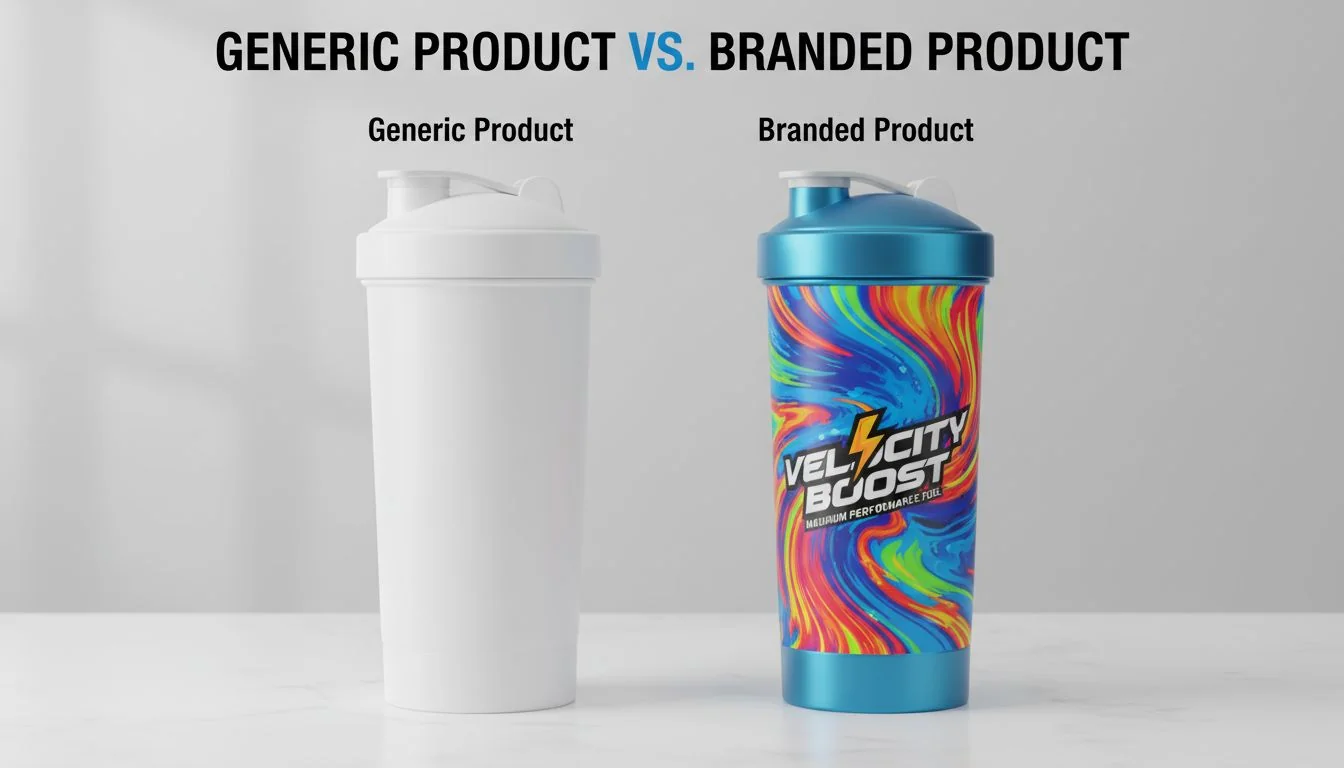

You found the perfect product, but it looks generic. It lacks your brand's soul and gets lost in the market. With the right strategy, you can transform it into a statement.

To customize a supplier's product, you apply your brand identity1 in layers. Start with essentials like logo printing and custom packaging. Then, advance to custom colors and finishes. Finally, consider unique functional or software features to create a truly distinct product and user experience.

