You found a supplier's product that's almost perfect, but you want to change it to fit your brand. You worry that any modification will lead to huge costs and delays.

Yes, you can absolutely change a supplier's product design. The real question is about cost and complexity. Simple changes like branding are easy and cheap, while altering the product's physical shape requires expensive new molds, a concept known as "tooling1," which is the key factor.

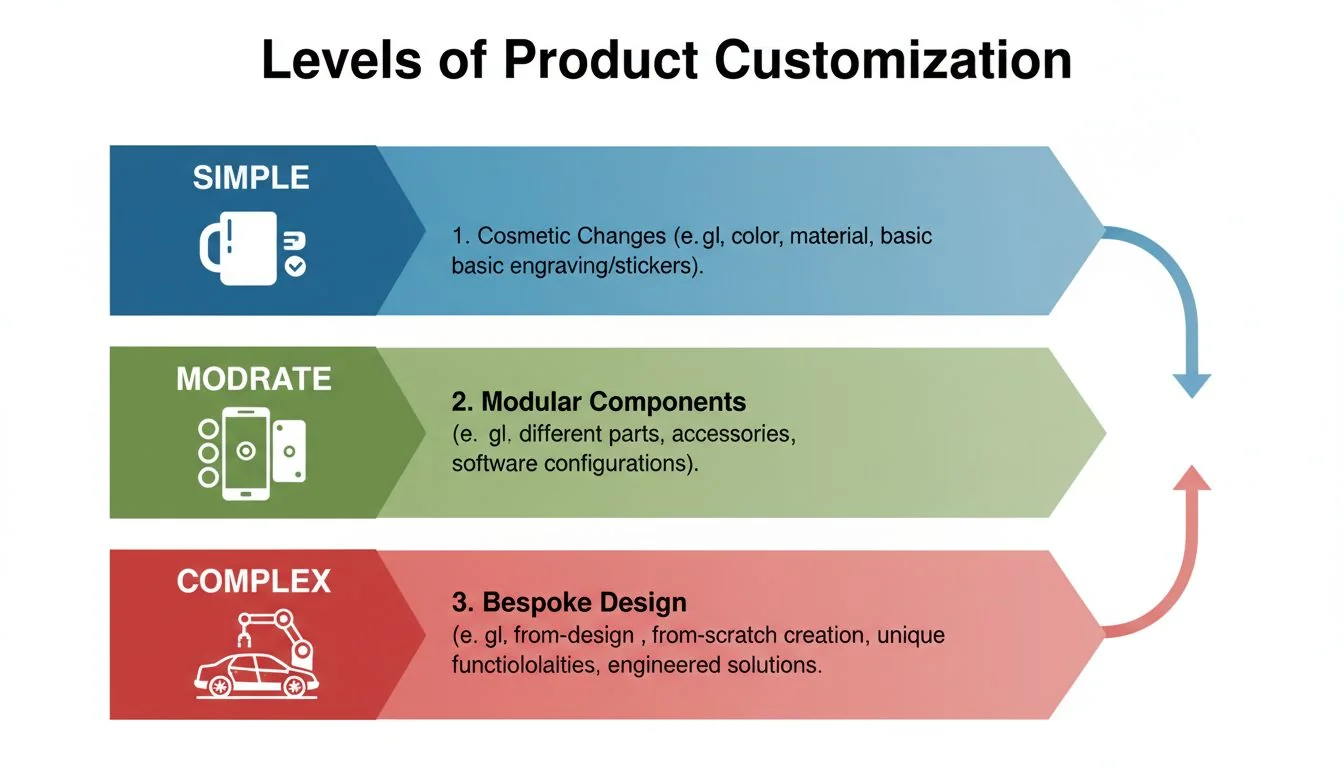

I've seen this question come up in hundreds of projects. A client sees an off-the-shelf product and their mind starts racing with ideas for improvement. But not all changes are created equal. A simple color swap is a world away from changing the curve of a handle. Understanding the difference is the key to a successful project that doesn't destroy your budget. Let's walk through the different levels of customization, from the easiest wins to the most involved projects. This will help you speak the same language as your factory and make smart decisions.

