response to geopolitical tensions, rising labor costs, and the desire to build a more resilient global supply chain.

Breaking Down the "Why Now"

For years, China was the undisputed "factory of the world." The ecosystem was just too good to ignore. You had everything in one place: raw material suppliers, component manufacturers, skilled engineers, and massive assembly lines. I built my entire career inside this ecosystem. But things have changed. The reasons everyone, from small D2C brands2 to giant corporations, is talking about "China+1" come down to a few key points:

- Risk Diversification: The pandemic showed us how dangerous it is to have all your production in one region. A single lockdown can halt your entire business. Spreading out your manufacturing is like not putting all your eggs in one basket.

- cost management3: Labor and operational costs in China have been rising. Companies are looking for places with lower labor costs to protect their margins, especially for products that are simple to assemble.

- Geopolitical Factors: tariffs and trade disputes4 have become a real cost of doing business. Moving some production can help companies avoid these tariffs and navigate complex international trade rules.

It’s a logical business move. On paper, it looks like a clear win.

The 'China+1' strategy was invented after the 2018 US-China trade war.Falso

The concept has been around since the early 2000s, used by Japanese companies to mitigate risks. It only became a mainstream global strategy after 2018.

Moving production to a '+1' country eliminates all supply chain risks.Falso

It diversifies risk but introduces new challenges, such as less mature infrastructure, different regulations, and potential quality control issues in the new location.

You found a factory in a new country with cheaper labor. Problem solved, right? But what if the product that comes off that line is a cheap copy of your vision?

The hidden cost of the "China+1" strategy is often the sacrifice of innovation. While a new factory might be great at assembly, it may lack the deep engineering and problem-solving ecosystem needed to create a truly great product. You trade R&D power for simple labor.

A Story from the Trenches

I remember a client, a sharp D2C founder with a brilliant idea for a new type of handheld massager. We spent months perfecting the design and the mold here in China. The ergonomics were perfect, the motor was quiet, and the plastic finish felt premium. The initial production run was a huge success.

Then, his investors pushed him to adopt a "China+1" strategy to lower costs. He found a factory in another country that promised a 15% lower assembly price. He sent them our perfect mold and the product specs. Six months later, he called me in a panic. The new products felt cheap. The seams didn't align perfectly, the motor was louder, and the plastic had a slight wobble.

What went wrong? The new factory was an assembler. They were experts at putting parts A, B, and C together. They were not innovators. They didn't have the engineers on-site to fine-tune the injection molding parameters when the local plastic material behaved differently. They didn't have the deep knowledge to troubleshoot the subtle vibration issues. The 15% he saved on assembly was lost ten times over in customer returns and brand damage.

Any factory with an injection molding machine can produce high-quality plastic parts.Falso

Quality depends on the machine's precision, the quality of the mold, the skill of the operator, and the deep knowledge of material science, not just the machine itself.

The cost of a bad product launch is higher than the cost of tariffs.Vero

Tariffs are a percentage of cost, but a failed product results in 100% loss of R&D, marketing, and inventory costs, plus significant damage to brand reputation.

