Dreaming of launching a unique hardware product but terrified of the OEM nightmare1? Endless delays, surprise costs, and compliance hurdles can kill your dream before it even starts.

A successful OEM project today isn't about starting from scratch. It's about "Platform Co-Development2." This smart strategy uses a pre-certified core, letting you focus on unique design and branding. It's the fastest, safest, and most affordable path from sketch to shelf.

I've seen too many great ideas die in the "valley of death" of traditional manufacturing. They get bogged down in the technical details, the certifications, the endless back-and-forth. But there is a better way. A smarter way. Let's walk through how a fictional brand, "Aura Wellness," turned their hardware dream into a reality, not a nightmare. This story will show you the new rules for winning in hardware.

Starting a new hardware product from scratch typically takes 6-9 months.False

A completely new, certified electronic product often takes 18-24 months or more due to R&D, tooling, and extensive compliance testing.

ETL and CARB certifications can cost over $50,000 and take a year to secure.True

These certifications involve rigorous testing for safety and emissions. The process is lengthy and expensive, representing a major hurdle for new products.

How Does a Simple Sketch Become a Market-Ready Product?

You have a brilliant design sketch for a new product. But turning that drawing into a physical, sellable item feels like an impossible mountain to climb. Let's meet "Aura Wellness."

A sketch becomes a product by first identifying a core, pre-certified "engine" or platform. This separates the complex internal engineering from the unique external design. This allows the brand to focus on aesthetics and user experience3, while the manufacturing partner handles the proven, compliant core technology.

Let's imagine our client, "Aura Wellness." They are a direct-to-consumer (D2C) brand focused on home wellness. They have a strong brand identity and a loyal following, but no hardware experience. Their dream was a premium, stainless steel humidifier that looked like a piece of art.

The Initial "Sketch"

Aura came to us with a beautiful concept. It was a sleek, minimalist cylinder with a unique wood-grain finish. They knew exactly what they wanted it to look like and how they wanted their customers to feel when using it.

The Common Pitfall

The traditional path would be to start from zero. This means designing the electronics, the water tank, the ultrasonic nebulizer, everything. This is the "OEM Nightmare." It involves:

| Traditional OEM Step | Estimated Time | Estimated Cost |

|---|---|---|

| R&D and Prototyping | 6-9 months | $50,000+ |

| Mold & Tooling | 3-4 months | $30,000+ |

| Compliance (ETL/CARB) | 12+ months | $50,000 - $100,000 |

| Total | ~2 years | ~$150,000+ |

Aura, like most D2C brands, couldn't afford to wait two years or risk that much capital. They needed a smarter path.

Most D2C brands have in-house hardware engineering teams.False

Many D2C brands excel at marketing and branding but lack the specialized engineering expertise for hardware development, making partnership essential.

A product's external design is often what drives the initial purchase decision for consumers.True

In a crowded market, visual appeal and design are key differentiators that attract customers and communicate brand value.

What is the "Platform Co-Development" Model?

Traditional OEM is too slow, expensive, and risky for your new product. You risk burning through your budget and missing your market window4. The "Smart OEM" strategy changes the game.

Platform Co-Development is a partnership model. We provide a pre-engineered, pre-certified "accelerator platform"—the core technology. You, the brand, then co-develop a unique external shell and user experience on top of this proven foundation. It's collaboration, not just supply.

I always tell my clients to stop thinking of us as a simple supplier. We are a Co-Development Partner. The key to this relationship is our "Accelerator Platform." In the case of Aura's humidifier, our platform is a high-performance, stainless steel humidifier engine.

The "Chassis" and the "Car"

Think of it like building a custom car. You wouldn't start by inventing a new engine and transmission. You'd start with a proven, high-performance chassis.

- Our Accelerator Platform (The Chassis): This is the core. It includes the stainless steel tank, the ultrasonic unit, the power supply, and all the electronics. Crucially, this entire platform is already ETL and CARB certified.

- Your Unique Product (The Car Body): This is where the brand's vision comes to life. Aura designed their unique outer shell, chose their custom wood-grain finish, and designed the packaging and user experience.

