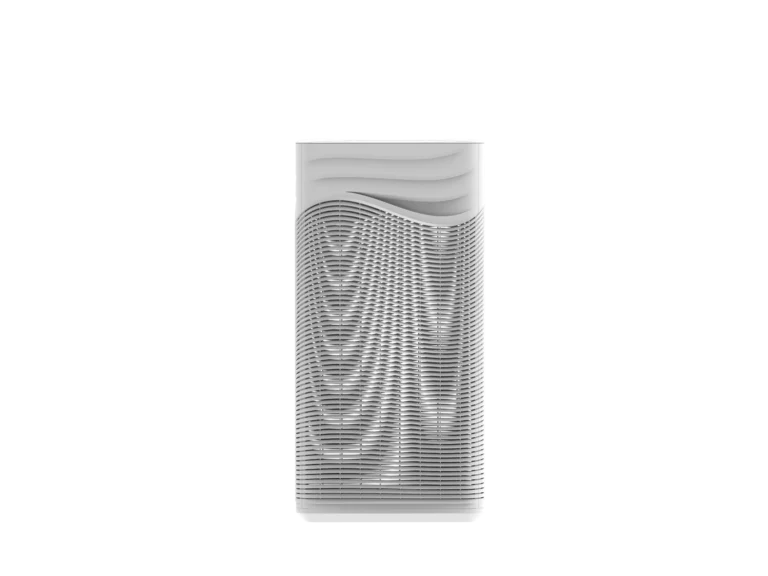

Bringing a new product to market is an exciting but challenging journey for first-time creators. This guide demystifies the manufacturing process, offering a clear, step-by-step roadmap for aspiring entrepreneurs. Whether your vision involves innovative indoor air quality solutions or other consumer electronics, understanding these fundamental stages is crucial for success. Companies like Hisoair, with over two decades of experience in OEM/ODM indoor air quality solutions, exemplify the expertise required to navigate this complex landscape. This article will break down the five key steps essential for manufacturing a product to sell, helping you transform your ideas into market-ready products.

Step 1: Plan The Scope For Manufacturing Your Product

The first step is to meticulously plan your product's scope. This phase sets the foundation for the entire manufacturing journey, transforming an abstract idea into a concrete, actionable blueprint.

Defining Your Vision: Clearly articulate what your product is, what problem it solves, and who it serves. For an indoor air quality solution, specify its core function, target environment, and unique selling propositions (e.g., ultra-quiet operation, smart connectivity).

Market Research and Validation: Validate your product idea with thorough market research. Understand your target audience's needs, analyze existing solutions, identify market gaps, and assess potential demand. This research helps refine your product's features and ensures it meets a genuine market need.

Setting Realistic Goals and Milestones: Break down the manufacturing process into manageable phases with defined goals and timelines. This includes product definition, industrial design, structured engineering, prototyping, tooling, and production stages.

Budgeting and Resource Allocation: Create a detailed budget covering all stages, from design to mass production. Accurately estimating costs and securing adequate funding is crucial. Identify the necessary human resources and expertise, whether in-house or through external partners.

Risk Assessment and Mitigation: Identify potential challenges such as supply chain disruptions, quality control issues, or regulatory compliance hurdles. Develop contingency plans to save time and resources.

Step 2: Research Your Product Before You Manufacture It

Thorough product research is essential before manufacturing. It involves understanding your market, potential customers, and the competitive landscape.

Understanding Your Target Audience: Define your target audience's demographics, pain points, and purchasing behaviors. For Hisoair's air quality solutions, this could range from health-conscious individuals to businesses seeking to improve air quality.

Identifying Market Needs and Gaps: Analyze existing solutions to identify unmet needs. HisoAir’s Decibel Cancellation™ Technology, for example, addresses the common issue of noise in air purifiers.

Competitive Analysis: Study your competitors' products, strengths, weaknesses, and market positioning to identify opportunities for differentiation.

Feasibility and Profitability Assessment: Evaluate the technical and economic feasibility of your product. Consider material costs, manufacturing processes, and potential profit margins. HisoAir’s multi-national production capabilities offer flexibility in optimizing manufacturing costs.

Regulatory and Certification Requirements: Research necessary certifications and compliance standards for your target markets. For air quality products, this includes standards like ETL and FCC.

Intellectual Property (IP) Considerations: Investigate existing patents and trademarks to avoid infringement and consider protecting your own IP.

Step 3: Create a Manufacturing Prototype

Prototyping is where your conceptual design becomes a tangible product. This stage allows you to visualize, test, and refine your product before mass production.

The Importance of Prototyping: A prototype helps validate design and functionality, test user experience, identify manufacturing challenges, gather feedback, and attract investors.

Types of Prototypes: You might create different types of prototypes, from basic concept mock-ups to functional and engineering prototypes, and finally pre-production samples.

The Prototyping Process:

- Detailed Design: Create comprehensive designs using CAD software, including precise measurements and material specifications.

- Material Selection: Choose appropriate materials based on durability, cost, and safety standards.

- Fabrication: Use methods like 3D printing or CNC machining to create the prototype.

- Assembly: Assemble all components to identify any design flaws or assembly difficulties.

- Testing and Iteration: Rigorously test the prototype against performance criteria and iterate on the design based on feedback. For air purifiers, this includes CADR testing, noise level measurements, and sensor calibration, as performed in Hisoair's CNAS-accredited laboratory.

Step 4: Find A Production & Manufacturing Partner

Once your prototype is perfected, the next step is to find the right production and manufacturing partner. This decision impacts the quality, cost, and delivery of your product.

Understanding Your Manufacturing Needs: Define your production volume, required expertise, location preferences, and certification requirements.

Where to Find Potential Partners: Use online B2B platforms, attend industry trade shows, leverage your professional network, or work with manufacturing consultants.

Vetting Potential Manufacturers: Conduct due diligence by assessing their experience, quality control processes, communication, pricing, and technical capabilities. HisoAir’s OEM/ODM services, for example, offer a partnership model for brands.

Building a Strong Relationship: Foster a collaborative relationship with your chosen partner based on clear communication and mutual respect.

Step 5: Go Time—How To Sell Your Product Online

With your product manufactured, the final step is to execute a robust online sales strategy.

Developing Your Online Sales Strategy: Decide whether to sell on marketplaces like Amazon or build your own e-commerce store. Develop a marketing plan to reach your target audience.

Key Elements of Online Selling:

- Product Listing Optimization: Use relevant keywords, high-quality images and videos, and compelling product descriptions to optimize your listings for search and conversion.

- Digital Marketing and Promotion: Drive traffic to your listings through SEO, paid advertising, social media marketing, and content marketing.

- Customer Service and Fulfillment: Ensure a seamless post-purchase experience with efficient order fulfillment and responsive customer support.

- Analytics and Iteration: Continuously monitor your sales performance and marketing effectiveness, and adapt your strategies based on data.

Conclusion

Bringing a product from concept to market is a journey that demands meticulous planning, research, prototyping, strategic partnerships, and a robust sales strategy. By following these five key steps, first-time creators can significantly increase their chances of success. Companies like HisoAir demonstrate that with dedication and expertise, even complex products can be brought to market with excellence. Embrace the process, leverage available resources, and persevere to turn your innovative idea into a tangible success.