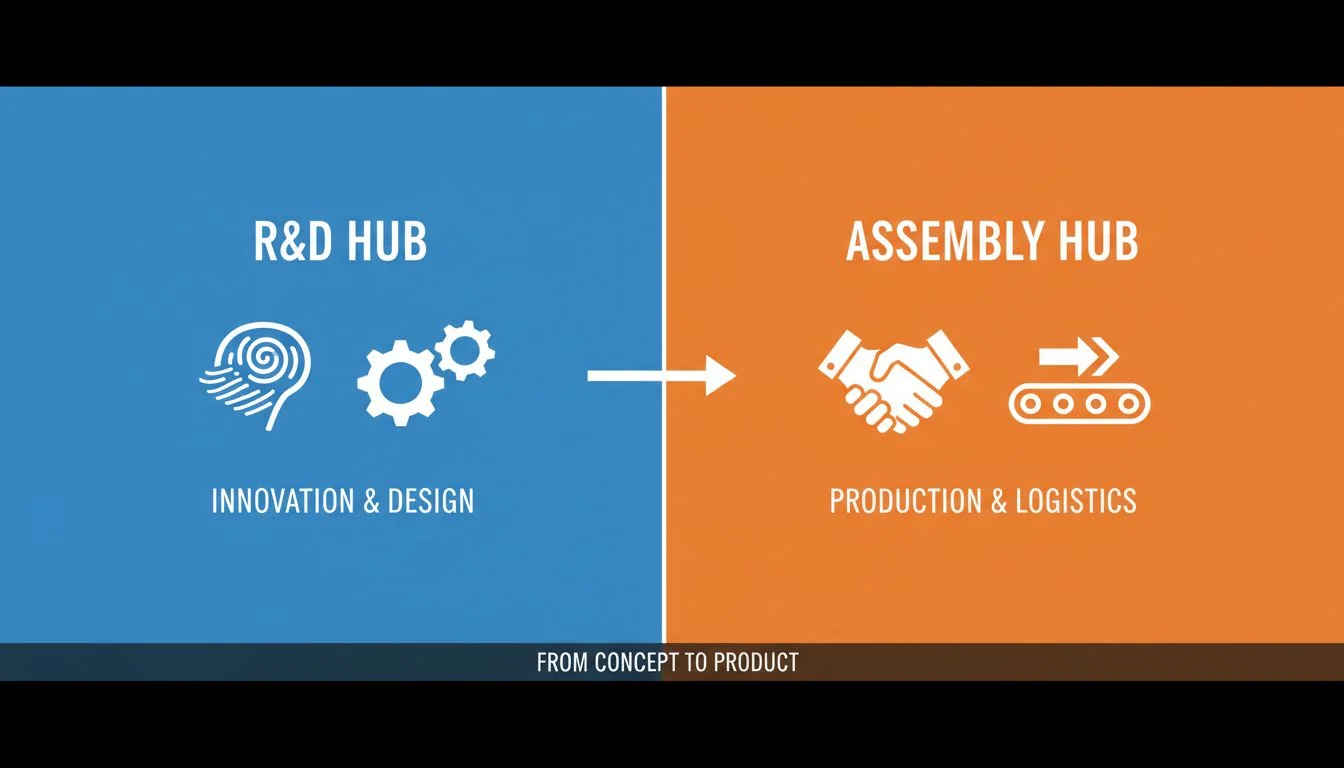

3. "R&D Hub" (China) vs. "Assembly Hub" (+1 Nations)?

Choosing a manufacturing partner feels like a huge decision. Are you hiring a team to build your vision, or just a pair of hands to put it together?

China has become a mature R&D Hub5, excelling at complex engineering, rapid prototyping, and integrated supply chains. In contrast, many "+1" nations are powerful Assembly Hubs, offering cost-effective labor for high-volume, established products. They serve different, but equally important, functions.

It's Not a Fight, It's a Different Job

Thinking of this as "China vs. Vietnam" or "China vs. Mexico" is the wrong way to look at it. As a product designer, you know that different tasks require different specialists. You wouldn't ask a graphic designer to write production code. The same logic applies here. It's an "apples vs. oranges" comparison.

Let's break down the different roles these manufacturing hubs play. This is how I explain it to my clients to help them build a smarter global strategy.

| Caratteristica | R&D Hub (e.g., China) | Assembly Hub6 (e.g., +1 Nation) |

|---|---|---|

| Core Strength | Complex engineering, mold making, prototyping. | Manual assembly, labor-intensive tasks. |

| Ecosystem | Highly integrated network of material suppliers, toolmakers, and engineers. | Developing infrastructure, often focused on specific industries like garments or simple electronics. |

| Best For... | New, innovative products requiring rapid iteration and problem-solving. | Mature, stable products where the design is locked and production is standardized. |

| Key People | Experienced engineers and mold designers who can solve problems. | A large, cost-effective labor force. |

Your wellness hardware isn't just a simple gadget. It has complex ergonomics, specific material requirements, and sensitive electronic components. The innovation happens in the design and tooling phase. That requires an R&D Hub.

China's manufacturing advantage is solely based on cheap labor.Falso

China's primary advantage now is its highly developed and integrated supply chain ecosystem, engineering talent, and massive infrastructure, not just labor costs.