This model redefines "OEM." It's not about us making your product from scratch. It's about us co-developing your product on our proven platform. This shifts the focus from risky R&D to creative design and speed to market.

Platform-based development is a new concept invented in the 2020s.False

This model has been used in the automotive and computer industries for decades. Think of how many different car models are built on a single shared platform.

Using a pre-certified platform bypasses the need for the final product to be certified.False

While the core is certified, the final assembled product still requires some level of verification. However, the process is vastly simplified, faster, and cheaper because the most complex components are already approved.

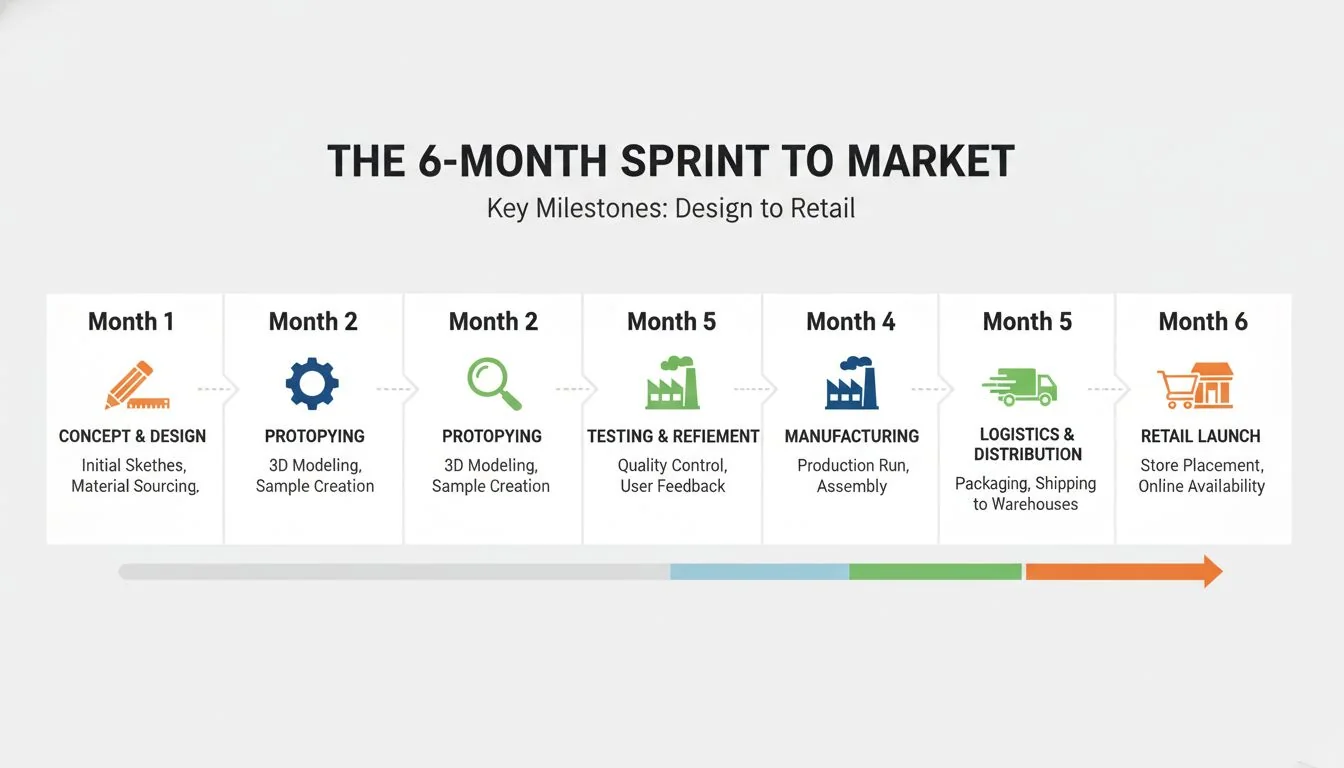

How Can You Really Launch a Product in Just 6 Months?

The typical 18-24 month product development cycle is a death sentence for agile brands5. Competitors can launch and dominate while you're still stuck in prototyping. A focused sprint is possible.

