Tariffs are eating into your profits. You are desperately searching for a "tariff-free" country to save your margins. But this search might be the biggest risk of all.

To truly optimize for the US market, you must first focus on creating a high-quality "hero product1" with a reliable innovation partner. The financial risk of a tariff is often much lower than the market risk of a failed product launch from an unproven supplier.

I talk to product designers and brand owners every single day. I hear the frustration in their voices. They've spent months, sometimes years, perfecting a new product. They've invested in tooling, marketing, and inventory. Then, a new tariff gets announced, and suddenly 15%, 20%, or even 25% of their margin is gone. It’s a real, painful cost, and I want to start by acknowledging that. Your concern is completely valid. It feels like you're being punished for building something great.

This pain sends many smart people on a frantic search for a "tariff-free" solution. They start looking at moving their manufacturing to a new country to avoid that extra cost. I've been in this industry for a long time, starting on the factory floor and later building my own trading company. I've seen this cycle play out many times. But I've also seen the hidden dangers in that search. I want to share what I've learned, so you don't fall into a trap that's far more expensive than any tariff.

The US has imposed Section 301 tariffs on over $300 billion worth of goods from China.Vero

These tariffs, ranging from 7.5% to 25%, were implemented by the USTR and affect a wide range of consumer and industrial goods.

Moving manufacturing out of a country completely eliminates all supply chain risks.Falso

Moving production introduces new risks, including logistical challenges, quality control issues, and reliance on less mature component ecosystems.

The Tariff Problem: Are You Just Searching for "Tariff-Free"?

Tariffs are a real, painful cost that can erase your hard-earned profits. It feels like a direct tax on your success. Let's acknowledge this pain and look at the common reaction.

The search for "tariff-free" manufacturing is a natural response to trade friction. Companies often look to countries like Vietnam, Mexico, or India. They hope to assemble products there to avoid direct tariffs and protect their margins.

I get it. When you see a 25% tariff, your first instinct is to eliminate it. I had a client, a sharp guy just like you, who ran a successful D2C brand for kitchen gadgets. The tariffs hit his main product line hard. He immediately started calling contacts in Vietnam and Mexico. His entire focus shifted from product development to geopolitical strategy. He was trying to solve a 25% problem, but as we'll see, he was about to create a 100% problem. This reaction is common. The "China Plus One" strategy has become a major talking point in boardrooms. The idea is to diversify your manufacturing footprint to reduce reliance on a single country. On paper, it makes perfect sense. But manufacturing isn't done on paper.

The Allure of the "Tariff Haven"

These "tariff-free" countries seem like the perfect solution. They offer lower labor costs and, most importantly, a way to sidestep those hefty import duties. The sales pitch is compelling: "Make the same product, just without the tax." It sounds simple. It sounds smart. But as I've learned from my years in the mold and trading business, if it sounds too simple, it's usually not the whole story.

The 'China Plus One' strategy involves companies diversifying their supply chains away from only China.Vero

This strategy gained popularity due to trade tensions and the COVID-19 pandemic, with companies moving parts of their production to other countries like Vietnam, India, and Mexico.

All 'tariff-free' countries have mature manufacturing ecosystems equivalent to China's.Falso

Many emerging manufacturing hubs lack the deep, integrated supply chains, specialized engineering talent, and rapid tooling capabilities found in more established regions.

The "Tariff-Free" Options: Are These "Assembly Hubs" the Real Solution?

You found a factory in a "tariff-free" country. But can they match the quality, speed, and innovation you need? It's time to understand the limitations of these new manufacturing hubs.

Many "tariff-free" options are primarily "assembly hubs2." They import complex components from established supply chains (like China) and perform final assembly. This creates new logistical challenges and may not offer the deep engineering expertise needed for innovative products.

When my client started getting quotes from Vietnam, he noticed something odd. The cost for his complex molded parts was still high. Why? Because the Vietnamese factory wasn't making them. They were planning to import the critical components from their supplier in China, assemble them in Vietnam, and then export them to the US. He wasn't escaping the Chinese supply chain; he was just adding a stop. This is the reality of many "assembly hubs." They are great at labor-intensive work but often lack the deep ecosystem for specialized tasks like complex mold making, precision CNC machining, or sourcing unique materials. For a designer like you, Jacky, this is a huge red flag. Your job is to ensure designs are optimized for large-scale production. That requires tight collaboration with engineers and toolmakers who have decades of experience.