Many designers I talk to think customization is an all-or-nothing game. They either stick with a generic product or imagine a hugely expensive, ground-up redesign. But that’s not how it works in the real world. The best approach is to see customization as a series of levels, from simple changes to deep engineering. This way, you can match your ambition to your budget and timeline. Let's break down this journey, from a generic item to a product that speaks for your brand.

Customizing a product always requires creating a completely new mold.Falsch

Many powerful customizations, like logo printing, custom colors, and packaging, can be done without any changes to the main product mold.

A strong brand identity can allow a product to command a higher retail price.Wahr

Branding increases perceived value. Customers are often willing to pay more for a product that feels premium, trustworthy, and aligned with their identity, even if the core function is similar to generic alternatives.

From a Generic Product to a Brand Statement?

Your product performs well, but it looks just like ten others on Amazon. This makes it a commodity, forcing you to compete on price alone. Let's fix that.

Transforming a generic product means layering your brand's identity onto it. This journey begins with visual basics like your logo and box. It can then grow to include unique colors and even functional changes, carving out a special place for you in the market.

When I started my trading company, I had a client who found a great air purifier. The specs were fantastic, but it was just a plain white box. He thought the features would sell themselves. He was wrong. Sales were slow because it looked cheap and untrustworthy. We didn't have the budget for a full redesign, so we focused on what I call the 80/20 rule of customization. For 80% of new brands, mastering the simple changes gives you the best return. We designed a beautiful box, silk-screened his logo on the unit, and suddenly it looked like a premium product. His sales tripled. This is the power of branding. It’s not just about looks; it’s about building trust and value. For most, focusing on these high-impact, low-cost changes is the smartest first step.

| Merkmal | Generic ODM Product | Branded Product |

|---|---|---|

| Perceived Value | Low to Medium | Mittel bis Hoch |

| Customer Trust | Niedrig | Hoch |

| Price Point | Low (Commodity) | Higher (Premium) |

| Memorability | Forgettable | Memorable |

| Marktposition | Just another option | A distinct brand |

The 80/20 rule of customization suggests that 20% of the customization effort yields 80% of the brand impact.Wahr

For new brands, focusing on high-impact, low-cost customizations like packaging and logos (the '20%') provides the majority of the visual and brand differentiation ('the 80%').

Consumers are unable to tell the difference between a generic product and a branded one.Falsch

Packaging, logos, color, and overall presentation create strong visual cues that consumers use to assess quality, trustworthiness, and value, easily distinguishing branded items from generic ones.

Level 1: The Essentials of Branding?

You want to brand your product, but your budget is tight and you need to launch fast. The idea of complex mold changes feels overwhelming. Don't worry, start with the essentials.

Level 1 branding focuses on the most cost-effective changes. This means applying your logo directly to the product and designing custom packaging2. These two steps are the foundation for building a real brand.

This is the absolute starting point. First, let's talk about your logo. You have a few options, and you need to discuss them with your supplier. Silk screening is most common for simple logos, while pad printing works on curved surfaces. For a more premium feel, you can ask for laser engraving. If you have a large enough order, you can even have the logo molded directly into the plastic part, which is the most durable option.

Second, and I can't stress this enough, your packaging is your most underrated marketing tool. I’ve seen clients increase their product's perceived value by 50% just by investing in a better box. The unboxing experience3 is your first physical handshake with your customer. A flimsy brown box says "cheap." A well-designed, sturdy box with custom inserts says "quality." It's often the single most cost-effective upgrade you can make.

| Personalisierung | Typical Cost | Typical MOQ | Brand Impact |

|---|---|---|---|

| logo printing4 | Niedrig | Low-Medium | Mittel |

| Custom Box Sleeve | Niedrig | Niedrig | Mittel |

| Full Custom Box | Mittel | Mittel | Hoch |

Packaging is just a container to protect the product during shipping.Falsch

Packaging is a critical marketing tool. The 'unboxing experience' is a key customer touchpoint that communicates brand quality, justifies a premium price, and creates a memorable first impression.

