In today's competitive, health-conscious market, developing a unique air purifier model is crucial for brand differentiation. This guide offers a comprehensive roadmap for collaborating with manufacturers, covering initial strategy, partner selection, legal frameworks, and production management. By mastering these steps, you can transform your innovative concept into a market-leading product.

Part I: Foundational Strategy - Defining the Partnership and Product

Launching an exclusive air purifier begins with two critical decisions: choosing your manufacturing partnership model and precisely defining your product. These choices significantly impact budget, timelines, intellectual property (IP) risks, and market positioning. A clear strategy here is vital for success.

Section 1: Choosing Your Manufacturing Model: OEM vs. ODM

The choice between an Original Equipment Manufacturer (OEM) and an Original Design Manufacturer (ODM) is a pivotal strategic decision, shaping your role in the value chain, resource allocation, and long-term competitive stance.

1.1. The Original Equipment Manufacturer (OEM) Model: Innovation and Control

In the OEM model, your company provides a complete, custom product design, and the manufacturer builds it to your exact specifications. You are the innovator, responsible for R&D, conceptual design, and feature specification. This model offers total design control and customization, enabling a truly unique and exclusive product. It also ensures strong intellectual property (IP) protection as you retain full ownership of the design and functional IP. However, it demands significant upfront investment in R&D, engineering, and tooling, leading to a longer time-to-market.

1.2. The Original Design Manufacturer (ODM) Model: Speed and Efficiency

The ODM model, often called "white-label" or "private-label" manufacturing, involves selecting an existing product from a manufacturer's portfolio and applying your branding. Customization is typically limited. This model excels in rapid time-to-market and cost-effectiveness due to amortized design and tooling costs. The ODM assumes the R&D burden. However, it offers limited customization and differentiation, making it hard to stand out. You also face weak intellectual property control, as the ODM retains ownership of the core product design, leading to high dependency and potential quality variance.

1.3. Hybrid Models and the Modern Manufacturing Landscape

Increasingly, the lines between OEM and ODM are blurring. Hybrid approaches balance innovation, cost, and speed. For an air purifier, a common hybrid involves leveraging an ODM for commoditized hardware (chassis, fan) while acting as an OEM for proprietary, value-adding components like high-performance filter composition, proprietary sensor arrays, and custom software/AI algorithms. This approach, often facilitated by a Contract Manufacturer (CM), allows you to outsource the "box" and insource the "brains".

1.4. The Strategic Choice: Reflecting Company Identity and Managing Modern Risks

Your choice of manufacturing model reflects your core strategy. A brand built on groundbreaking technology needs the control of the OEM model. A company focused on agile marketing might prefer the speed of ODM. Attempting a truly exclusive product via pure ODM is contradictory unless exclusivity is purely branding-based. With smart, IoT-enabled devices, meticulous IP delineation is crucial. Who owns the firmware, sensor data, or mobile app code? Failure to define these boundaries creates significant risk, as an ODM could leverage your innovations for competitors .

Table 1: OEM vs. ODM Strategic Decision Matrix

| Feature/Criteria | Original Equipment Manufacturer (OEM) Model | Original Design Manufacturer (ODM) Model |

|---|---|---|

| Product Design Control | Full control; product is built to client's exact specifications. | Limited control; based on manufacturer's existing designs with minor cosmetic changes. |

| Intellectual Property (IP) Ownership | Client retains ownership of the design and functional IP. | Manufacturer retains ownership of the design and functional IP. |

| Product Differentiation & Exclusivity | High; allows for a completely unique and exclusive product. | Low; high risk of competitors selling identical products under different brands. |

| Initial Investment (R&D, Tooling) | High; client is responsible for all development and tooling costs. | Low; development and tooling costs are shared across multiple clients. |

| Unit Cost | Can be higher due to custom components and lower initial volumes. | Often lower due to economies of scale and standardized parts. |

| Time-to-Market | Long; requires a full design, prototyping, and validation cycle. | Fast; leverages pre-existing designs and established processes. |

| Required In-House Expertise | High; requires strong R&D, engineering, and product design capabilities. | Low; relies on the manufacturer's design and engineering expertise. |

| Supplier Dependency / Risk | Lower; IP ownership makes it easier to switch suppliers. | High; heavily dependent on a single supplier for both design and production. |

| Scalability | Dependent on the chosen OEM's capacity and processes. | High; ODMs are typically set up for large-scale, efficient production. |