Ecosystem Comparison: Established vs. Assembly Hub

| Caratteristica | Established Ecosystem (e.g., China) | Emerging "Assembly Hub" (e.g., Vietnam) |

|---|---|---|

| Approvvigionamento di componenti | Vast, integrated network. Get any part in days. | Limited local suppliers. Relies on imports. |

| Engineering Talent | Deep pool of experienced mold & product engineers. | Smaller talent pool, less specialized experience. |

| Tooling Expertise | World-class, rapid mold making and iteration. | Basic tooling capabilities, longer lead times. |

| Scalabilità | Can scale from prototype to millions of units quickly. | Challenges with rapid scaling and consistency. |

Vietnam's manufacturing sector relies heavily on imported intermediate goods, especially from China.Vero

A significant portion of the raw materials and components used in Vietnamese manufacturing are sourced from China, making it an 'assembly hub' for many industries.

Moving assembly to a new country severs all ties with the original supply chain.Falso

In many cases, companies still rely on their original suppliers for critical components, adding complexity and shipping costs to the new assembly location.

You avoided a 25% government tariff. Great. But your new product is getting 1-star reviews and failing in the market. You just paid the "Innovation Tariff," and it's a brutal lesson.

The "Innovation Tariff" is the massive, hidden cost you pay when a product fails due to poor quality or design compromises. This happens when you prioritize avoiding a government tariff over partnering with a supplier who can deliver a 5-star product.

I coined this term, the "Innovation Tariff," after seeing too many brands make the same mistake. They spend all their energy dodging a 25% financial risk, only to run headfirst into a 100% market risk3. For a D2C brand or any company launching a new product, market risk is the only risk that matters. You can survive a tariff. You can adjust your pricing or find efficiencies. You cannot survive a 1-star product. A failed launch means your investment in R&D, design, marketing, and tooling is gone. All of it. That is the Innovation Tariff. It's the price you pay for de-prioritizing quality. It's the cost of a tarnished brand reputation. It's the loss of future sales because customers don't trust you anymore.

The True Killer: Market Risk

As a designer, you know that the difference between a 2-star product and a 5-star product is in the details. It's in the precision of the mold, the feel of the material, the perfect fit and finish. These are the things that an experienced, innovative manufacturing partner delivers. When you switch to a less experienced "assembly hub" to save on tariffs, you are gambling with those details. You are betting that they can replicate the expertise of a mature ecosystem. That is a dangerous bet.

Product-market fit is the single most important factor for a new product's success.Vero

Studies and startup post-mortems consistently show that a lack of market need or a poor product is a top reason for failure, far outweighing issues like pricing or external costs.

A 25% tariff will bankrupt any business.Falso

While significant, a tariff is a calculable cost that can be managed through pricing strategy, cost optimization, or negotiation. A failed product, however, often results in a total loss of investment.

The Real Math: Which "Cost" Is Actually Higher?