Any design change to an off-the-shelf product requires a full product re-certification for standards like UL or CE.Falsch

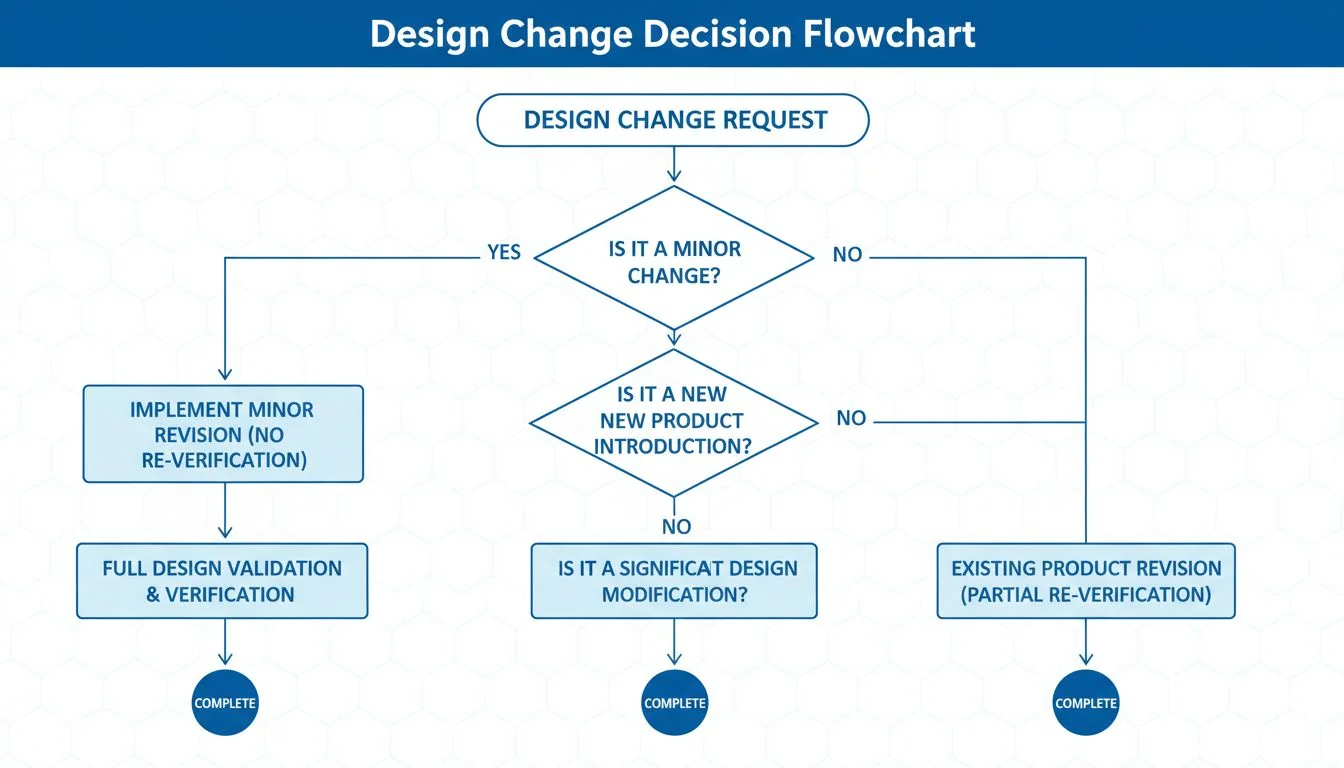

Only functional or structural changes that affect safety or performance typically require re-certification. Simple aesthetic changes like color or logos do not.

ODM (Original Design Manufacturer) refers to a factory's pre-existing product which other companies can brand and sell.Wahr

This is a common practice allowing brands to bring products to market quickly by leveraging existing designs and tooling.

What Does "Changing a Design" Really Mean?

You say "small change," but your supplier hears "new project." This simple misunderstanding can lead to sticker shock and frustration. To avoid this, you need to be specific about what you want.

"Changing a design" isn't one single action. It's a spectrum, from swapping a logo (aesthetic), to upgrading a motor (functional), to altering the plastic shell (structural). Each level has vastly different costs, timelines, and tooling requirements, so being specific is critical for clear communication.

When a client asks me if they can change a design, my first response is always another question: "What exactly do you want to change?" The answer tells me everything I need to know about the potential scope of the project. Most products you see from suppliers are ODM (Original Design Manufacturer) products. This means the factory already has the design, the engineering, and most importantly, the molds. Your job is to figure out how to customize it without breaking the bank. To do that, we need to break down "change" into three distinct levels. Think of it like customizing a car: you can get a new paint job, upgrade the engine, or completely change the body style. Each is a "change," but they are worlds apart in cost and effort.

The term 'design change' is universally understood by all manufacturers to mean minor aesthetic tweaks.Falsch

This term is highly ambiguous. A good supplier will always ask for clarification to determine if the change is aesthetic, functional, or structural.