An 'Assembly Hub' is ideal for launching a brand new, unproven product.Falso

New products require iteration and problem-solving, which are strengths of an R&D Hub. An Assembly Hub is better for scaling a product after it's been perfected.

4. The Real Risk for D2C: Is a "Me-Too" Product a Bigger Threat Than Tariffs?

You spend nights worrying about a 10% tariff wiping out your margin. But what if the real threat is a product that gets a 2-star average review and never sells?

For any brand, especially in the competitive D2C space, market failure is a far greater and more immediate risk than geopolitical tariffs. A "me-too" product, born from a weak R&D process, will fail no matter how cheaply it was assembled. True innovation is your only real security.

Shifting Your Focus from Geopolitics to the Customer

As a designer like Jacky, your name is on that product. Your professional pride is tied to its success. Let's be honest, your customer in Canada or the US doesn't know or care about your supply chain strategy. They don't give you extra points because you avoided a tariff.

What do they care about?

- Does the product feel solid and well-made? (This comes from a perfect mold and precise process control).

- Does it work as advertised, every time? (This comes from rigorous testing and engineering problem-solving).

- Is it better or more interesting than the ten other options on Amazon? (This comes from true innovation in the design phase).

A 10% tariff is a math problem you can solve. You can adjust your price or find efficiencies elsewhere. But a fundamental product flaw is a trust problem. Once your brand gets a reputation for low quality, it's almost impossible to recover. The risk of launching a generic, poorly executed "me-too" product is a 100% loss. You lose your investment in tooling, inventory, and marketing. That's a risk you can't afford. The best way to de-risk your business is to first secure your innovation.

Customers are willing to pay more for a product with unique features and high quality.Vero

Studies consistently show that consumers prioritize value, which includes quality, durability, and innovation, over just the lowest price, especially for wellness and electronics products.

A strong marketing campaign can save a bad product.Falso

Marketing can generate initial sales, but it cannot overcome poor quality. Bad reviews and word-of-mouth will quickly kill a product's momentum and damage the brand's reputation.