Section 2: Defining an "Exclusive" Product in a Competitive Market

To develop an exclusive air purifier, you must understand its competitive landscape. This requires a data-driven approach to defining the product, from core technology to smart features. Exclusivity stems from superior engineering, targeted features, and deep consumer understanding.

2.1. Market Analysis: Identifying Your Niche

The global air purifier market is dynamic, projected to grow from $17-24 billion in 2024 to nearly $49 billion by 2034. This growth is driven by heightened health consciousness (especially post-COVID-19), rising environmental pollution, and expanding residential demand. Online e-commerce is the fastest-growing sales channel, emphasizing a digital-first strategy.

2.2. Core Technology Deep Dive: The Science of Clean Air

An air purifier's effectiveness hinges on its filtration technology. An exclusive model combines technologies tailored to specific needs:

- [HEPA (High-Efficiency Particulate Air)](https://hisoair.com/filter-solution/ "HEPA (High-Efficiency Particulate Air): The market leader, capturing 99.97% of particles as small as 0.3 microns, including allergens, bacteria, and viruses. It's the foundation for serious air purification.

- Activated Carbon: The fastest-growing segment, absorbing gases, odors, and VOCs that HEPA filters miss . Often used with HEPA for comprehensive purification.

- UV-C (Ultraviolet Germicidal Irradiation): Uses UV light to inactivate microorganisms, a powerful feature for germicidal protection.

- Emerging Technologies: Ionic filters, electrostatic precipitators, Photocatalytic Oxidation (PCO), and active polarization offer further differentiation.

Creating an exclusive product involves synergistically combining these. For instance, an "allergy-focused" model might feature a medical-grade H13 HEPA filter with substantial activated carbon. A "health-focused" model could add a strategically placed UV-C lamp. The specific combination and quality, tailored to a consumer problem, define your product's unique story.

2.3. Performance Metrics: Substantiating Claims with Data

Verifiable performance metrics are crucial for credibility. Key metrics include:

- Clean Air Delivery Rate (CADR): Indicates how quickly an air purifier removes pollutants (smoke, pollen, dust) from a room. Higher CADR means faster cleaning.

- Air Changes Per Hour (ACH): Shows how many times room air is replaced by purified air per hour. 4-5 ACH is general, 5-6 ACH or higher for allergy sufferers.

Consider other metrics like noise levels, energy efficiency (Energy Star certification), and filter lifespan. Clear, independently tested metrics build consumer trust and validate exclusivity.

2.4. Smart Features: Beyond Basic Filtration

Modern air purifiers integrate into smart home ecosystems, offering enhanced convenience and data. Intelligent features elevate exclusivity:

- Advanced Sensors: Beyond PM2.5, integrate sensors for VOCs, CO2, humidity, and temperature for comprehensive indoor air quality monitoring.

- AI and Machine Learning: Optimize fan speed, predict pollution patterns, and personalize settings based on user habits.

- Seamless Smart Home Integration: Compatibility with platforms like Amazon Alexa, Google Home, and Apple HomeKit for voice control and automation.

- Mobile App Control and Data Analytics: Remote control, real-time monitoring, historical data, and personalized reports. This data is invaluable for product improvement.

- Connectivity: Standard Wi-Fi and Bluetooth, with consideration for Thread or Matter for future interoperability.

Combining cutting-edge filtration with intelligent features creates a superior, data-driven user experience, truly setting your product apart.

Part II: Sourcing and Engagement - Finding and Vetting Your Partner

Once your product vision is clear, finding a manufacturing partner capable of bringing that vision to life is the next critical step. This involves rigorous identification, vetting, and engagement.

Section 3: Identifying and Vetting Manufacturers

Finding the right manufacturer is paramount. It's about finding a partner who shares your commitment to quality, innovation, and IP protection.