Different logo application methods, like silk screening and laser engraving, have different costs and aesthetic results.Wahr

Silk screening is cost-effective for colors, while laser engraving offers a permanent, high-end look. The choice depends on the product material, design, and budget.

Level 2: Advanced Visual Customization?

Your logo is on and the box looks great, but the product itself is still a standard color. A competitor could use the same base unit and copy your Level 1 branding. Let's make it harder for them.

Advanced visual customization means changing the product's core look. The most powerful way to do this is by changing the plastic color to match your brand's specific Pantone. This creates a much stronger and more unique identity.

Here is something many designers don't realize until it's too late. Changing the color of a plastic part isn't like painting a wall. You can't just make a few. The factory has to produce a huge batch of custom-colored plastic pellets specifically for your order. They mix raw plastic with color masterbatch to get your exact Pantone shade. This process requires a large amount of material to be consistent.

Because of this, the Minimum Order Quantity (MOQ) for a custom color is always much higher than for a standard black or white unit. I've seen MOQs for custom colors5 be 3,000 or 5,000 units, while the standard color was only 500. You must be transparent about this with your team. It's a major production step, not a simple cosmetic tweak. Another option is changing the finish by modifying the mold surface, for example from glossy to matte. This also adds cost and complexity but can really set your product apart.

| Color Option | MOQ | Cost per Unit | Lead Time | Brand Uniqueness |

|---|---|---|---|---|

| Standard (Black/White) | Niedrig | Base | Standard | Niedrig |

| Custom Pantone Color | Hoch | Base + 10-20% | + 2-4 weeks | Sehr hoch |

| Custom Mold Finish | Hoch | N/A (Tooling Cost) | + 4-6 weeks | Hoch |

Changing the color of a plastic product is a simple and cheap customization with a low MOQ.Falsch

Custom colors require producing large batches of custom-colored plastic pellets, leading to significantly higher Minimum Order Quantities (MOQs) and longer lead times compared to standard colors.

Using a specific Pantone color for your product helps reinforce brand identity and makes it harder for competitors to copy.Wahr

A unique brand color is a powerful visual differentiator that makes a product instantly recognizable and protects the brand's unique aesthetic.

Level 3: Functional and Feature Customization?

Your product now looks completely unique. But a smart customer might notice it works just like the cheaper competition. This can hurt your credibility. The solution is to customize the experience itself.

Level 3 customization goes beyond appearance to change how the product actually works. This can be a "soft" change like a custom user interface, or a "hard" change like adding a new component or sensor.

This is where you create a product that is truly yours. I've found that "soft" customizations offer incredibly high perceived value. Think about the user interface on a small LED screen. Customizing the startup logo, the menu icons, or even the beeps and chimes the machine makes can dramatically change how premium it feels. Developing a simple companion app is another powerful tool. These changes create a unique user experience6 that is very difficult for a competitor to replicate.

"Hard" functional changes are the next step up. This is for more established brands that have a deep understanding of their market. It could mean working with the supplier's engineers to use a quieter motor, add a specific type of HEPA filter, or integrate a new smart sensor. This often requires significant engineering resources and potentially new tooling, so it's a bigger investment. But it results in a product with a real performance advantage.

| Customization Type | Development Cost | Perceived Value | Defensibility |

|---|---|---|---|

| UI/Sound Customization | Low-Medium | Hoch | Hoch |

| Companion App (Simple) | Mittel | Sehr hoch | Sehr hoch |

| Component Upgrade | Medium-High | Hoch | Mittel |

| New Feature/Sensor | Hoch | Sehr hoch | Sehr hoch |

Software and UI customizations offer little value compared to hardware changes.Falsch

So-called 'soft' customizations like a custom UI, unique sounds, or a companion app can dramatically increase the perceived quality and user experience, often at a lower cost than hardware modifications.

Modifying a product's firmware to show a brand's logo on startup is a form of functional customization.Wahr

This changes the user's experience with the device's function, reinforcing the brand identity every time the product is turned on.