Communicating the specific level of desired change upfront can prevent significant budget and timeline miscalculations.Wahr

Clarity at the beginning of a project helps the manufacturer provide an accurate quote for costs, tooling, and potential re-certification, avoiding surprises later.

What Are Level 1 Surface-Level Changes (Branding & Aesthetics)?

You need to make a product feel like it belongs to your brand, but you have a tight budget and an even tighter deadline. You're worried any change will be a major headache.

Level 1 changes2 are the fastest, cheapest, and easiest way to customize a product. They are purely cosmetic, focusing on Color, Material, Finish (CMF), logos, and packaging. These changes don't alter the product's shape or function and require no new tooling.

This is where you get the most bang for your buck. I call these the "low-hanging fruit" of product customization3. You are leveraging the supplier's massive investment in engineering and tooling, and you're just adding your own branding on top. I once had a client who was selling an air purifier. The original product was a standard glossy white. We didn't change a single thing about the shape or function. We simply changed the plastic to a premium matte black, used a subtle laser-etched logo instead of a printed one, and designed a high-end retail box. The perceived value skyrocketed, and they were able to command a higher retail price, all without touching the expensive molds. These changes are simple, but their impact on customer perception is huge.

| Change Type | Typical Cost | Tooling Required? | Certification Impact? |

|---|---|---|---|

| Logo Printing/Etching | Niedrig | Nein | Keine |

| Custom Color (Pantone) | Low (may have MOQ) | Nein | Keine |

| Surface Finish (Matte, etc.) | Low-Medium | Nein | Keine |

| Custom Packaging | Low-Medium | New print plates (cheap) | Keine |

Changing the color of a plastic product is always free.Falsch

Factories often require a Minimum Order Quantity (MOQ) to justify the cost of purchasing a custom color masterbatch and cleaning the injection machine.

Adding a printed logo to a plastic housing does not affect its UL or ETL safety certification.Wahr

As long as the ink and printing process do not alter the material's flammability or electrical insulation properties, re-certification is not necessary.

What Are Level 2 Functional Changes (Internal Components & Features)?

You like the product's look, but you want to improve how it works or what it does. You think this means you have to start from scratch with a massive R&D budget.

Level 2 changes4 modify a product's performance or user experience without changing its core physical structure. This can involve updating software, redesigning a control panel's interface, or swapping internal components like motors or sensors for different versions that fit the existing housing.

This is where you can get really clever and create a true competitive advantage. My favorite example is the control panel UI. For a product like an air purifier or a kitchen appliance, the user interacts with the control panel. You can keep the exact same plastic housing, but by changing the software and the printed graphic layer on the panel, you can completely transform the user experience. It feels like a totally different machine to the customer, but for the factory, it's a relatively simple change. Another common Level 2 change is upgrading a component. Maybe the base model uses a standard AC motor, but you want to offer a premium version with a quieter, more efficient brushless DC motor. As long as the new motor fits in the same mounting points, it's a functional change. But be careful: changing functional parts, especially electrical ones, can trigger the need for re-certification5 (UL, CE, ETL), which adds time and cost.

Changing a product's firmware to add new features is a structural (Level 3) change.Falsch

Firmware and software modifications are classic examples of functional (Level 2) changes, as they alter behavior without changing the physical form.

Swapping a product's power cord for a longer version may require the product to be re-certified.Wahr

Changes to critical electrical components, including the power cord, can affect safety compliance and often necessitate a review or full re-certification by bodies like UL or ETL.

What Are Level 3 Structural Changes (Modifying the Physical Mold)?

You have a specific vision for the product's shape, but your supplier quoted you a shocking price for what seems like a minor adjustment. You're wondering why it costs so much.

A Level 3 change means altering the physical shape of a molded part. This requires creating a new injection mold, also known as "tooling." Molds are massive, precision-machined steel blocks that can cost from thousands to tens of thousands of dollars, making this the most expensive type of change.

This is the single most important concept I try to get across to clients. The word you must understand is tooling. When you want to change the shape of a plastic part—even slightly—you are asking for a new mold. You can't just "patch" a piece of steel to change a curve from square to round. A new, multi-ton block of high-grade steel must be precision-machined for weeks. This is why it's so expensive. This is also where I shift from being an order-taker to a partner. A client once asked, "Can I make this air outlet round instead of square?" I could have just said, "Yes, that will be $15,000 for new tooling." Instead, I asked, "What is your goal with that change?" He replied, "I want it to look more premium." I was able to guide him: "We can achieve a more premium feel for a fraction of that cost by using a high-end matte finish and a redesigned touch panel. Would you like to see samples?" We achieved his goal for 1/10th the cost. Always ask "why" before you commit to a Level 3 change.