3.1. Sourcing Channels: Where to Look

- Online B2B Platforms: Alibaba and Global Sources offer vast directories, but require thorough due diligence.

- Industry Directories and Associations: Organizations like the Association of Home Appliance Manufacturers (AHAM) provide more vetted options.

- Trade Shows: Attending industry-specific trade shows (e.g., CES, AHR Expo, Canton Fair) allows direct interaction, capability assessment, and relationship building. This is often the most effective way to find high-quality partners.

- Referrals: Personal recommendations from trusted industry contacts can lead to reliable manufacturers.

3.2. Vetting Framework: A Checklist for Due Diligence

Systematic vetting is crucial. Consider:

- Experience and Specialization: Track record in air purifiers or similar electronics.

- Technical Capability: Engineering team, R&D capabilities, and handling complex designs.

- Quality Certifications: Look for ISO 9001, ISO 14001, UL, CE, RoHS, and Energy Star. These indicate adherence to rigorous quality and safety standards.

- Production Capacity and Scalability: Ability to meet current and future demand.

- Supply Chain Management: How they manage raw material suppliers.

- Communication and Transparency: Responsiveness and willingness to share information.

- Ethical and Environmental Practices: Labor practices and sustainability commitment.

3.3. The On-Site Audit: Why a Factory Visit is Non-Negotiable

An on-site factory audit is indispensable for firsthand insight into operations, quality control, and working conditions. Pay attention to cleanliness, production processes, quality control points, equipment, worker skills, and inventory management. If an in-person visit isn't feasible, engage a third-party inspection company.

Section 4: The Request for Quotation (RFQ)

The Request for Quotation (RFQ) is more than a price inquiry; it defines your project's scope and evaluates a manufacturer's professionalism.

4.1. Crafting a Detailed RFQ: The Essential Components

Your RFQ should be comprehensive:

- Product Specifications: Detailed descriptions, dimensions, materials, aesthetics.

- Bill of Materials (BOM): Complete list of components, sub-assemblies, and raw materials.

- Technical Drawings and Schematics: Precise engineering drawings (CAD files, Gerber files for PCBs).

- Performance Requirements: Desired CADR, ACH, noise levels, energy consumption.

- Testing Procedures and Quality Standards: Outline QC expectations and specific tests.

- Packaging Specifications: Details on primary, secondary, and tertiary packaging.

- Target Price and Volume: Provide a target price range and estimated order volumes.

- Timeline: Specify desired development and production timelines.

- Intellectual Property (IP) Considerations: Briefly mention IP protection and confidentiality expectations.

4.2. The RFQ as a Competency Test

Evaluate the manufacturer's RFQ response based on clarity, completeness, insightful questions, suggestions for improvement, responsiveness, and professionalism. This reveals their expertise and collaborative spirit.

Part III: The Legal Framework - Architecting a Robust Agreement

Protecting your intellectual property and ensuring a clear, enforceable partnership are paramount. A robust legal framework shields against disputes and unauthorized use of your innovations.

Section 5: Protecting Your Intellectual Property (IP)

Safeguarding your innovation is critical. A multi-layered IP strategy is essential:

5.1. Multi-Layered Strategy: Patents, Trademarks, and Copyrights

- Patents:

- Utility Patents: Protect functional aspects (filtration mechanisms, smart algorithms).

- Design Patents: Protect ornamental design and aesthetic appearance.

- Provisional Patents: Establish an early filing date.

- Trademarks: Protect your brand name, logo, and slogans.

- Copyrights: Protect software code, user manuals, marketing materials, and unique visual designs.

Apply for patents and register trademarks in all relevant jurisdictions. Consult IP attorneys specializing in international IP law.

5.2. Tooling and Mold Ownership: Avoiding the "Factory Hostage" Situation

Tooling refers to custom equipment, molds, and dies for production. If the manufacturer owns it, you risk a "factory hostage" situation. Your manufacturing agreement MUST explicitly state that you retain full ownership of all tooling and molds paid for. This clause should include clear ownership transfer, storage and maintenance details, and a return or transfer process. Securing tooling ownership provides crucial leverage and flexibility.