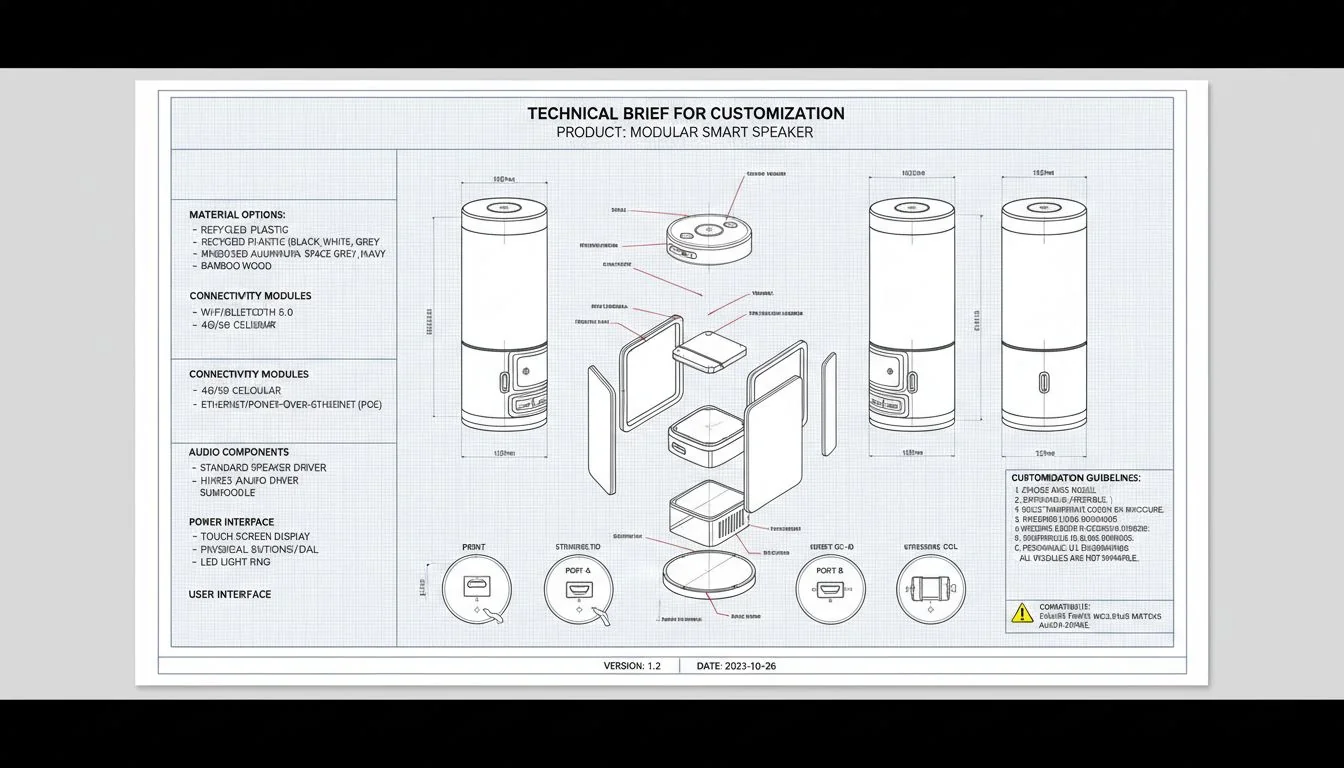

How to Prepare for a Successful Customization Project?

You're ready to customize, but you're not sure where to begin. Rushing into a project without a clear plan is a recipe for delays, mistakes, and wasted money.

To prepare, you must create a detailed technical brief7 and brand guide. This document should include vector logos, Pantone color codes, and clear mockups. The more specific you are, the smoother it will go.

Think of yourself as giving the factory a perfect set of instructions. If the instructions are vague, the result will be wrong. Your preparation is everything.