Minor changes to a plastic part's shape can be made by easily modifying the existing steel mold.Falsch

It is extremely difficult and often impossible to add steel back to a mold. Therefore, most shape changes require a completely new and expensive mold cavity or core.

The cost of a new injection mold is the primary driver behind the high cost of structural product changes.Wahr

Tooling is a non-recurring engineering (NRE) cost that represents the largest upfront investment when changing the physical form of a mass-produced plastic product.

What if I Need More Than Just a Modification?

Your idea is completely unique, and no off-the-shelf product comes close. The idea of a full development project from scratch seems overwhelming, costly, and slow.

When modifications aren't enough, you need an OEM (Original Equipment Manufacturer) project, where a product is designed from the ground up. While this offers total design freedom, a smarter "hybrid" approach often provides the best balance of uniqueness and efficiency.

An OEM project means you are paying for everything: the industrial design, mechanical engineering, prototyping, testing, certifications, and all the tooling. You own the final IP, but it's a long and expensive road, often 12-24 months before you have a product to sell. However, there is a powerful middle ground that I've used to help many clients succeed. I call it the "hybrid project6." We take the supplier's proven, certified "chassis"—the internal guts like the motor, fan, PCBA, and power supply. These are the parts that take the longest to engineer and certify. Then, you invest in new tooling for the external plastic housing only. This gives you a product that looks completely unique and is protected as your own design, but you save 6-12 months of R&D time and cost on the internal components. It's the sweet spot between a simple ODM re-brand and a full-blown OEM project.

In a standard OEM project, the factory owns the intellectual property for the design and the molds.Falsch

In a true OEM relationship, the client pays for the development and tooling, and therefore owns the intellectual property (IP) and the physical molds.

The 'hybrid' approach uses a supplier's pre-engineered internal components with a client's custom-designed external housing.Wahr

This strategy significantly reduces R&D time and certification complexity while still allowing for a unique product appearance and brand identity.

How Do I Decide Which Path is Right for Me?

You now see the options, from a simple logo swap to a full custom body, but you're not sure how to choose the best path for your business.

To decide, you must align your design goals with your budget and timeline. Start by asking your supplier for itemized quotes for Level 1, 2, and 3 changes, making sure to include any potential re-certification costs and timelines for each.

Making the right choice comes down to asking the right questions, both to yourself and to your manufacturing partner. Before you even talk to a supplier, you should have clear answers to these questions:

- What is my primary goal? Is it simple brand differentiation, improved performance, or a completely unique physical product?

- What is my budget for one-time costs? This means your budget for tooling and certification, separate from the per-unit cost.

- What is my required time-to-market? Can you wait 12 months for a custom product, or do you need to be on shelves in 3?

Once you know this, you can have a very productive conversation with your supplier. Ask them to quote you on a few scenarios:

- Scenario A: Only Level 1 changes (custom color, logo, packaging).

- Scenario B: Scenario A plus a Level 2 change (like a new UI).

- Scenario C: A "hybrid" project with a new external housing (Level 3).

A good partner won't just give you numbers; they will help you analyze the trade-offs and find the most efficient way to achieve your business goals.

Suppliers prefer clients who don't ask questions and just want the lowest price.Falsch

Experienced suppliers value strategic partners who ask intelligent questions. It shows they understand the process and are focused on building a successful, long-term product, which is mutually beneficial.

NRE (Non-Recurring Engineering) costs, like tooling, are separate from the per-unit production cost.Wahr

NRE costs are one-time investments to prepare for production, while the unit cost is the ongoing price to manufacture each individual product.

Schlussfolgerung

Understanding the levels of design change and the central role of tooling costs is the key. It empowers you to make smart, strategic decisions for customizing your product effectively and affordably.

References

-

Understanding tooling is crucial for managing costs and timelines in product design changes. ↩

-

Discover the easiest and most cost-effective ways to customize products without major alterations. ↩

-

Explore the spectrum of customization options available to enhance product appeal and functionality. ↩

-

Explore how functional changes can enhance product performance without altering its structure. ↩

-

Learn about the conditions under which product changes necessitate re-certification for safety standards. ↩

-

Find out how a hybrid approach can balance uniqueness and efficiency in product design. ↩