Section 6: Negotiating the Manufacturing Service Agreement (MSA)

The Manufacturing Service Agreement (MSA) is the cornerstone of your collaboration. A well-negotiated MSA protects your interests and ensures a smooth production process.

6.1. Core Components of an MSA

Key clauses to include:

- Scope of Work: Define services from prototyping to production.

- Pricing and Payment Terms: Unit costs, tooling costs, payment schedules.

- Quality Standards and Acceptance Criteria: Specify quality metrics, testing, and acceptance criteria.

- Delivery and Lead Times: Production schedules and penalties for delays.

- Warranties and Indemnification: Manufacturer's warranties for quality and IP infringement.

- Confidentiality and Non-Disclosure: Robust NDA for proprietary information.

- Termination Clause: Conditions for agreement termination.

- Governing Law and Dispute Resolution: Jurisdiction and dispute resolution process.

6.2. The Exclusivity Clause: Defining the Terms of Your Unique Product

For an exclusive air purifier, the exclusivity clause in your MSA is paramount. It prevents the manufacturer from producing similar products for competitors. It should cover:

- Product Definition: Clearly define the specific product(s) covered.

- Scope of Exclusivity: Global or specific territories, manufacturing, sales, or both.

- Duration of Exclusivity: Clear timeframe with renewal provisions.

- Performance-Based Exclusivity: Link exclusivity to meeting production volumes or quality standards.

- Non-Compete Provisions: Prevent working with direct competitors.

- Remedies for Breach: Consequences for breaching the clause.

Legal counsel specializing in international manufacturing contracts is indispensable.

Part IV: From Prototype to Production - Managing the Development Lifecycle

With a solid strategy and vetted partner, the focus shifts to practical execution: rigorous testing, meticulous quality control, and efficient logistics.