First, create a "Brand Tech Pack." This is non-negotiable. It must include:

- Logos: In vector format (.ai, .eps). A .jpeg is not good enough.

- Colors: Provide exact Pantone codes for your brand colors. Don't just say "dark blue."

- Fonts: The names of your brand fonts.

- Mockups: Clear images showing exactly where the logo goes, how big it should be, and what the packaging should look like.

Second, think about your needs in tiers. What are your "must-haves" for launch (Level 1)? What are your "nice-to-haves" if the budget allows (Level 2)? And what is your long-term vision (Level 3)? This helps you prioritize and have a clear conversation with your supplier about what's possible now versus later. Finally, prepare a list of questions for your supplier. Ask about MOQs for custom colors, tooling costs, and lead times. A good supplier will appreciate your detailed preparation.

A factory can perfectly match your brand color from a simple JPEG image of your logo.Falsch

Color on screens is not the same as color on a physical product. Factories require standardized Pantone color codes to accurately mix pigments and match your brand color.

Providing a supplier with a detailed 'tech pack' reduces the risk of errors and miscommunication.Wahr

A comprehensive technical package with vector logos, Pantone codes, and precise mockups serves as a clear and unambiguous instruction manual, ensuring everyone understands the project requirements.

Finding a Partner Who Can Bring Your Vision to Life?

You have a perfect plan, but you need a factory that can execute it. The wrong partner can destroy your project with bad quality, missed deadlines, and endless frustration.

Look for a manufacturing partner with proven experience in OEM/ODM customization8. Ask to see their portfolio and case studies. Clear communication and a collaborative attitude are just as important as their technical skills.

In my years of sourcing, I've learned that the cheapest supplier is almost never the right choice for a custom project. You need a true partner, not just an order-taker. Look for suppliers on platforms like Alibaba who market themselves as OEM/ODM specialists. Their websites will often showcase customization as a core service.

Don't be afraid to ask for proof. A good partner will be proud to show you examples of products they have customized for other brands (they may hide the brand names, which is normal). If they are secretive or unwilling to share, it's a major red flag. Pay close attention to their communication. Are they responsive? Do their engineers offer helpful suggestions, or do they just say "no"? I once had a project saved because the factory engineer suggested a slightly different way to mold a part that achieved the same look but saved us $20,000 in tooling fees. That's a partner. A good way to test the relationship is to start with a Level 1 or 2 project before committing to something more complex.

The supplier with the lowest unit price is always the best choice for a complex customization project.Falsch

For customization, factors like engineering support, communication, quality control, and experience are far more critical than the lowest possible price. A cheap supplier with poor capabilities can lead to costly errors and delays.

A good manufacturing partner will often suggest alternative solutions to help you achieve your design goals more efficiently.Wahr

Experienced partners act as collaborators. They use their manufacturing expertise to solve problems and improve your design, rather than just blindly following instructions.

Schlussfolgerung

Transforming a generic product is a journey. By starting with the essentials and strategically adding layers of customization, you can build a powerful brand that truly stands out in the market.

References

-

Understanding brand identity is crucial for effective product customization, as it shapes how consumers perceive your brand. ↩

-

Custom packaging is a powerful marketing tool that can significantly increase perceived value and customer trust. ↩

-

The unboxing experience is a key touchpoint that can significantly influence customer perception and brand loyalty. ↩

-

Exploring various logo printing methods can help you choose the most effective way to enhance your product's branding. ↩

-

Custom colors can create a unique identity for your product, making it instantly recognizable and harder for competitors to copy. ↩

-

Customizing user experience can significantly enhance customer satisfaction and loyalty, making your product stand out. ↩

-

A well-prepared technical brief ensures clear communication with suppliers, reducing the risk of errors in product customization. ↩

-

Understanding OEM/ODM customization is essential for finding the right manufacturing partner to bring your vision to life. ↩