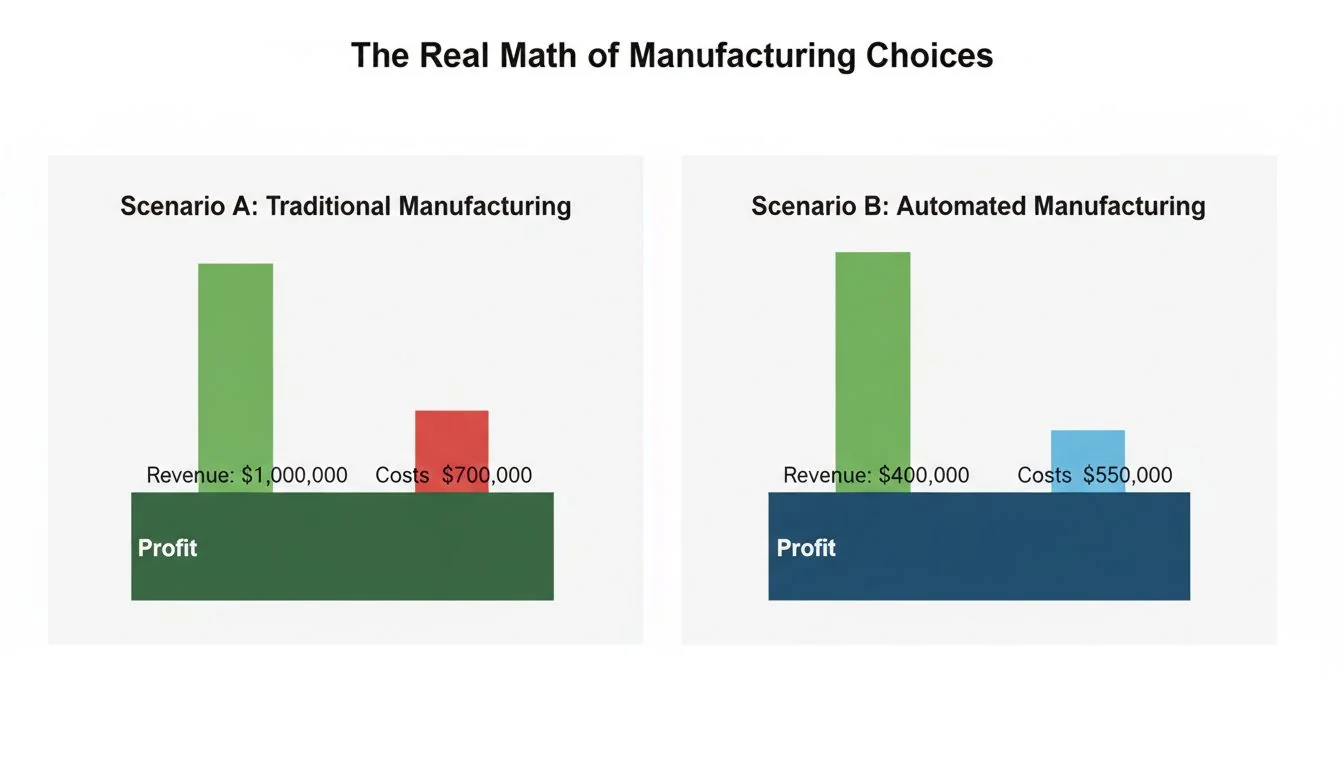

You are stuck between two choices. One has a tariff, but guaranteed quality. The other is tariff-free, but has quality risks. Let's do the simple math to see which path is smarter.

The math is brutally simple. A profitable product that pays a 25% tariff is infinitely better than an unprofitable product that pays a 0% tariff. The goal of business is profitability, not just tariff avoidance. Let's compare two scenarios.

Let's go back to my client with the kitchen gadgets. He was facing this exact choice. We sat down and mapped it out. I told him, "Let's forget the noise and just look at the numbers." As a designer, you appreciate data. This is the data that matters most. We created two scenarios based on a hypothetical 10,000-unit run of a product that sells for $50. This simple exercise changed his entire perspective. It showed him he was focused on the wrong "cost." He was trying to save a few dollars per unit on tariffs but was risking the entire project by compromising on the manufacturing partner.

Scenario A vs. Scenario B: A Clear Choice

| Metric | Scenario A: "Hero Product" (with Tariff) | Scenario B: "Tariff-Free" Gamble |

|---|---|---|

| Partner | Proven innovation partner4 (Mature Ecosystem) | New "Assembly Hub" (Unproven) |

| Product Quality | 5-Star Reviews, Low Returns | 2-Star Reviews, High Returns |

| Revenue | 10,000 units @ $50 = $500,000 | 2,000 units @ $50 = $100,000 (sales stop due to bad reviews) |

| Unit Cost | $15 | $14 (Slightly cheaper) |

| Total COGS | $150,000 | $140,000 (for all 10k units produced) |

| Tariff (25% on COGS) | $37,500 | $0 |

| Total Cost | $187,500 | $140,000 |

| Gross Profit / Loss | +$312,500 | -$40,000 (plus 8,000 units of dead inventory) |

The result is clear. In Scenario A, you have a successful product and a healthy profit, even after paying the tariff. In Scenario B, you have a failed product, a financial loss, and a warehouse full of useless inventory. You paid the Innovation Tariff.

Customer reviews directly impact e-commerce sales, with negative reviews significantly deterring potential buyers.Vero

Multiple studies show that products with higher average star ratings have substantially higher conversion rates. A drop from 5 stars to 3 can cut sales by more than half.

The "Smart" Strategy: How Do You Secure Your "Hero Product" First?