Section 7: Prototyping and Testing

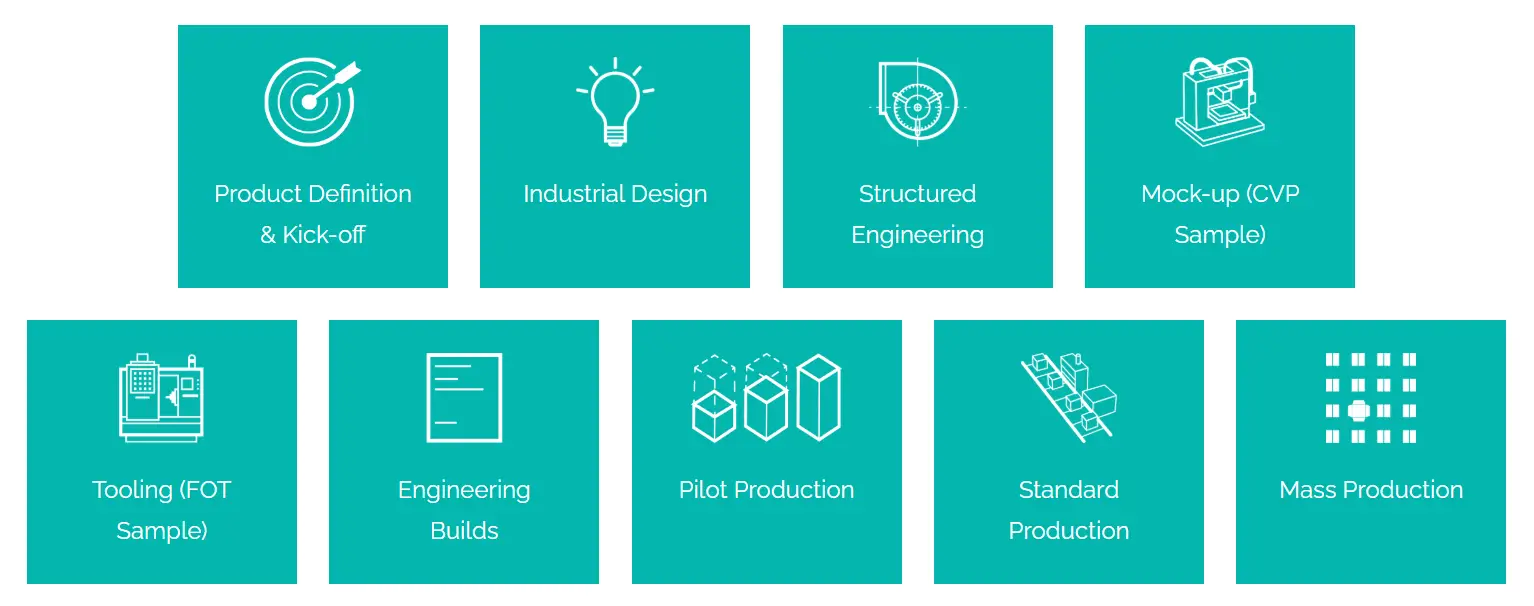

The journey from concept to market-ready product is iterative, involving multiple rounds of prototyping and testing.

7.1. Iterative Process: From Low-Fidelity to Functional Prototypes

- Concept Prototypes: Early-stage models (3D prints) for form and ergonomics.

- Functional Prototypes: Working models demonstrating core functionalities.

- Engineering Validation Test (EVT) Prototypes: Verify engineering design and system integration.

- Design Validation Test (DVT) Prototypes: Closely resemble final product for comprehensive testing.

- Production Validation Test (PVT) Prototypes: Small-batch runs using final tooling to validate manufacturing process.

7.2. Collaborative Validation: Design for Manufacturability (DFM) and Testing Protocols

Close collaboration with your manufacturer is essential for Design for Manufacturability (DFM). DFM optimizes design for efficient, cost-effective, high-quality production. Regular DFM reviews with the manufacturer's teams are crucial. Develop detailed test plans for each prototype stage, including functional, performance, durability, safety, and regulatory compliance tests. Document all results for design revisions.

Section 8: Scaling to Mass Production

Transitioning to mass production requires meticulous planning and robust quality control systems.

8.1. Quality Control Systems: Maintaining Consistency

Implement a comprehensive quality control (QC) system at every stage:

- Incoming Quality Control (IQC): Inspect raw materials upon arrival.

- In-Process Quality Control (IPQC): Regular checks during assembly.

- Final Quality Control (FQC): Thorough inspection of finished products before packaging.

- Quality Assurance (QA): Overseeing all QC processes, auditing, and data analysis.

Work closely with your manufacturer to establish and adhere to these QC points.

8.2. The Pre-Shipment Inspection (PSI): Your Final Quality Gate

The Pre-Shipment Inspection (PSI) is your final opportunity to verify quality and quantity before shipment. Typically conducted by a third-party, it covers quantity, workmanship, functionality, packaging, and documentation. PSI is a critical safeguard against defective products.

Section 9: Logistics and Customs

Bringing your exclusive air purifier to market involves navigating international shipping, customs, and distribution.

9.1. Packaging: Designing for Protection and the "Unboxing Experience"

Packaging protects your product and enhances the customer's experience. Consider protection, branding, sustainability, and compliance with regulations.

9.2. Navigating Logistics: The Essential Role of Freight Forwarders and Customs Brokers

Engage experienced professionals:

- Freight Forwarders: Manage logistics from factory to destination, handling booking, documents, and coordination.

- Customs Brokers: Specialize in customs clearance, preparing documentation, calculating duties, and ensuring compliance.

9.3. Tariffs and Duties: Understanding HTS Codes

Tariffs and duties significantly impact costs. Harmonized Tariff Schedule (HTS) codes classify products for accurate duty calculation. Work with your customs broker to ensure correct classification and leverage any free trade agreements.

Conclusion

Developing an exclusive air purifier is a complex yet rewarding endeavor. Success hinges on a holistic strategy encompassing product innovation, careful partner selection, strong legal protections, and rigorous quality management. By meticulously defining your product, choosing the right manufacturing model, safeguarding your intellectual property, and implementing robust quality control, you can launch a unique product and build a sustainable brand in the thriving air purification industry.