You launch in 6 months by skipping the 12+ months of core R&D and compliance testing6. With a pre-certified platform, the project immediately jumps to the design and tooling phase for the external shell. This parallel process makes the timeline achievable.

When I told Aura we could go from their sketch to a retail-ready product in six months, they were skeptical. I've been in this business a long time, and I've seen the delays. But the Platform Co-Development model changes the entire timeline. Here’s how we did it.

The Sprint Breakdown

We broke the project into clear, parallel-pathed phases. The key is that we've already done the hardest part.

| Month | Aura Wellness (Brand) Focus | Moldle (Partner) Focus |

|---|---|---|

| 1-2 | Finalize 3D CAD for the outer shell. Select colors, materials, and finishes. | Review CAD for manufacturability (DFM). Begin mold design for the shell. |

| 3-4 | Approve mold design. Review first-shot samples (T1). | Fabricate the injection molds. Produce T1 samples. |

| 5 | Finalize packaging design. Plan marketing launch. | Make mold adjustments. Begin pilot production run. |

| 6 | Place the first mass production order. | Mass production and assembly. Ship final product. |

This aggressive timeline is only possible because the 12+ months of electronic engineering and certification for the core platform were already complete before Aura even contacted us. We weaponized compliance and cost to give them an unbeatable advantage.

Design for Manufacturability (DFM) analysis is an optional step to save time.False

DFM is a critical step. Skipping it leads to costly mold rework, production delays, and poor product quality. It actually saves time and money in the long run.

The longest phase in traditional hardware development is often compliance and certification.True

Certifications like FCC, CE, ETL, and CARB require extensive testing and documentation, often creating a bottleneck that can last over a year.

What Does a "Hero Product" Without the "OEM Nightmare" Look Like?

You fear your finished product will be a compromise, plagued by factory errors. The "OEM nightmare" ends with a product that doesn't match your vision. A smart partnership avoids this.

A "hero product7" launched this way is a high-quality, compliant device that perfectly matches the brand's unique design. It gets to market fast, on budget, and without engineering headaches, allowing the brand to focus on what it does best: marketing and selling.

Six months after our first meeting, the "Aura Humidifier" was a reality. It was featured on design blogs and quickly became their top-selling item—a true "hero product."

The Win-Win Outcome

This success wasn't an accident. It was the direct result of the "Smart OEM" strategy. Let's compare the outcome to the traditional path.

- Speed to Market: Aura launched in 6 months, capturing the peak winter season. The traditional path would have missed this window by over a year.

- Budget Control: The project costs were predictable. The biggest variable, R&D and certification, was a fixed, known quantity from day one. They avoided the $50k-$100k certification gamble.

- Brand Focus: Aura's team didn't get bogged down in circuit board design. They focused their energy on creating a beautiful product, a compelling story, and a killer marketing campaign.

- Reduced Risk: By using a proven, reliable platform, the risk of product failure, recalls, or performance issues was dramatically lowered.

This is what a successful OEM project looks like today. It's not about finding the cheapest supplier. It's about finding a true co-development partner who de-risks the journey.

A 'hero product' is simply a company's best-selling item.False

A hero product is more than that. It's an item that strongly defines the brand, attracts new customers, and often has higher profit margins.

Predictable costs are a major advantage of the platform co-development model.True

By eliminating the unpredictable R&D and certification phases, brands can budget far more accurately, reducing financial risk significantly.

Conclusion

Don't start from scratch. The smartest way to bring a hardware product to life is to find a co-development partner with a proven platform and build your dream on it.

References

-

Learn about the pitfalls of traditional OEM processes and how to avoid them. ↩

-

Explore how Platform Co-Development can streamline your product launch and reduce risks. ↩

-

Understand the importance of user experience in creating successful products. ↩

-

Learn how to identify and capitalize on market windows for product launches. ↩

-

Explore the strategies that agile brands use to stay competitive in the market. ↩

-

Find out why compliance testing is crucial for product safety and market readiness. ↩

-

Learn how a hero product can elevate your brand and drive sales. ↩