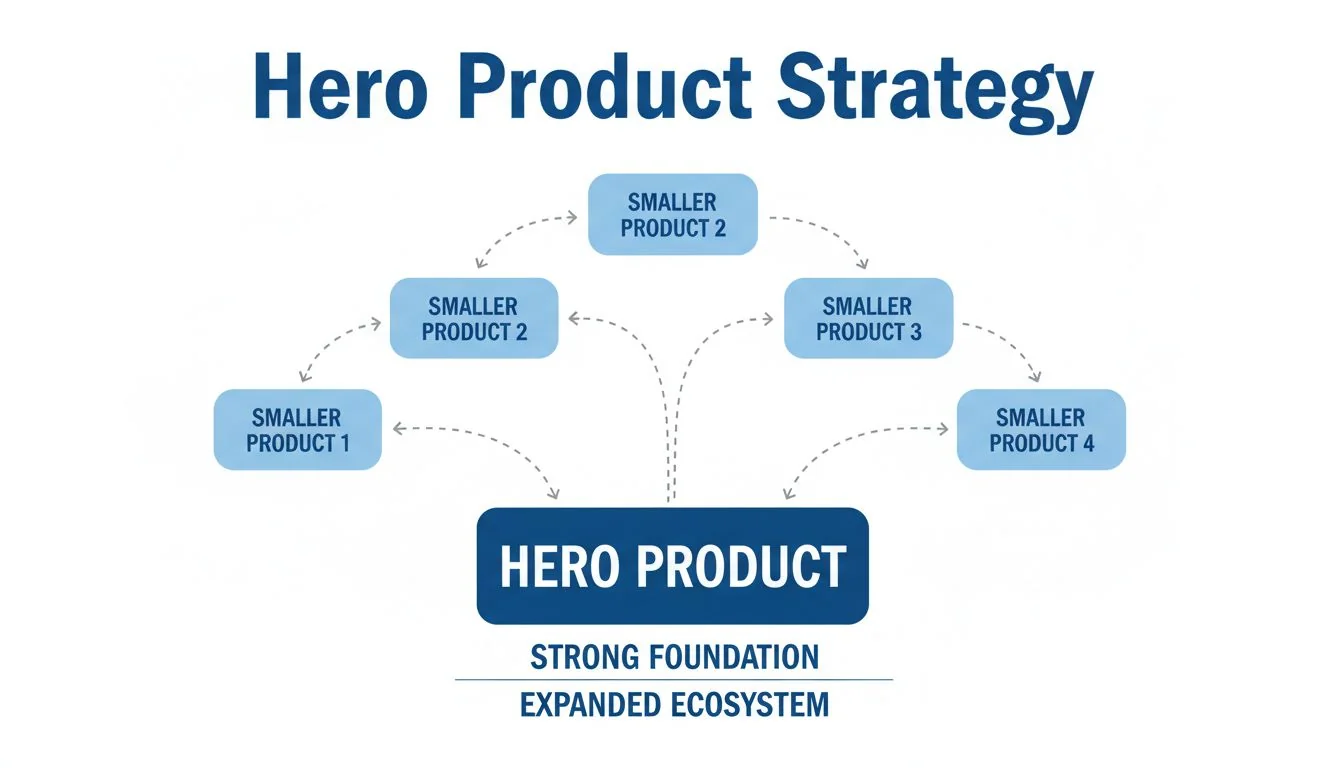

You understand the risk, but you still need a long-term plan. How do you balance the need for quality now with diversification later? The answer is to focus all your energy on your "Hero Product."

The smart strategy is to first secure your "hero product" with an innovation partner who guarantees quality, even if it means paying a tariff. Use the profits from this successful launch to fund future diversification into "tariff-free" options.

After we did the math, my client's path became clear. He wasn't just looking for a supplier anymore; he was looking for an "Innovation Partner." This is a term I use for a manufacturing partner who is invested in your success. They have the engineering depth and tooling expertise to solve problems and help you create a 5-star product. This is the kind of partnership I built my trading company on—not just moving boxes, but helping clients build profitable businesses. The right strategy isn't about avoiding all tariffs forever. It's about winning the most important battle first.

Step 1: Nail the Hero Product

Your primary focus must be on your most innovative, highest-margin product. Partner with the absolute best manufacturer you can find for this product, regardless of their location. This is your foundation. Pay the tariff if you have to. A profitable product with a tariff is the goal.

Step 2: Bank the Profits

Launch your hero product and establish it in the market. Build your brand reputation on quality. Generate the cash flow and financial stability that give you options.

Step 3: Diversify Intelligently

Once your hero product is a success, you can use those profits to explore a "China Plus One" strategy for simpler, secondary products. You can afford to test an assembly hub with a lower-risk product line. You are now diversifying from a position of strength, not fear.

The 80/20 rule often applies to product portfolios, where roughly 80% of profits come from 20% of products.Vero

This principle, known as the Pareto Principle, suggests that businesses should focus their resources on securing the success of their most profitable 'hero' products.

Conclusione

Don't let short-term tariff fears dictate your brand's future. Prioritize innovation and quality to build a resilient, profitable business that can withstand any geopolitical shift.

References

-

Understanding the concept of a hero product can help you prioritize quality and innovation in your offerings. ↩

-

Understanding the limitations of assembly hubs can help you assess their viability for your production needs. ↩

-

Grasping the concept of market risk can help you prioritize product quality over cost-cutting measures. ↩

-

Finding the right innovation partner is crucial for product success; explore resources to guide your selection. ↩