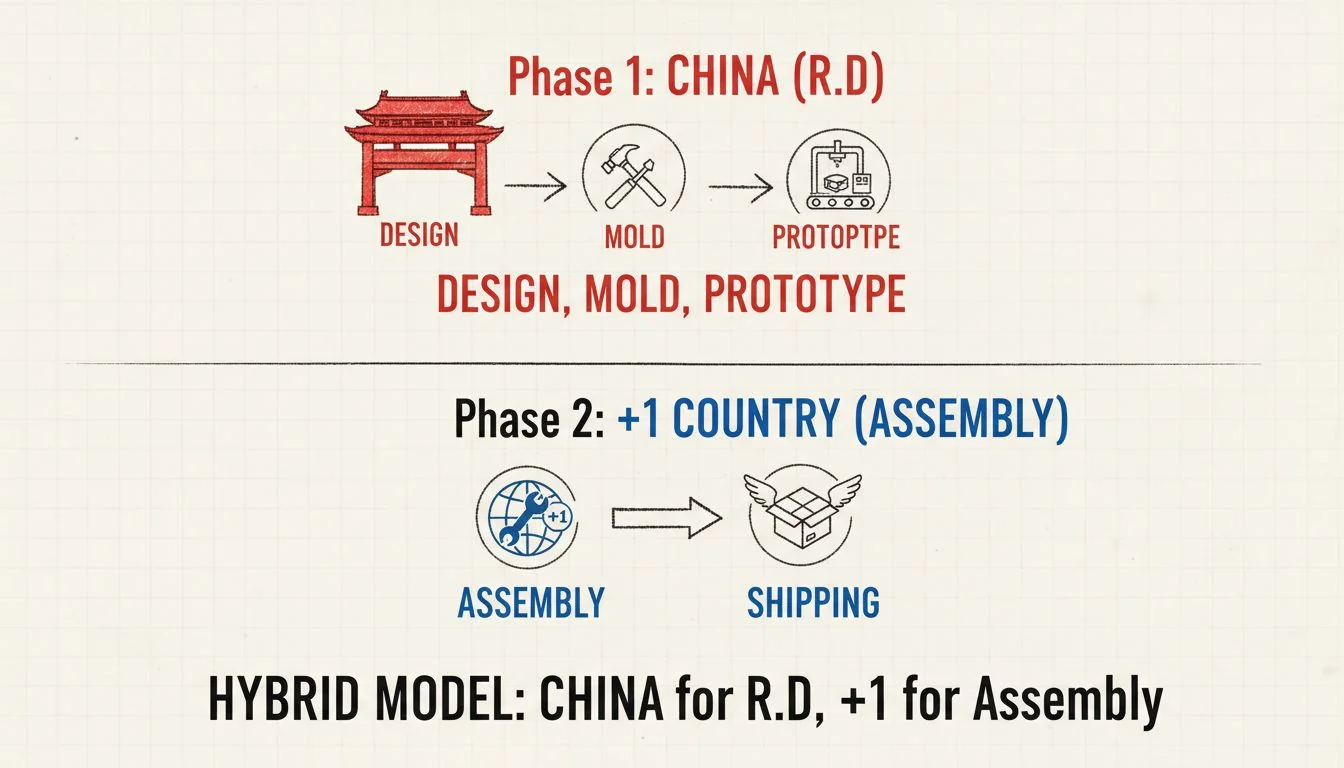

5. The "Smart" Future: "China for R&D, +1 for Assembly"?

You want the cost benefits of diversification. But you also need the innovation to create a winning product. How can you get the best of both worlds?

The most sophisticated global manufacturing strategy is a hybrid model. Use China's powerful R&D ecosystem to innovate: design, prototype, and perfect your product and molds. Then, leverage a "+1" country for the high-volume assembly of that finalized, de-risked product.

A Practical, Two-Phase Approach

This isn't about choosing one country over another. It's about using each for its core strength. This is the strategy I now recommend to all my most successful clients. It protects their innovation while building long-term resilience.

Phase 1: Innovation and Tooling (The R&D Hub - China)

This is the most critical phase. Get this wrong, and nothing else matters.

- Design & Engineering: Work with experienced engineers to refine your CAD files, conduct Design for Manufacturability (DFM) analysis, and select the right materials. This is where knowledge from platforms like Moldle is invaluable.

- Mold Making & Prototyping: Create your high-precision molds. This is a craft. The quality of your mold determines the quality of every single unit you produce.

- Pilot Run & De-bugging: Run the first few thousand units. Solve all the small issues—the imperfect seams, the slight color mismatch, the motor vibration. Perfect the process until it's stable and repeatable.

Phase 2: Scale & Assembly (The Assembly Hub - +1 Nation)

Once your product and process are absolutely perfect, you can consider moving the labor-intensive part.

- Mature Product Assembly: You ship your perfected, Chinese-made molds and components to your "+1" factory.

- Standardized Process: Their job is not to innovate or problem-solve. Their job is to execute a simple, proven assembly process that you have already defined and de-risked.

This strategy gives you the ultimate advantage: world-class innovation from the R&D hub and cost-effective scale from the assembly hub.

Transferring a complex mold to a new factory is a simple 'plug-and-play' process.Falso

Molds are calibrated to specific machines, materials, and environments. Transferring one often requires significant recalibration and expertise to replicate the original quality.

A hybrid 'China for R&D, +1 for Assembly' model is more resilient to global disruptions.Vero

This model diversifies assembly locations to mitigate regional shutdowns while keeping the core innovation and tooling in a stable, mature ecosystem, protecting the most valuable part of the process.

Conclusione

Il Strategia Cina+17 is a smart move for supply chain resilience. But true success comes from securing your innovation first. Perfect your design and tooling, then diversify your assembly.

References

-

Learning about supply chain disruptions can provide insights into risk management and operational continuity. ↩

-

Exploring the challenges faced by D2C brands can provide valuable insights for improving product success. ↩

-

Effective cost management strategies are vital for maintaining profitability in manufacturing. ↩

-

Understanding tariffs and trade disputes is essential for navigating international business challenges. ↩

-

Exploring the concept of an R&D Hub can help businesses leverage innovation in their product development. ↩

-

Understanding the role of an Assembly Hub can guide companies in choosing the right manufacturing partners. ↩

-

Understanding the China+1 strategy is crucial for businesses looking to diversify their manufacturing and mitigate risks. ↩